Patents

Literature

41 results about "Guanidine Sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging 100, 500 g in poly bottle General description The multicomponent condensation of guanidine sulfate salt with H 2 S and CH 2 O was studied.

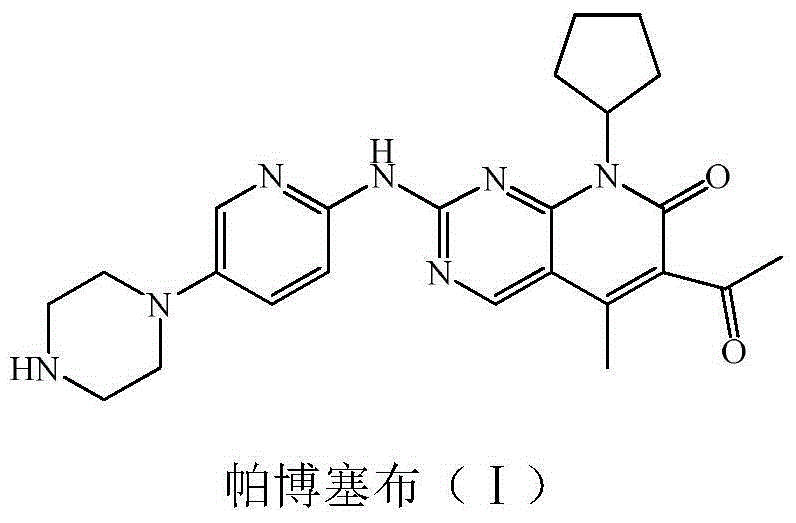

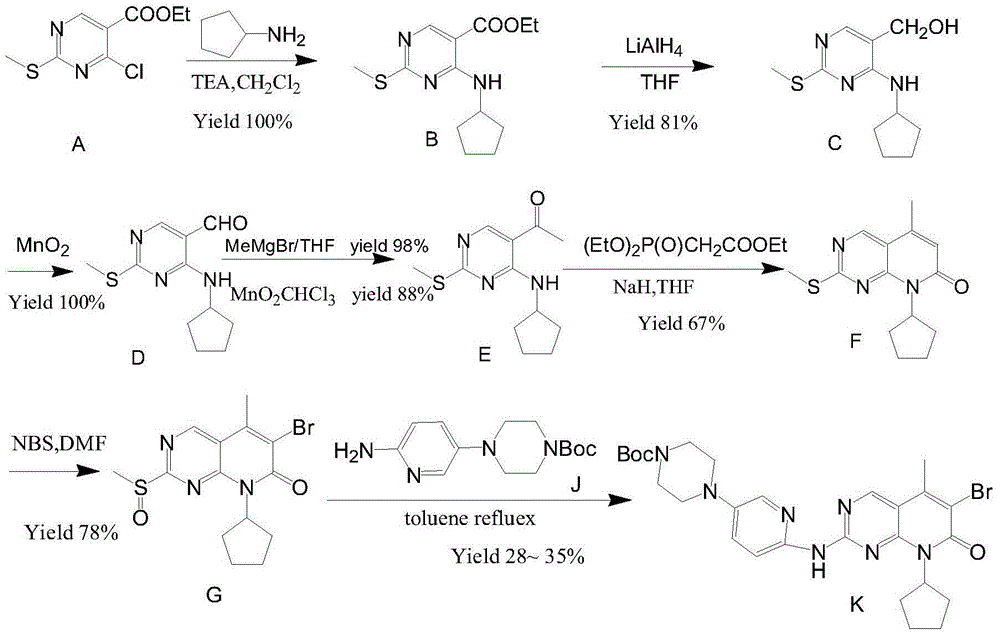

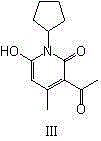

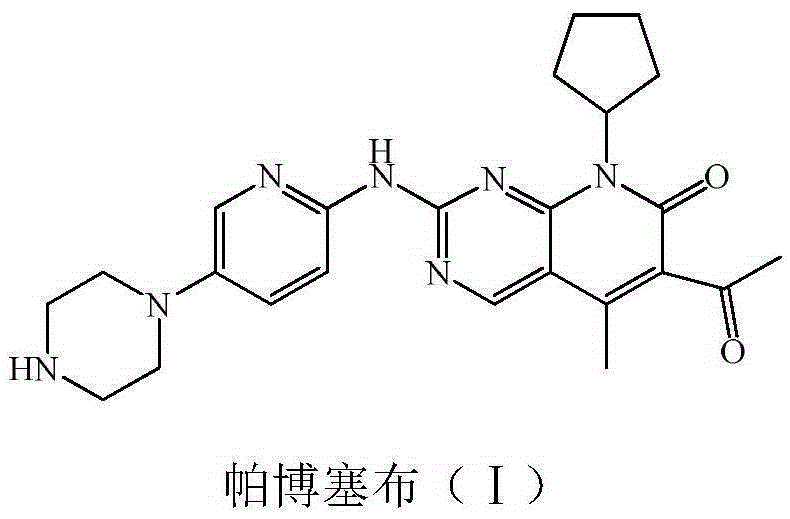

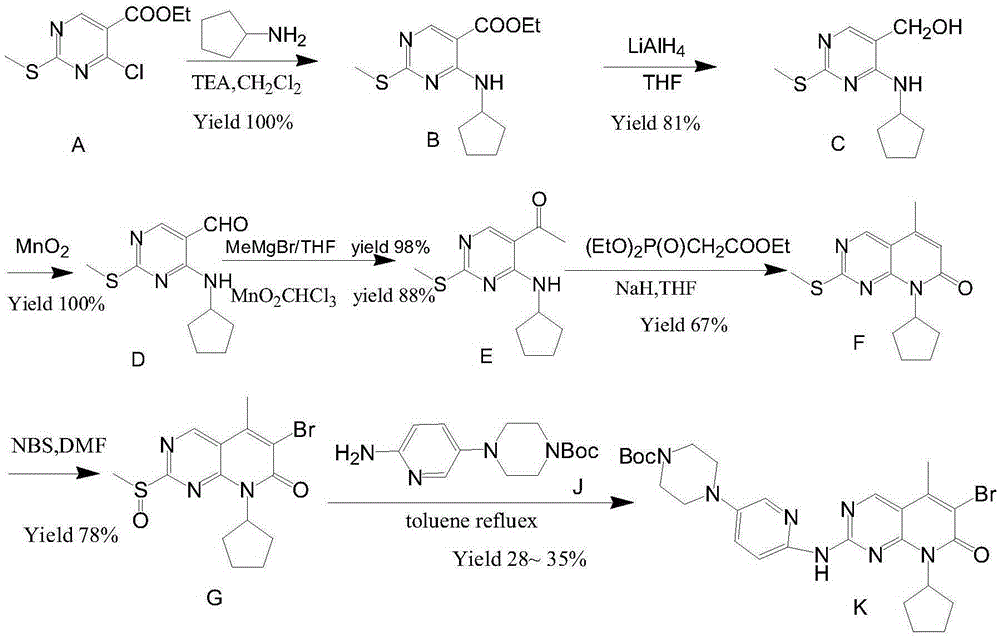

Preparation method of palbociclib

ActiveCN104478874AHigh yieldRaw materials are cheap and easy to getOrganic chemistry2-PyridoneMethyl group

The invention relates to a preparation method of palbociclib. The method comprises the following steps: carrying out N-acetoacetylation reaction by using cyclopentylamine and an acetoacetylation agent to obtain N,N-di(acetoacetyl) cyclopentylamine (II), carrying out intramolecular condensation on N,N-di(acetoacetyl) cyclopentylamine (II) in the presence of an alkaline reagent to obtain N-cyclopentyl-3-acetyl-4-methyl-6-hydroxy-2-pyridone (III), enabling N-cyclopentyl-3-acetyl-4-methyl-6-hydroxy-2-pyridone (III) to react with a formylation reagent to prepare N-cyclopentyl-3-acetyl-4-methyl-5-formyl-6-chlorine-2-pyridone (IV), carrying out pyrimidine ring reaction by using N-cyclopentyl-3-acetyl-4-methyl-5-formyl-6-chlorine-2-pyridone (IV) and N-(5-(4-tert-butoxy carbonyl-1-hexahydropyrazinyl)-2-pyridyl) guanidine sulfate (V), and then hydrolyzing under the alkaline condition to prepare palbociclib. The preparation method of palbociclib is easily available in raw materials, short in process, simple and convenient to operate and safe and environmentally friendly in process.

