Industrial explosive energy focusing linear type cutter

A linear cutter and industrial explosive technology, applied in the field of blasting equipment, can solve problems such as poor safety, large critical detonation diameter, unsuitable rock surface protection, etc., and achieve the effect of increasing cutting capacity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

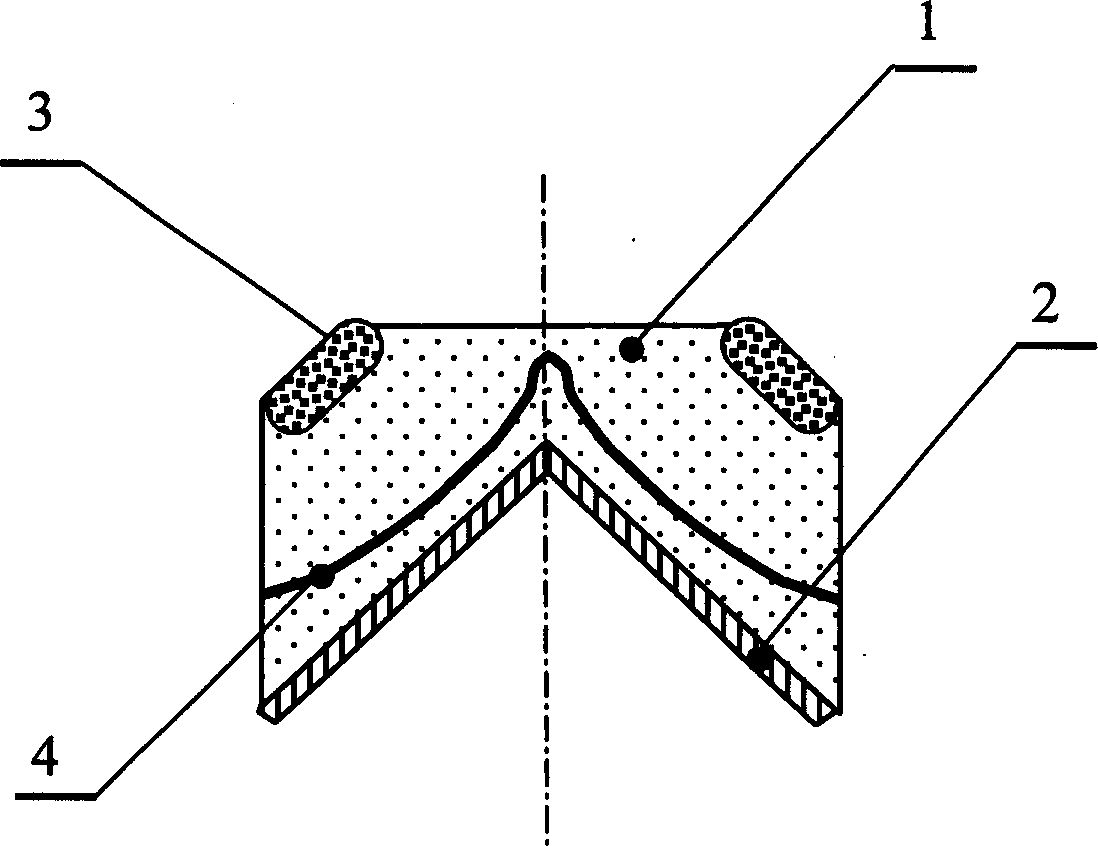

[0027] Use 2# rock explosive as the main explosive 1 (the detonation velocity is generally 3500m·s -1 ), press the attached figure 1 The form is made into a linear shaped energy cutter, and the high-explosive velocity charge 3 adopts a detonation velocity of 6500m·s -1 3 x 10mm sticks of explosives. The cutter energy-gathering cover 2 is a 0.8mm iron sheet right-angle cover, the length of the cover side is 20mm, and the length of the bottom side is 28.3mm. The distance between two high-explosive charge strips 3 is 15mm (0.53 times of the length of the bottom edge of the cover), and the minimum connecting line between the two primary explosive strips 3 is 20mm (0.7 times of the length of the bottom edge of the cover) apart from the bottom distance of the cover. The charge of cutter is 600g·m -1 . Carry out the cutting steel target experiment, the cutting depth is between 18-22mm, which is equivalent to the cutting depth of the high-energy explosive cutter with the same char...

