Flux core for nano-modified boron-containing high-chromium iron hardfacing self-protection flux-cored wire

A high-chromium cast iron, nano-modified technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as poor wear resistance of alloys, improve wear resistance, increase volume fraction, and ensure toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

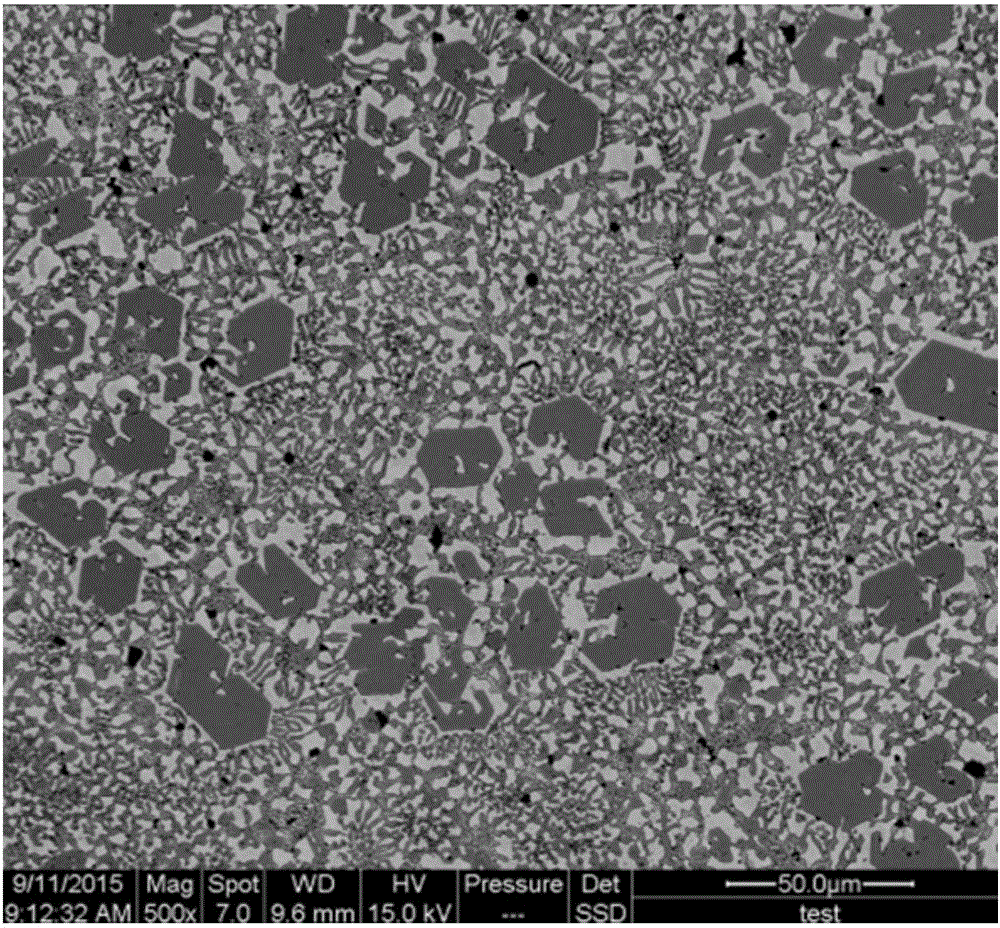

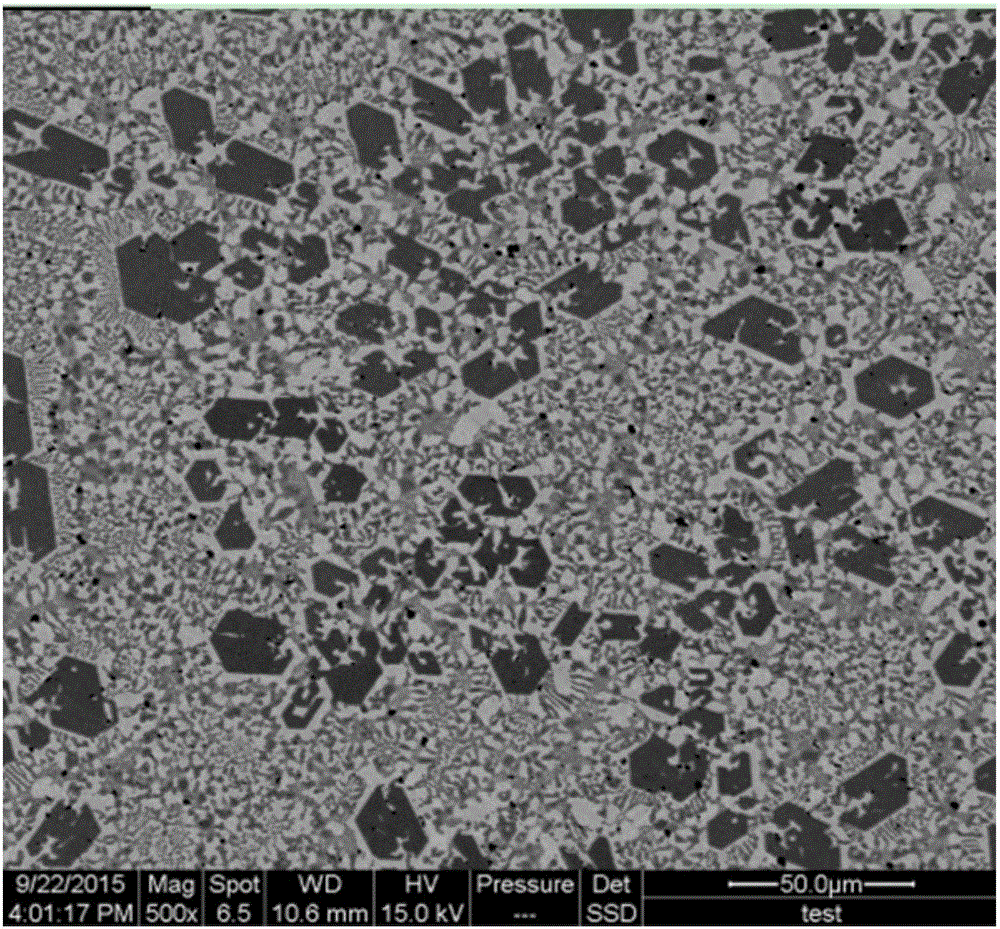

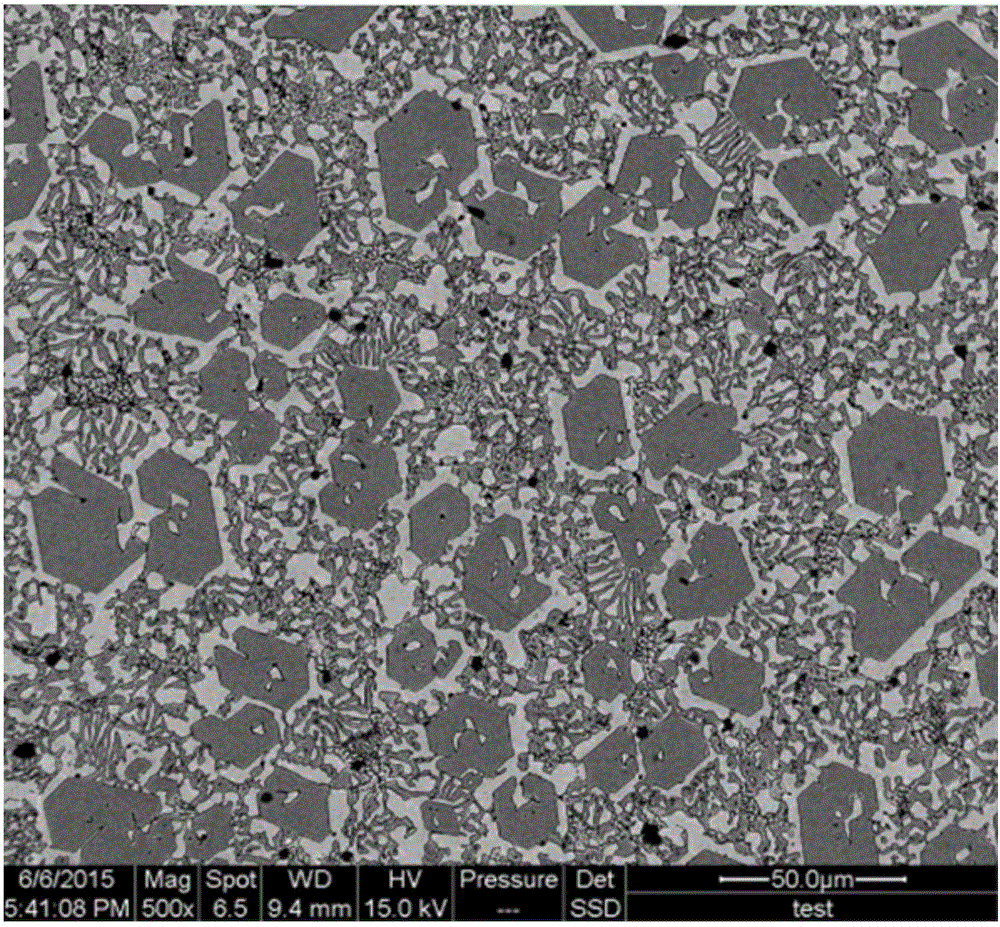

[0033] Embodiment 1: This embodiment is a nano-modified flux core of boron-containing high-chromium cast iron wear-resistant surfacing welding self-shielding flux-cored wire, which is composed of 72% to 85% of high-chromium cast iron powder, 1% ~4% electrolytic manganese powder, 2%~6% ferrosilicon powder, 4%~8% ferroboron powder, 2%~6% graphite powder, 2%~4% aluminum-magnesium alloy powder and 0.3% ~1.5% nanomodifier composition.

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the nano-modifier is one or a mixture of nano-rare earth oxides, nano-rare-earth carbides and nano-rare-earth nitrides. Others are the same as the first embodiment.

specific Embodiment approach 3

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the nanometer rare earth oxide is La 2 o 3 , Nb 2 o 3 、Eu 2 o 3 、Gd 2 o 3 , Tb 2 o 3 、Er 2 o 3 , Yb 2 o 3 , CeO 2 and Y 2 o 3 one or a mixture of several. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com