Flange resurfacing welding method

A flange and surfacing technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high price of corrosion-resistant alloys, waste of materials, increase production costs, etc., and achieve difficult quality control, low efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

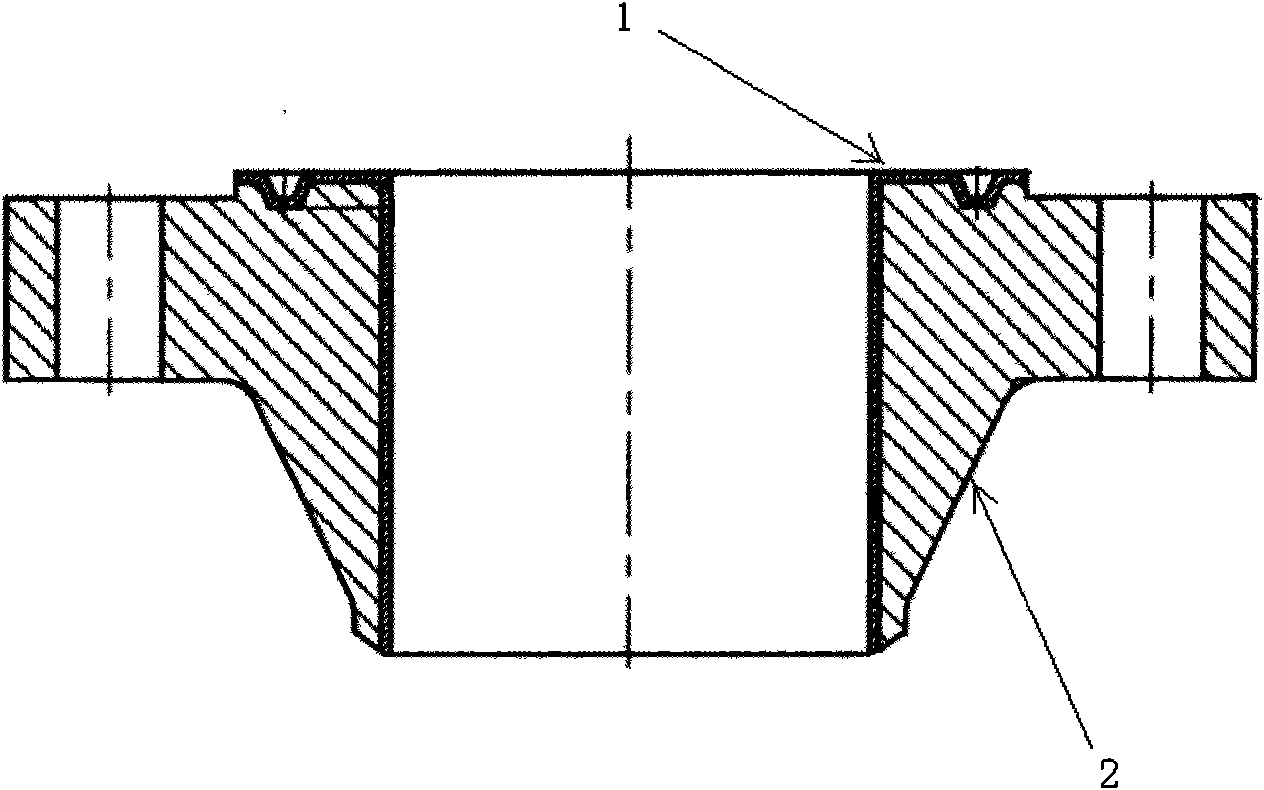

[0013] Such as figure 1 As shown, it is a schematic diagram of the flange after surfacing. The material of the flange body 1 is A350 LF2, and the corrosion-resistant alloy layer 2 is surfacing on the inner hole wall and sealing surface, and the material is nickel alloy ERNiCrMo-3 (Inconel 625).

[0014] The flange surfacing method is as follows:

[0015] Step 1: Roughly process the surface of the flange, and reserve a machining allowance of 3mm to ensure that the weld layer can meet the specified size requirements after processing; The above-mentioned defects need to be repaired and removed by welding, and then surfacing can be done after rough turning; dry the electrode, and use acetone to remove the rust, oil and oxides on the surface of the electrode;

[0016] Step 2: Preheat the surface of the flange to 75°C with an oxyacetylene flame, the preheating time is 0.5h, and the interlayer temperature is 150°C;

[0017] The third step: use tungsten argon arc welding to weld the...

Embodiment 2

[0020] Such as figure 1 As shown, it is a schematic diagram of the flange after surfacing. The material of the flange body 1 is A350 LF2, and the corrosion-resistant alloy layer 2 is surfacing on the inner hole wall and sealing surface, and the material is nickel alloy ERNiCrMo-3 (Inconel 625).

[0021] The flange surfacing method is as follows:

[0022] Step 1: Roughly process the surface of the flange, and reserve a machining allowance of 5mm to ensure that the weld layer can meet the specified size requirements after processing; The above-mentioned defects need to be repaired and removed by welding, and then surfacing can be done after rough turning; the electrodes are dried, and then the butanone (model: Q / GHSA-233-1999) produced by Shanghai Reagent No. 1 Factory is used to remove the rust, oil stains and oxide;

[0023] Step 2: Preheat the surface of the flange to 150°C with an oxyacetylene flame, the preheating time is 1h, and the interlayer temperature is 250°C;

[0...

Embodiment 3

[0027] Such as figure 1 As shown, it is a schematic diagram of the flange after surfacing. The material of the flange body 1 is AISI 4130, and the corrosion-resistant alloy layer 2 is surfacing on the inner hole wall and sealing surface, and the material is nickel alloy ERNiCrMo-3 (Inconel 625).

[0028] The flange surfacing method is as follows:

[0029] Step 1: Roughly process the surface of the flange, and reserve a machining allowance of 3mm to ensure that the weld layer can meet the specified size requirements after processing; The above-mentioned defects need to be repaired and removed by welding, and then surfacing can be done after rough turning; the electrodes are dried, and then the butanone (model: Q / GHSA-233-1999) produced by Shanghai Reagent No. 1 Factory is used to remove the rust, oil stains and oxide;

[0030] Step 2: Preheat the surface of the flange to 150°C with an oxyacetylene flame, the preheating time is 0.5h, and the interlayer temperature is 200°C;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com