Vulcanizing agent containing selenium and preparing method and application thereof

A technology of vulcanizing agent and selenium powder, applied in organic chemistry and other directions, can solve the problems of easy sublimation of elemental sulfur, inactivation of catalysts, harmful to human body, etc., and achieve the effect of solving the problem of waste of raw materials, easy industrial production and good chemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Sulfur powder (95% of sulfur content) and selenium powder (95% of selenium content) are mixed by mass ratio after being 25:1, be placed in autoclave, then add the NaOH solution that pH is 8.0 and mix evenly, obtain Mixture; Wherein, the consumption of NaOH solution is 3% of the total mass of sulfur and selenium powder;

[0030] (2) Inject isobutene gas into the autoclave in step (1), and the amount of isobutene is 40% of the total molar weight of sulfur and selenium powder; the temperature of the reaction system is slowly raised to 245°C and then reacted at a constant temperature for 300min to obtain selenium-containing Vulcanizing agent, wherein the mass percent of selenium is 2.18%.

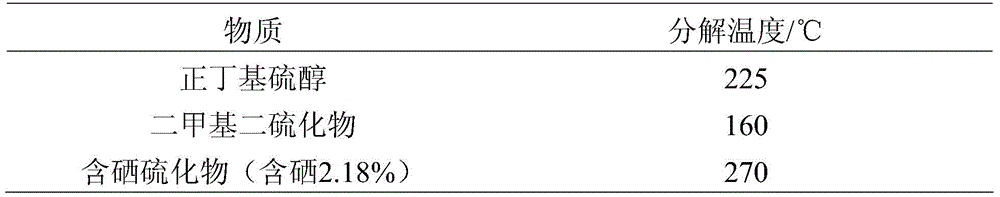

[0031] The decomposition temperature of the selenium-containing vulcanizing agent prepared in this example is shown in Table 1. Compared with n-butyl mercaptan and dimethyl disulfide, the thermal stability of the selenium-containing vulcanizing agent prepared in this example is signi...

Embodiment 2

[0035] (1) after sulfur powder (95% of sulfur content) and selenium powder (95% of selenium content) are mixed by mass ratio after being 15:1, be placed in autoclave, then add the NaOH solution that pH is 8.5 and mix evenly, obtain Mixture; Wherein, the consumption of NaOH solution is 3% of the total mass of sulfur and selenium powder;

[0036] (2) Inject isobutene gas into the autoclave in step (1), and the amount of isobutene is 40% of the total molar weight of sulfur and selenium powder; the temperature of the reaction system is slowly raised to 250°C and then reacted at a constant temperature for 300min to obtain selenium-containing Vulcanizing agent, wherein, the mass percent of selenium is 5.41%;

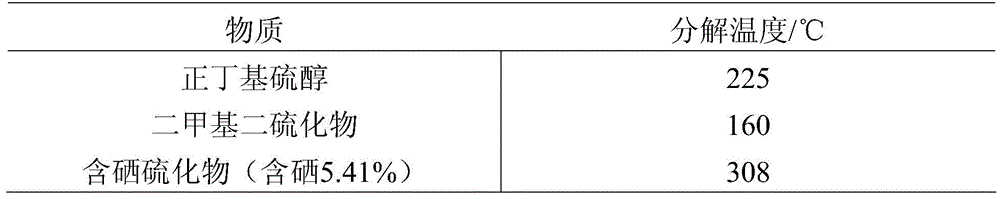

[0037] The decomposition temperature of the selenium-containing vulcanizing agent prepared in this example is shown in Table 2. Compared with n-butyl mercaptan and dimethyl disulfide, the thermal stability of the selenium-containing vulcanizing agent prepared in this example i...

Embodiment 3

[0041] (1) After mixing sulfur powder (95% of sulfur content) and selenium powder (95% of selenium content) by mass ratio, it is placed in an autoclave, and then adding a NaOH solution with a pH of 9.0 and mixing to obtain Mixture; Wherein, the consumption of NaOH solution is 3% of the total mass of sulfur and selenium powder;

[0042] (2) Inject isobutene gas into the autoclave in step (1), and the amount of isobutene is 40% of the total molar weight of sulfur and selenium powder; the temperature of the reaction system is slowly raised to 250°C and then reacted at a constant temperature for 300min to obtain selenium-containing Vulcanizing agent, wherein the mass percentage of selenium is 13.97%.

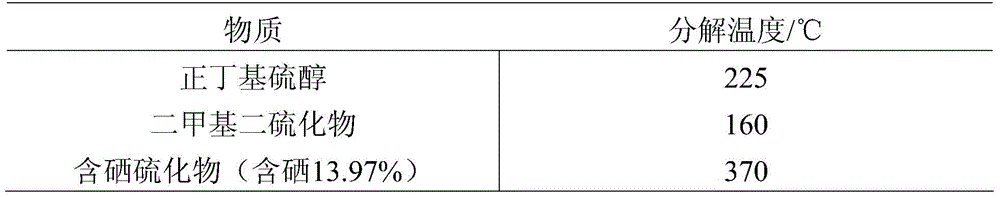

[0043] The decomposition temperature of the selenium-containing vulcanizing agent prepared in this example is shown in Table 1. Compared with n-butyl mercaptan and dimethyl disulfide, the thermal stability of the selenium-containing vulcanizing agent prepared in this example is sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com