Owner:XINFA PHARMA

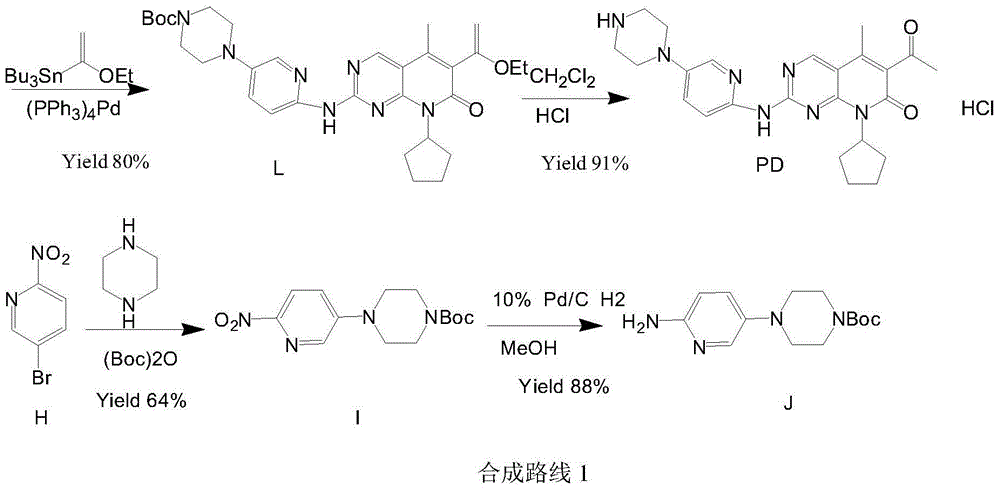

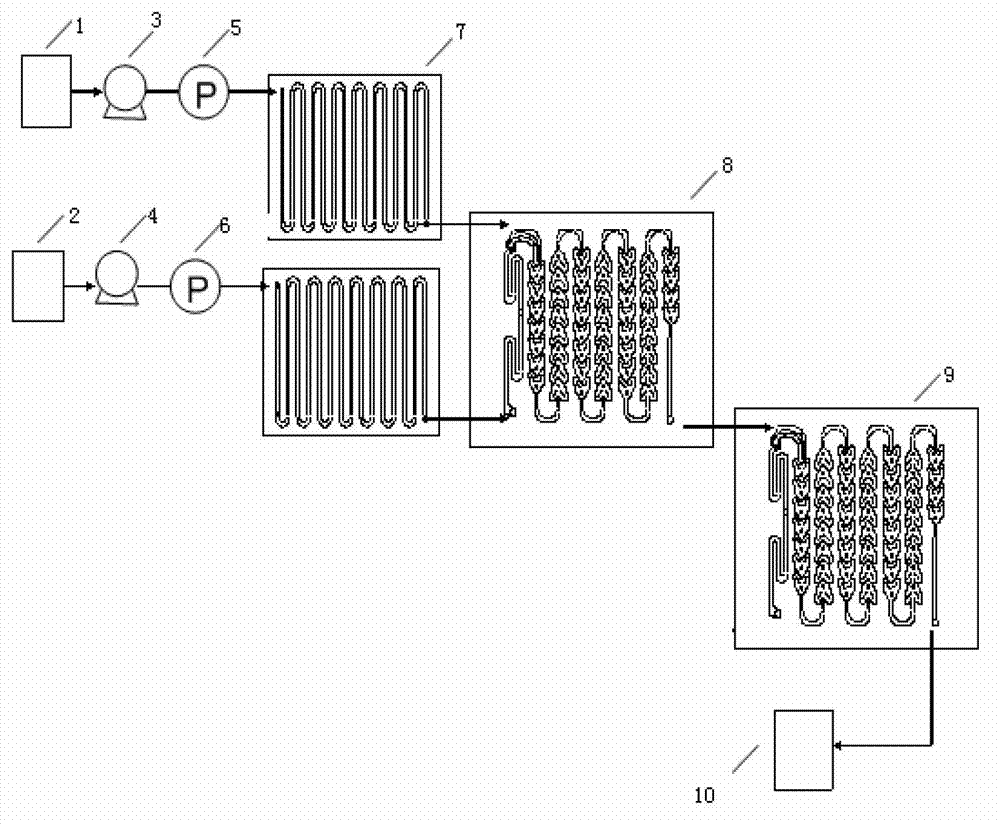

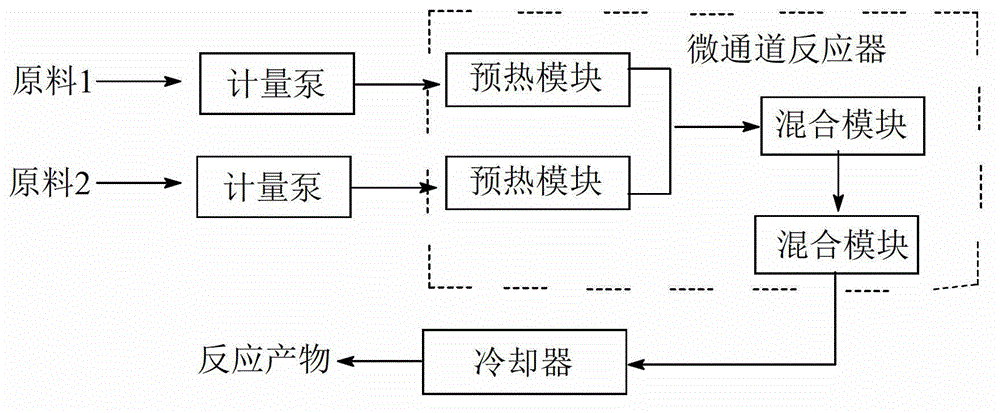

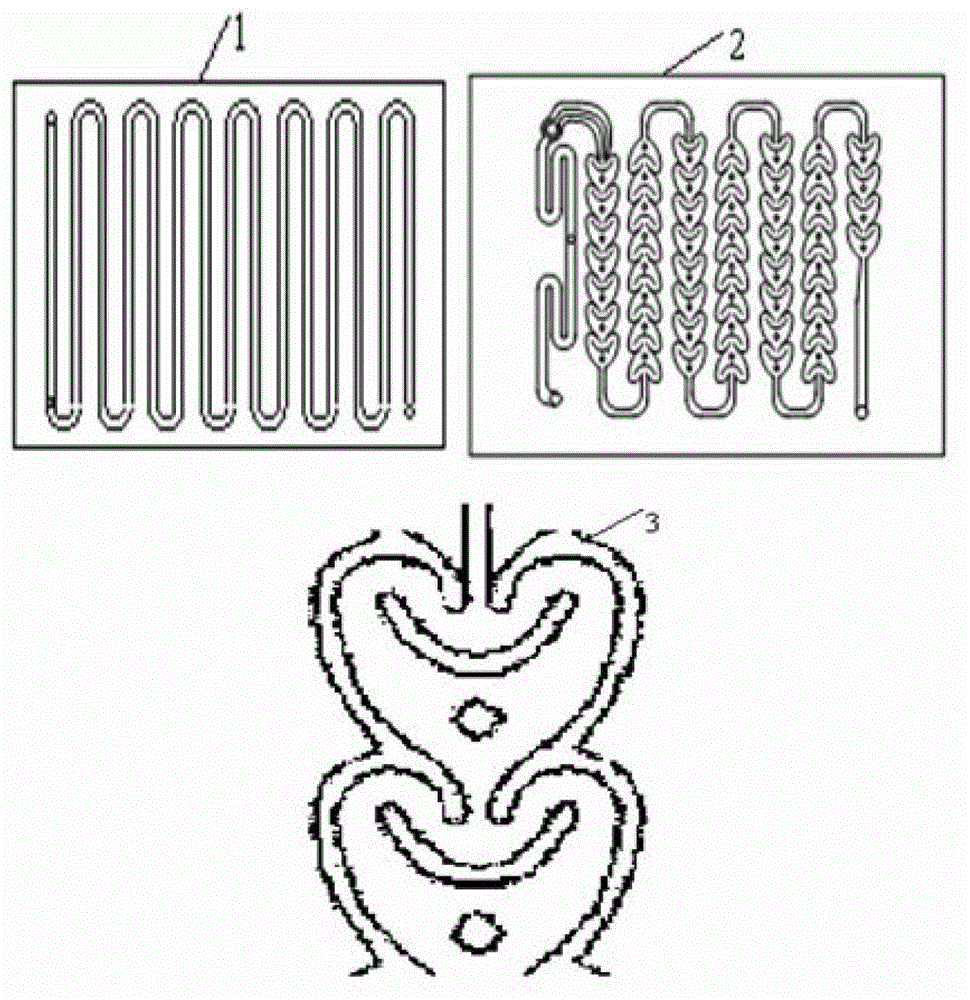

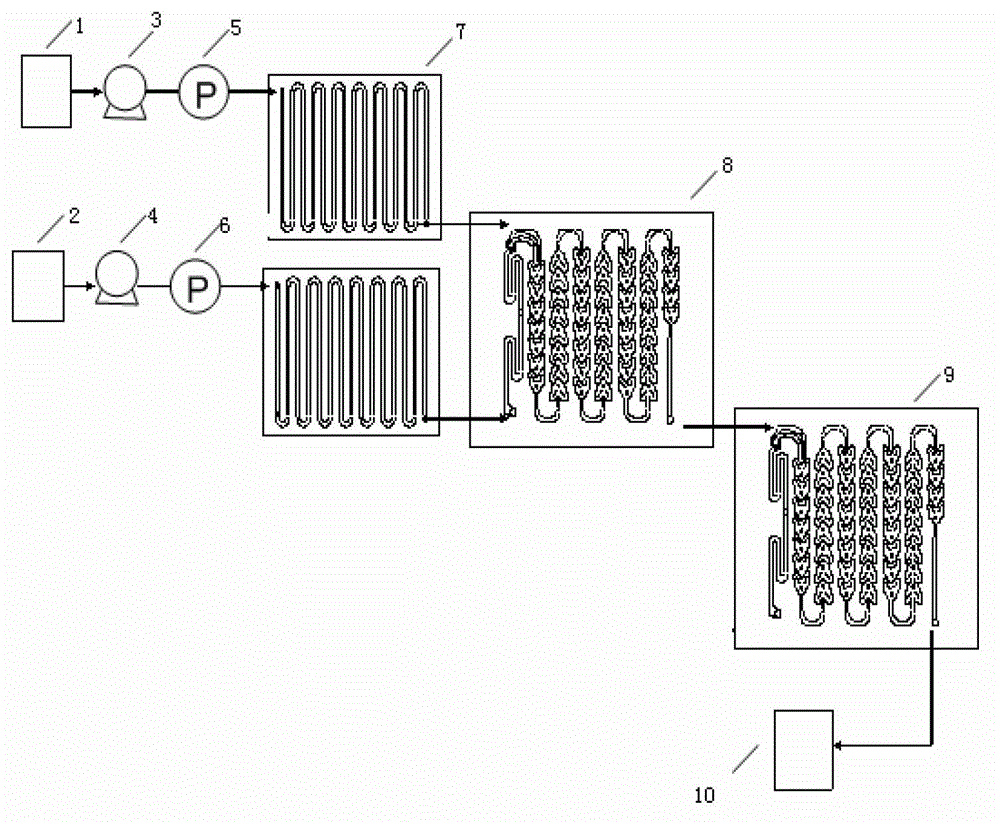

Method for preparing nitroguanidine by adopting micro-channel reactor

ActiveCN103172546AShort reaction timeImprove reaction efficiencyOrganic chemistryOrganic compound preparationNitroguanidineOrganic synthesis

The invention relates to a method for preparing nitroguanidine by adopting a micro-channel reactor, belonging to the technical field of organic synthesis applications. The mehtod is a new process for synthesizing nitroguanidine by taking a sulfuric acid solution of guanidine sulfate and nitric acid as raw materials and performing nitrification and dehydration in the Corning micro-channel reactor within a short reaction time from tens of seconds to a few minutes. Materials are introduced into the Corning micro-channel reactor through a metering pump, a nitroguanidine product is obtained by preheating, mixing, reaction and post-treatment, and the method has the advantages of simplicity, convenience and safety in operation, high yield and continuous production of the nitroguanidine product; and in addition, by adopting the process, the environmental pollution can be greatly reduced. The yield of the product according to the method disclosed by the invention is 90-93%, and the melting point of the product is 230-232 DEG C.

Owner:CHANGZHOU UNIV

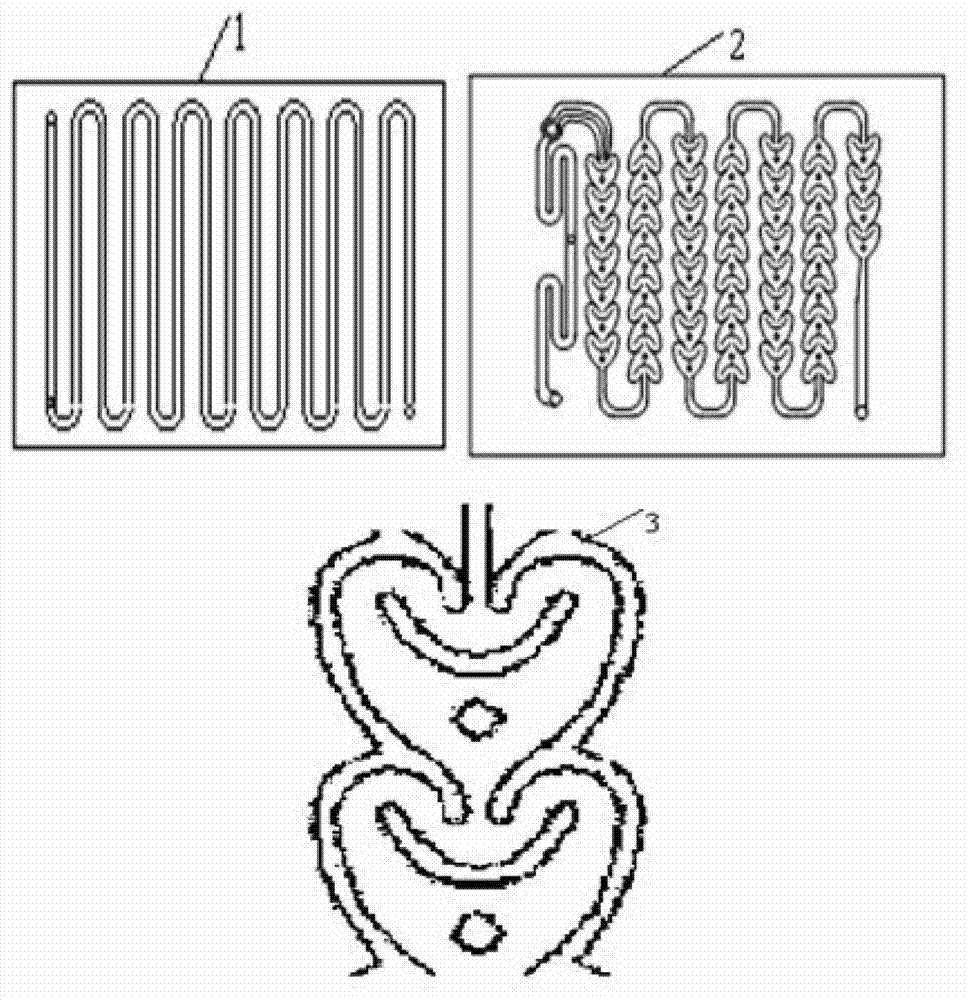

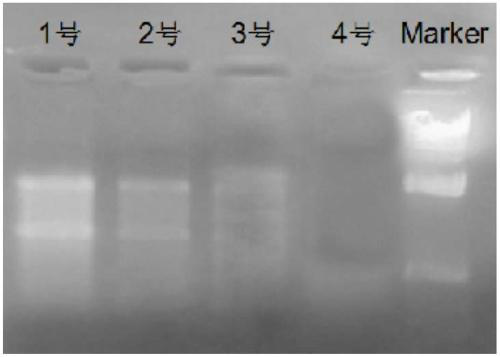

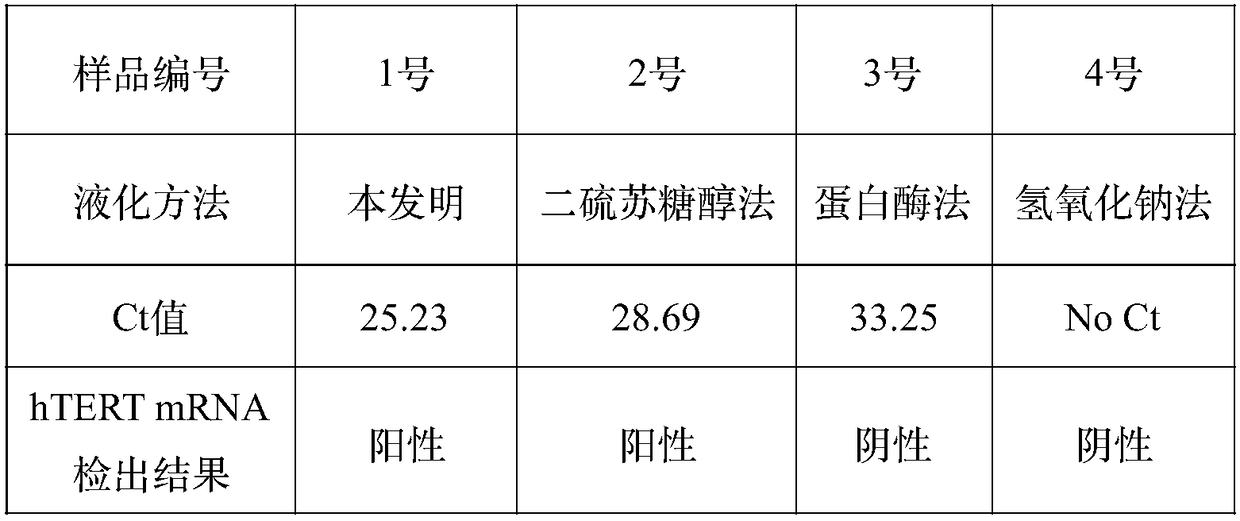

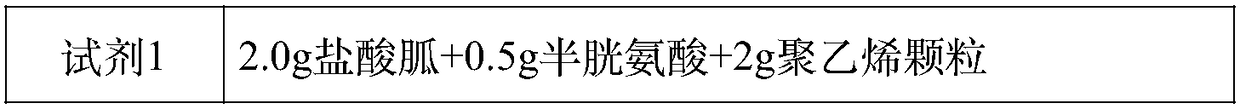

Reagent for liquefying phlegm and protecting nucleic acid

ActiveCN108949748AFully liquefiedProtection from degradationDNA preparationSimple componentPolyvinyl chloride

The invention provides a reagent for simultaneously liquefying phlegm and effectively protecting nucleic acid. The reagent contains guanidine, a cysteine derivative and a macromolecule inert particle,wherein guanidine is one or more of guanidine hydrochloride, guanidinium isothiocyanate, guanidine sulfate and guanidine carbonate; the cysteine derivative is one or more of cysteine, acetylcysteine,homocysteine, methylcysteine and cysteine hydrochloride; and the macromolecule inert particle is one or more of a polypropylene particle, a polyethylene particle, a polyvinyl chloride particle and apolystyrene particle. The reagent is a mixed solid of powder and particles and is capable of well permeating into a phlegm sample, and the phlegm sample is adequately mixed, so that phlegm can be adequately liquefied; and meanwhile, the reagent is capable of protecting nucleic acid in the phlegm sample from being degraded at a normal temperature for a long time. The reagent contains simple components and is low in cost, and the production process is simple, and the reagent is easy to use and operate and very suitable for wide clinical use.

Owner:ZHEJIANG JFK BIOLOGICAL TECH

Oilfield reinjection water sterilizing agent

InactiveCN101884337ANon-irritatingNo irritating smellWaste water treatment from quariesBiocidePolyolefinSulfate-reducing bacteria

The invention relates to a sterilizing agent for an oilfield, in particular to an oilfield reinjection water sterilizing agent, which solves problems on the sterilization of oilfield reinjection water. The oilfield reinjection water sterilizing agent consists of the following raw materials in part by weight: 1 to 3 parts of butanediamine, 3 to 5 parts of guanidine sulfate, 1 to 2 parts of polyhexamethylene guanide and 1 to 2 parts of polyolefin-based guanide. The oilfield reinjection water sterilizing agent can serve as the sterilizing agent of the oilfield reinjection water, and has specially good effects on fungi, heterotrophic bacteria, particularly saprophytic bacteria, sulfate reducing bacteria and iron bacteria in the oilfield reinjection water, no pungent smell, nonirritant to the skin of an operator, stable chemical performance, long sterilizing time, incombustibility, no explosion and secure transport and storage.

Owner:JINZHONG JIELONG INDAL

Adsorption preparation for wastewater treatment and preparation method thereof

PendingCN106669633AImprove adsorption capacityDestabilizingOther chemical processesAlkali metal oxides/hydroxidesAluminateManganese oxide

The invention discloses an adsorption preparation for wastewater treatment. The adsorption preparation for the wastewater treatment is prepared from the following raw materials in parts by weight: 14-18 parts of aluminum sulfate, 19-20 parts of oxalic acid, 22-25 parts of polyacrylamide, 16-18 parts of sodium carbonate, 9-17 parts of activated carbon, 10-16 parts of calcium aluminate, 5-8 parts of ammonium sulfate, 4-11 parts of sodium metaaluminate, 12-14 parts of calcium disodium versenate, 9-16 parts of potassium ferrate, 8-10 parts of polyvinylpyrrolidone, 3-4 parts of sodium carbonate, 9-14 parts of ferric citrate, 8-10 parts of polysulfide ferric chloride, 2-5 parts of cellulose powder, 3-8 parts of sodium lignosulphonate, 1-2 parts of dibenzoyl peroxide, 7-14 parts of nano-manganese oxide, 16-24 parts of guanidine sulfate, 22-25 parts of dodecyl triphenyl phosphorus chloride and 9-16 parts of isopropanol. The adsorption preparation for the wastewater treatment provided by the invention has a sterilizing function, and has the advantages of small material density and high processing efficiency.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Nonconsumable wood flame retardant and its preparation

InactiveCN1490137ASolve moisture absorptionAntisepticWood impregnation detailsFoaming agentPentaerythritol

An anti-losing flame-retarding agent for wood or other organic fibre materials is prepared from formaldehyde, urea, ammonia water, phosphoric acid, cyanuramide and / or guanidine phosphate and / or guanidine sulfate, and polyethanediol and / or pentacrythrite and / or dextrin.

