Step releasing type solidifying stabilizing remediating method for heavy metal polluted soil

A technology of polluted soil and remediation method is applied in the field of solidification and stabilization remediation of step-release heavy metal polluted soil, which can solve the problems of high re-treatment cost, heavy metal infiltration, and short stabilization time, and achieves low treatment cost, low price, and time. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

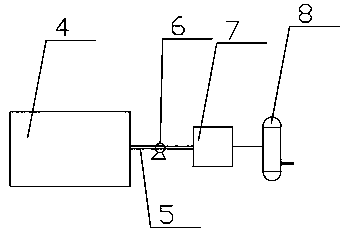

Method used

Image

Examples

Embodiment 1

[0029] A commercial land in Guangdong was polluted by heavy metals, and the key pollutants were copper, cadmium, lead, nickel, and zinc. The soil polluted by heavy metals was taken for testing. The test results are shown in Table 1.

[0030] Excavate and sieve the detected contaminated soil, then divide it into four equal parts, and transport it to the curing, stabilization and restoration workshop for stabilization treatment;

[0031] The first contaminated soil stabilization treatment method mainly includes the following steps:

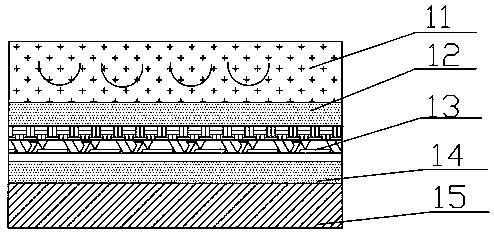

[0032] (1) Preparation of ladder release control agent

[0033] Dilute pure acrylic acid liquid 20 times with deionized water, called base liquid A;

[0034] Dissolve pure cellulose powder in deionized water at 58-62°C to make a cellulose suspension for later use, the weight ratio of the cellulose powder to deionized water is 2:25; add to the cellulose suspension Add fly ash and zeolite to prepare base liquid B, the weight ratio of the cellulose s...

Embodiment 2

[0043] The second contaminated soil stabilization treatment method mainly includes the following steps:

[0044] (1) Preparation of ladder release control agent

[0045] Dilute pure acrylic acid liquid 20 times with deionized water, called base liquid A;

[0046] Dissolve pure cellulose powder in deionized water at 58-62°C to make a cellulose suspension for later use, the weight ratio of the cellulose powder to deionized water is 2:25; add to the cellulose suspension Add fly ash and zeolite to prepare base liquid B, the weight ratio of the cellulose suspension: fly ash: zeolite is 25:4:3; the particle size of zeolite is 50-100 mesh;

[0047] Mix base liquid A and base liquid B at 65-70°C, and mix and add volume ratio of base liquid A: base liquid B is 32:67; stir after mixing and adding, stir for 3 hours, and mix the suspension The step release control agent colloid obtained by modification is used as the step release control agent; the stirring speed after mixing base liqui...

Embodiment 3

[0055] The third contaminated soil stabilization treatment method mainly includes the following steps:

[0056] (1) Preparation of ladder release control agent

[0057] Dilute pure acrylic acid liquid 20 times with deionized water, called base liquid A;

[0058] Dissolve pure cellulose powder in deionized water at 58-62°C to make a cellulose suspension for later use, the weight ratio of the cellulose powder to deionized water is 2:25; add to the cellulose suspension Add fly ash and zeolite to prepare base liquid B, the weight ratio of the cellulose suspension: fly ash: zeolite is 25:4:3; the particle size of zeolite is 50-100 mesh;

[0059] Mix base liquid A and base liquid B at 65-70°C, and mix and add volume ratio of base liquid A: base liquid B is 32:67; stir after mixing and adding, stir for 3 hours, and mix the suspension The step release control agent colloid obtained by modification is used as the step release control agent; the stirring speed after mixing base liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com