Injection gel composite microsphere and preparation method thereof

A technology of composite microspheres and gels, applied in the field of medical materials, can solve problems such as high risk, bubbles, redness, etc., achieve high biological safety, and reduce side effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

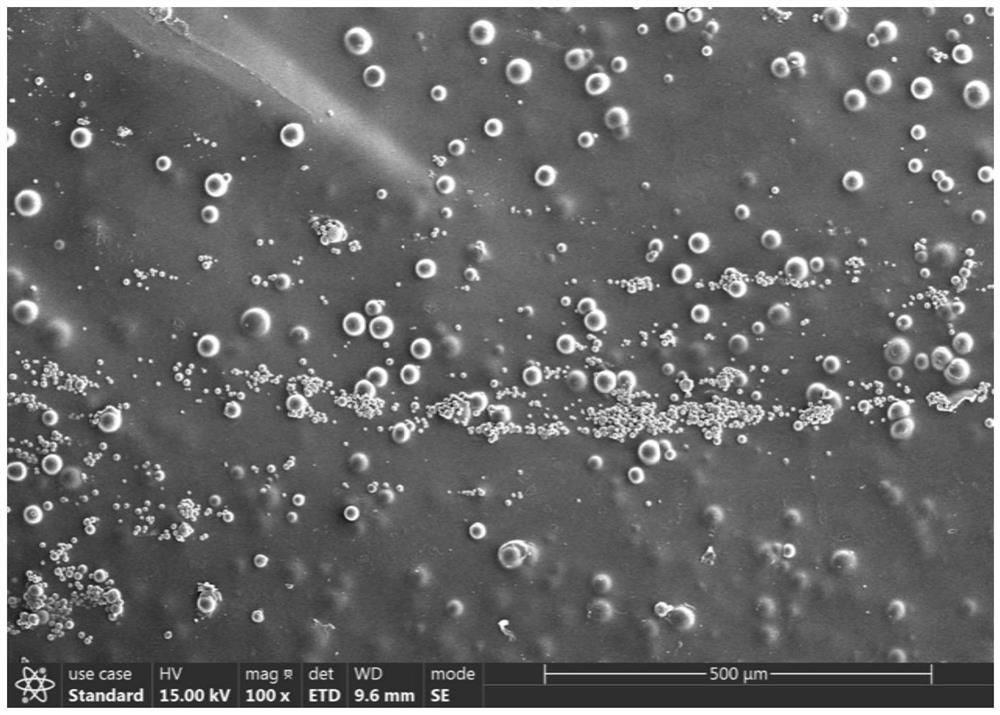

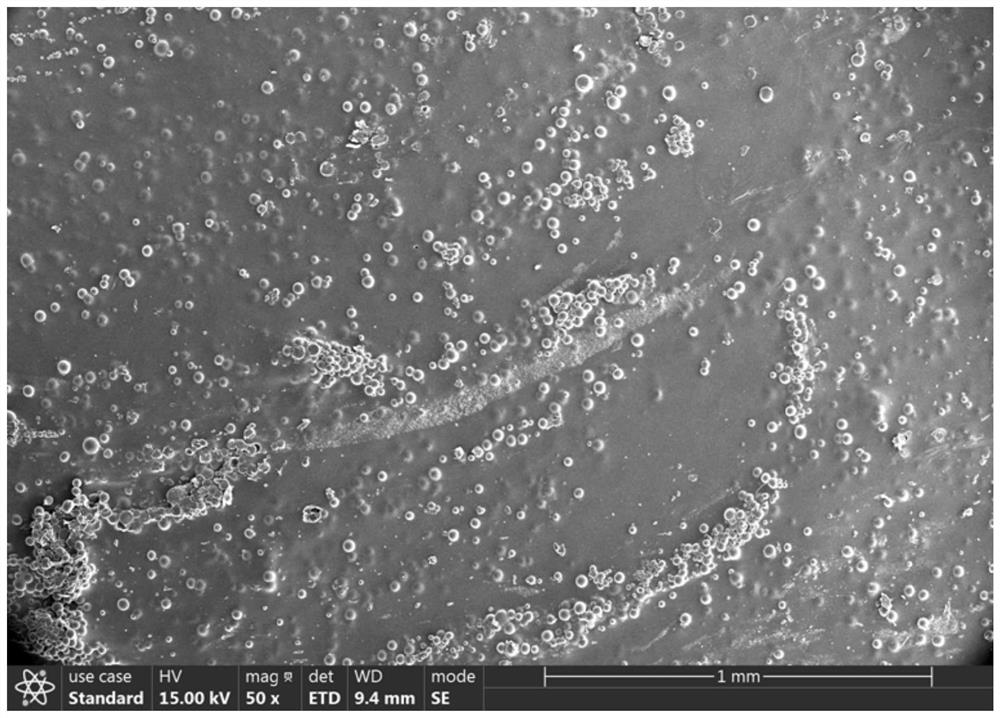

Image

Examples

Embodiment 1

[0037] S1: L-polylactic acid microspheres were added to sodium chloride solution under the conditions of osmotic pressure 250mOsm / L and pH 7.0 for dispersion, followed by adding anesthetic lidocaine hydrochloride, sodium hyaluronate, silk fibroin and Organosilicon defoamer, after mixing uniformly, a mixture is obtained;

[0038] S2: put the mixture into a cellulose dialysis belt and use PBS buffer for dialysis, wherein the molecular weight of dialysis is 500, and dialysis is performed twice, after 10h dialysis each time; ℃, the pressure of 42kPa moist heat high pressure steam sterilization for 10 minutes, to obtain injection gel composite microspheres.

[0039] The mass fraction of the L-polylactic acid microspheres is 1%, the molecular weight is 50000, and the particle size is 20 μm, which is obtained by self-preparation; The preparation methods are similar, except that the molecular weight of L-polylactic acid is different: the molecular weight of L-polylactic acid used in E...

Embodiment 2

[0045] S1: L-polylactic acid microspheres were added to sodium chloride solution under the conditions of an osmotic pressure of 350 mOsm / L and pH 7.0 for dispersion, followed by the addition of anesthetic lidocaine hydrochloride, sodium hyaluronate, silk fibroin and Polyether defoamer for fermentation, after mixing uniformly, a mixture is obtained;

