Subjective-objective explosive with high crystal density and preparation method of subjective-objective explosive

A crystal density, host-guest technology, applied in the direction of explosives processing equipment, explosives, explosives composite components, etc., can solve the problems of hydroxylamine application and storage difficulties, hydroxylamine solution explosion, instability, etc., to achieve good thermal stability, mild experimentation, increase The effect of outgassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Weigh 7g of dried hydroxylamine hydrochloride, slowly pour it into a 250ml conical flask, add 100ml of butanol solution at the same time, stir magnetically for 10min, and dissolve all the solids;

[0050] (2) Slowly add 9.6 g of sodium butoxide into the hydroxylamine hydrochloride solution, and simultaneously stir rapidly with a magnetic force at a rate of 500 ml / min. After reacting for 60 minutes, remove the solid residue by filtration to obtain a hydroxylamine solution with a concentration of about 1 mol / L;

[0051] (3) Dissolve 10 g of CL-20 in 25 ml of ethyl acetate to obtain a CL-20 solution with a concentration of about 0.91 mol / L;

[0052] (4) Using the solvent-anti-solvent method, slowly add the hydroxylamine solution to the CL-20 solution at a rate of 1ml / min, and stir for crystallization for 1h;

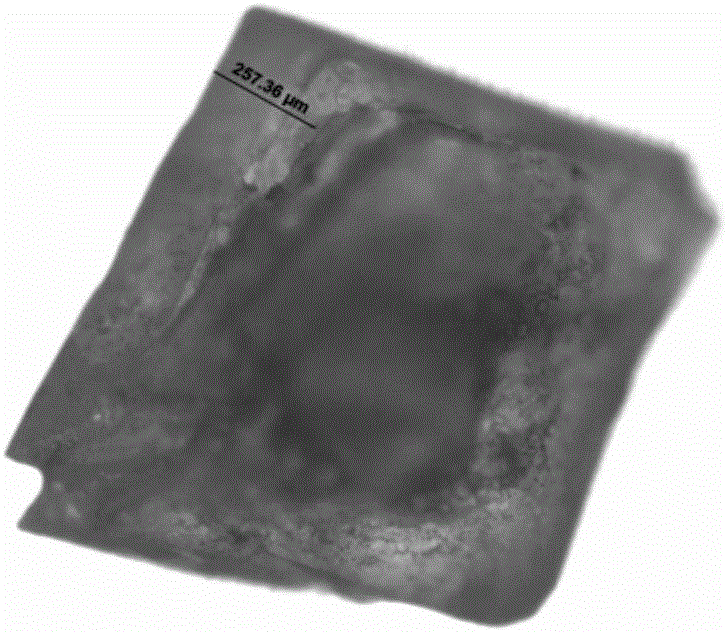

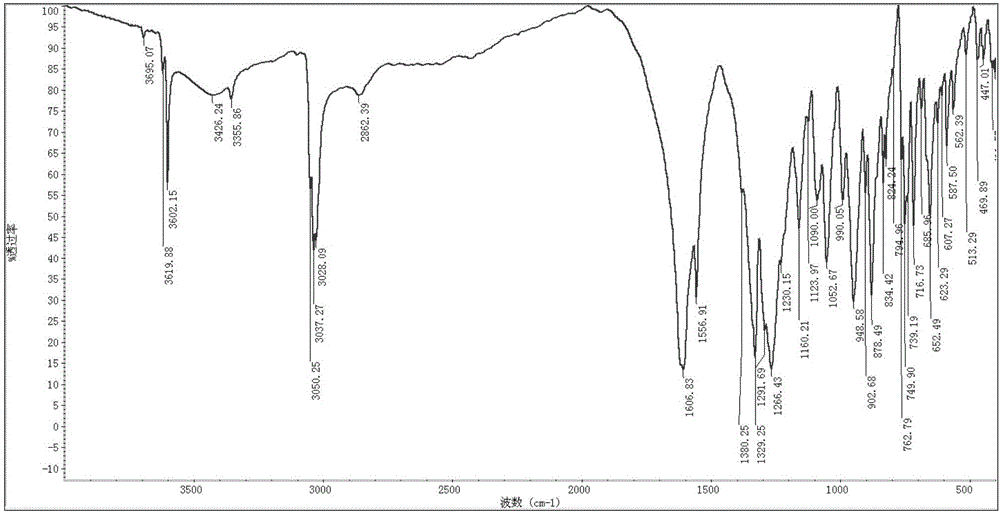

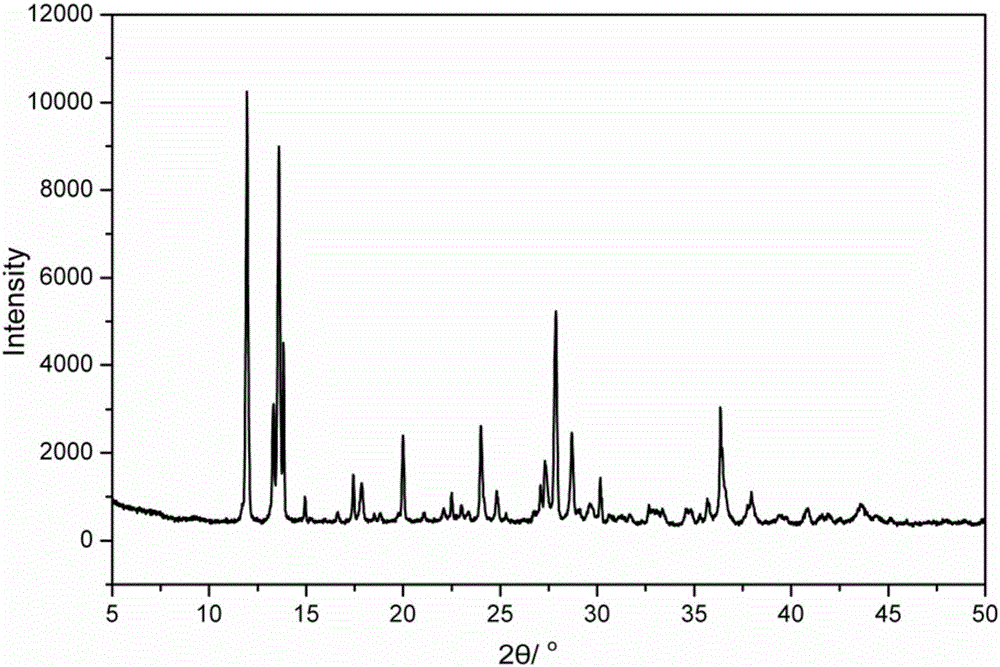

[0053] (5) Filter and wash the precipitated solid, and dry it in an oven at 60°C for 1 hour to obtain CL-20 / NH 2 OH host-guest explosive crystal.

Embodiment 2

[0055] (1) Weigh 3.28g of dried hydroxylamine sulfate, slowly pour it into a 250ml Erlenmeyer flask, add 100ml of propanol solution at the same time, stir magnetically for 10min, and dissolve all the solids;