Owner:陈万利 +3

Bactericidal agent for water injection well and preparation method and application of bactericidal agent

InactiveCN107751230ANot volatileNot easy to decomposeWaste water treatment from quariesBiocidePolyhexamethylene guanidineBenzyltrimethylammonium chloride

The invention discloses a bactericidal agent for a water injection well and a preparation method and application of the bactericidal agent, and belongs to the field of oilfield reinjection water. Thebactericidal agent for the water injection well is prepared from, by mass, 14.6-26.3% of quaternary ammonium salt bactericide, 4.9-13.2% of aldehyde bactericide, 0.9-3.4% of guanidine bactericide, 0.5-3% of isothiazolinone and the balance water. The quaternary ammonium salt bactericide refers to dodecyl dimethyl benzyl ammonium chloride and / or dodecyl benzyl trimethyl ammonium chloride; the aldehyde bactericide refers to glutaraldehyde; the guanidine bactericide refers to guanidine sulfate and / or polyhexamethylene guanidine. The provided bactericidal agent for the water injection well is smallin toxicity, not easy to volatilize and difficult to decompose and has the advantages of being good in chemical stability, long in sterilization time, free of secondary pollution and the like.

Owner:PETROCHINA CO LTD

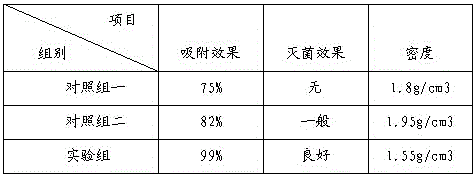

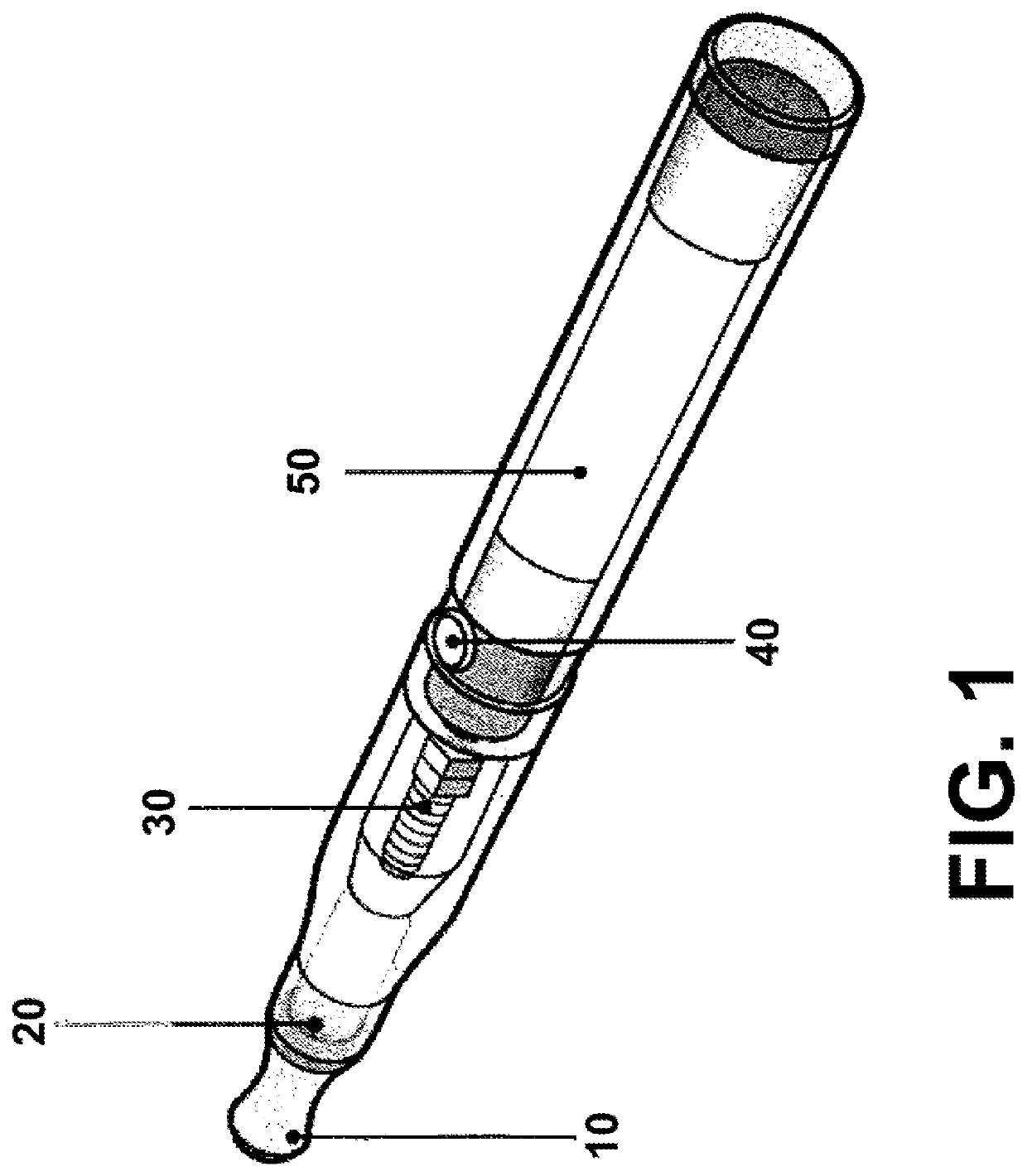

Composition of Athletic and Fitness Supplements, Method for Production and Method for Pulmonary Administration of Same

InactiveUS20200306187A1Improve athletic performanceIncrease physical strengthPowder deliverySpray deliveryTyrosineGlycerol

Disclosed is a performance-enhancing supplement for pulmonary administration wherein the supplement consists of a base e-liquid and a selected combination of supplement ingredients. The base liquid is selected from vegetable glycerin or propylene glycol, and the combination of ingredients is selected from at least three of pineapple lime extract, riboflavin, L-tyrosine, L-theanine, taurine, caffeine, agmatine sulfate, citrulline malate, and beetroot. The resulting performance-enhancing supplement is provided in a standard vape cartridge for use in an electronic cigarette device.

Owner:V RUSH VAPES LLC

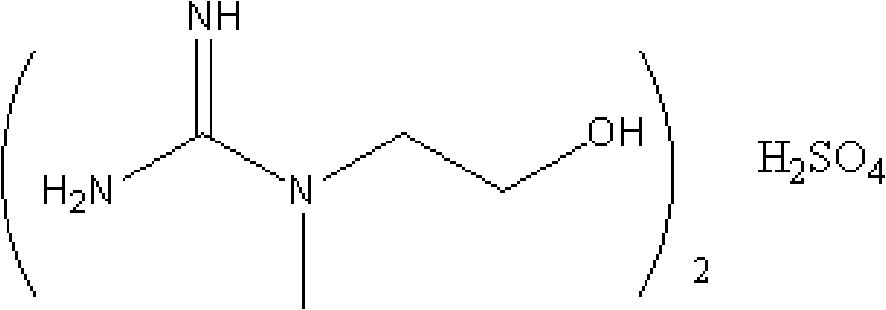

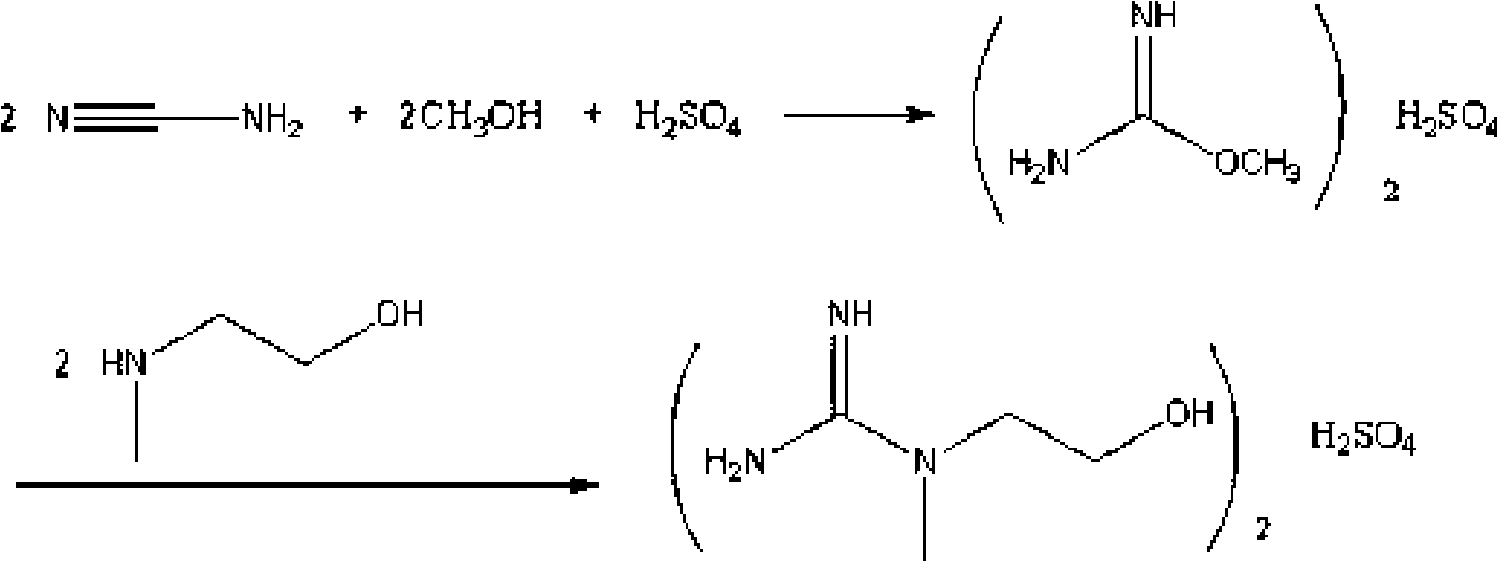

Preparation method for creatinol sulphate

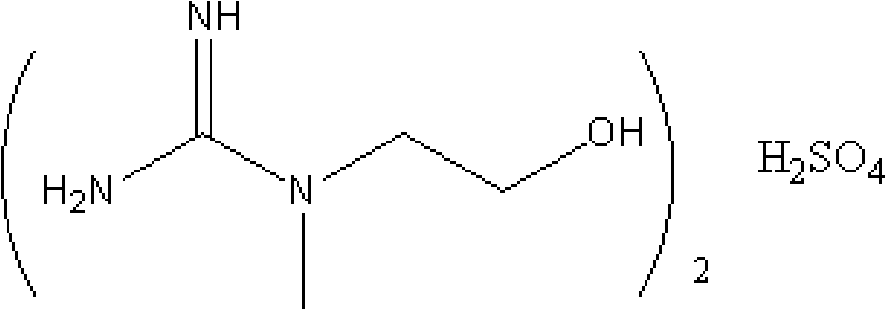

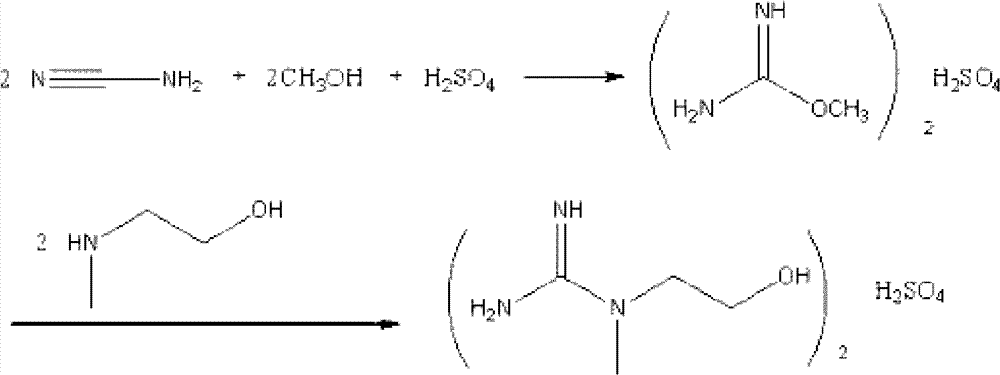

InactiveCN101671282AMild reaction conditionsEasy to operateOrganic chemistryOrganic compound preparationGuanidine derivativesSolvent

The invention relates to a preparation method for 1-methyl-1-(beta-hydroxy ethyl) guanidine sulfate (creatinol sulphate), belonging to the preparation method for guanidine derivatives. The preparation method for creatinol sulphate comprises the following steps: (1) cyanamide aqueous solution, methyl alcohole and concentrated sulfuric acid reacting in the temperature of 10 DEG C to 40 DEG C for 30min to 90 min; (2) dropwise adding N-methyl amino-alcohol into the solution in the step (1), reacting for 3h-5h in the temperature of 30-80 DEG C, decompressing and concentrating; (3) adding organic solvent into the concentrated solution, separating out creatinol sulphate and crystallizing, and obtaining creatinol sulphate finished product after washing and drying. The preparation method has mildreactive conditions, is simple and convenient to operate and practical, has low toxicity owing to taking water as solvent, low cost and low vitality, simultaneously is simple and practical in the post treatment, and saves time and energy. The obtained product has high yield and good purity; and the purity of the product can reach 93%-99%.

Owner:TIANJIN TIANCHENG PHARMA

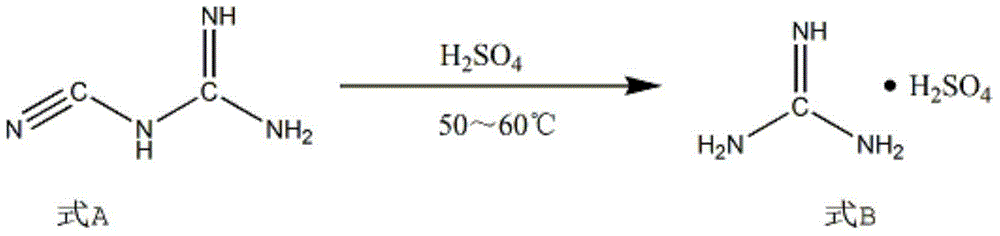

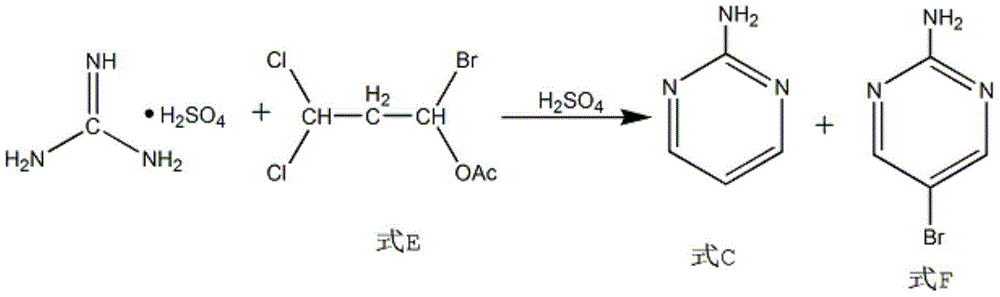

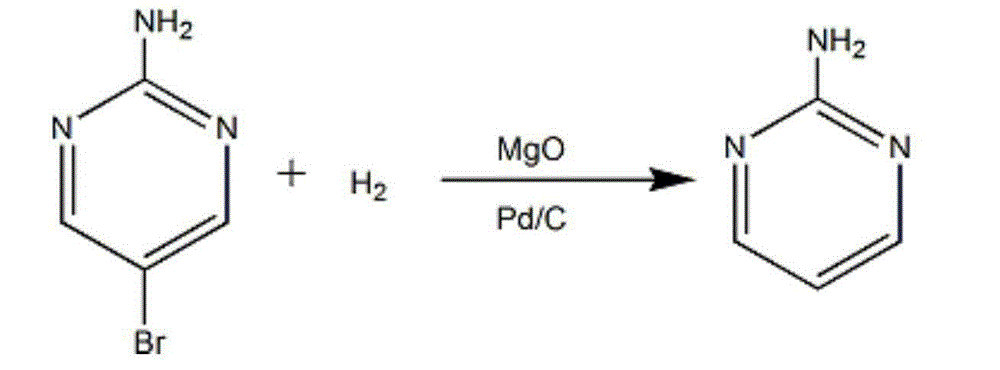

Synthesis method of 2-chloropyrimidine

The invention discloses a synthesis method of 2-chloropyrimidine. The synthesis method comprises the steps of dissolving dicyandiamide in sulfuric acid at 2-6 DEG C, heating at 50-60 DEG C for hydrolysis reaction for 4-6h to form guanidine sulfate, allowing guanidine sulfate to carry out cyclization reaction with 1-bromine-1-acetyl-3,3-propylene dichloride (Formula E) for 5-8h at 50-60 DEG C in the presence of sulfuric acid at a mass concentration of 94-96wt% to form 2-aminopyrimidine and 2-amino-5-bromopyrimidine, hydrogenizing and reducing 2-aminopyrimidine and 2-amino-5-bromopyrimidine to 2-aminopyrimidine at 55-65 DEG C under the catalysis of a palladium-carbon catalyst and magnesium oxide at the same time, and reducing 2-aminopyrimidine to the product at subzero10-5 DEG C by taking NaNO2, HCl and ZnCl2 as catalysts. Through the preparation route, higher-purity and upper-yield 2-chloropyrimidine is obtained.

