Adsorption preparation for wastewater treatment and preparation method thereof

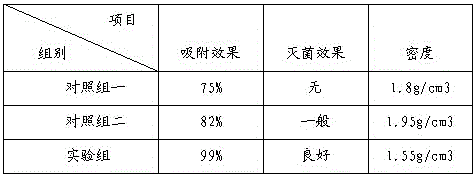

A technology for sewage treatment and preparation, applied in water/sewage treatment, adsorbed water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of no sterilization function, low processing efficiency, low adsorption efficiency, etc. High processing efficiency, increased contact area, and low material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An adsorption preparation for sewage treatment, made of the following raw materials in parts by weight, including 14 parts of aluminum sulfate, 19 parts of oxalic acid, 22 parts of polyacrylamide, 16 parts of sodium carbonate, 9 parts of activated carbon, and 10 parts of calcium aluminate , 5 parts of ammonium sulfate, 4 parts of sodium metaaluminate, 12 parts of disodium edetate, 9 parts of potassium ferrate, 8 parts of polyvinylpyrrolidone, 3 parts of sodium carbon, 9 parts of ferric citrate, polysulfide chloride 8 parts of iron oxide, 2 parts of cellulose powder, 3 parts of sodium lignosulfonate, 1 part of dibenzoyl peroxide, 7 parts of nano-manganese oxide, 16 parts of guanidine sulfate, 22 parts of dodecyltriphenylphosphorus chloride parts and 9 parts isopropanol.

[0021] A preparation method for an adsorption preparation for sewage treatment, comprising the following steps:

[0022] 1) Mix 14 parts of aluminum sulfate, 19 parts of oxalic acid, 22 parts of polyac...

Embodiment 2

[0029] An adsorption preparation for sewage treatment, made of the following raw materials in parts by weight, including 16 parts of aluminum sulfate, 19.5 parts of oxalic acid, 23.5 parts of polyacrylamide, 17 parts of sodium carbonate, 12.5 parts of activated carbon, and 13 parts of calcium aluminate , 6.5 parts of ammonium sulfate, 7.5 parts of sodium metaaluminate, 13 parts of disodium edetate, 12.5 parts of potassium ferrate, 9 parts of polyvinylpyrrolidone, 3.5 parts of sodium carbon, 11.5 parts of iron citrate, polysulfur chloride 9 parts of iron oxide, 3.5 parts of cellulose powder, 5.5 parts of sodium lignosulfonate, 1.5 parts of dibenzoyl peroxide, 10.5 parts of nano-manganese oxide, 20 parts of guanidine sulfate, 23.5 parts of dodecyltriphenylphosphorus chloride parts and 12.5 parts of isopropanol.

[0030] A preparation method for an adsorption preparation for sewage treatment, comprising the following steps:

[0031]1) 16 parts of aluminum sulfate, 19.5 parts of ...

Embodiment 3

[0038] An adsorption preparation for sewage treatment, made of the following raw materials in parts by weight, including 18 parts of aluminum sulfate, 20 parts of oxalic acid, 25 parts of polyacrylamide, 18 parts of sodium carbonate, 17 parts of activated carbon, and 16 parts of calcium aluminate , 8 parts of ammonium sulfate, 11 parts of sodium metaaluminate, 14 parts of disodium edetate, 16 parts of potassium ferrate, 10 parts of polyvinylpyrrolidone, 4 parts of sodium carbon, 14 parts of ferric citrate, polysulfur chloride 10 parts of iron oxide, 5 parts of cellulose powder, 8 parts of sodium lignosulfonate, 2 parts of dibenzoyl peroxide, 14 parts of nano manganese oxide, 24 parts of guanidine sulfate, 25 parts of dodecyltriphenylphosphorous chloride parts and 16 parts of isopropanol.

[0039] A preparation method for an adsorption preparation for sewage treatment, comprising the following steps:

[0040] 1) Mix 18 parts of aluminum sulfate, 20 parts of oxalic acid, 25 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com