Positive paste mixing technology

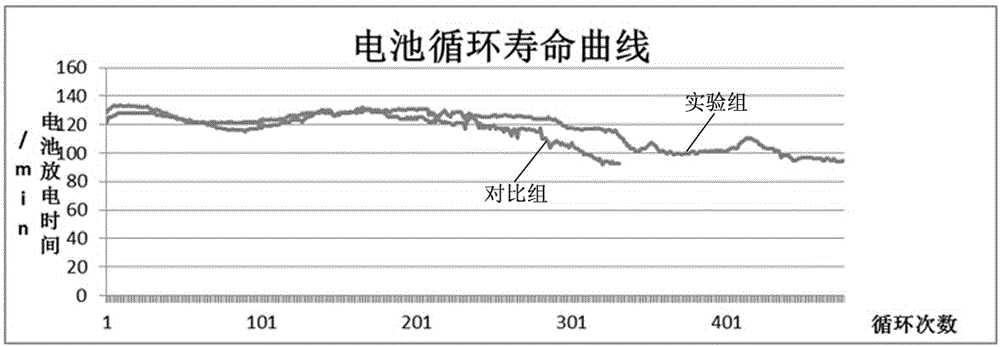

A positive electrode and process technology, applied to battery electrodes, lead-acid battery electrodes, structural parts, etc., can solve the problems of large differences in the acid absorption value and porosity of the plates, and achieve the effect of increasing the acid absorption value and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

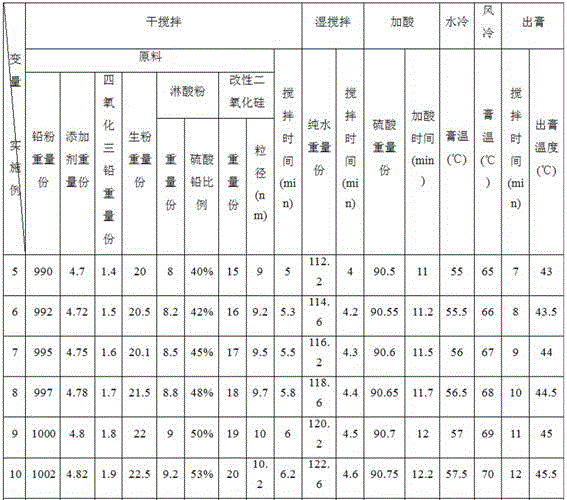

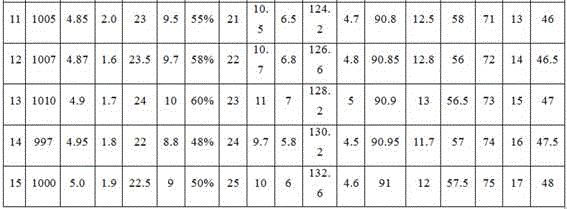

[0015] Positive electrode and paste process, including the following steps: (1) dry stirring: mix and stir the raw materials with a weight part of 1039.2-1076 for 5-7 minutes; (2) wet stirring: add pure water with a weight part of 112.2-132.6, and continue stirring 4-5min; (3) Adding acid: 90.5-91.0 parts by weight, density 1.4g / cm 3 sulfuric acid, add acid for 11-13min, and keep stirring; (4) water cooling: when the paste temperature is 55-58°C, start circulating water to cool down; (5) air cooling: when the paste temperature is between 65-75°C (6) Paste output: the stirring time after acid addition is greater than or equal to 7 minutes, the paste output temperature is less than or equal to 48°C, and the paste density during paste output is 4.4-4.5g / cm 3 .

[0016] The raw materials in the step (1) are composed of the following components by weight: 990-1010 parts of lead powder, 4.7-5.0 parts of additives, 1.4-2 parts of trilead tetraoxide, 20-24 parts of raw powder, leachi...

Embodiment 2

[0022] The positive electrode and paste process includes the following steps: (1) dry stirring: mix and stir 1039.2 parts by weight of raw materials for 5 minutes; (2) wet stirring: add pure water with 112.2 parts by weight and continue stirring for 4 minutes; (3) add Acid: adding weight parts is 90.5, density is 1.4g / cm 3 (4) Water cooling: when the paste temperature is 55°C, start circulating water to cool down; (5) Air cooling: when the paste temperature is 65°C, start air cooling; ( 6) Paste: the stirring time after adding acid is equal to 7min, the paste temperature is equal to 43°C, and the paste density is 4.4g / cm 3 .

[0023] The raw materials in the step (1) are composed of the following components by weight: 990 parts of lead powder, 4.7 parts of additives, 1.4 parts of trilead tetraoxide, 20 parts of raw powder, 8 parts of acid powder, solid modified two 15 parts of silicon oxide.

[0024] The particle size of the solid modified silicon dioxide is 9 nanometers. ...

Embodiment 3

[0029] The positive electrode and paste process includes the following steps: (1) dry stirring: mix and stir 1076 parts by weight of raw materials for 7 minutes; (2) wet stirring: add pure water with 132.6 parts by weight and continue stirring for 5 minutes; (3) add Acid: adding weight parts is 91.0, density is 1.4g / cm 3 sulfuric acid, add acid for 13 minutes, and continue to stir; (4) water cooling: when the paste temperature is 58 ℃, start circulating water to cool down; (5) air cooling: when the paste temperature is between 75 ℃, start air cooling ; (6) Paste: the stirring time after acid addition is equal to 17min, the paste temperature is equal to 48°C, and the paste density is 4.5g / cm 3 .

[0030] The raw materials in the step (1) are composed of the following components by weight: 1010 parts of lead powder, 5.0 parts of additives, 2 parts of trilead tetraoxide, 24 parts of raw powder, 10 parts of acid powder, solid modified two 25 parts of silicon oxide.

[0031] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com