Modified corn straw composite fiber reinforced friction material and its preparation method

A technology of corn stalk fiber and composite fiber, which is applied in the fields of plant fiber, fiber treatment, chemical instruments and methods, etc., can solve problems such as unsatisfactory, and achieve the effects of improving modification efficiency, ensuring uniformity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

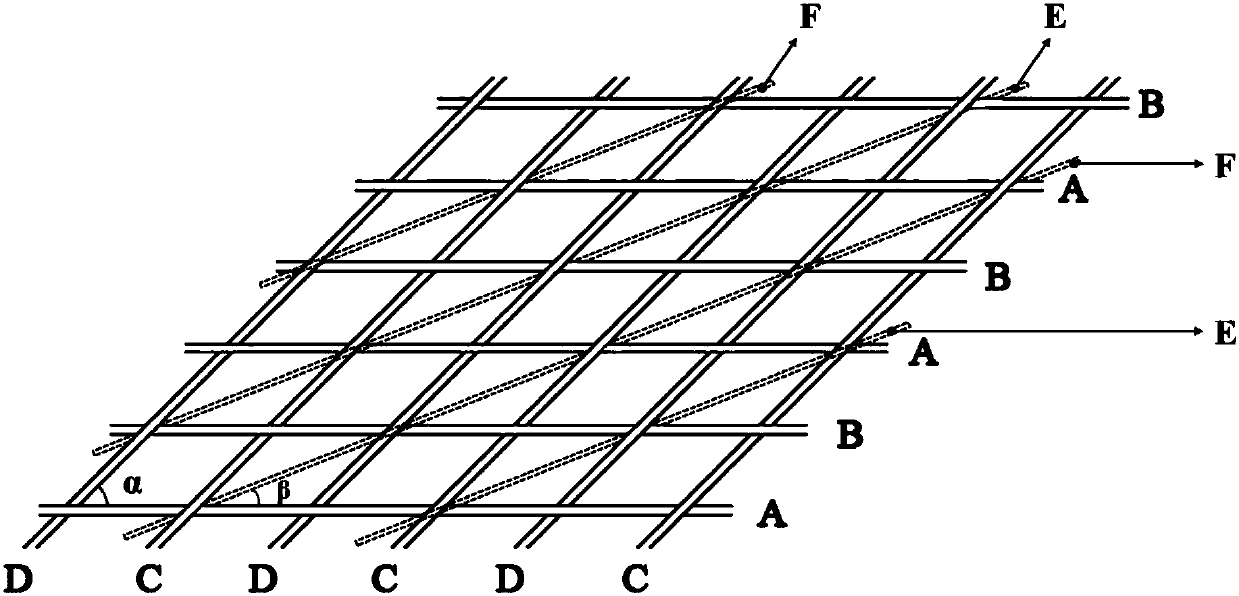

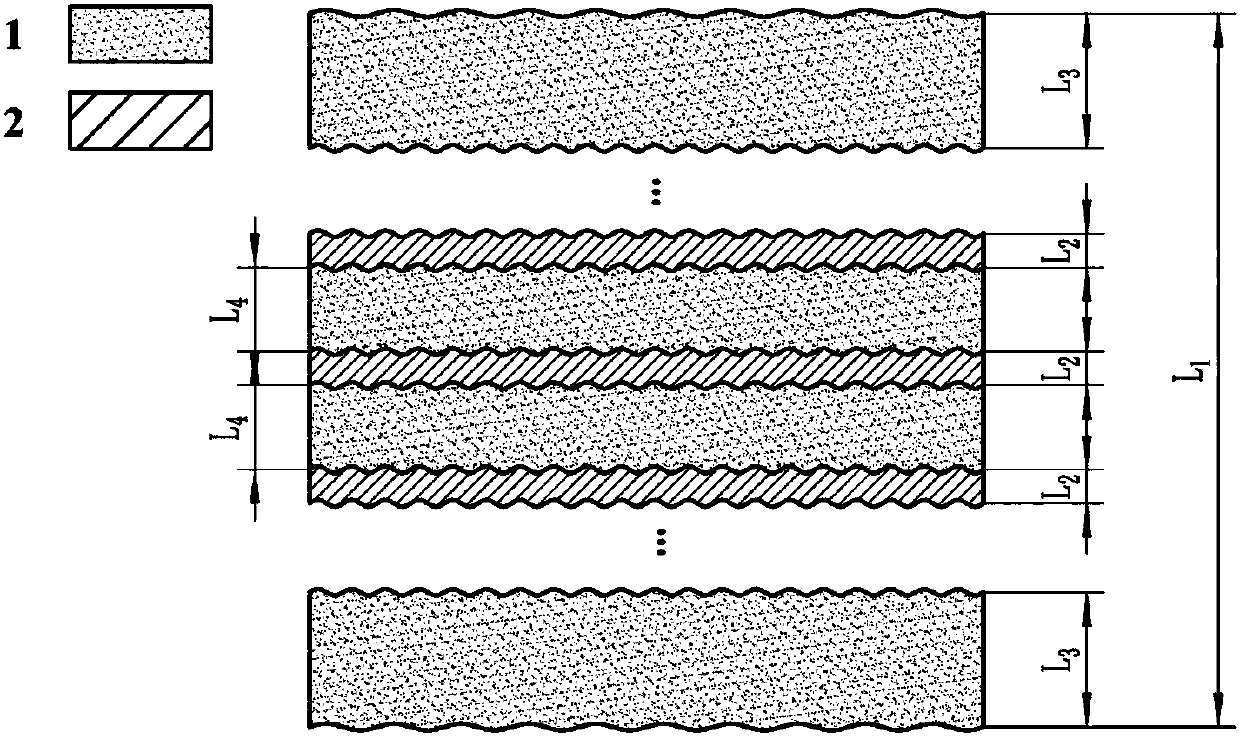

Method used

Image

Examples

Embodiment 1

[0051] 1. The content of the two components of the modified corn stalk composite fiber reinforced friction material by mass percentage is: 8% of the composite fiber interwoven structure layer material, and 92% of the filler layer material; wherein the content of each component of the filler layer material by mass percentage is : 38% phenolic resin, 5% aramid fiber particles, 4% flake graphite, 5% antimony trisulfide, 3% zeolite, 26% barium sulfate, 3% foam iron powder, 7% wollastonite, 2 red vermiculite %, petroleum coke 7%.

[0052] 2. The composite fiber interweaving structure layer material is prepared through the following steps:

[0053] (1) ① Soak the corn stalk fiber in the mixed solution of ethanol and sodium hexametaphosphate (the mass ratio of the fiber to the mixed solution is 1:22), and the content of each component by mass percentage is: absolute ethanol 30%, six 15% sodium metaphosphate, 55% distilled water, the treatment time is 15 minutes; then wash with disti...

Embodiment 2

