Detonation performance test method for high-energy imploding explosive

A technology of detonation performance and test method, applied in the field of high-energy internal explosive detonation performance test, can solve the problems of high test cost, inability to accurately quantitatively compare, inability to flexibly select test environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

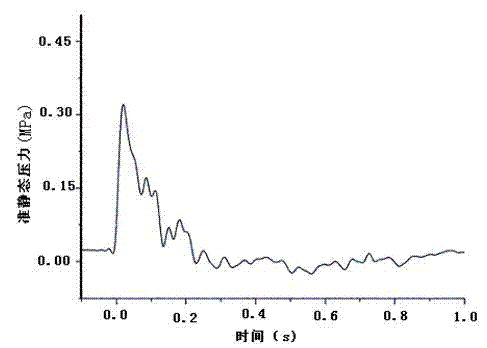

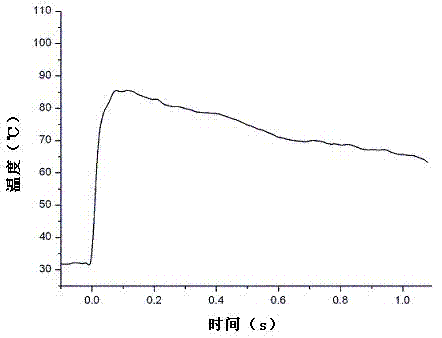

[0054] Present embodiment is that the TNT explosive of 20g carries out quasi-static pressure, transient temperature, detonation velocity, gas composition test in air medium, and its test method comprises the following steps:

[0055] 1) Press 20g of explosive samples from the same batch of tests into a cylindrical explosive column 6 of the same specification, and leave a detonator hole with a diameter of 7mm and a depth of 10-15mm on the explosive column 6. The compressed explosive grain column 6 is stored in the explosive temporary storage area;

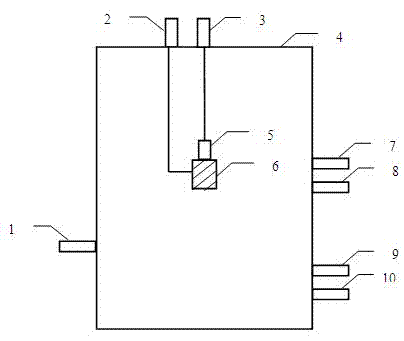

[0056] 2) Arrange the detonator, detonation velocity test equipment, pressure sensor, temperature sensor, and gas collection and test system at the corresponding interface of the explosion vessel, and connect the temperature sensor and pressure sensor to the corresponding paperless recorder and temperature transmitter respectively. , data acquisition instrument, and oscilloscope are connected for data recording. Debug the instrumen...

Embodiment 2

[0080] Present embodiment is to test respectively the quasi-static pressure, transient temperature, detonation velocity, gas composition test of the PBXIH-18 explosive of 10g, 15g, 31g, 40g, and experimental procedure is identical with embodiment 1, and its experimental data are as shown in table 2:

[0081] Table 2 PBXIH-18 explosion gas expansion test data

[0082]

[0083] The calculation results obtained from the test data of this embodiment are shown in Table 3, the test data is calculated according to formula (1), and compared with the reference value E TNT The test results were divided to obtain the ratio, which is used to characterize the strength of work ability. The results are shown in Table 3.

[0084] table 3 E PBX-IH and E TNT The result comparison

[0085]

[0086] It can be seen from Table 3 that the working ability of PBX-IH explosive is far greater than that of 20gTNT, and with the increase of the amount of PBX-IH, E PBX-IH also gradually incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com