[0056] (2) Slowly add 1.64 g of sodium propoxide into the hydroxylamine sulfate solution, and simultaneously stir rapidly with a magnetic force at a rate of 500 ml / min. After reacting for 60 minutes, remove the solid residue by filtration to obtain a hydroxylamine solution with a concentration of about 0.2 mol / L;

[0057] (3) Dissolve 0.438g of CL-20 in 10ml of methyl acetate to obtain a CL-20 solution with a concentration of about 0.1mol / L;

[0058] (4) Using the solvent-anti-solvent method, slowly add the hydroxylamine solution to the CL-20 solution at a rate of 5ml / min, and stir for crystallization for 10min;

[0059] (5) Then measure 50ml of diethyl ether, drop it into the solution at a rate of 5ml / min, stir and crystallize for 1h;

[0060] (6) Filter and wash the p...

Embodiment 3

[0062] (1) Weigh 19.7g of dried hydroxylamine phosphate, slowly pour it into a 250ml Erlenmeyer flask, add 80ml of ethanol solution at the same time, stir magnetically for 10min, and dissolve all the solids;

[0063] (2) Slowly add 5.4 g of sodium ethylate into the hydroxylamine phosphate solution, and simultaneously stir rapidly with a magnetic force at a rate of 500 ml / min. After reacting for 60 minutes, remove the solid residue by filtration to obtain a hydroxylamine solution with a concentration of about 0.125 mol / L;

[0064] (3) Dissolve 10 g of CL-20 in 80 ml of tetrahydrofuran to obtain a CL-20 solution with a concentration of about 0.285 mol / L;

[0065] (4) Add the hydroxylamine solution to the CL-20 solution, and the solution remains clear at this moment;

[0066] (5) Adopt solvent evaporation method, feed nitrogen into the solution surface, continue purging for 5 hours, and exhaust the tail gas, and assist magnetic stirring crystallization at the same time;

[0067]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com