[0065] 1. The content of the two components of the modified corn stalk composite fiber reinforced friction material by mass percentage is: 23% of the composite fiber interwoven structure layer material, and 77% of the filler layer material; wherein the content of each component of the filler layer material by mass percentage is : phenolic resin 10%, aramid particles 9%, flake graphite 7%, antimony trisulfide 12%, zeolite 9%, barium sulfate 11%, foam iron powder 11%, wollastonite 15%, red vermiculite 5 %, petroleum coke 11%.

[0066] 2. The composite fiber interweaving structure layer material is prepared through the following steps:

[0067] (1) ① Soak the corn stalk fiber in the mixed solution of ethanol and sodium hexametaphosphate (the mass ratio of the fiber to the mixed solution is 1:24), and the content of each component by mass percentage is: absolute ethanol 45%, six Sodium metaphosphate 10%, distilled water 45%, the treatment time is 20min; then wash with distilled w...

Embodiment 3

[0079] 1. The content of the two components of the modified corn stalk composite fiber reinforced friction material by mass percentage is: 16% of the composite fiber interwoven structure layer material, and 84% of the filler layer material; wherein the content of each component of the filler layer material by mass percentage is : 13% phenolic resin, 6% aramid fiber particles, 19% flake graphite, 7% antimony trisulfide, 5% zeolite, 13% barium sulfate, 17% foam iron powder, 9% wollastonite, 3 red vermiculite %, petroleum coke 8%.

[0080] 2. The composite fiber interweaving structure layer material is prepared through the following steps:

[0081] (1) ① Soak the corn stalk fiber in the mixed solution of ethanol and sodium hexametaphosphate (the mass ratio of the fiber to the mixed solution is 1:23), and the content of each component according to the mass percentage is: absolute ethanol 38%, six Sodium metaphosphate 13%, distilled water 49%, the treatment time is 18min; then was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com