Hot dip zinc plated steel sheet having high strength and method for producing the same

A technology of hot-dip galvanized steel sheet and manufacturing method, which can be applied to manufacturing tools, hot-dip galvanizing process, heat treatment furnace, etc., and can solve problems such as difficulty in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] What table 1 shows is that the steel A-R in the composition range of the present invention and the steel a-k outside the composition range are placed in the converter to cast ingots, and the billet is obtained by continuous casting. After hot rolling under the conditions in the scope of the present invention shown in Table 2, Carry out cold rolling with cold rolling ratio 60%, carry out galvanizing according to the condition in the scope of the present invention shown in Table 2 on continuous hot-dip galvanizing production line, the high-strength hot-dip galvanized steel sheet of the thickness 1.4mm of making.

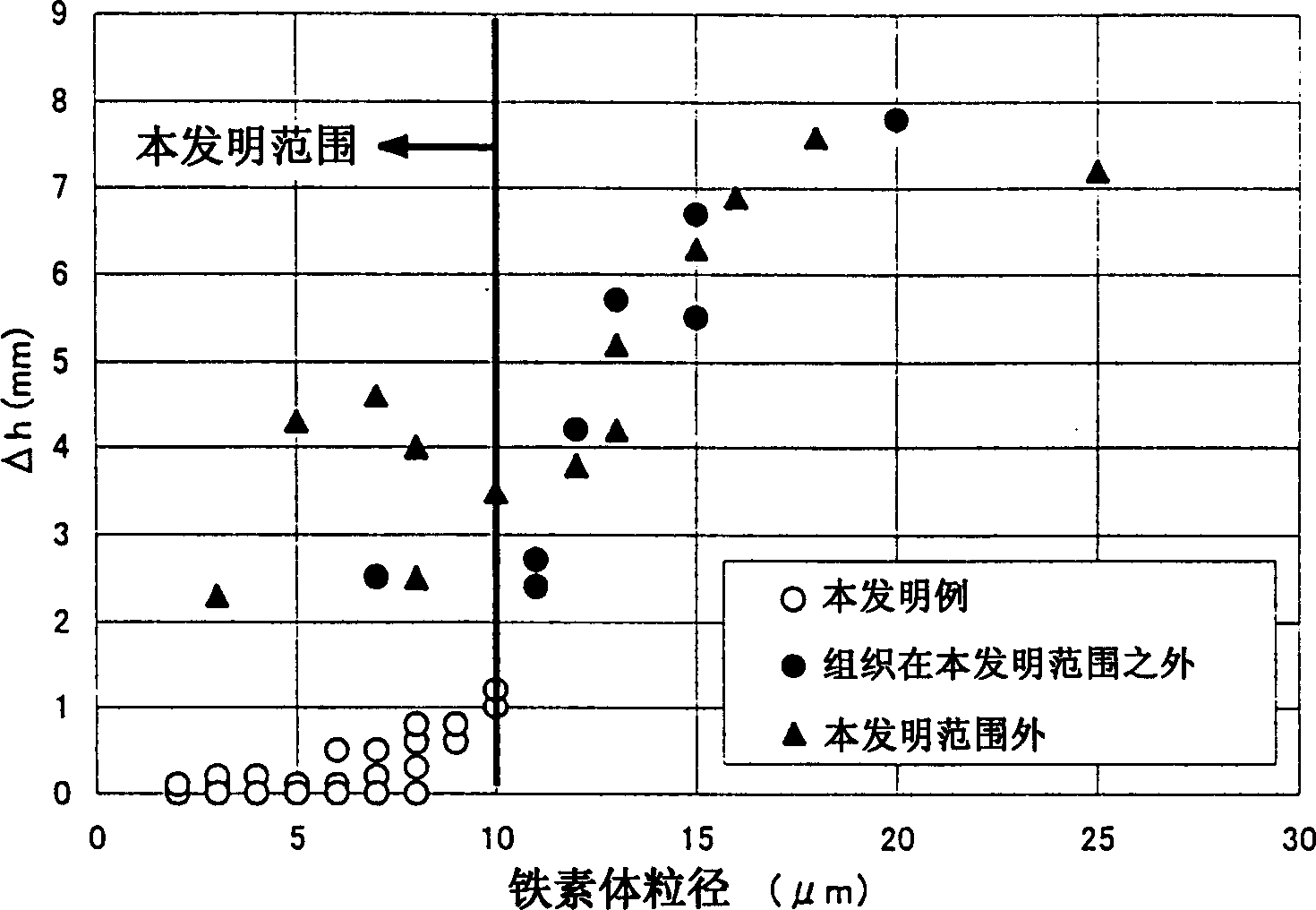

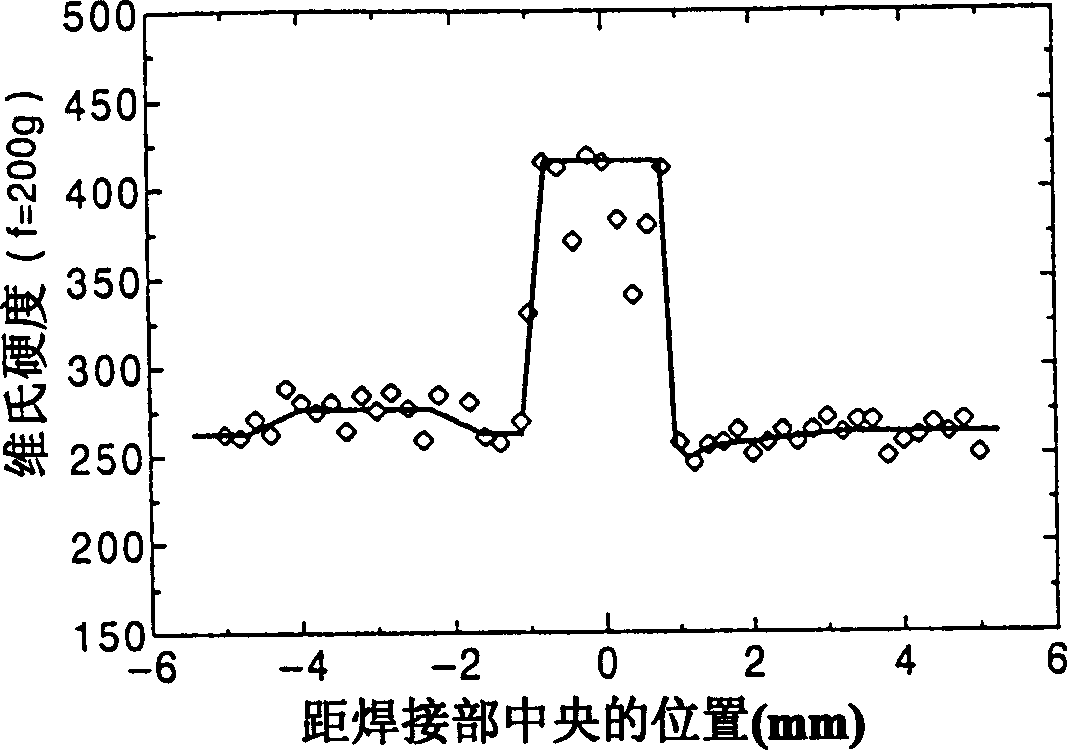

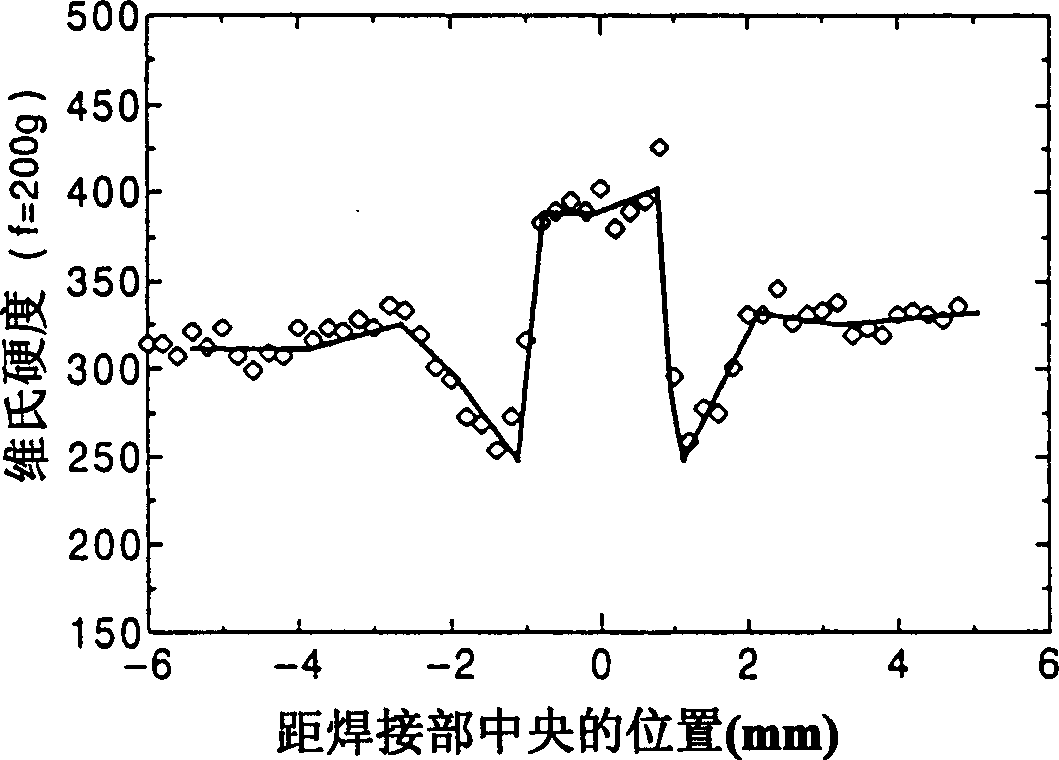

[0038] Then, the second phase was observed with an electron microscope, the amount of remaining austenite was measured by X-ray diffraction, and the tensile strength TS was measured by a tensile test. In addition, in order to evaluate the characteristics of the HAZ after laser welding, an Ericsson test (cupping test) was performed on the base material and the las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com