Composite additive slurry for super capacitor batteries and preparation method thereof

A supercapacitor battery and composite additive technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of shortened life of supercapacitor batteries, achieve high specific energy, long specific power, and enhance the effect of hydrophilicity and specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

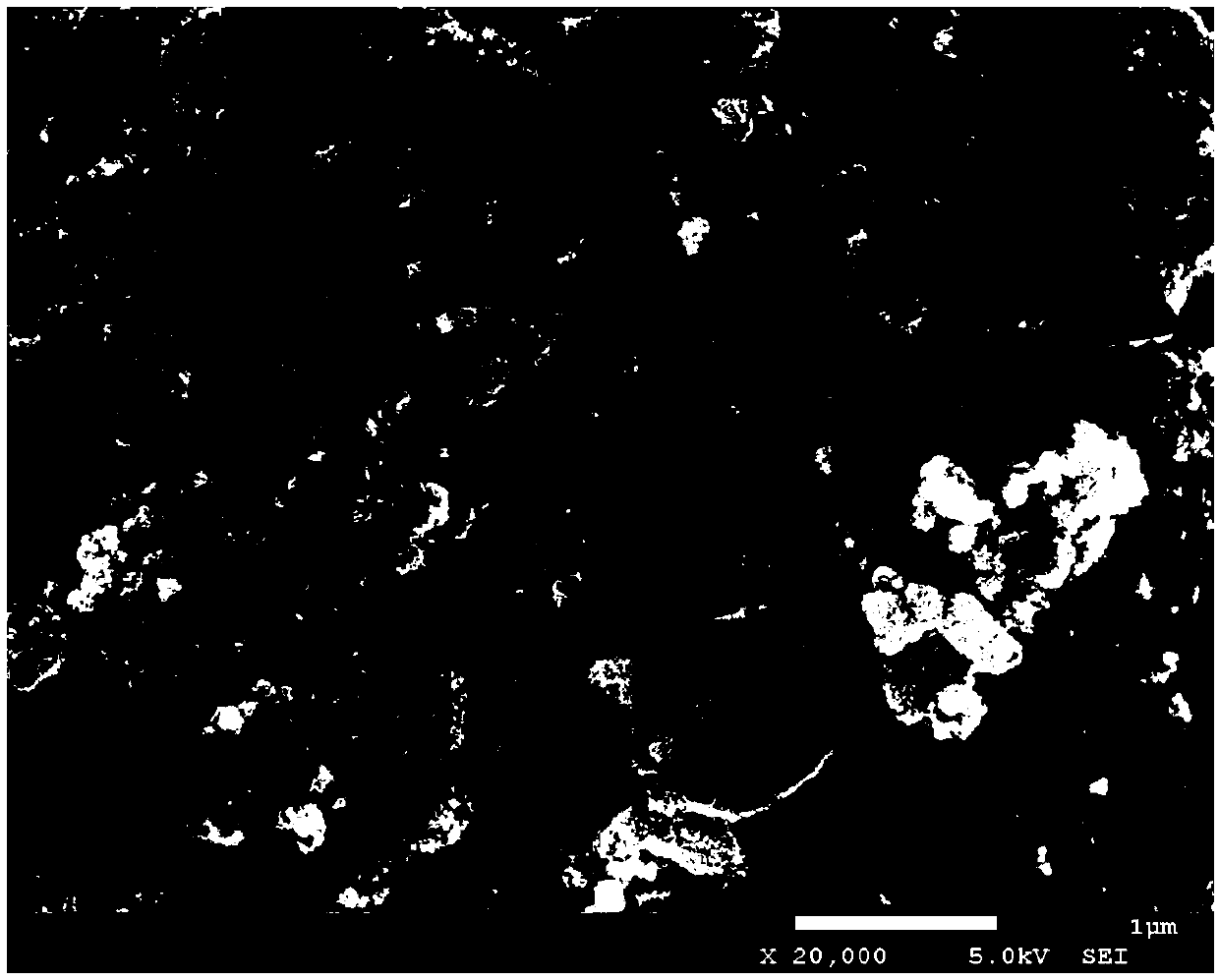

[0060] A special compound additive slurry for supercapacitor batteries, which is composed of the following components: carbon nanotubes with a wall thickness of 30-45nm and a length of 5-20μm; metal salts are tetravalent lead salts, and activated carbon has a specific surface of 2150m 2 / g~2250m 2 / g, the specific gravity is 0.35g / cm 2 ~0.5g / cm 2 , the pore volume is 0.3cm 3 / g~5cm 3 / g, high specific area activated carbon with a pore size of 3nm-5nm and a particle size (D50) of 15μm-25μm, graphene oxide prepared by "low-temperature oxidation intercalation" combined with "mechanical grinding and peeling" method for no more than 6 hours. For yellow graphene oxide, the reducing agent is thiourea, the surfactant is polyvinyl alcohol, and deionized water.

Embodiment 2

[0062] A special composite additive slurry for supercapacitor batteries, consisting of the following components by mass: 8 parts of carbon nanotubes, 86 parts of activated carbon, 6 parts of metal salts, 3 parts of graphene oxide, 3 parts of reducing agents, and 3 parts of surfactants And 120 parts of deionized water, the carbon nanotubes are carbon nanotubes with a wall thickness of 30-45nm and a length of 5-20 μm, the metal salt is a tetravalent bismuth salt, and the graphene oxide adopts "low temperature oxidation intercalation Combining the "mechanical grinding and peeling" method to prepare brown-yellow graphene oxide for no more than 6 hours, the reducing agent is urea, and the surfactant is sodium dodecylsulfonate.

Embodiment 3

[0064] A special composite additive slurry for supercapacitor batteries, consisting of the following components by mass: 5 parts of carbon nanotubes, 84 parts of activated carbon, 4 parts of metal salts, 1 part of graphene oxide, 1 part of reducing agent, and 1 part of surfactant And 100 parts of deionized water; choose carbon nanotubes with a wall thickness of 30-45nm and a length of 5-20μm; use tetravalent tin salt as the metal salt, and use "low temperature oxidation intercalation" combined with "mechanical grinding and peeling" for graphene oxide Methods The brownish-yellow graphene oxide is prepared within 6 hours, the reducing agent is hydrazine hydrate, and the surfactant is cetyltrimethylammonium bromide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com