Owner:TAICANG YUNTONG BIOCHEM ENG

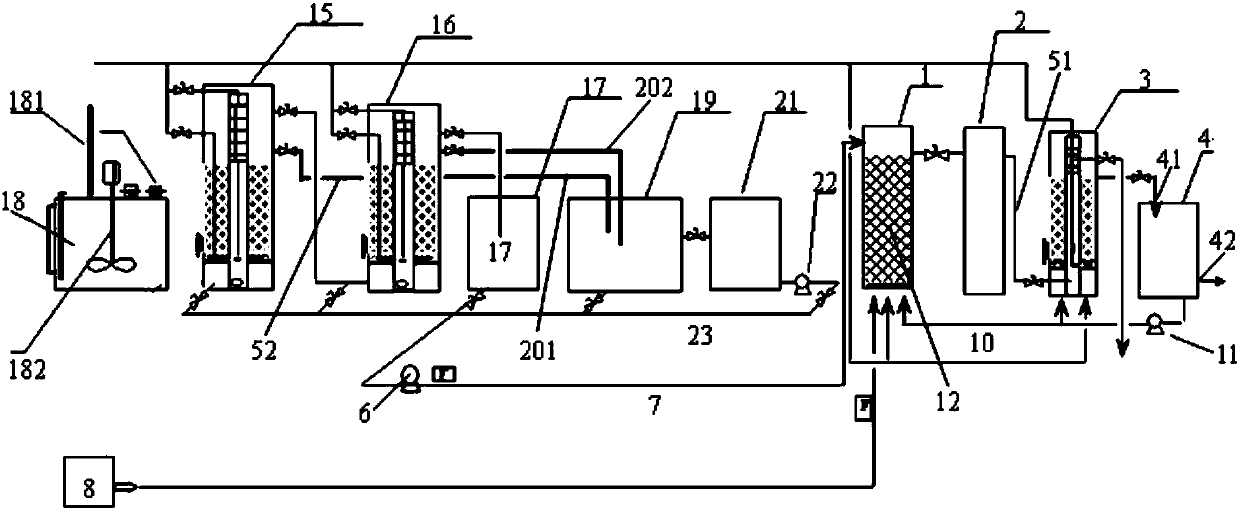

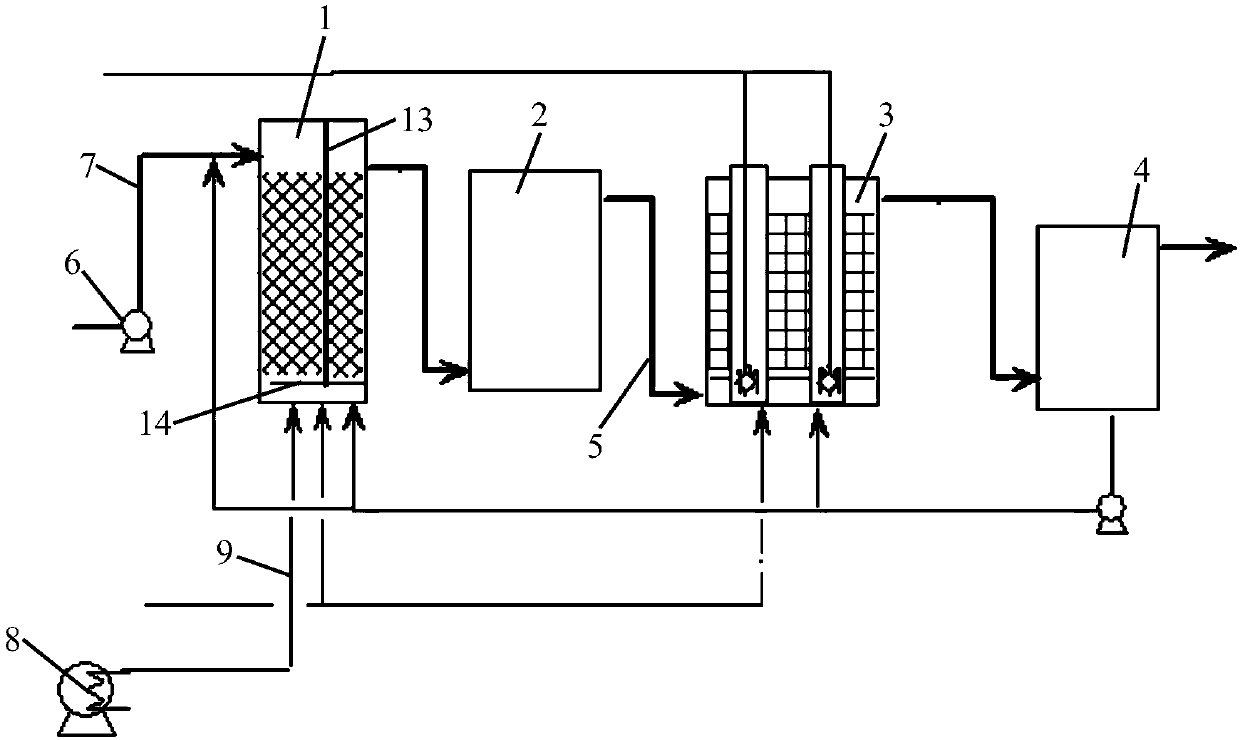

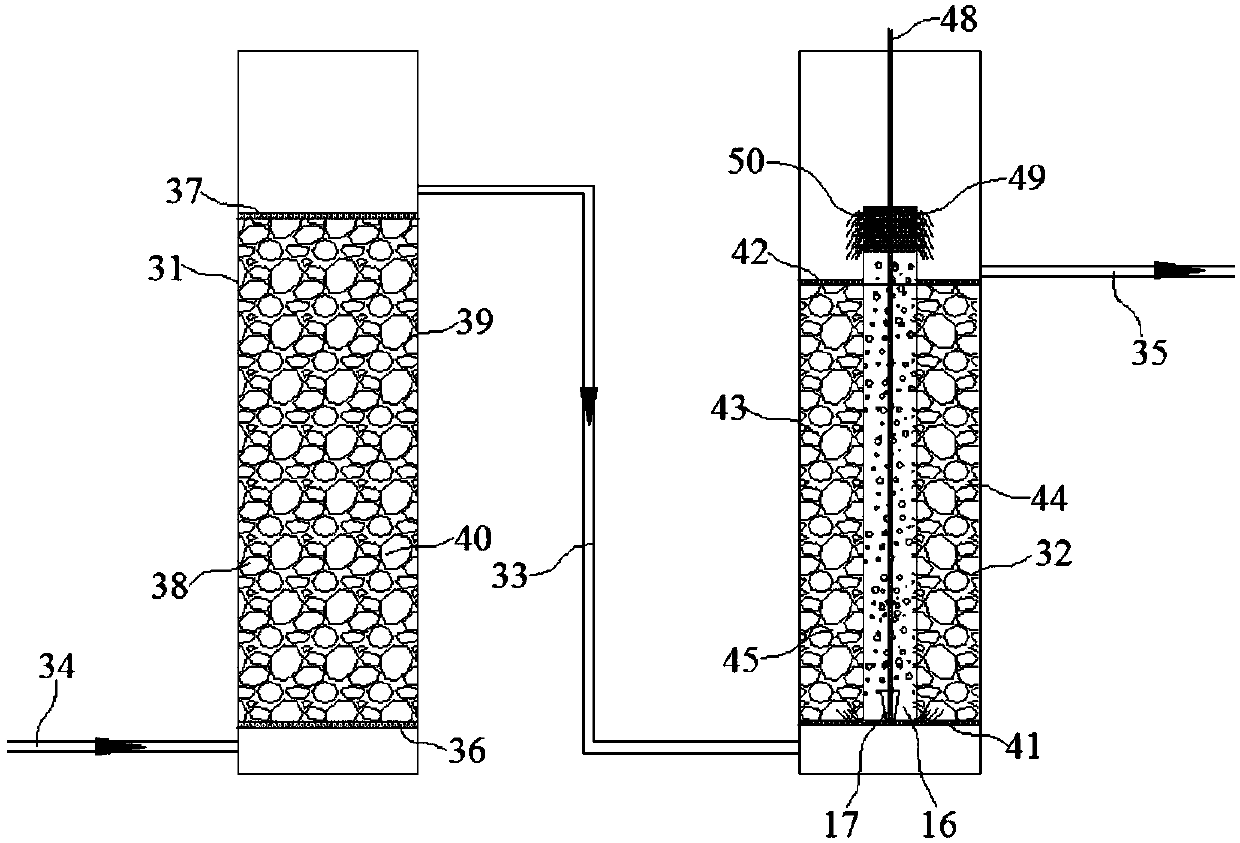

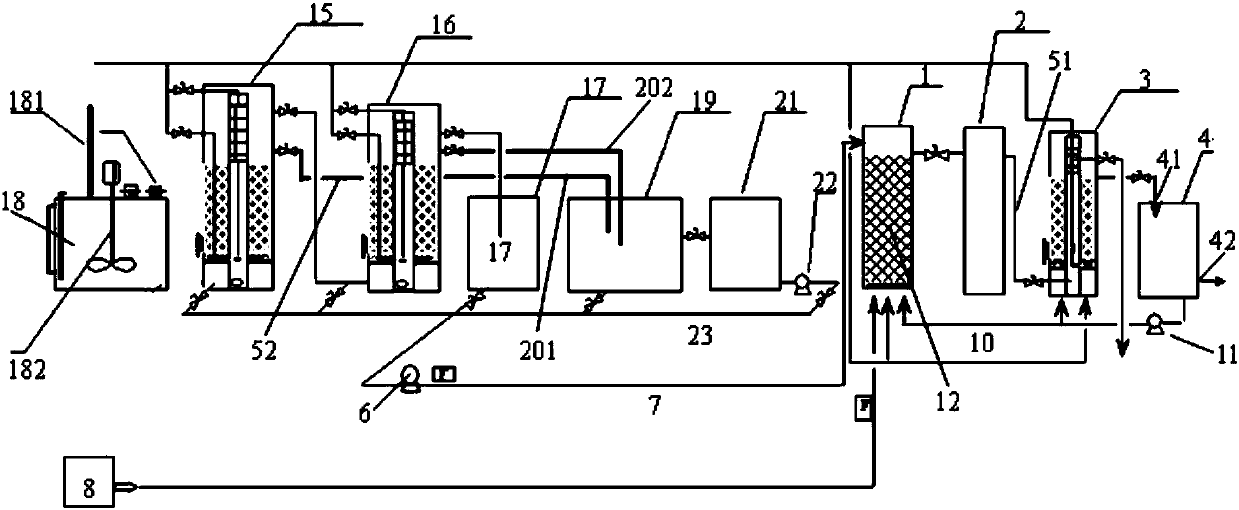

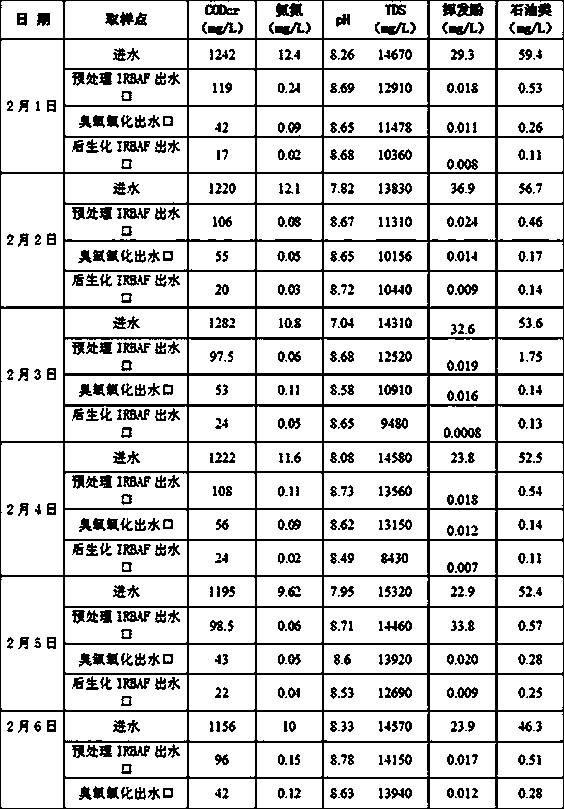

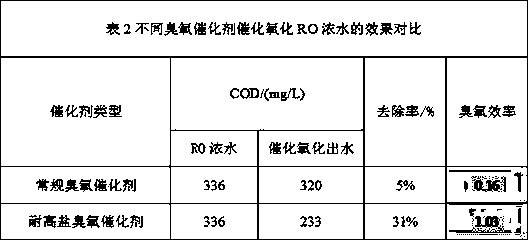

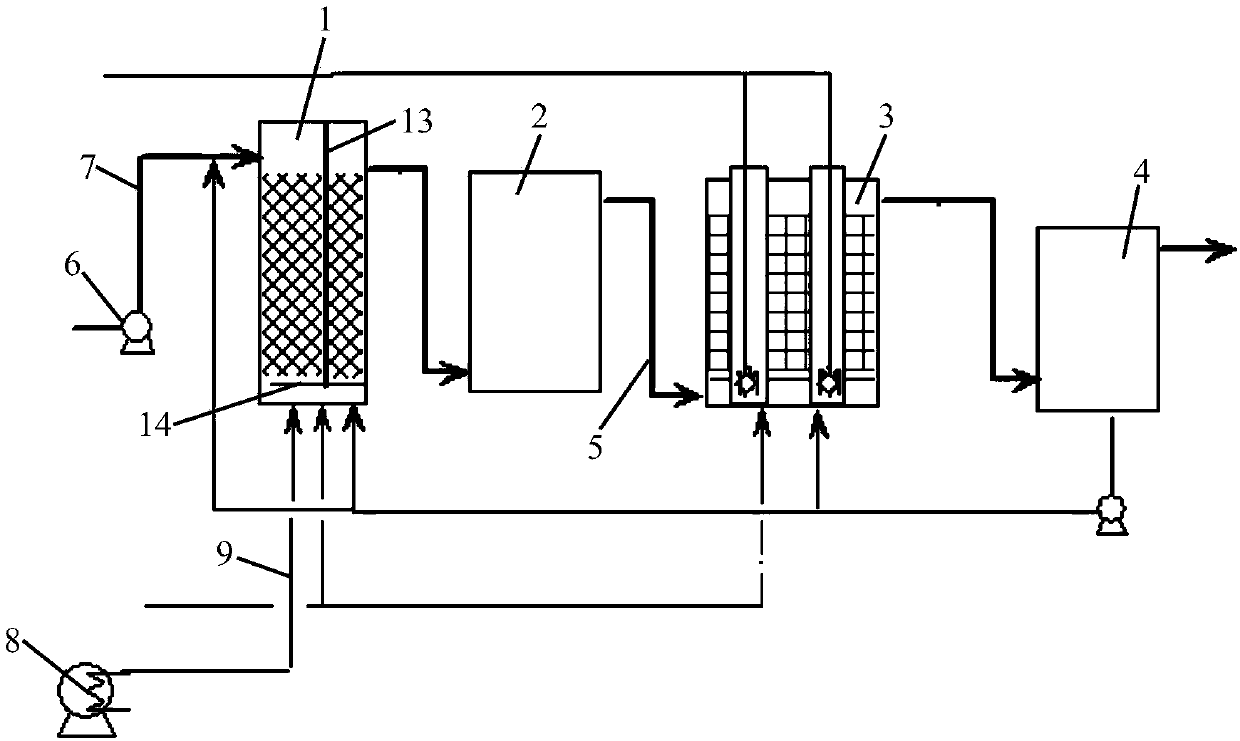

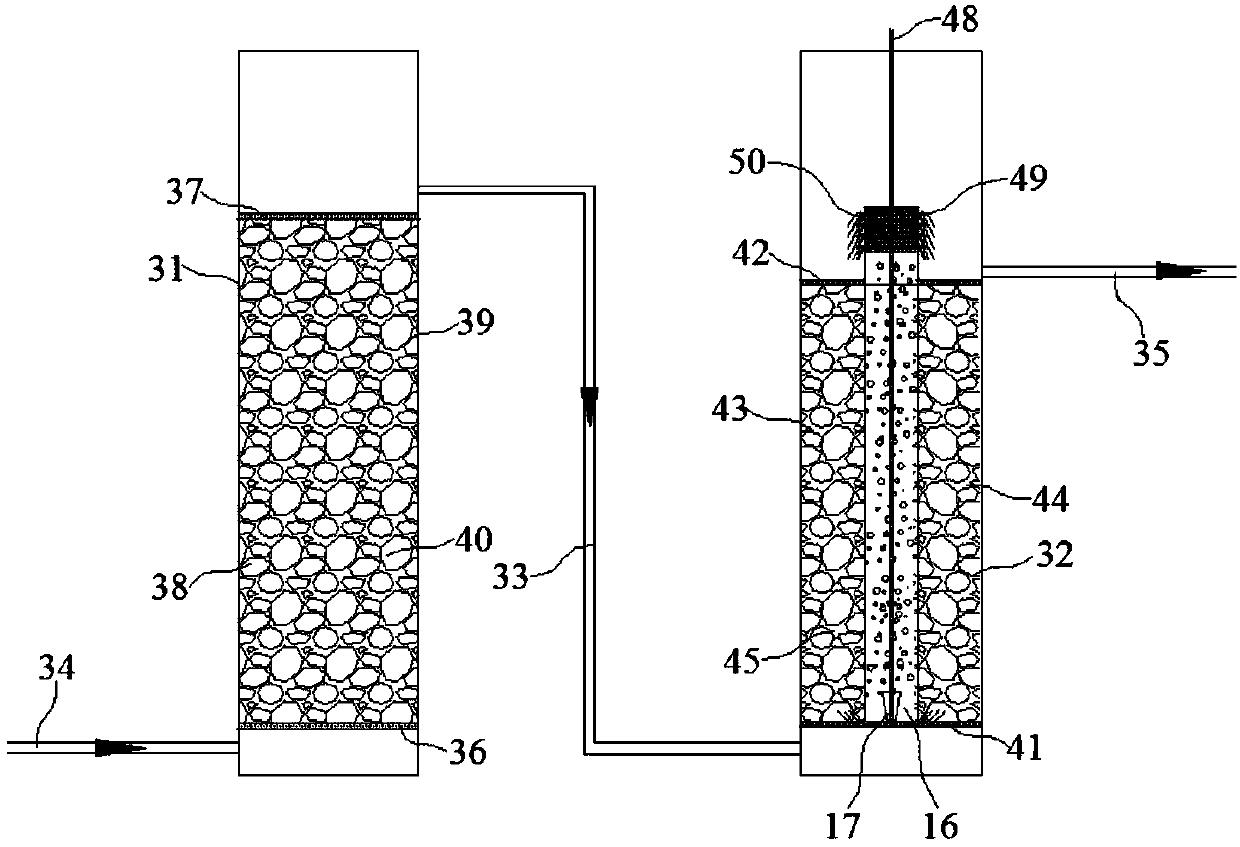

High salinity wastewater recycling system

InactiveCN107759003AImprove hydrophilic abilityBiological affinityWater contaminantsMultistage water/sewage treatmentLow-density polyethylenePolyvinyl alcohol

The invention discloses a high salinity wastewater recycling system. The high salinity wastewater recycling system comprises a catalysis oxidation pond, an oxidation stabilization pond, an after-biochemical BAF pond, a clean water pond, a diluting comprehensive tank, a pretreatment primary BAF pond, a pretreatment secondary BAF pond and a water outlet pond, the catalysis oxidation pond, the oxidation stabilization pond, the after-biochemical BAF pond and the clean water pond are connected in sequence through a rear transmission pipeline, and the catalysis oxidation pond is filled with ozone catalysis particles in the form of a static bed; the ozone catalysis particles are composed of activated aluminum oxide particles, copper oxide, titanium oxide, polyethylene glycol and polyvinyl alcohol; a carrier is prepared from, by weight, high-density polyethylene, polypropylene resin, low-density polyethylene, bamboo charcoal powder, wood powder, lignin, dichloromethane, diethyl guanidine sulfate, N,N'-ethylene bis stearamide, maleic anhydride and dicumyl peroxide. The high salinity wastewater recycling system has the good effects of removing COD, removing color, removing odor, degrading poisonous pollutants for wastewater and maintaining the biodegradability of the wastewater.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

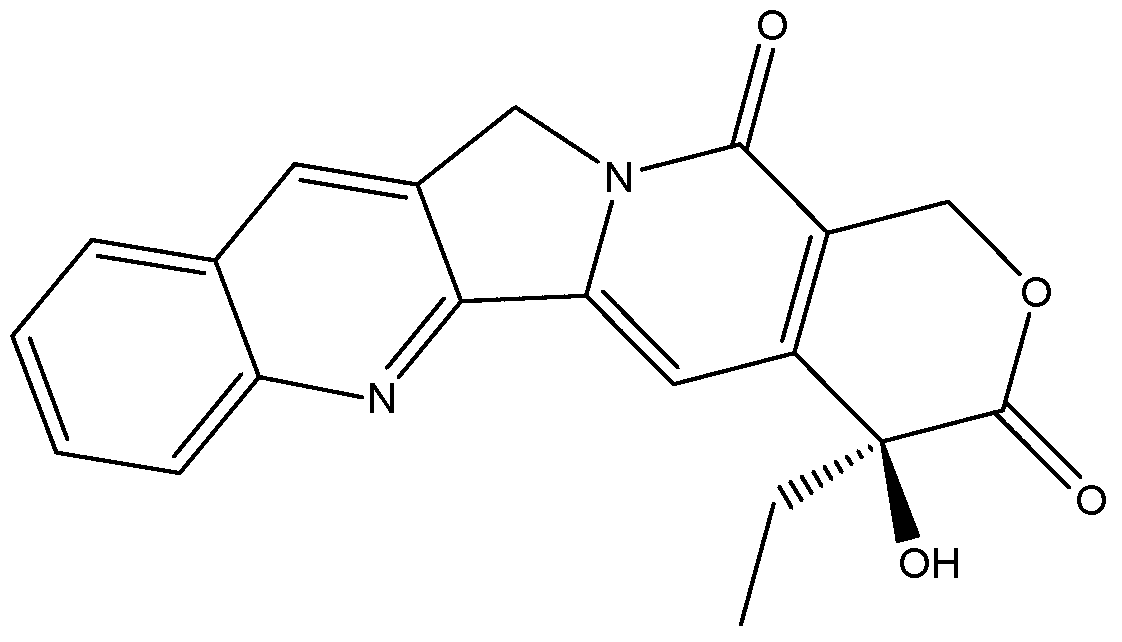

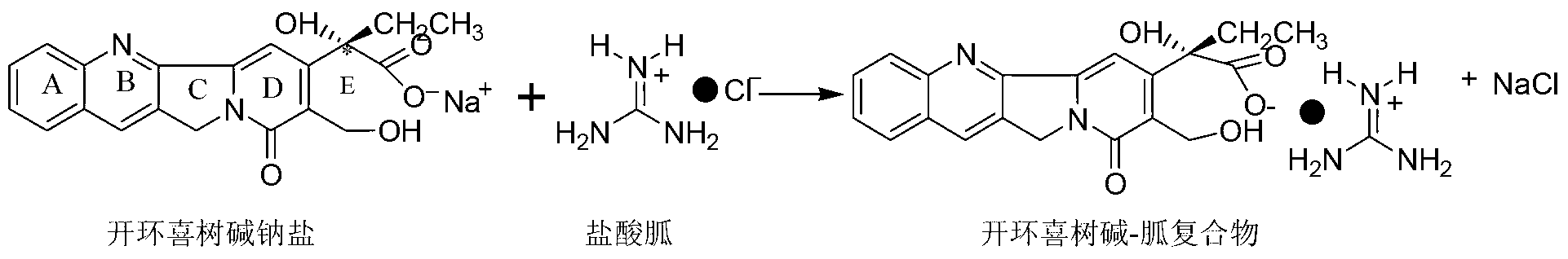

Separating and purifying method of camptothecin

