Double-coated electrode and preparation method thereof

A coated electrode and coating technology, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems that the welding speed of two welding cores cannot be guaranteed to be consistent, affecting the normal use of electrodes, and the breakdown of electrodes between double cores. Achieve the effects of reducing wear loss, improving high temperature wear resistance, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: A TiC-VC-NbC electrode with double-coated and double-deposited electrodes

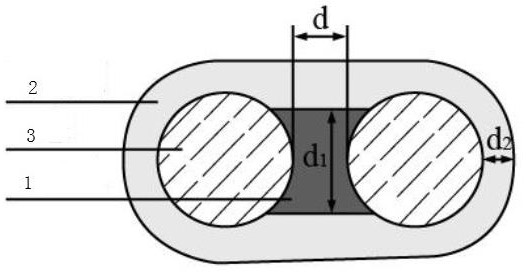

[0044] Such as figure 1 As shown, it includes inner coating 1, outer coating 2, two layers of coating and two welding cores 3. The inner coating 1 is located between the two welding cores 3, and its graphite content is at the critical graphite content 4 for electrode breakdown. % or less, the outer coating 2 wraps two parallel welding cores 3, the graphite content in the outer coating ranges from 10-15%, the distance between the two welding cores ranges from 0.8-2.0mm, and the two layers of coating are bonded agent bonding. The binder is potassium water glass: sodium water glass 4:1 mixed aqueous solution.

[0045] As a specific example, the list of inner coating, outer coating, electrode composition and mass fraction is as shown in Table 1:

[0046] Table 1 Double-coated electrodes with different components and mass fractions

[0047]

[0048]

[0049] In this embodiment, t...

Embodiment 2

[0050] Embodiment 2: a kind of preparation method of double-coated electrode, comprises the steps:

[0051] Step (1), making the welding core according to the required electrode specifications; preparing the inner coating and the outer coating respectively, and bonding the coating powder with binder and water;

[0052] Step (2), using a welding rod coating press to coat the inner drug skin coating between two welding cores arranged in parallel;

[0053] Step (3), using an electrode coating press to apply the outer coating to the outer peripheries of the two welding cores with inner coatings obtained in step (2), and then dry them to obtain the double coating welding rod.

[0054] The drying step is a conventional process in the field of electrode preparation. As a typical example, the specific drying steps are: first place the double-coated electrode at room temperature for 24 hours, and then put it in a drying furnace and heat it at 50°C for 1 hour. Hours, 120 ° C for 0.5 h...

Embodiment 3

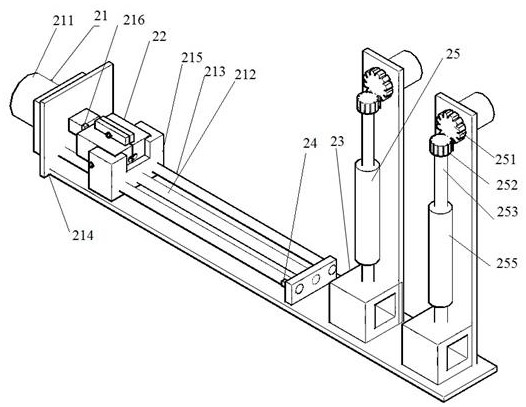

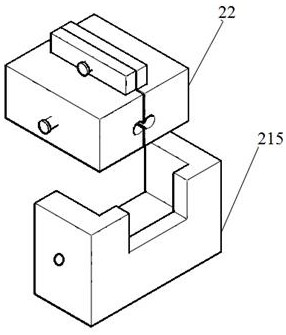

[0055] Embodiment 3: Prepare the coating press used in step (2) and step (3) in the preparation method of the double-coated electrode, such as figure 2 As shown, it includes a moving mechanism 21, a welding core fixing mechanism 22, a coating mechanism 23, an in-position detection mechanism 24 and a drug delivery mechanism 25. The coating mechanism 23 is arranged at one end of the moving mechanism, and the welding core to be coated passes through the welding The core fixing mechanism 22 is connected to the moving mechanism 21 and moves to the coating mechanism driven by the moving mechanism 21. The in-position detection mechanism 24 detects the position of the welding core on the moving mechanism 21. When the welding core penetrates the coating mechanism 23 and finally crosses the When the coating mechanism 23 is applied, the in-position detection mechanism 24 controls the moving mechanism 21 to return; the drug delivery mechanism 25 is connected to the coating mechanism 23 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com