Modified expanded ammonium nitrate explosive and preparation method thereof

A technology of expanded ammonium nitrate explosive and expanded ammonium nitrate, which is applied in the field of modified expanded ammonium nitrate explosive and its preparation, can solve the problems of high production cost, explosion resistance, and low charge density, and achieve low raw material cost and energy consumption for processing The effect of low and increased detonation velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

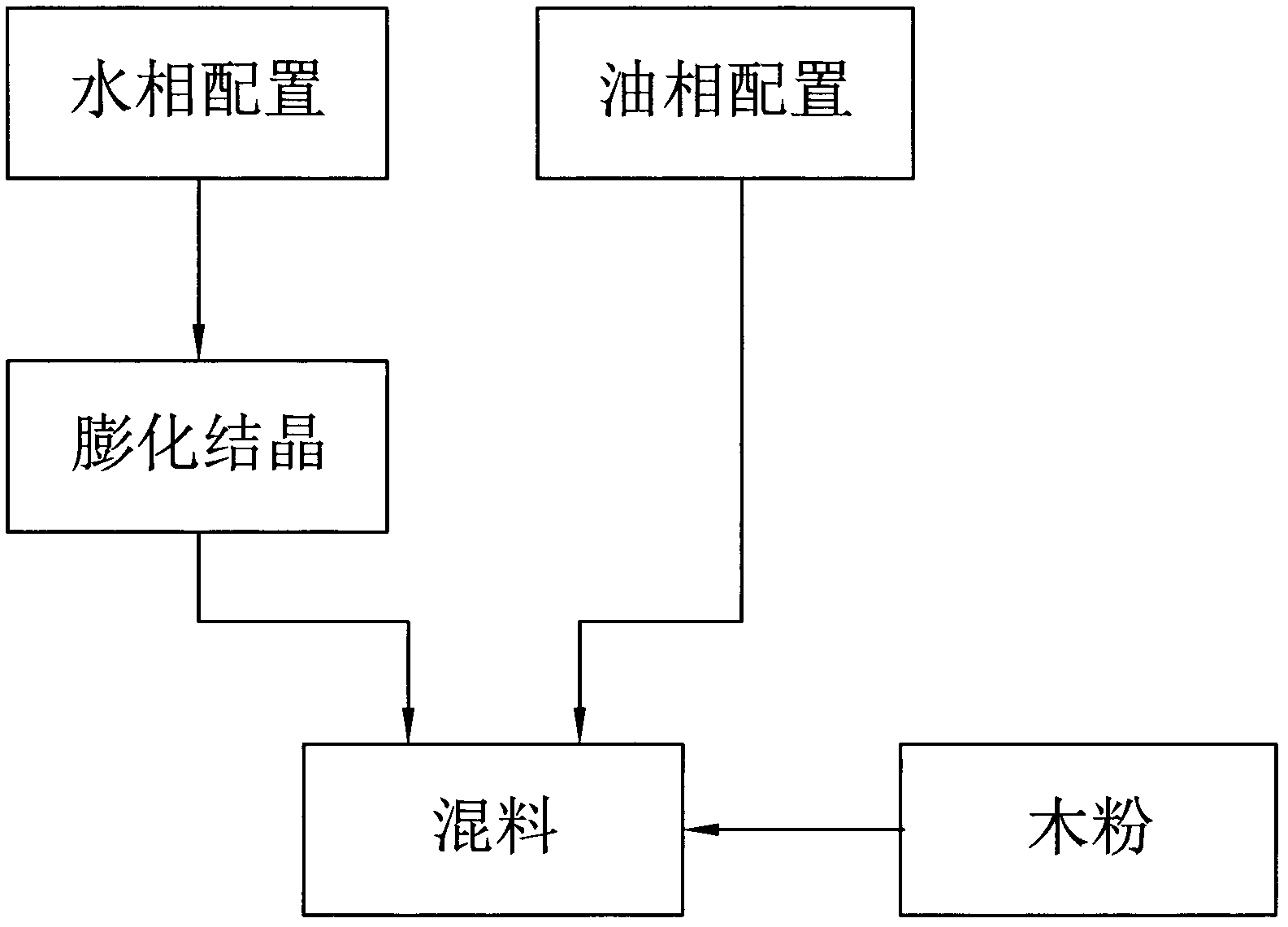

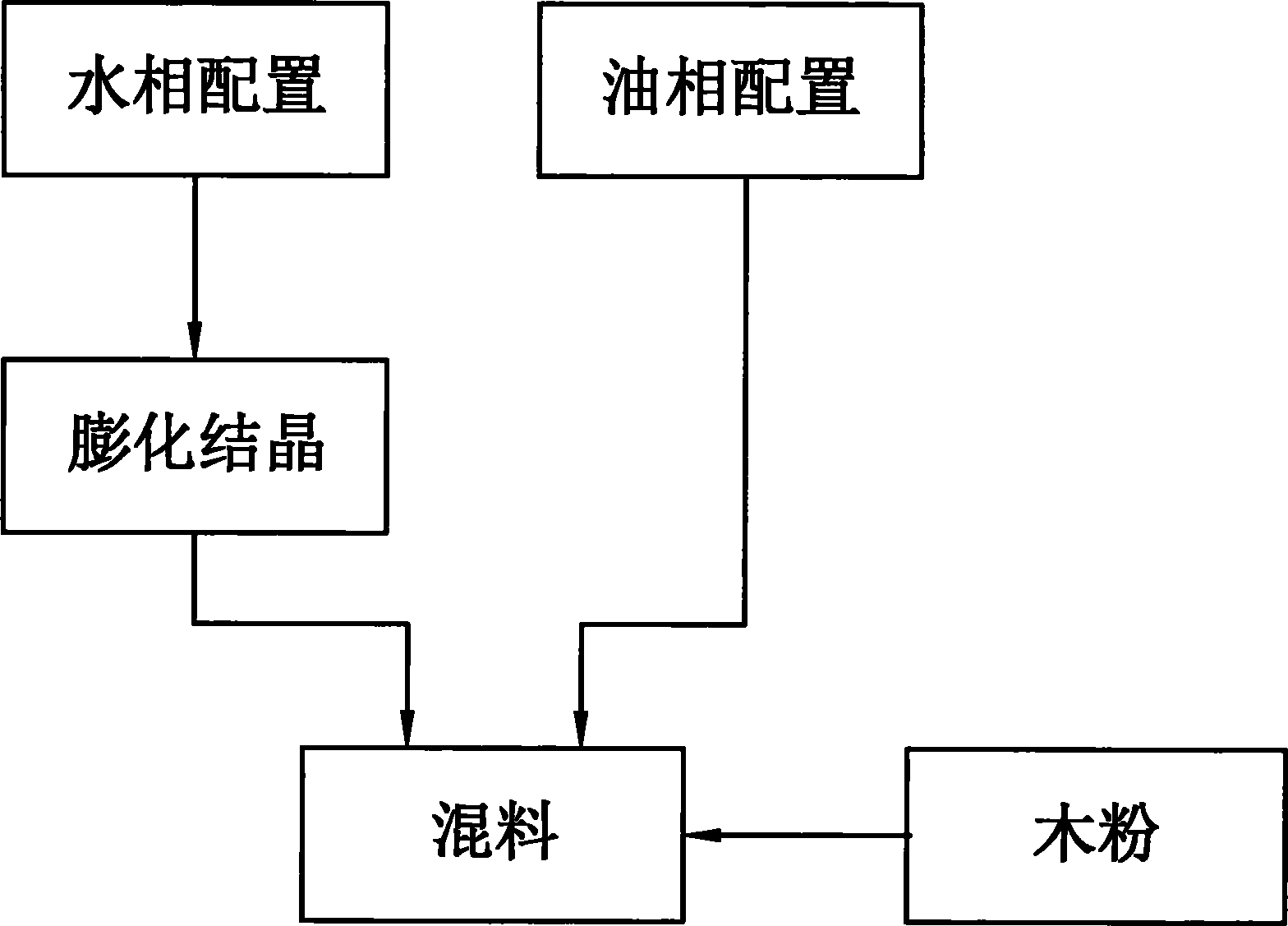

Method used

Image

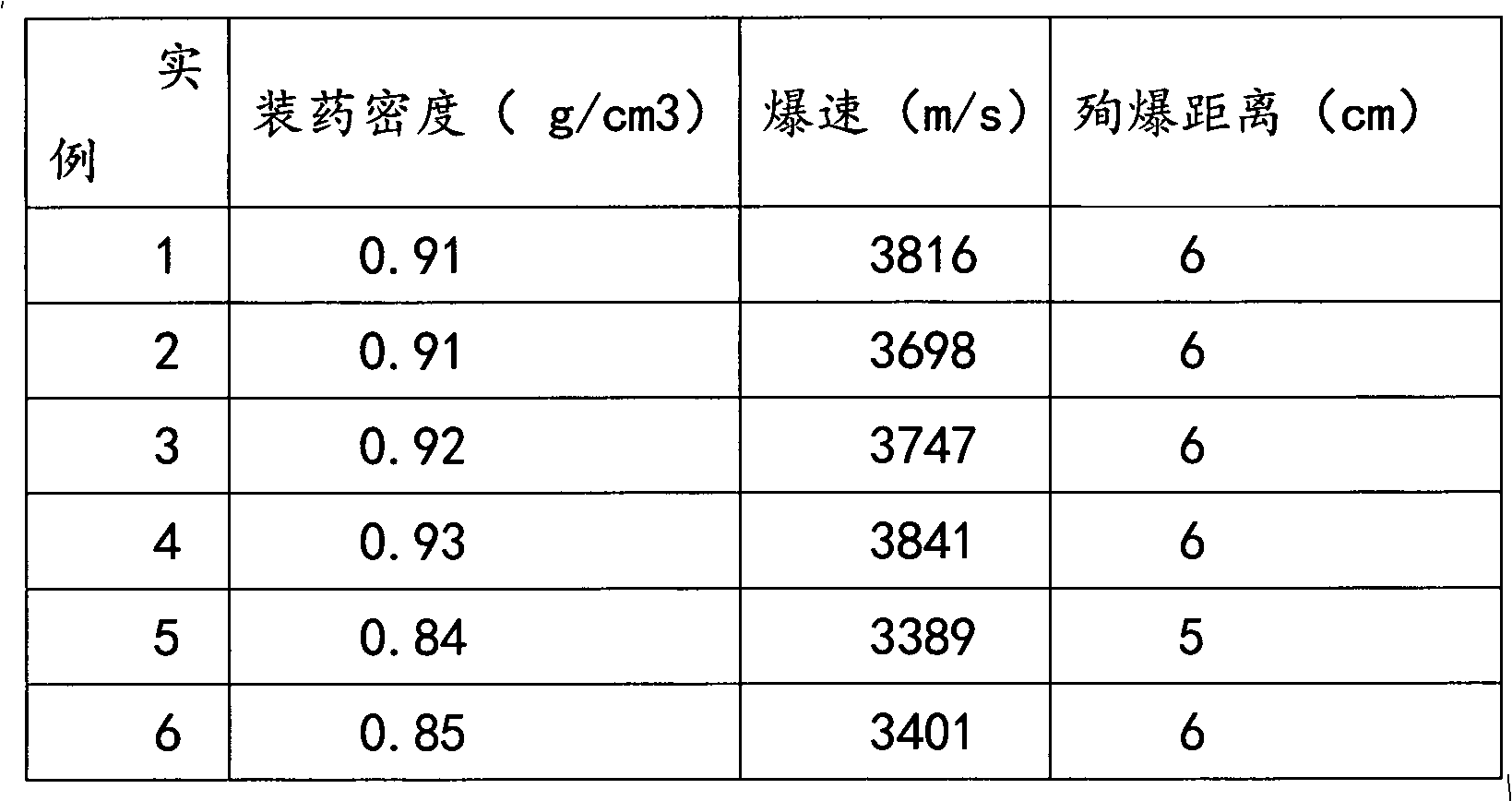

Examples

Embodiment 1

[0034] Water phase preparation: first, 10 parts of water was added to the container, and then 100 parts of crushed ammonium nitrate was slowly added, during which the heating was continued and heated to 70°C. Stir at a speed of 65 revolutions per minute during the ammonium nitrate dissolution process until the ammonium nitrate is completely dissolved.

[0035] Then, add 0.12 parts of expanding agent, and heat the solution to raise the temperature of the solution to 120°C. After the expanding agent is completely dissolved, add 2.5 parts of ammonium nitrate expanding crystal modifier. After miscibility, the aqueous phase forms a suspension, and the temperature of the suspension is kept at 120°C before use.

