Method for enhancing air poison resistance of Zr2Fe alloy

A performance and air technology, applied in the field of enhancing the anti-air poisoning performance of Zr2Fe alloy, can solve the problems of poor anti-air poisoning performance, shorten the time of ball milling, ensure the modification effect, and reduce the effect of impact frequency and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

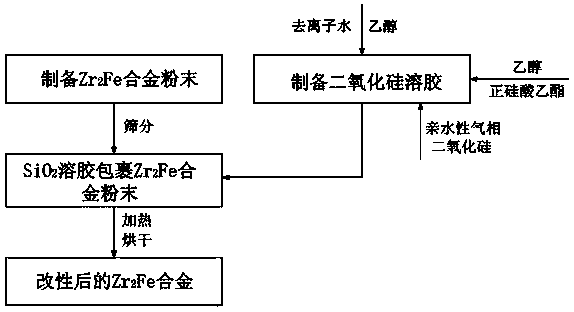

[0053] The present invention is mainly used for Zr 2 Fe alloys are modified to enhance their resistance to air poisoning. like figure 1 Shown, the present invention for Zr 2 The technological process of Fe alloy powder modification can be divided into the preparation of Zr 2 Fe alloy powder, sieved Zr 2 Fe alloy powder, preparation of silica sol, wrapping Zr 2 The steps of Fe alloy powder and heating and drying are as follows:

[0054] Preparation of Zr 2 Fe alloy powder

[0055] The present invention adopts the method of ball milling combined with vacuuming, Ar gas cleaning and charging to prepare Zr 2 Fe alloy powder, Zr under inert gas Ar protective atmosphere 2 Fe alloy particles were ball milled; at the same time, the Zr after ball milling 2 The Fe alloy was passivated with Ar gas and placed in a glove box, so that the cracked Zr 2 The Fe alloy slowly contacts the air. Adopt the Zr prepared by process of the present invention 2 Fe alloy powder, cooperates othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com