Device and method for measuring detonating velocity of explosive

A technology for measuring devices and explosives, applied in measuring devices, linear/angular velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of differences, inability to reflect the actual detonation velocity of explosives and changes in detonation velocity, and achieve simple structure of the device, The measurement method is simple and practical, and the design is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

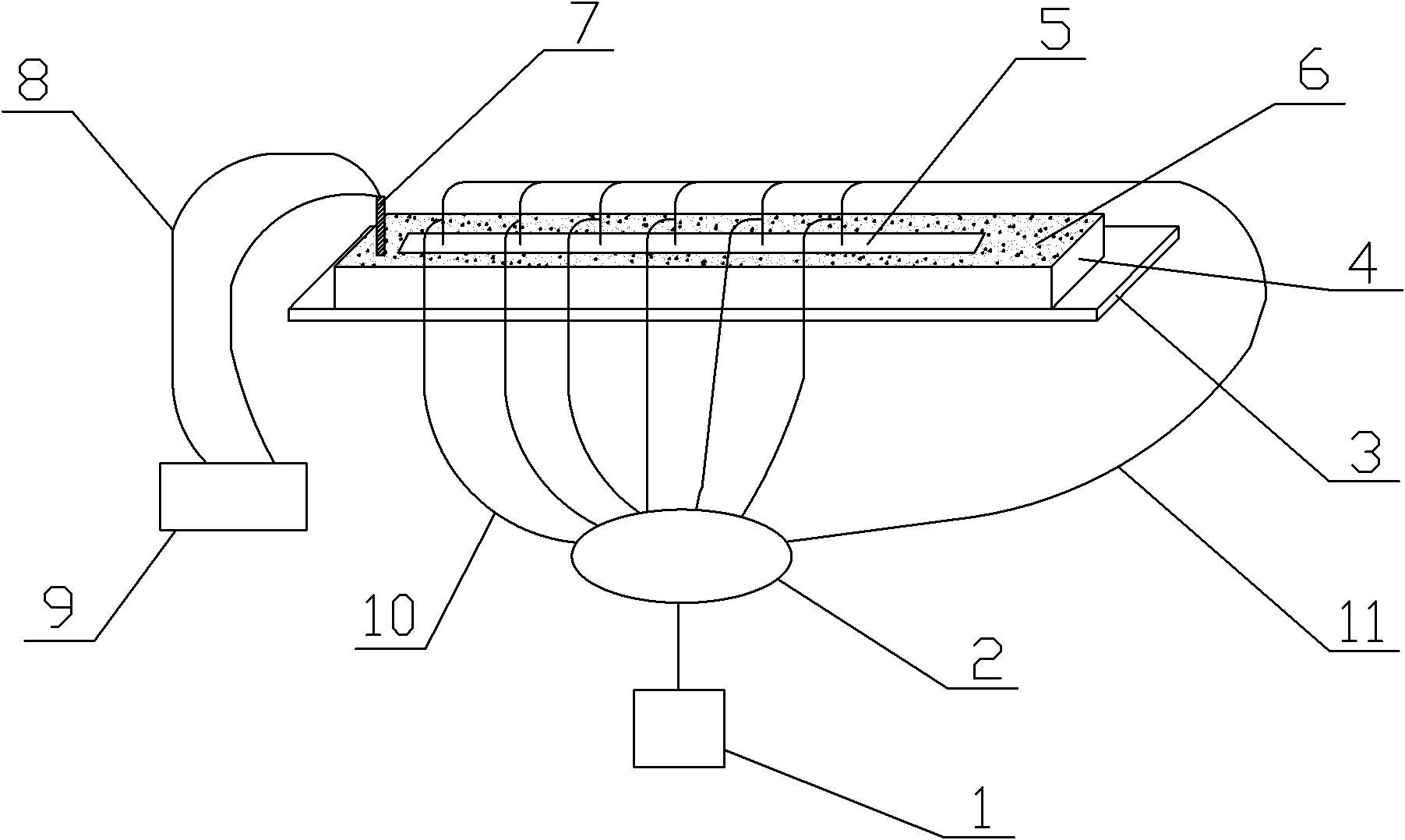

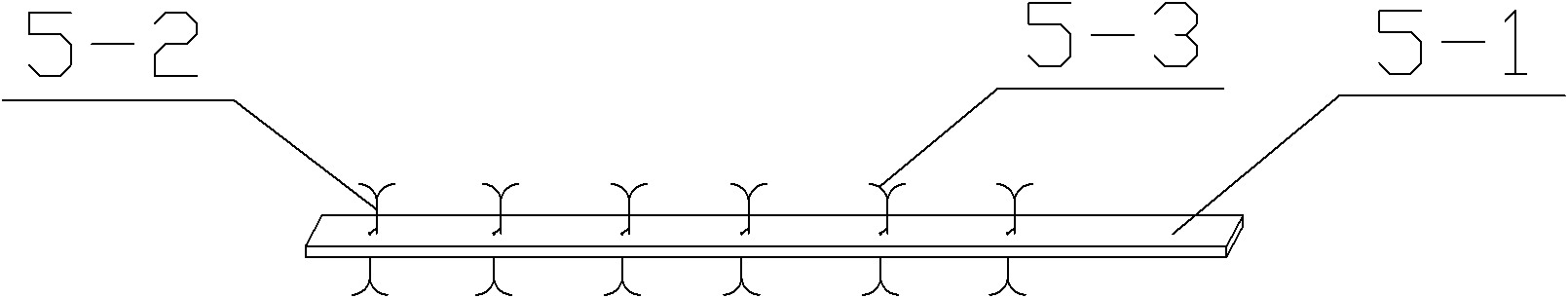

[0023] Such as figure 1 and figure 2 Shown a kind of explosive detonation velocity measuring device, comprises detonation velocity instrument 1, and the signal formation circuit 2 that is connected with detonation velocity instrument 1, also comprises backing plate 3, is installed on the backing plate 3 and is used to place the medicine frame 4 of explosive 6, place The continuous probe 5 on the surface of the explosive 6 and the detonator 7 placed in the charge frame 4, and the detonator 9 connected to the detonator 7 through the detonating wire 8; the continuous probe 5 is formed by a fixed plate 5-1, uniformly It consists of a plurality of supports 5-2 fixed on the fixed plate 5-1 arranged in a straight line, and a sensing element 5-3 wound on