The invention relates to a separating and purifying method of camptothecin. The method comprises the following steps of: (1) adding a camptothecin mixture into a sodium hydroxide solution for a ring opening treatment; (2) sequentially adding a separating reagent and a separating solvent to the reaction solution in the step (1) and reacting for 2-3 hours at 40-80 DEG C; naturally cooling; and standing at -10-40 DEG C till compound crystals of the camptothecin with opened rings and the separating reagent for separation; and filtering to obtain a compound crystal crude product of the camptothecin and the separating reagent, wherein the separating reagent is guanidine hydrochloride, guanidine carbonate, guanidine sulfate or guanidine nitrate, and the separating solvent is methanol-water, ethanol-water or acetone-water; and (3) recrystallizing the compound crystal crude product of the open-ring and the separating reagent and filtering, and adding filter cakes into concentrated hydrochloric acid to be uniformly mixed; and then, carrying out suction-filtering, washing and drying to obtain the camptothecin. The method provided by the invention can be used for reasonably and efficiently separating the camptothecin, and provides great convenience for experimental and production works, and meanwhile avoids material and energy source wastes.

Owner:THE NORTHERN RES INST OF NJUST

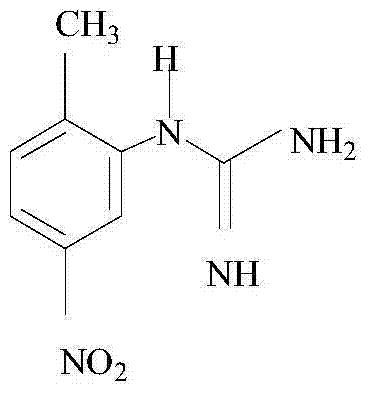

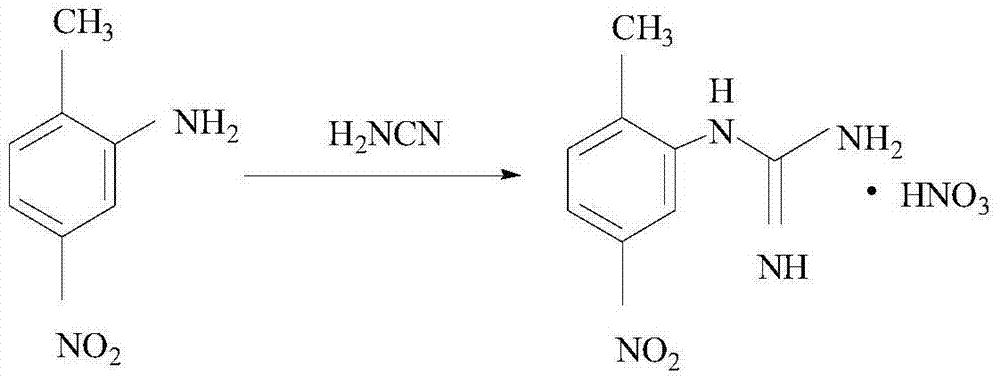

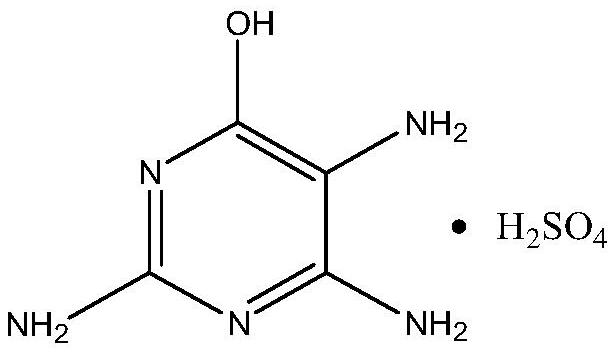

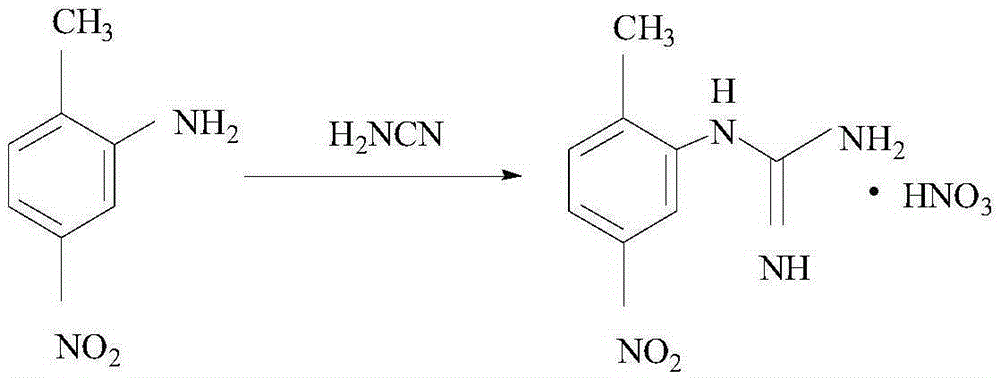

Synthetic method of (2-methyl-5-nitro phenyl) guanidine sulfate

ActiveCN103694145ARaw materials are easy to getSimple reaction conditionsOrganic chemistryOrganic compound preparationAlcoholFiltration

The invention belongs to the technical field of medicine intermediates and particularly relates to a synthetic method of an imatinib mesylate intermediate, namely (2-methyl-5-nitro phenyl) guanidine sulfate. The synthetic method comprises the following steps of by adopting 2-amino-4-nitrotoluene and oxy-methylisothiourea sulfate as a material, reacting in alcohol and DMF under the alkaline condition, then carrying out acid adjustment and suction filtration to obtain the (2-methyl-5-nitro phenyl) guanidine sulfate. The synthetic method has the advantages that the oxy-methylisothiourea sulfate is adopted for replacing cyanamide to carry out reaction, the material is easily available, the reaction condition is simple, no side products difficult to treat are generated, the purity of a product is high and is up to more than 99.7% and the yield is high.