[0036] Expanded crystallization:

[0037] Firstly, the water phase obtained in the above steps is puffed and crystallized in a vacuum environment of -0.095MPa for 8 minutes, then the vacuum is broken and discharged to obtain the modified puffed ammonium nitrate, and the tem...

Embodiment 2

[0043] The steps of this embodiment are basically the same as those of Embodiment 1, the difference being the configuration of the water phase,

[0044] First, add 10 parts of water into the container and heat it to about 70°C, then slowly add 100 parts of crushed ammonium nitrate and heat to keep it warm. During the process of dissolving ammonium nitrate, stir at a speed of 65 rpm until the ammonium nitrate is completely dissolved. Then, 0.12 parts of swelling agent was added to raise the temperature of the solution to 115°C. After the puffing agent is completely dissolved, add 3 parts of ammonium nitrate puffing crystal modifier, the water phase will form a suspension after miscibility, and keep the temperature of the suspension at 115°C.

[0045] The crystallization expansion, the preparation of the oil phase, the mixing steps and the configuration ratio in the subsequent steps of this embodiment are the same as those in the first embodiment.

Embodiment 3

[0047] The steps of this embodiment are basically the same as those of Embodiment 1, the difference being the expanded crystallization:

[0048] First, add 10 parts of water into the container and heat it to about 70°C, then slowly add 100 parts of crushed ammonium nitrate and heat up, stirring at a speed of 65 revolutions per minute during the ammonium nitrate dissolution process until the ammonium nitrate is completely dissolved. Then, 0.12 parts of swelling agent was added to raise the temperature of the solution to 120°C. After the puffing agent is completely dissolved, add 2.5 parts of ammonium nitrate puffing crystal modifier, the water phase will form a suspension after miscibility, and keep the temperature of the suspension at 120°C.

[0049] Crystallization expansion: first expand and crystallize the water phase obtained in the above steps in a vacuum environment of -0.092MPa for 8 minutes, then break the vacuum and discharge to obtain modified expanded ammonium nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com