[0046] S2: Put the mixture into a cellulose dialysis belt and use PBS buffer for dialysis, wherein the molecular weight of dialysis is 1000, and dialysis is performed for 4 times, 13 hours each time, after the dialysis is completed; then the material is filled into a pre-filled syringe, and the temperature is 121 DEG C, pressure 103kPa moist heat high pressure steam sterilization for 30 minutes to obtain injection gel composite microspheres.

[0047] The mass fraction of the L-polylactic acid microspheres is 4%, the molecular weight is 80000, and the particle size of the microspheres is 30 μm, which is obtained by self-preparatio...

Embodiment 3

[0053] S1: L-polylactic acid microspheres were added to phosphate buffer under the conditions of an osmotic pressure of 300 mOsm / L and pH 7.0 for dispersion, followed by the addition of anesthetic lidocaine hydrochloride, sodium hyaluronate, silk fibroin and Polyether defoamer for fermentation, after mixing uniformly, a mixture is obtained;

[0054] S2: put the mixture into a cellulose dialysis belt and use PBS buffer for dialysis, wherein the molecular weight of dialysis is 1000, dialysis 3 times, each 12h, after the dialysis is completed; then fill the material into a pre-filled syringe, and the temperature is 120 DEG C, pressure 97kPa moist heat high pressure steam sterilization for 30 minutes to obtain injection gel composite microspheres.

[0055] The mass fraction of the L-polylactic acid microspheres is 2%, the molecular weight is 100,000, and the particle size of the microspheres is 50 μm, which is obtained by self-preparation; the preparation method of the L-polylact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com