A high-efficiency welding method for stainless steel clad plates

A welding method and composite plate technology, applied to welding equipment, arc welding equipment, workpiece edge parts, etc., can solve the problems of low welding efficiency, achieve the effects of improving welding efficiency, ensuring weld penetration, and improving welding construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this example, 022Cr17Ni12Mo2 stainless steel is used as composite material, and the stainless steel clad steel plate with low alloy structural steel Q345B as the base material is taken as an example to illustrate the embodiment of the present invention. The thickness of the stainless steel clad layer is 2.5mm, and the thickness of the base layer is 8.0mm. The following steps are used for efficient welding of this stainless steel clad plate.

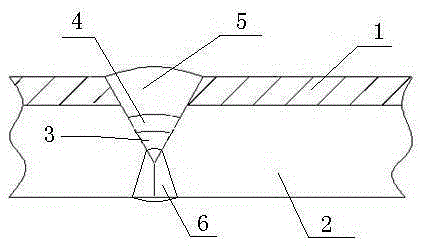

[0028] (a) Process the welding end of the stainless steel clad plate into such figure 1 The Y-shaped groove shown. The groove angle is 60°, and the blunt edge size is 3mm.

[0029] (b) Use an angle grinder to grind the processed groove to remove oil stains and iron oxide scales within 20mm of the groove surface and its vicinity, so as to avoid defects such as pores in the weld during welding. After polishing, follow the figure 1 Groove pairing as shown.

[0030] (c) Use gas shielded welding to weld the base weld and fill the...

Embodiment 2

[0034] In this example, 022Cr17Ni12Mo2 stainless steel is used as composite material, and the stainless steel clad steel plate with low alloy structural steel Q345B as the base material is taken as an example to illustrate the embodiment of the present invention. The thickness of the stainless steel clad layer is 2.5mm, and the thickness of the base layer is 8.0mm. The following steps are used for efficient welding of this stainless steel clad plate.

[0035] (a) Process the welding end of the stainless steel clad plate into such figure 1 For the Y-shaped bevel shown, the bevel angle is 60°, and the blunt edge size is 3mm;

[0036] (b) Use an angle grinder to grind the processed groove to remove oil stains and iron oxide scales within 20mm of the groove surface and its vicinity. After polishing, follow the figure 1 Groove pairing as shown.

[0037] (c) Use gas-shielded welding to weld the base weld, select ER50-6 solid wire with a diameter of 1.2mm, and the shielding gas is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com