A black edge cleaning method of aluminum nitride ceramic substrate for rail transit chip packaging

A technology of aluminum nitride ceramics and chip packaging, which is applied in the manufacture of electrical components, electrical solid devices, semiconductors/solid devices, etc., and can solve problems affecting the insulation of aluminum nitride, blackening, and decomposition of aluminum nitride into aluminum elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

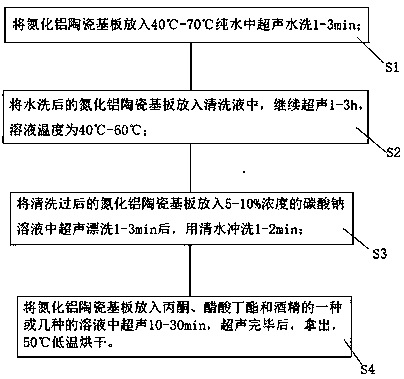

Image

Examples

Embodiment 1

[0016] A method for cleaning black edges of an aluminum nitride ceramic substrate for rail transit chip packaging, comprising the following steps:

[0017] (1) Put the aluminum nitride ceramic substrate into 40°C pure water for ultrasonic washing for 3 minutes;

[0018] (2) Put the washed aluminum nitride ceramic substrate into the cleaning solution, continue ultrasonication for 1 hour, and the solution temperature is 60°C;

[0019] The formula of the cleaning solution includes 1% concentration of dilute hydrochloric acid, 5% concentration of hydrogen peroxide and cationic surfactant, wherein the ratio of hydrogen peroxide to dilute hydrochloric acid is 1:2. The pH value of the cleaning solution is 3. The cationic surfactants used in the cleaning solution are cetyltrimethylammonium sodium bromide, dimethylbenzyldodecylammonium bromide, alkylpyridinium and N,N dimethyldodecyl At least one of the base amines, preferably, the cationic surfactant is dimethyl benzyl dodecyl ammon...

Embodiment 2

[0023] A method for cleaning black edges of an aluminum nitride ceramic substrate for rail transit chip packaging, comprising the following steps:

[0024] (1) Put the aluminum nitride ceramic substrate into 55°C pure water for ultrasonic washing for 2 minutes;

[0025] (2) Put the washed aluminum nitride ceramic substrate into the cleaning solution, continue ultrasonication for 2 hours, and the solution temperature is 50°C;

[0026] The formula of the cleaning solution includes 10% concentration of dilute hydrochloric acid, 30% concentration of hydrogen peroxide and cationic surfactant, wherein the ratio of hydrogen peroxide to dilute hydrochloric acid is 1:3. The pH value of the cleaning solution is 2. The cationic surfactants used in the cleaning solution are cetyltrimethylammonium sodium bromide, dimethylbenzyldodecylammonium bromide, alkylpyridinium and N,N dimethyldodecyl At least one of the base amines, preferably, the cationic surfactant is dimethyl benzyl dodecyl am...

Embodiment 3

[0030] A method for cleaning black edges of an aluminum nitride ceramic substrate for rail transit chip packaging, comprising the following steps:

[0031] (1) Put the aluminum nitride ceramic substrate into 70°C pure water for ultrasonic washing for 1 min;

[0032] (2) Put the washed aluminum nitride ceramic substrate into the cleaning solution, continue ultrasonication for 3 hours, and the solution temperature is 40°C;

[0033] The formula of the cleaning solution includes 20% concentration of dilute hydrochloric acid, 50% concentration of hydrogen peroxide and cationic surfactant, wherein the ratio of hydrogen peroxide to dilute hydrochloric acid is 1:5. The pH value of the cleaning solution is 1. The cationic surfactants used in the cleaning solution are cetyltrimethylammonium sodium bromide, dimethylbenzyldodecylammonium bromide, alkylpyridinium and N,N dimethyldodecyl At least one of the base amines, preferably, the cationic surfactant is dimethyl benzyl dodecyl ammoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com