Owner:YIYUAN XINQUAN CHEM

Method for preparing nitroguanidine by adopting micro-channel reactor

ActiveCN103172546BShort reaction timeImprove reaction efficiencyOrganic chemistryOrganic compound preparationNitroguanidineOrganic synthesis

The invention relates to a method for preparing nitroguanidine by adopting a micro-channel reactor, belonging to the technical field of organic synthesis applications. The mehtod is a new process for synthesizing nitroguanidine by taking a sulfuric acid solution of guanidine sulfate and nitric acid as raw materials and performing nitrification and dehydration in the Corning micro-channel reactor within a short reaction time from tens of seconds to a few minutes. Materials are introduced into the Corning micro-channel reactor through a metering pump, a nitroguanidine product is obtained by preheating, mixing, reaction and post-treatment, and the method has the advantages of simplicity, convenience and safety in operation, high yield and continuous production of the nitroguanidine product; and in addition, by adopting the process, the environmental pollution can be greatly reduced. The yield of the product according to the method disclosed by the invention is 90-93%, and the melting point of the product is 230-232 DEG C.

Owner:CHANGZHOU UNIV

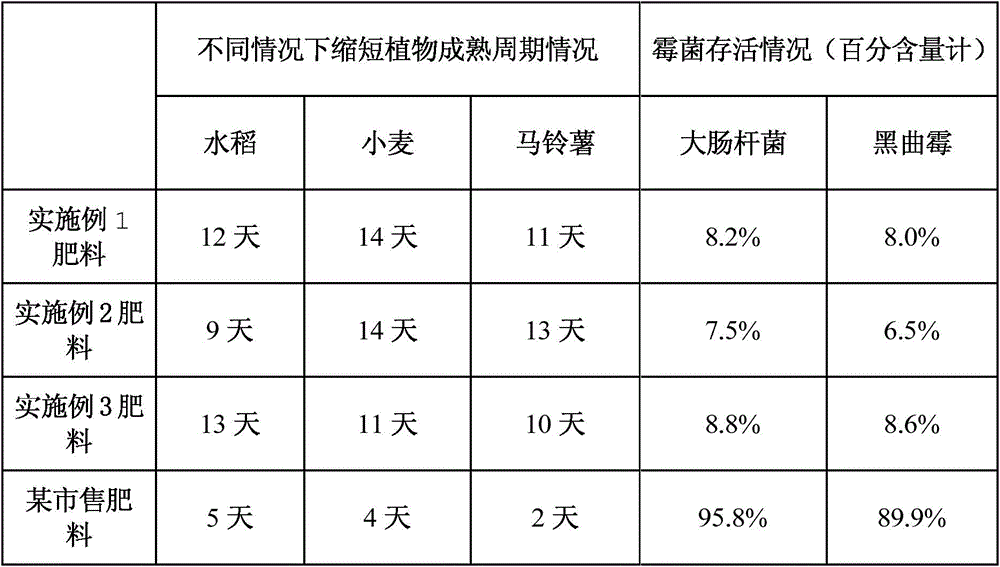

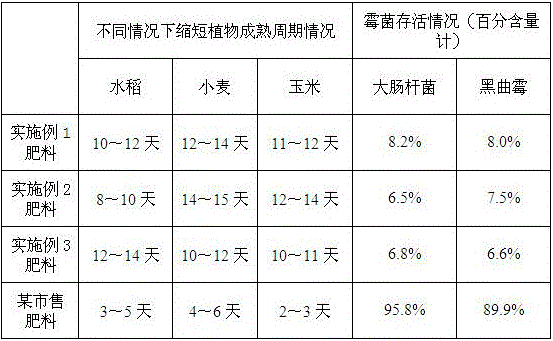

Antibacterial and insecticidal slow-release agriculture and forestry fertilizer

InactiveCN106187519ASimple processing methodShortened maturation timeCalcareous fertilisersAlkali orthophosphate fertiliserAluminateMethyl carbamate

The invention relates to an antibacterial and insecticidal slow-release agriculture and forestry fertilizer composed of the following components in parts by mass: 18-22 parts of calcium sulfate, 20-24 parts of cane molasses, 16-20 parts of a beer yeast powder, 14-18 parts of an iron ore powder, 20-24 parts of sea mud, 16-20 parts of bacillus subtilis, 14-18 parts of methyl carbamate, 20-24 parts of guanidine sulfate, 16-20 parts of diatomite, 14-18 parts of metalaxyl-M, 20-24 parts of fenarimol, 16-20 parts of diallyl phthalate, 16-20 parts of celangulin, 14-18 parts of azone, 20-24 parts of metalaxyl, 16-20 parts of pyraclostrobin, 14-18 parts of citric acid, 20-24 parts of calcium aluminate, 16-20 parts of potassium nitrate, 14-18 parts of imidacloprid, 20-24 parts of bentonite, 16-20 parts of monoammonium phosphate, 14-18 parts of indole acetic acid, 20-24 parts of methylene succinic acid, and 16-20 parts of pine pollen. The fertilizer has good antibacterial and insecticidal performance, is suitable for use in the field of agriculture and shortens the time of plant maturation.

Owner:丁悦

Multifunctional compound fertilizer with sterilization function

InactiveCN106116920AThe preparation process is simpleGood antibacterial and insecticidal effectMagnesium fertilisersAlkali orthophosphate fertiliserMethyl carbamateGibberellin

The invention relates to a multifunctional compound fertilizer with a sterilization function. The compound fertilizer is prepared from components in parts by mass as follows: 18-22 parts of phosphorus pentoxide, 20-24 parts of triacontanol, 16-20 parts of magnesium sulfate, 14-18 parts of rice bran, 20-24 parts of gibberellin, 16-20 parts of fulvic acid, 14-18 parts of manganese sulfate, 20-24 parts of rose willows, 16-20 parts of sessile stemona roots, 14-18 parts of carbendazim, 20-24 parts of peptone, 16-20 parts of sodium ortho-nitrophenol, 16-20 parts of ammonium magnesium phosphate, 14-18 parts of amino acid powder, 20-24 parts of itaconic acid, 16-20 parts of mepiquat chloride, 14-18 parts of compound sodium nitrophenolate, 20-24 parts of fluroxypr-mepthyl, 16-20 parts of deltamethrin, 14-18 parts of volcanic ash, 20-24 parts of zeolite, 16-20 parts of sepiolite, 14-18 parts of chloral hydrate, 20-24 parts of polyglycerol, 16-20 parts of methyl carbamate and 16-20 parts of guanidine sulfate. The compound fertilizer is suitable for being used in the agriculture field, and the plant maturation time is shortened.

Owner:龚灿锋

Preparation method for creatinol sulphate

InactiveCN101671282BMild reaction conditionsEasy to operateOrganic chemistryOrganic compound preparationGuanidine derivativesVitality

Owner:TIANJIN TIANCHENG PHARMA

A kind of preparation method of palbocyb

ActiveCN104478874BHigh yieldRaw materials are cheap and easy to getOrganic chemistry2-PyridoneMethyl group

The invention relates to a preparation method of palbociclib. The method comprises the following steps: carrying out N-acetoacetylation reaction by using cyclopentylamine and an acetoacetylation agent to obtain N,N-di(acetoacetyl) cyclopentylamine (II), carrying out intramolecular condensation on N,N-di(acetoacetyl) cyclopentylamine (II) in the presence of an alkaline reagent to obtain N-cyclopentyl-3-acetyl-4-methyl-6-hydroxy-2-pyridone (III), enabling N-cyclopentyl-3-acetyl-4-methyl-6-hydroxy-2-pyridone (III) to react with a formylation reagent to prepare N-cyclopentyl-3-acetyl-4-methyl-5-formyl-6-chlorine-2-pyridone (IV), carrying out pyrimidine ring reaction by using N-cyclopentyl-3-acetyl-4-methyl-5-formyl-6-chlorine-2-pyridone (IV) and N-(5-(4-tert-butoxy carbonyl-1-hexahydropyrazinyl)-2-pyridyl) guanidine sulfate (V), and then hydrolyzing under the alkaline condition to prepare palbociclib. The preparation method of palbociclib is easily available in raw materials, short in process, simple and convenient to operate and safe and environmentally friendly in process.

Owner:XINFA PHARMA

Nonconsumable wood flame retardant and its preparation

InactiveCN1304183CSolve moisture absorptionAntisepticWood impregnation detailsFoaming agentPentaerythritol

An anti-losing flame-retarding agent for wood or other organic fibre materials is prepared from formaldehyde, urea, ammonia water, phosphoric acid, cyanuramide and / or guanidine phosphate and / or guanidine sulfate, and polyethanediol and / or pentacrythrite and / or dextrin.

Owner:陈万利 +3

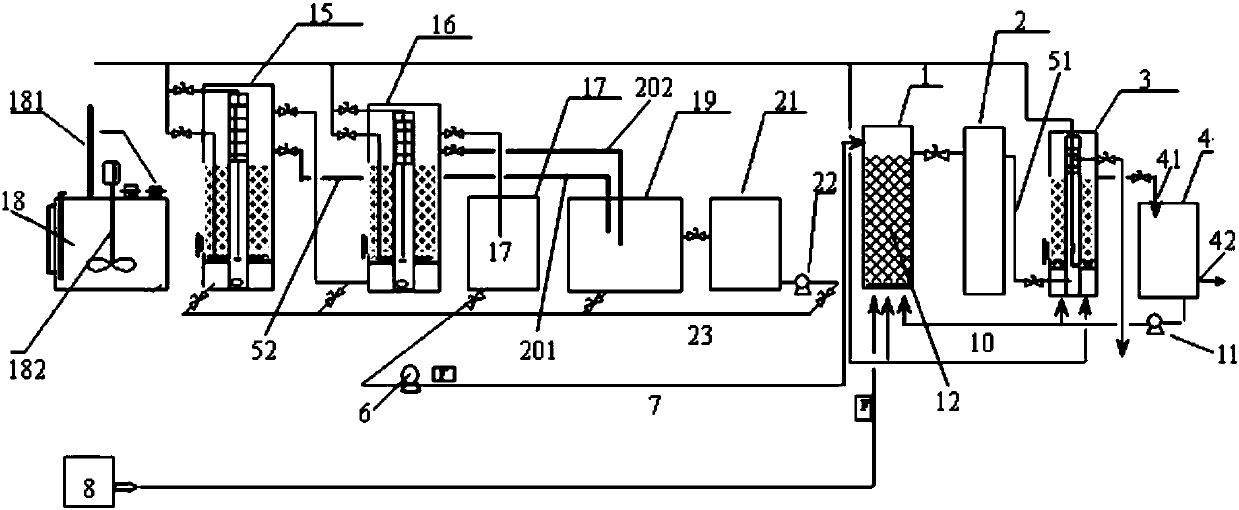

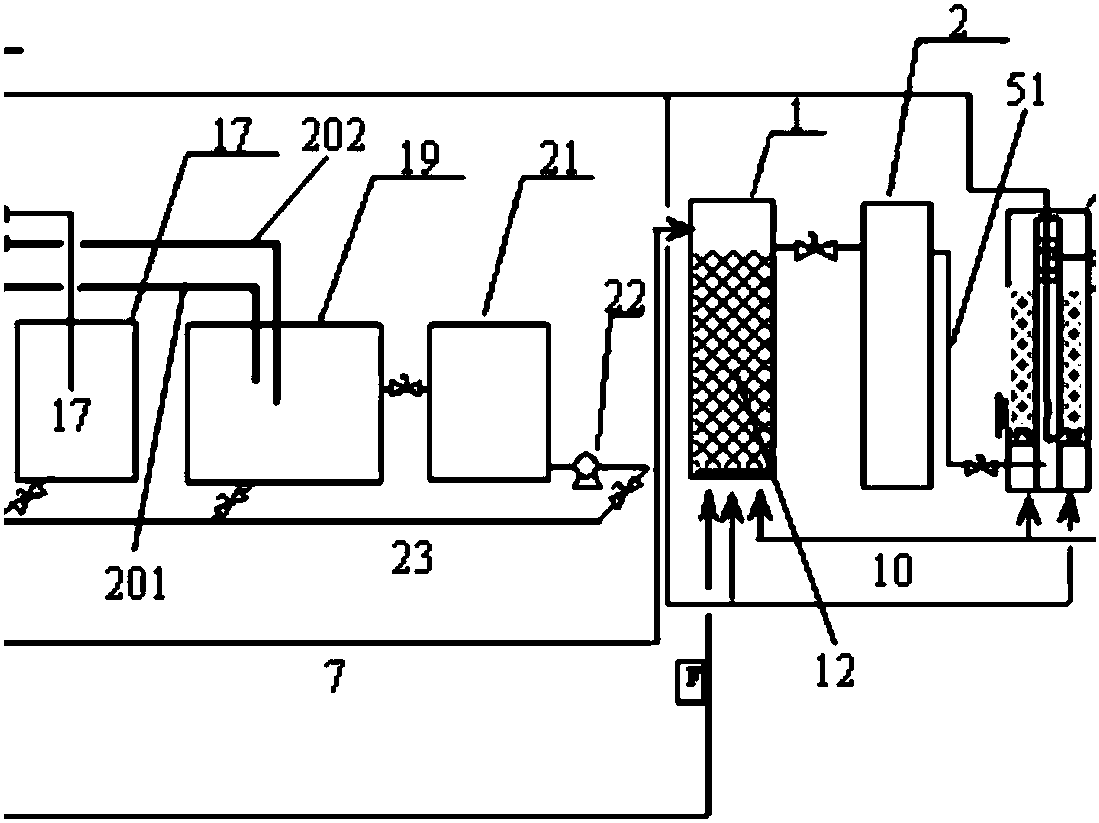

Intermittent aeration and biochemical nitrogen and phosphorus removal treatment system

InactiveCN107758997AImprove biodegradabilityImprove toleranceWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsLow-density polyethylenePolyvinyl alcohol

The invention discloses an intermittent aeration and biochemical nitrogen and phosphorus removal treatment system. A catalytic oxidation tank of the device is filled with ozone catalysis particles inthe form of a fixed bed, and the ozone catalysis particles are prepared from, by weight, activated alumina particles, copper oxide, titanium dioxide, polyethylene glycol and polyvinyl alcohol. Post-biochemical BAF tanks also include an anaerobic tank and an aerobiotic tank, a lower screening plate and an upper screening plate are installed at the lower portion and the upper portion of the aerobiotic tank respectively, a carrier is prepared from, by weight, high-density polyethylene resin, low-density polyethylene, bamboo charcoal powder, wood powder, lignin, methylene dichloride, diethyl guanidine sulfate, N,N'-ethylene bis-stearamide, maleic anhydride, dicumyl peroxide, gelatin, magnetic powder and pentaerythritol stearate. The intermittent aeration and biochemical nitrogen and phosphorusremoval treatment system achieves wastewater COD removal, decolorization, deodorization and degradation of toxic pollutants in the catalytic oxidation treatment process of sewage in the coal chemicalindustry.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Production process of guanidine sulfate

PendingCN114436898AEfficient removalHigh purityOrganic chemistryOrganic compound preparationAqueous sodium hydroxideHydrogen chloride

The invention relates to the field of guanidyl compound preparation, and particularly discloses a guanidine sulfate production process which comprises the following steps: S1, mixing guanidine hydrochloride and sulfuric acid in a molar ratio of 2: (1-2), and reacting at 30-100 DEG C for 1-48 hours to generate a reaction product and hydrogen chloride gas; s2, cooling and crystallizing the reaction product prepared in S1, and filtering to obtain crude guanidine sulfate; introducing hydrogen chloride gas into the sodium hydroxide aqueous solution to generate a sodium chloride solution and water; s3, recrystallizing the crude guanidine sulfate prepared in S2 to prepare a guanidine sulfate finished product; the prepared guanidine sulfate finished product has the advantages of few impurities and high purity.

