Positive lead paste for lead-acid storage battery and preparation method of positive lead paste

A lead-acid battery, positive lead paste technology, applied in lead-acid batteries, battery electrodes, circuits, etc., can solve problems such as low battery capacity and battery performance impact, and achieve the effect of extending service life, prolonging life, and inhibiting decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

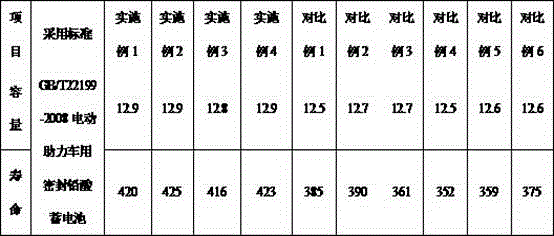

Examples

Embodiment 1

[0017] A kind of lead-acid battery positive lead paste, the mass parts of each component of this positive lead paste is 82 parts of lead powder, 5 parts of red lead, 0.5 part of calcium phosphate, 6.5 parts of dilute sulfuric acid, 0.2 part of hydroxylated graphene, EDTA- 0.7 parts of 2Na, 5.1 parts of deionized water.

[0018] The preparation method of above-mentioned a kind of lead-acid accumulator anode lead paste, comprises the following steps: according to above-mentioned lead paste formula, each component is weighed, and hydroxylated graphene, calcium phosphate, EDTA-2Na are stirred and mixed in deionized water, Quickly add it to the paste machine within 2 minutes and mix it evenly with lead powder and red lead, slowly add dilute sulfuric acid into the paste machine, keep stirring during the addition process, continue stirring for 10 minutes after adding acid, stir evenly and wait to cool to After room temperature, the paste can be released.

Embodiment 2

[0020] The difference from Example 1 is that a positive lead paste for a lead-acid storage battery, the mass parts of each component of the positive lead paste is 78.5 parts of lead powder, 7 parts of red lead, 0.7 part of calcium phosphate, 7 parts of dilute sulfuric acid, hydroxyl 0.3 parts of graphene, 0.7 parts of EDTA-2Na, 5.8 parts of deionized water.

Embodiment 3

[0022] The difference from Example 1 is that a positive lead paste for a lead-acid storage battery, the mass parts of each component of the positive lead paste is 82 parts of lead powder, 5 parts of red lead, 0.5 part of calcium phosphate, 6.5 parts of dilute sulfuric acid, carboxyl 0.2 parts of graphene, 0.7 parts of EDTA-2Na, 5.1 parts of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com