Carbon-based nano material for lithium battery and preparation method of carbon-based nano material

A technology of carbon-based nanomaterials and lithium batteries, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unsealable batteries and low utilization of active materials, and achieve improved electrochemical behavior, suppressed hydrogen evolution, and enhanced dispersion effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a carbon-based nanomaterial for lithium batteries, comprising: 91.40g of electrolytic graphene, 8.60g of inhibitors; the inhibitors include: 2.4596g of zinc nitrate, 2.5284g of silver nitrate, 2.5972g of Bismuth nitrate pentahydrate, 1.0148g sodium hydroxide;

[0027] A method for preparing carbon-based nanomaterials for lithium batteries, the specific preparation steps are as follows:

[0028] Step 1: according to the above weight ratio, weigh electrolytic graphene, zinc nitrate, silver nitrate, bismuth nitrate pentahydrate, and sodium hydroxide in the inhibitor;

[0029] Step 2: adding the electrolytic graphene in step 1 to deionized water, and performing ultrasonic treatment for 10 minutes to obtain an electrolytic graphene dispersion;

[0030] Step 3: Add zinc nitrate, silver nitrate, bismuth nitrate pentahydrate, and sodium hydroxide in the inhibitor of step 1 to the electrolytic graphene dispersion, add deionized water, stir evenly, adjust ...

Embodiment 2

[0037] Different from Example 1, it includes: 92.40g of electrolytic graphene, 7.60g of inhibitors; the inhibitors include: 2.2648g of zinc nitrate, 2.3104g of silver nitrate, 2.3864g of bismuth nitrate pentahydrate, 0.6384g g sodium hydroxide.

Embodiment 3

[0039] All different from Examples 1-2, including: 91.90g of electrolytic graphene, 8.10g of inhibitors; the inhibitors include: 2.3652g of zinc nitrate, 2.4219g of silver nitrate, 2.4948g of nitric acid pentahydrate Bismuth, 0.8181g sodium hydroxide.

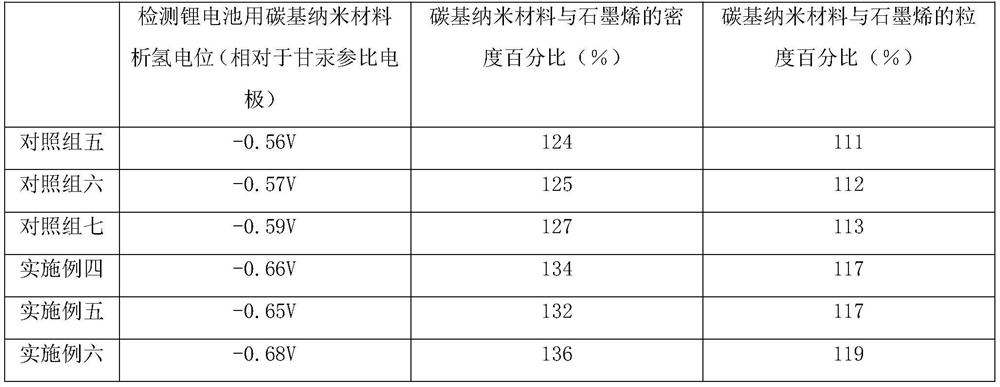

[0040]Take the carbon-based nanomaterials for lithium batteries prepared in the above-mentioned Examples 1-3 and the carbon-based nanomaterials for lithium batteries of the control group 1, the carbon-based nanomaterials for lithium batteries of the control group 2, and the lithium battery of the control group 3 respectively. With carbon-based nanomaterials, the carbon-based nanomaterials for lithium batteries of the control group four and the carbon-based nanomaterials for lithium batteries of the control group five, the carbon-based nanomaterials for lithium batteries of the control group one compared with the examples without zinc nitrate, Compared with the examples, the carbon-based nanomaterials for lithium batteries of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com