A method for hydrolyzing hydrogen and hydrogen peroxide

A technology of hydrogen peroxide and hydrogen, applied in chemical instruments and methods, production of hydrogen, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, etc., can solve safety hazards, difficult to carry out and other issues, to achieve the effects of improving efficiency, high preparation efficiency, obvious economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

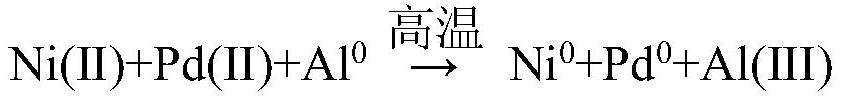

[0031] A method for producing hydrogen and hydrogen peroxide by hydrolysis, adding micron-sized aluminum powder, nickel chloride and palladium chloride to the container, the mol ratio of the aluminum powder, nickel chloride and palladium chloride being 2:1:0.1, And add deionized water to carry out hydrogen production and displacement reaction, the mass ratio of aluminum powder and deionized water is 1:1, the reaction time of hydrogen production and displacement reaction is 0.5min, makes hydrogen and aluminum-nickel-palladium ternary alloy; Add deionized water and oxygen to the aluminum-nickel-palladium ternary alloy to produce hydrogen peroxide. The mass ratio of the aluminum-nickel-palladium ternary alloy to the deionized water is 1:20, and the amount of oxygen added to the oxygen is 0.04kg / (m 3 *min), the reaction time of the hydrogen peroxide production reaction is 0.5h, the reaction temperature is 20°C, the solution is separated from the solid and the liquid after the react...

Embodiment 2

[0033] A method for producing hydrogen and hydrogen peroxide by hydrolysis, adding micron-sized aluminum powder, nickel chloride and palladium chloride to the container, the mol ratio of the aluminum powder, nickel chloride and palladium chloride being 20:1:0.1, And add deionized water to carry out hydrogen production and displacement reaction, the mass ratio of aluminum powder and deionized water is 1:20, the reaction time of hydrogen production and displacement reaction is 5min, makes hydrogen and aluminum-nickel-palladium ternary alloy; Add deionized water and oxygen to the nickel-palladium ternary alloy to produce hydrogen peroxide. The mass ratio of the aluminum-nickel-palladium ternary alloy to the deionized water is 1:1000, and the amount of oxygen added to the oxygen is 0.01kg / (m 3 *min), the reaction time of the hydrogen peroxide-generating reaction is 5 hours, the reaction temperature is 25°C, and the solution is separated from solid and liquid after the reaction, and...

Embodiment 3

[0035]A method for producing hydrogen and hydrogen peroxide by hydrolysis, adding micron-sized aluminum powder, nickel chloride and palladium chloride to the container, the mol ratio of the aluminum powder, nickel chloride and palladium chloride being 12:1:0.1, And add deionized water to carry out hydrogen production and displacement reaction, the mass ratio of aluminum powder and deionized water is 1:8, the reaction time of hydrogen production and displacement reaction is 3min, makes hydrogen and aluminum-nickel-palladium ternary alloy; Add deionized water and oxygen to the nickel-palladium ternary alloy to produce hydrogen peroxide. The mass ratio of the aluminum-nickel-palladium ternary alloy to the deionized water is 1:500, and the amount of oxygen added to the oxygen is 0.07kg / (m 3 *min), the reaction time of the hydrogen peroxide production reaction is 3 hours, the reaction temperature is 23°C, the solution is separated from the solid and liquid after the reaction, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com