Cheto-type bentonite sodium modification method and device thereof

A technology of sodium bentonite and open mill, applied in the direction of aluminum silicate, silicate, etc., can solve the problems of ineffective cheto-type bentonite and increased processing costs, so as to facilitate drying and reprocessing and reduce drying time and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

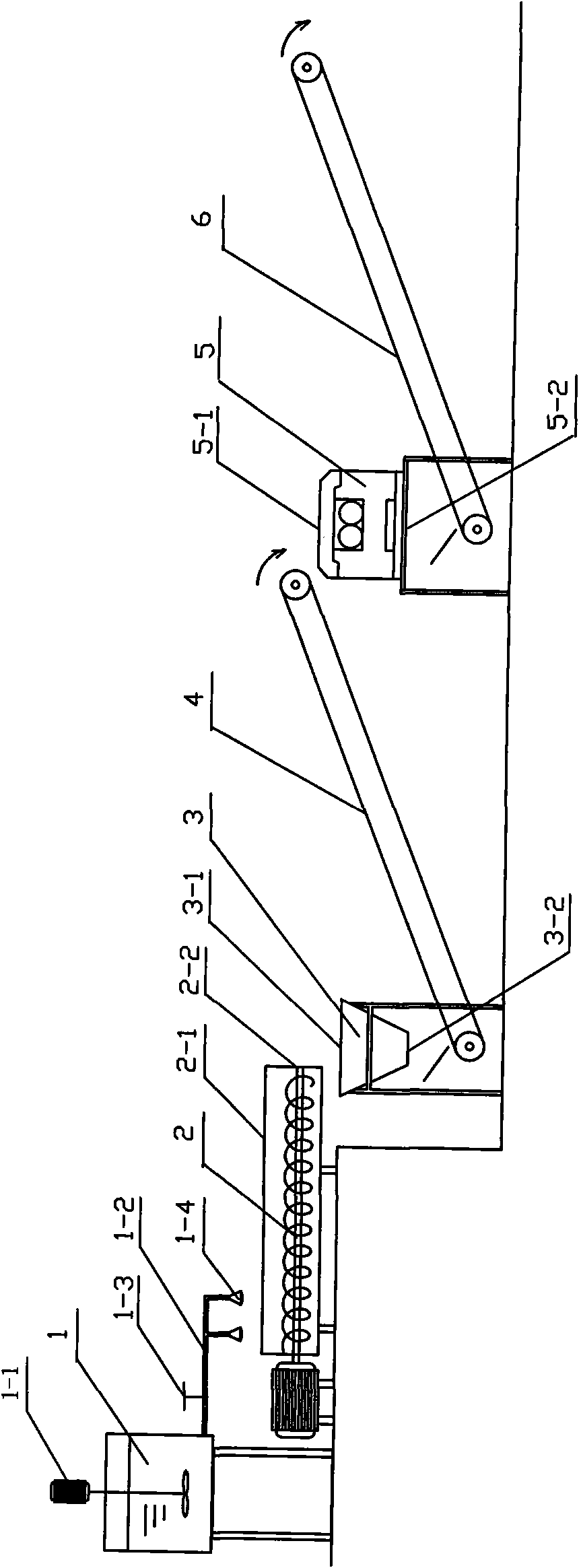

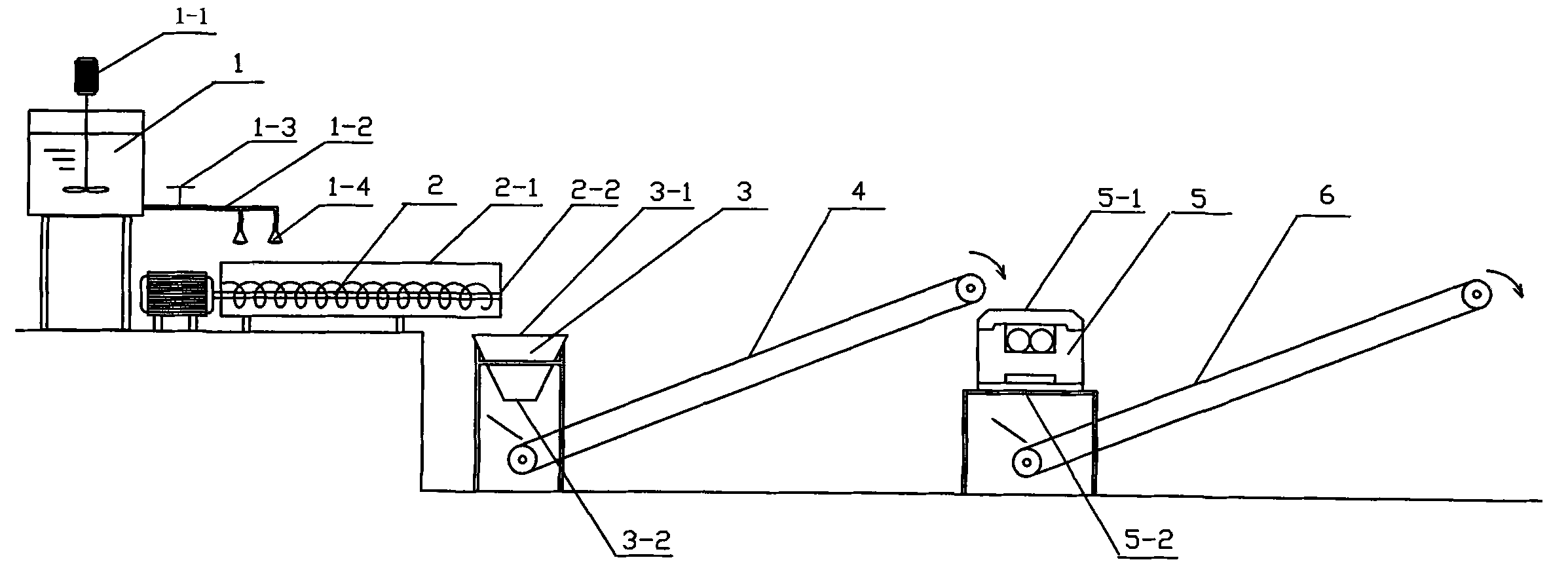

[0020] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

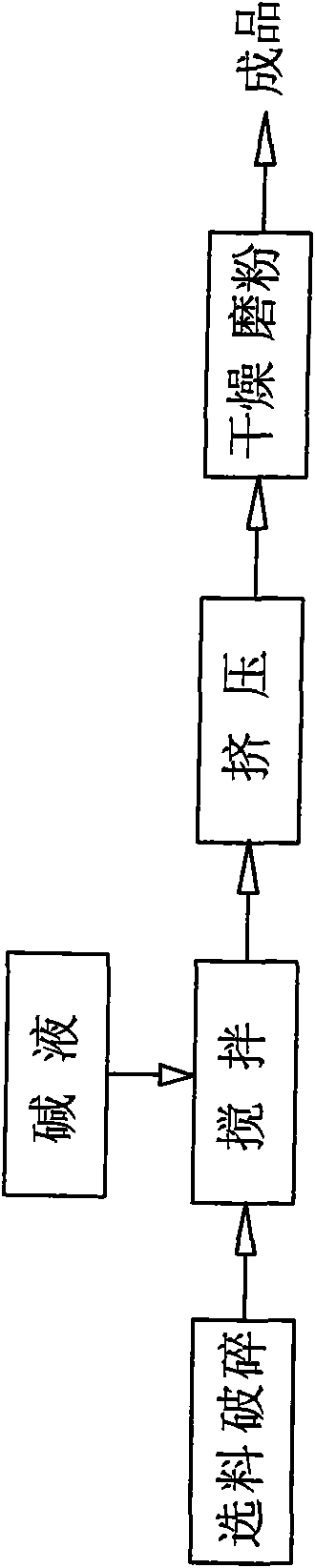

[0021] See figure 1 , a kind of cheto-type bentonite sodium modification method, comprising the following process steps and process parameters:

[0022] 1. Select materials. The medium and high-grade natural cutto-type calcium-based bentonite raw ore with a blue absorption amount of 35g / 100g is air-dried or dried until the moisture content is less than 13%, and then crushed by a hammer crusher until the particle size is less than 5mm.

[0023] 2. Add alkali and mix. Soda ash is mixed with water in the lye barrel to form lye with a concentration of 20%, and then the mineral material is transported to the double-helix mixer, and the lye is sprayed on the surface of the mineral material through the nozzle while stirring, and the amount of lye added is 20% of the mineral material 12% of the volume, stir to mix until uniform.

[0024] 3. Strong extrusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com