Embodiment 2

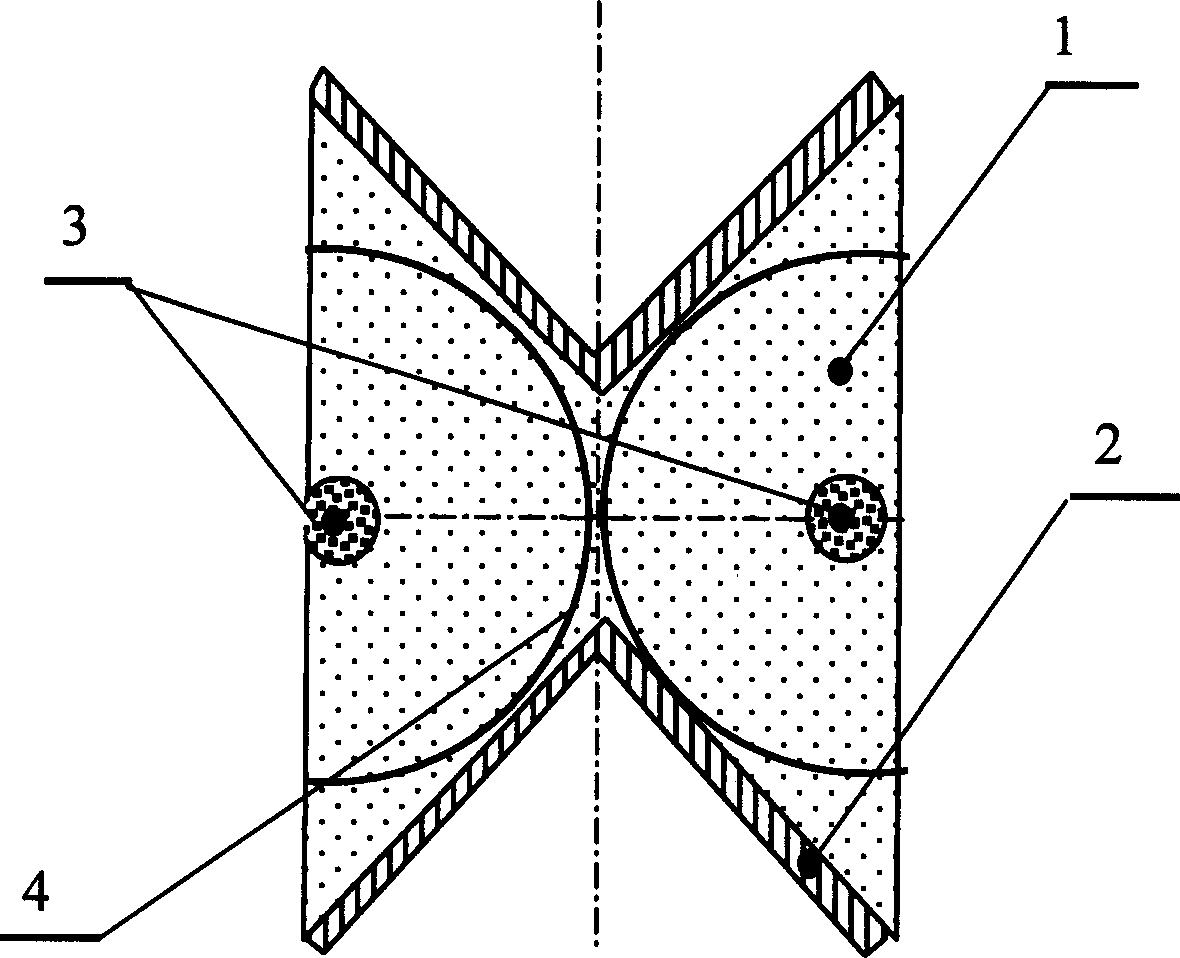

[0029] Use ammonium oil explosives as the main explosive 1 (the detonation velocity is generally 3300m·s -1 ), press the attached figure 2 The form is made into a double-sided linear shaped energy-concentrating cutter, and the high-explosive velocity drug bar 3 adopts a detonation velocity of 6900m·s -1 detonating cord. The cutter energy-gathering cover 2 is a 1mm iron sheet right-angle cover with a cover edge length of 20mm and a bottom edge length of 28.3mm. The distance between two high-explosive charge strips 3 is 16mm (0.56 times of the length of the bottom edge of the cover), and the minimum connection between the two primary explosive strips 3 is 26mm (0.91 times of the length of the bottom edge of the cover). The charge of cutter is 1240g·m -1 . Place a 300mm-long double-sided cutter every 400mm, connect it with a detonating cord in the middle, and place it in a Φ100mm drill hole. The jet flow direction of the cutter points to the direction of the connection betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com