Mixing process control experimental apparatus

An experimental device and process control technology, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of high cost and no relatively complete mixed process control experimental device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

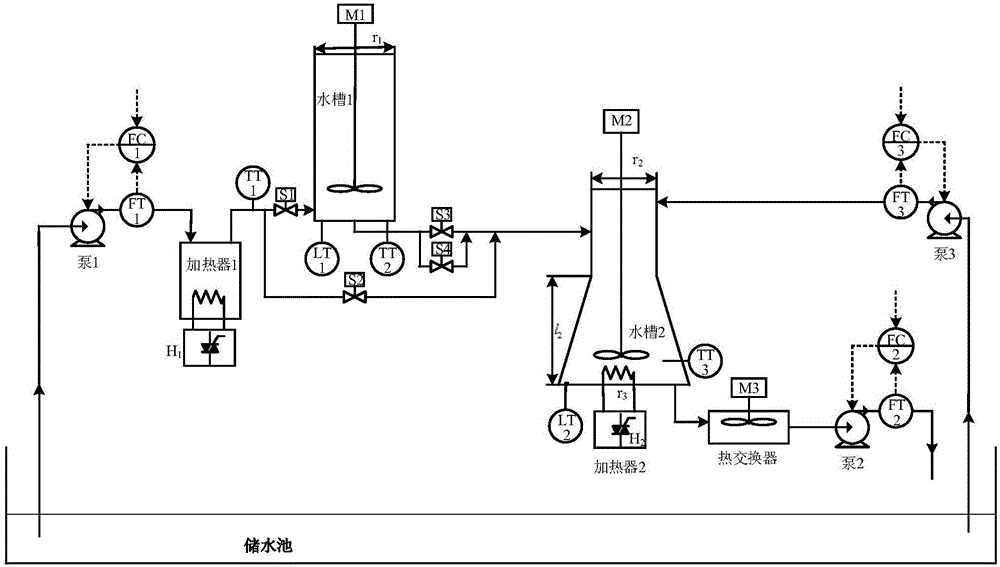

[0038] The hybrid process control experimental device of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] Such as figure 1 As shown, a hybrid process control experimental device includes:

[0040] storage tank;

[0041] sinks, the first sink (sink1) and the second sink (sink2);

[0042] The water pumps are respectively the first water pump (pump 1), the second water pump (pump 2) and the third water pump (pump 3);

[0043] The heating devices are respectively a first heating device (heater 1) and a second heating device (heater 2). Wherein, the heating power of heater 1 is 2kw, and the heating power of heater 2 is 800W;

[0044] As well as the pipelines connecting these components and the valves (including solenoid valves and hand valves) on the pipelines.

[0045] Agitators are installed in both the water tank 1 and the water tank 2, and a heater 2 is installed at the bottom of the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com