Wheel-sticking-free emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and non-stick wheels, which is applied to building components, building insulation materials, buildings, etc., can solve the problem of adhesion to construction vehicle tires, etc., and achieve the effects of increasing the softening point of asphalt, improving the softening point, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

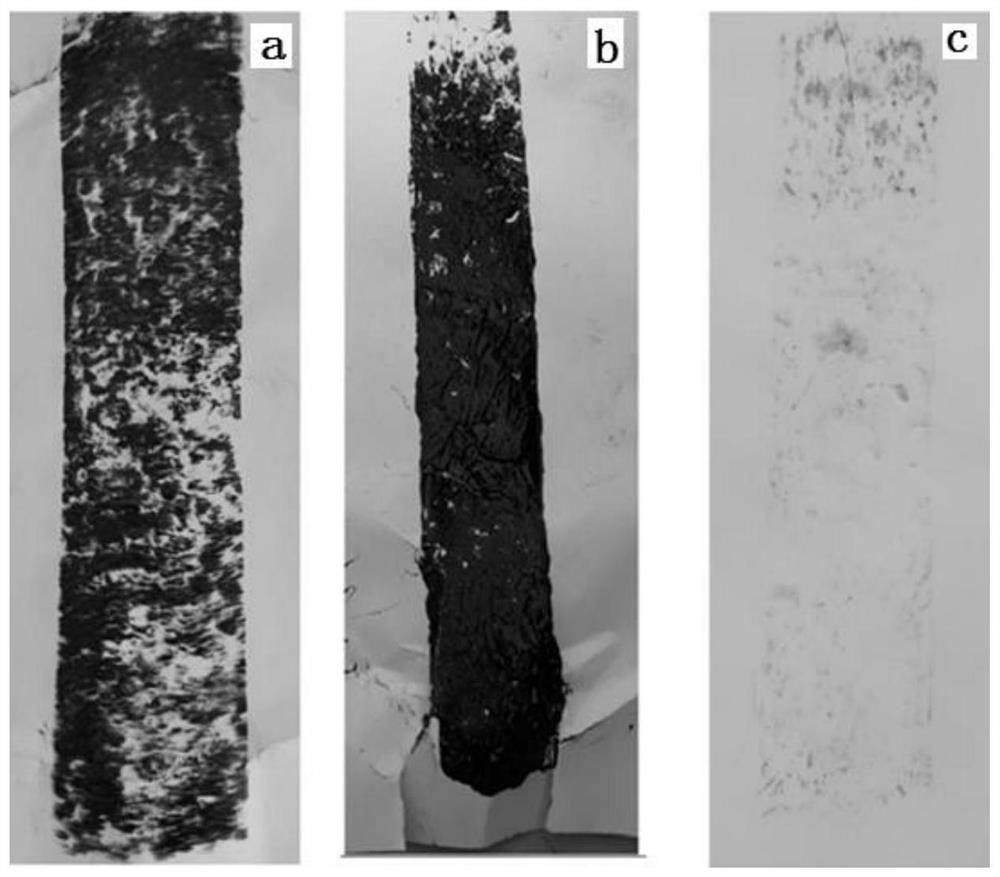

Image

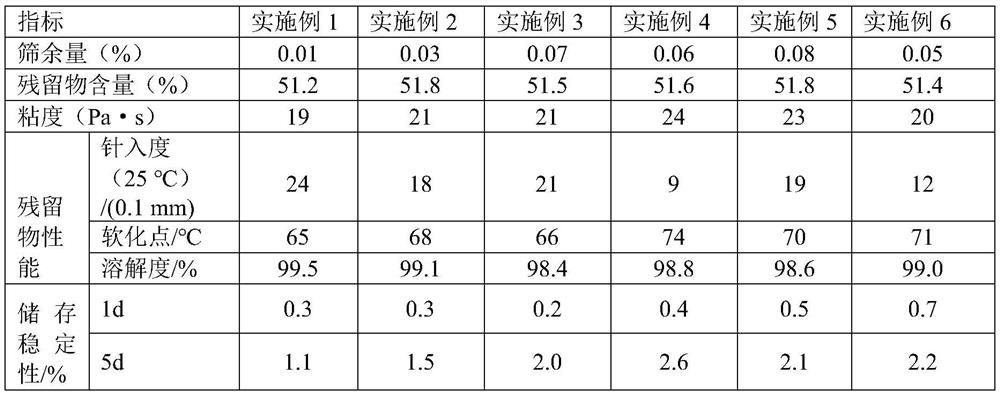

Examples

Embodiment 1

[0048] 30# base asphalt 500g, fast-cracking cationic emulsifier 10g, hydroxymethyl cellulose 8g, sulfonated asphalt powder 60g, water 500g.

[0049] Put 10g of emulsifier in the container for later use, heat the water to 70°C, add it into the container containing the emulsifier, stir until the emulsifier is completely dissolved in hot water, add 8g of hydroxymethylcellulose, and mix well. Get soap. Keep the temperature of the soap solution at 70°C; heat 500g of asphalt to 160°C, and add 60g of sulfonated asphalt powder to it. Stir well. Keep the temperature at 160°C; preheat the colloid mill to 70°C, add the configured soap solution to it, turn on the colloid mill, set the speed of the colloid mill to 7000r / min, and add base asphalt to it after the rotation is stable. Put the mixed asphalt and soap solution together through a colloid mill and shear at high speed for 5 minutes to obtain non-stick wheel emulsified asphalt.

Embodiment 2

[0051] 20# base asphalt 520g, cationic emulsifier 10g, methyl cellulose 8g, sulfonated asphalt powder 50g, water 500g.

[0052] Put 10g of emulsifier in the container for later use, heat the water to 70°C, add it into the container containing the emulsifier, stir until the emulsifier is completely dissolved in hot water, add 8g of hydroxymethylcellulose, and mix well. Get soap. Keep the temperature of the soap solution at 70°C; heat 520g of asphalt to 170°C, and add 50g of sulfonated asphalt powder to it. Stir well. Keep the temperature at 170°C; preheat the colloid mill to 70°C, add the configured soap solution to it, turn on the colloid mill, set the speed of the colloid mill to 8000r / min, and add base asphalt to it after the rotation is stable. Put the mixed asphalt and soap solution together through a colloid mill and shear at high speed for 8 minutes to obtain non-stick wheel emulsified asphalt.

Embodiment 3

[0054] 20# base asphalt 180g, 30# base asphalt 200g, quaternary ammonium salt cationic emulsifier 8g, hydroxymethyl cellulose 5g, sulfonated asphalt powder 30g, rock asphalt powder 10g, water 350g.

[0055] Put 8g of emulsifier in the container for later use, heat the water to 70°C, add it into the container containing the emulsifier, stir until the emulsifier is completely dissolved in hot water, add 5g of hydroxymethylcellulose, and mix well. Get soap. Keep the temperature of the soap solution at 70°C; heat 180g of 20# asphalt and 200g of 30# asphalt to 170°C, mix well and add 30g of sulfonated asphalt powder and 10g of rock asphalt powder to it. Stir well. Keep the temperature at 170°C; preheat the colloid mill to 70°C, add the configured soap solution to it, turn on the colloid mill, set the speed of the colloid mill to 7500r / min, and add base asphalt to it after the rotation is stable. Put the mixed asphalt and soap solution together through a colloid mill and shear at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com