Owner:田雨

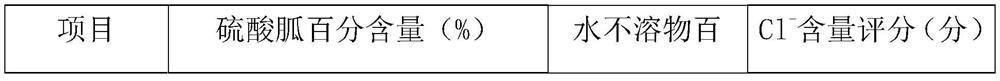

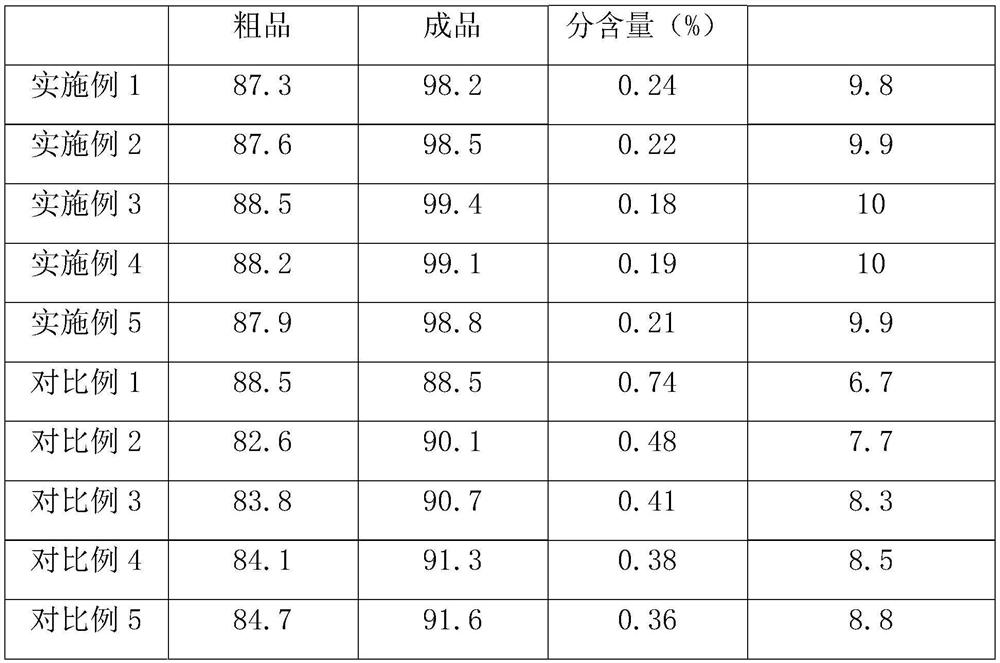

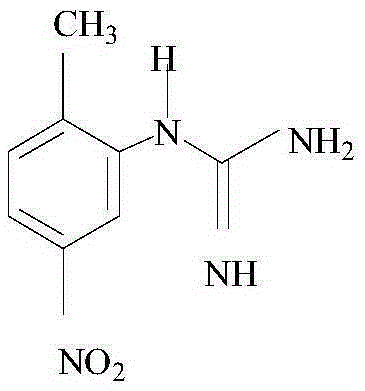

Preparation method of 6-hydroxy-2, 4, 5-triaminopyrimidine sulfate

PendingCN114524771AAvoid generatingReduce total nitrogenOrganic chemistryChemical recyclingCyanoacetic acidNitration

In order to solve the technical problem that in a traditional preparation method of 6-hydroxy-2, 4, 5-triaminopyrimidine sulfate, a process for cyclization by guanidine nitrate or guanidine hydrochloride is not beneficial to safety, environmental protection and product quality, the invention provides a novel method for preparing 6-hydroxy-2, 4, 5-triaminopyrimidine sulfate, guanidine sulfate is adopted to replace the traditional guanidine nitrate or guanidine hydrochloride, and the yield of 6-hydroxy-2, 4, 5-triaminopyrimidine sulfate is increased. The 6-hydroxy-2, 4, 5-triaminopyrimidine sulfate is prepared by cyclization with methyl cyanoacetate, nitrosation, catalytic hydrogenation and sulfuric acid acidification salification, so that sodium nitrate or sodium chloride is avoided, total nitrogen or total chlorine in subsequent wastewater is reduced, and environmental protection is facilitated. Meanwhile, the reaction safety risk caused by guanidine nitrate or the product quality risk caused by guanidine hydrochloride can be avoided, and sustainable development is facilitated.

Owner:江苏八巨药业有限公司

The synthetic method of (2-methyl-5-nitrophenyl) guanidine sulfate

ActiveCN103694145BRaw materials are easy to getSimple reaction conditionsOrganic chemistryOrganic compound preparationPhosphoniumFiltration

The invention belongs to the technical field of medicine intermediates and particularly relates to a synthetic method of an imatinib mesylate intermediate, namely (2-methyl-5-nitro phenyl) guanidine sulfate. The synthetic method comprises the following steps of by adopting 2-amino-4-nitrotoluene and oxy-methylisothiourea sulfate as a material, reacting in alcohol and DMF under the alkaline condition, then carrying out acid adjustment and suction filtration to obtain the (2-methyl-5-nitro phenyl) guanidine sulfate. The synthetic method has the advantages that the oxy-methylisothiourea sulfate is adopted for replacing cyanamide to carry out reaction, the material is easily available, the reaction condition is simple, no side products difficult to treat are generated, the purity of a product is high and is up to more than 99.7% and the yield is high.

Owner:YIYUAN XINQUAN CHEM

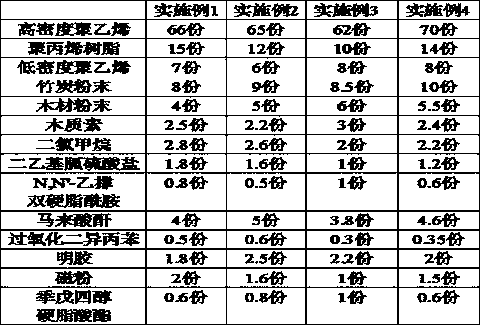

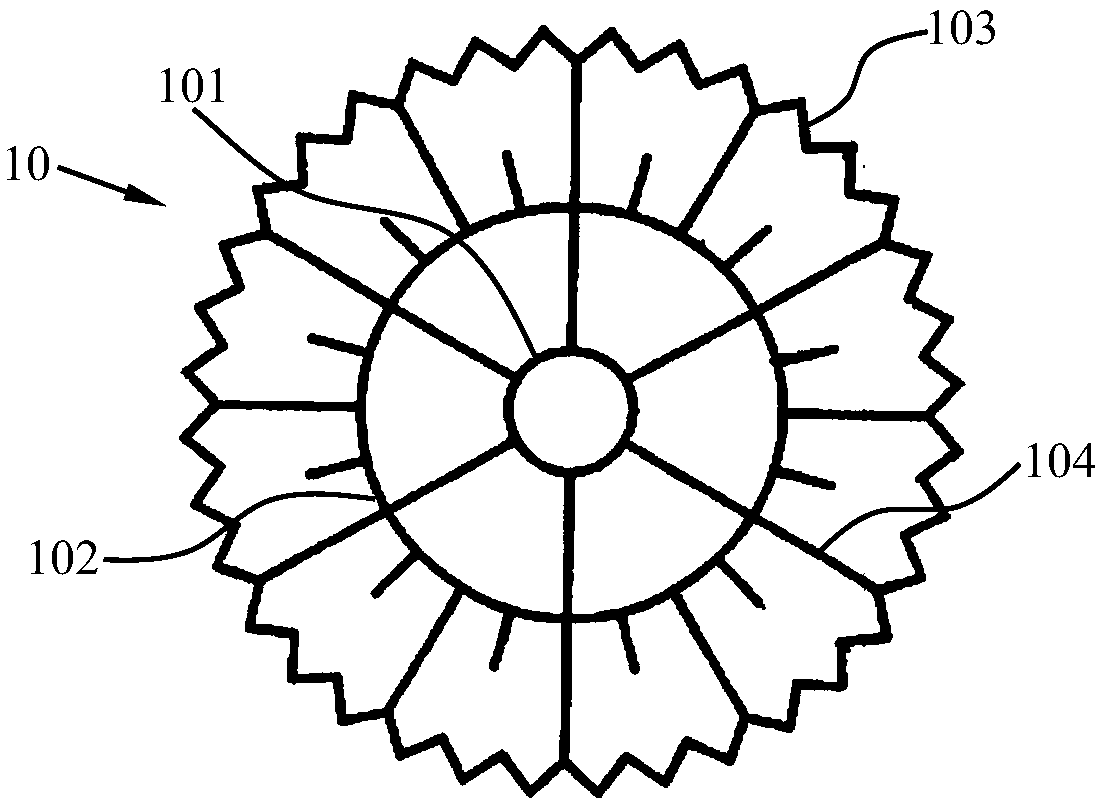

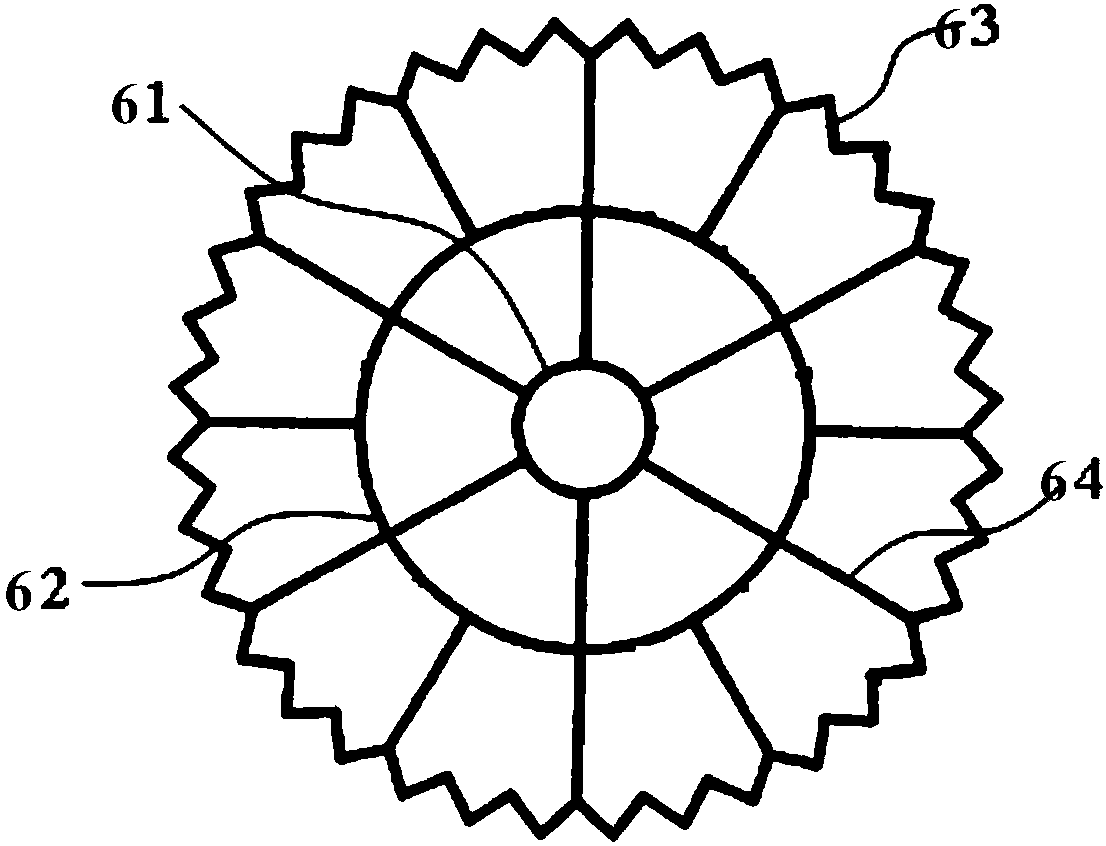

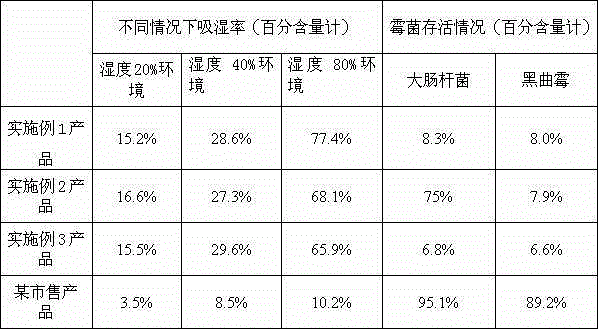

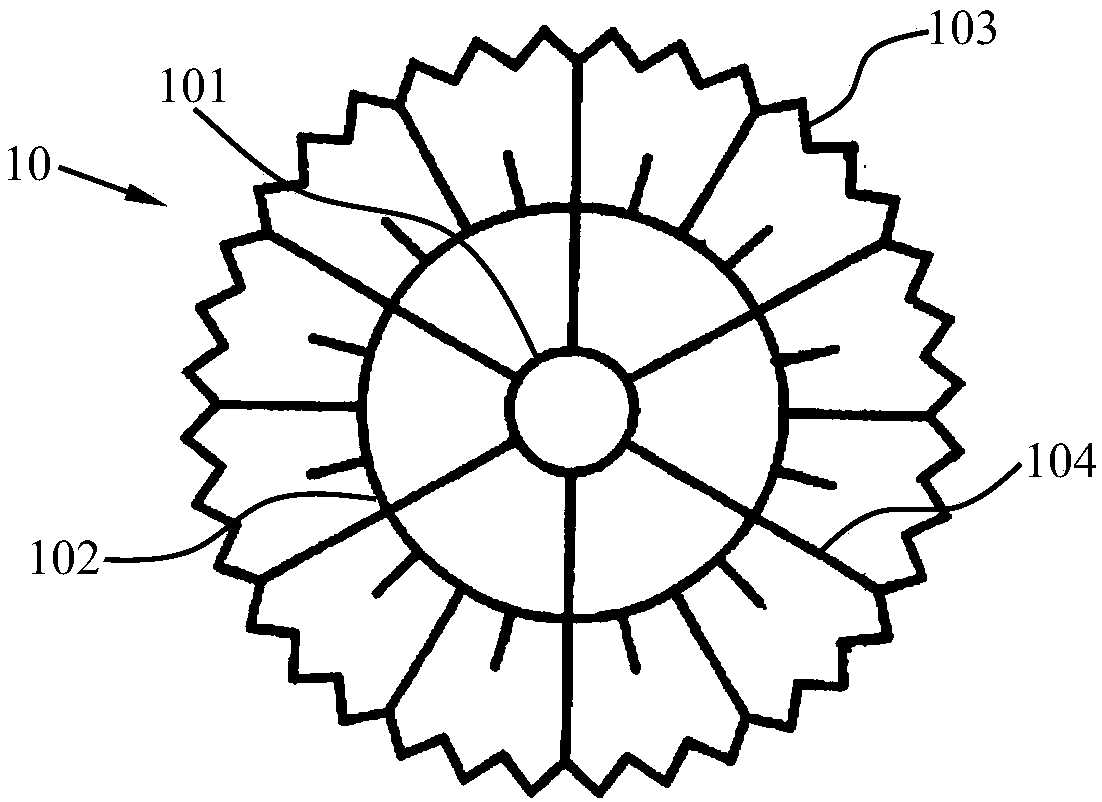

Microorganism-loaded filling material and preparation method thereof

InactiveCN107758843AImprove processing efficiencyIncrease the amount of filmWater treatment parameter controlSustainable biological treatmentLow-density polyethylenePolymer science