the supports 5-2. The fixed frame 5-1 is located on each support A through hole is opened on one side of the object 5-2, and the sensing element 5-3 passes through the through hole and is divided into upper and lower parts by the fi...

Embodiment 2

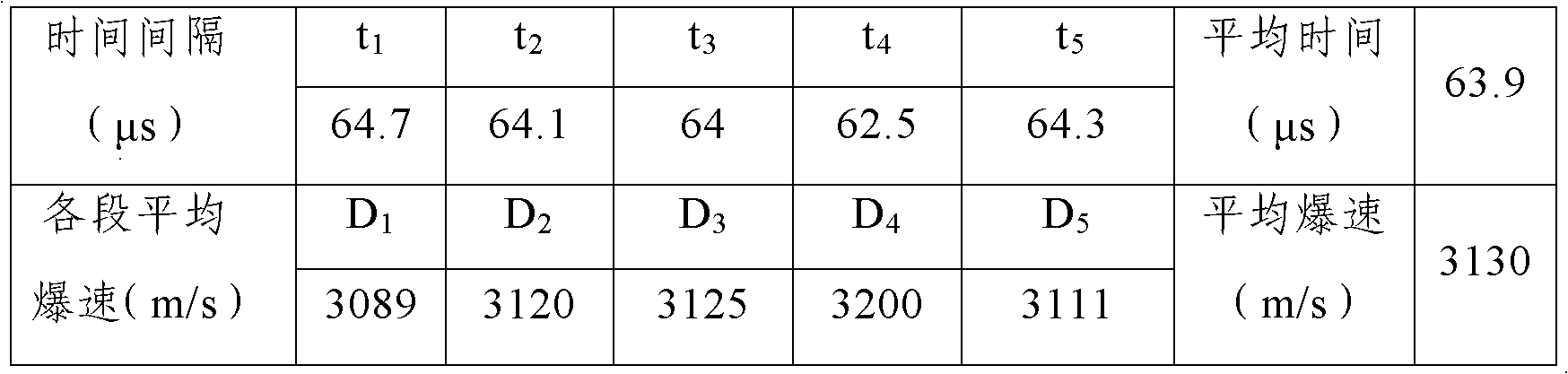

[0026] A method for measuring the detonation velocity of explosives: placing explosives 6 in the charge frame 4 of the explosive detonation velocity measuring device, detonating the explosives 6 through the detonator 9 and the detonator 7, when the detonation wave reaches the first one on the continuous probe 5 In the case of the sensing element 5-3, the sensing element 5-3 perceives the information of the detonation wave arrival under the effects of high temperature and (or) high pressure, ionization, and luminescence accompanied by the detonation wave front, and passes the signal Form a circuit and convert it into an electrical signal, measure the time interval t between the two signals given by the first sensing element and the second sensing element on the continuous probe 5 with the detonation velocity meter 1, and then according to the two The average detonation velocity D in the explosive section can be obtained by the distance of the sensing element. As the detonation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com