The invention discloses a microorganism-loaded filling material. The microorganism-loaded filling material comprises, by weight part, high-density polyethylene, polypropylene resin, low-density polyethylene, bamboo charcoal powder, wood powder, lignin, dichloromethane, diethyl guanidine sulfate, N,N'-ethylene bis-stearamide, maleic anhydride, dicumyl peroxide, gelatin, magnetic powder and pentaerythritol stearate, and the density of the microorganism-loaded filling material is 0.96-0.98 g / <cm>3. The filling material is high in biofilm culturing speed, not likely to fall off, high in treatmentefficiency and suitable for treating low-concentration organic substances and ammonia nitrogen in sewage and low-concentration organic wastewater. The biological filling material has extremely high hydrophilicity and biocompatibility, the filling material has high adsorption strength on biofilms, and interception and accumulation of biomass on a filling material carrier are facilitated.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

High salinity wastewater drainage and treatment system

InactiveCN107758996AImprove hydrophilic abilityBiological affinityWater contaminantsTreatment with aerobic and anaerobic processesLow-density polyethylenePolyvinyl alcohol

The invention discloses a high salinity wastewater drainage and treatment system. The high salinity wastewater drainage and treatment system comprises a catalysis oxidation pond, an oxidation stabilization pond, an after-biochemical BAF pond, a clean water pond, a diluting comprehensive tank, a pretreatment primary BAF pond, a pretreatment secondary BAF pond and a water outlet pond, the catalysisoxidation pond, the oxidation stabilization pond, the after-biochemical BAF pond and the clean water pond are connected in sequence through a rear transmission pipeline, and the catalysis oxidation pond is filled with ozone catalysis particles in the form of a static bed; the ozone catalysis particles are composed of activated aluminum oxide particles, copper oxide, titanium oxide, polyethylene glycol and polyvinyl alcohol; a carrier is prepared from, by weight, high-density polyethylene, polypropylene resin, low-density polyethylene, bamboo charcoal powder, wood powder, lignin, dichloromethane, diethyl guanidine sulfate, N,N'-ethylene bis stearamide, maleic anhydride, dicumyl peroxide and gelatin. The high salinity wastewater drainage and treatment system has the good effects of removingCOD, removing color, removing odor, degrading poisonous pollutants for wastewater and maintaining the biodegradability of the wastewater.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

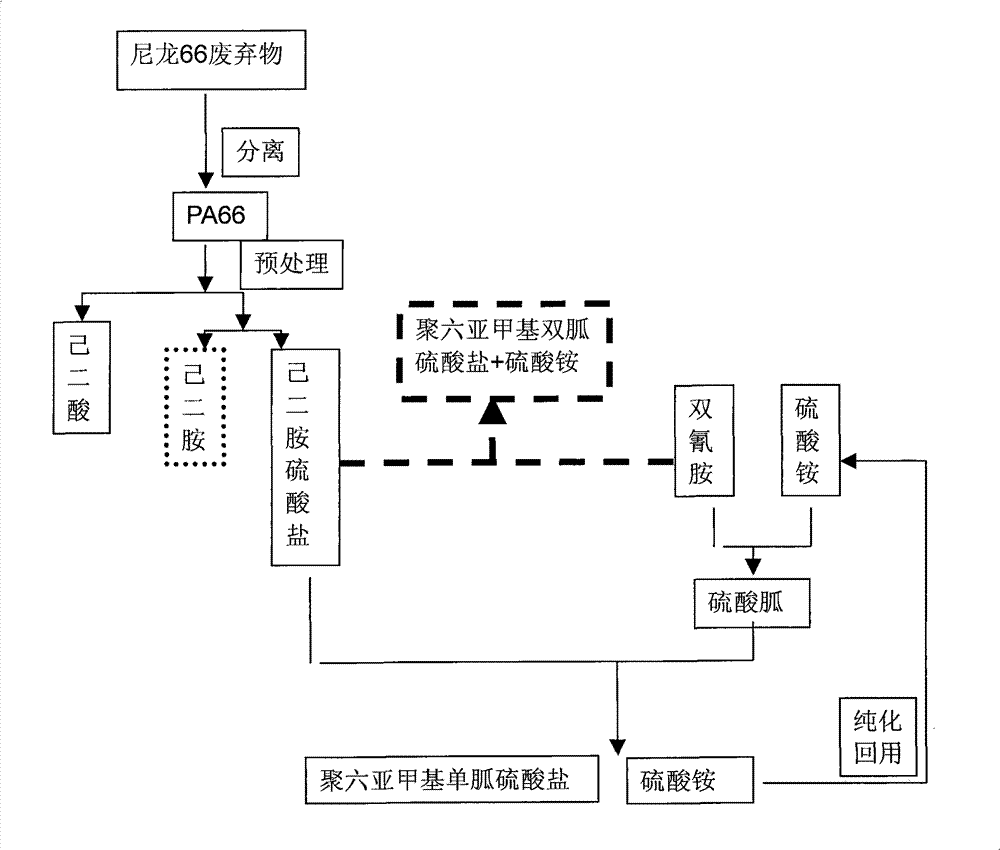

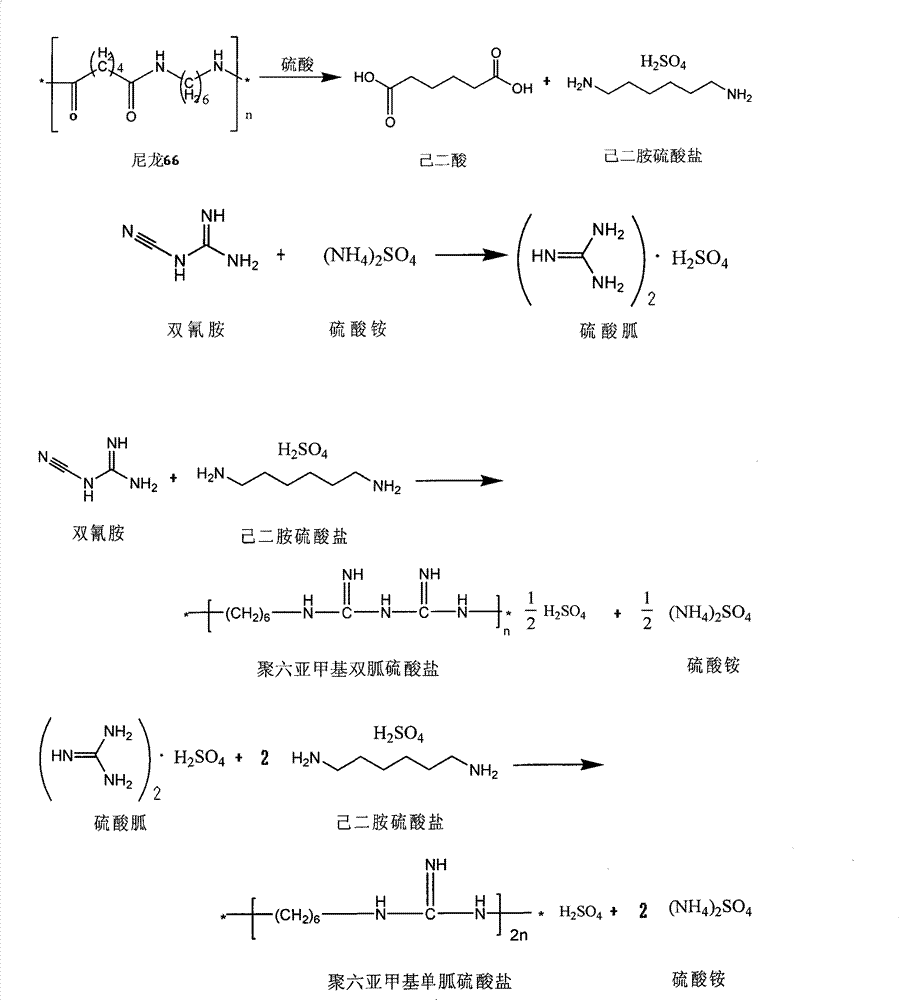

Method for producing adipic acid, hexamethylenediamine sulfate and polyhexamethylene (di)guanidine sulfate from nylon-66 through depolymerization

InactiveCN101857539BReduce manufacturing costExtended reaction timeBiocideOrganic compound preparationDepolymerizationHexamethylenediamine

The invention discloses a method for producing adipic acid, hexamethylenediamine sulfate and polyhexamethylene (di)guanidine sulfate from nylon-66 through depolymerization, which is characterized by comprising the following steps of: depolymerizing the waste nylon-66 by using 28 to 35 percent sulfuric acid to obtain refined adipic acid and hexamethylenediamine sulfate; polymerizing the hexamethylenediamine sulfate serving as a raw material and dicyandiamide at the temperature of between 170 and 200 DEG C for 3 to 9 hours to obtain white or pale yellow polyhexamethylene diguanidine sulfate; reacting the dicyandiamide with ammonium sulfate at the temperature of between 170 and 190 for 1 to 3 hours, and adding the hexamethylenediamine sulfate to continue the reaction for 3 to 7 hours to obtain white or pale yellow polyhexamethylene guanidine sulfate. The method solves the problems of low recovery rate of the hexamethylenediamine sulfate and poor benefit in the conventional nylon-66 recovering process, and develops the stable, low-toxin and high-efficiency disinfectant polyhexamethylene (di)guanidine sulfate; and the technological process is simple, convenient, environment-friendly and safe.

Owner:NINGBO UNIV

Process for advanced treatment of phenolated water at gas station

InactiveCN107758994AImprove hydrophilic abilityBiological affinityWater contaminantsHeterogenous catalyst chemical elementsLow-density polyethylenePolyvinyl alcohol

The invention discloses a process for advanced treatment of phenolated water at gas station. The treatment process is based on a special treatment device, and the special treatment device comprises acatalytic oxidation tank, an oxidation stabilization tank, a post-biochemical BAF tank, a clean-water tank, an integrated dilution tank, a pretreating primary BAF tank, a pretreating secondary BAF tank and an effluent tank, wherein the catalytic oxidation tank, the oxidation stabilization tank, the post-biochemical BAF tank and the clean-water tank are sequentially connected through a rear-sectiontransmission pipeline. The ozone catalyzing particles are prepared from activated aluminum oxide particles, copper oxide, titanium dioxide, polyethylene glycol and polyvinyl alcohol. A carrier is prepared from, by weight, 60-70 parts of high-density polyethylene, 10-15 parts of polypropylene resin, 6-8 parts of low-density polyethylene, 8-10 parts of bamboo charcoal powder, 4-6 parts of wood powder, 2-3 parts of lignin, 2-3 parts of dichloromethane, 1-2 parts of diethyl guanidine sulfate, 0.5-1 part of N,N'-ethylene bis-stearamide and 3-5 parts of maleic anhydride. Macromolecular refractory organic matter is oxidized into micromolecular biodegradable organic matter and thus the biodegradability of effluent is improved by adopting the process.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

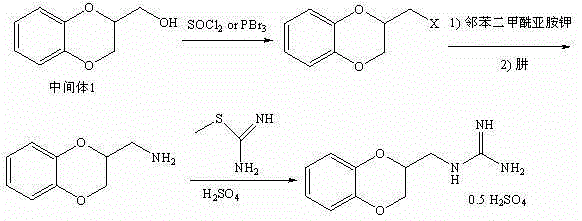

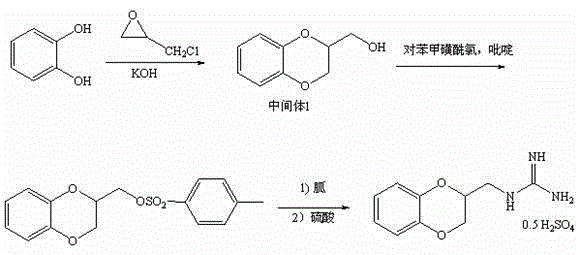

Guanoxan sulfate synthesis method

The invention belongs to the technical field of organic drug synthesis, and particularly relates to a guanoxan sulfate synthesis method. The method comprises steps as follows: 1), 2-hydroxymethyl-1,4-benzodioxane and thionyl chloride have a chlorination reaction under the condition of existence of a solvent I, and 2-chloromethyl-1,4-benzodioxane is obtained; 2), 2-chloromethyl-1,4-benzodioxane and guanidine are condensed under the condition of existence of alkali and a solvent II, guanoxan is obtained, guanoxan and sulfuric acid are salified, and a finished product guanoxan sulfate is obtained. According to the guanoxan sulfate synthesis method, technological synthesis steps are simple, a route is short, raw material toxicity is relatively lower, and the yield and the purity of the product are high.

Owner:SHANGHAI MODERN HASEN SHANGQIU PHARMA

Sterilization and drying treating agent for agricultural seeds

InactiveCN105076254AThe preparation process is simpleImprove the bactericidal effectBiocideSeed and root treatmentBiotechnologyEpoxy

The invention relates to a sterilization and drying treating agent for agricultural seeds. The sterilization and drying treating agent comprises the following ingredients by mass: 26 to 30 parts of chitosan oligosaccharide, 28 to 32 parts of tebuconazole, 24 to 28 parts of myclobutanil, 28 to 32 parts of cinnamomum cassia essential oil, 24 to 28 parts of tetramethyl thiuram disulfide, 28 to 32 parts of amino-oligosaccharide, 24 to 28 parts of malathion, 30 to 34 parts of methyl carbamate, 24 to 28 parts of guanidine sulfate, 28 to 32 parts of diatomite, 24 to 28 parts of sodium tripolyphosphate, 28 to 32 parts of aluminum potassium sulfate, 24 to 28 parts of polysulfide modified epoxy resin, 28 to 32 parts of sepiolite, 24 to 28 parts of dried pepper, 28 to 32 parts of konjac glucomannan, 24 to 28 parts of pulverized anthracite, 28 to 32 parts of natural stellerite powder, and 24 to 28 parts of dimethyl maleate. The treating agent has the advantages that the preparation technology is simple in method; the prepared product is relatively superior in mold prevention, sterilization and drying, thereby being suitable for the field of agricultural seeds, and being better in product performance.

Owner:王璐

Energy-saving biochemical nitrogen and phosphorus removal treatment device

InactiveCN107758837AImprove hydrophilic abilityBiological affinityTreatment using aerobic processesWater contaminantsLow-density polyethyleneFixed bed

The invention discloses an energy-saving biochemical nitrogen and phosphorus removal treatment device. A catalytic oxidation tank of the device is filled with ozone catalysis particles in the form ofa fixed bed, and the ozone catalysis particles are prepared from, by weight, activated alumina particles, copper oxide, titanium dioxide, polyethylene glycol and polyvinyl alcohol. Post-biochemical BAF tanks also include an anaerobic tank and an aerobiotic tank, a lower screening plate and an upper screening plate are installed at the lower portion and the upper portion of the aerobiotic tank respectively, a carrier is prepared from, by weight, high-density polyethylene resin, low-density polyethylene, bamboo charcoal powder, wood powder, lignin, methylene dichloride, diethyl guanidine sulfate, N,N'-ethylene bis-stearamide, maleic anhydride, dicumyl peroxide, gelatin, magnetic powder and pentaerythritol stearate. The energy-saving biochemical nitrogen and phosphorus removal treatment device achieves wastewater COD removal, decolorization, deodorization and degradation of toxic pollutants in the catalytic oxidation treatment process of sewage in the coal chemical industry.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com