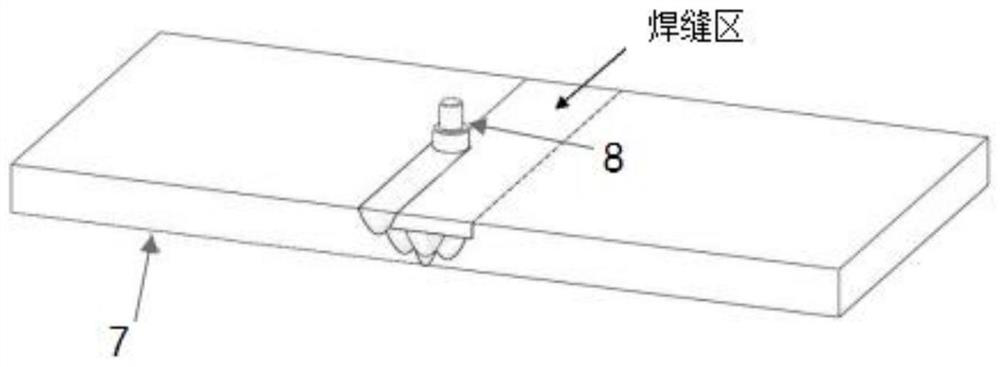

Additive stirring head with small shaft shoulder acting area and high specific surface area stirring needle

A technology with high specific surface area and stirring needle, used in manufacturing tools, metal processing equipment, welding equipment, etc., can solve problems such as inability to meet friction stir welding, reduce adverse effects, reduce groove size, and increase welding. The effect of closing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

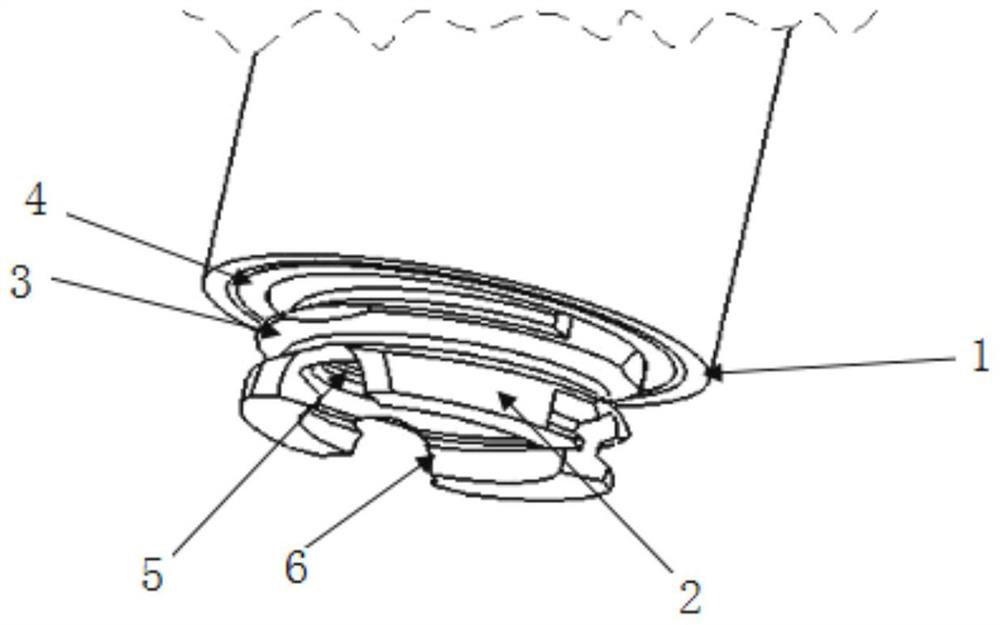

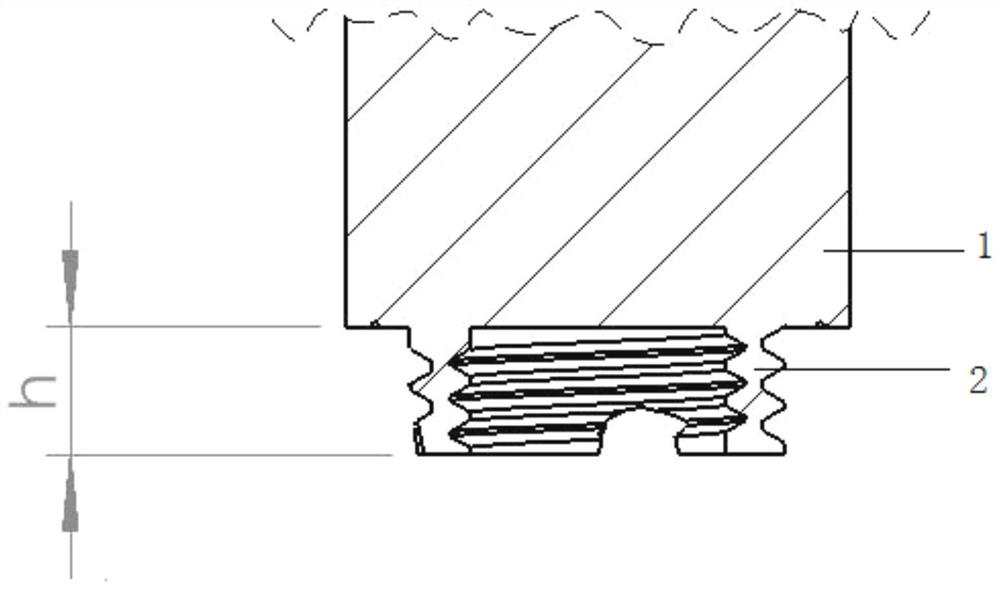

[0036] Embodiment 4, using the stirring head in Embodiment 3 to weld a 5083 aluminum alloy plate with a thickness of 5 mm. The diameter of the shoulder 1 of the stirring head is D=8mm, the diameter of the stirring needle 2 is d=6mm, α=60°, and the length of the stirring needle 2 is 3mm. The rotation speed of the stirring head is 800 rpm, and the travel speed is 30 mm / min. The obtained weld nugget morphology is as follows Figure 5 shown. Depend on Figure 5 It can be seen that the cross-section shape of the obtained nugget area is approximately a regular rectangle, the width is slightly larger than the diameter of the stirring needle 2 , and the height is slightly longer than the length of the stirring needle 2 .

Embodiment 5

[0037] Example 5, using the stirring head in Example 3 to weld a 5mm thick 5083 aluminum alloy plate. Set the diameter of the stirring head shoulder 1 to D=10mm, the diameter of the stirring needle 2 to d=7.5mm, α=60°, and the length of the stirring needle 2 to h=3.8mm. The rotation speed of the stirring head is 800 rpm, and the travel speed is 30 mm / min. The obtained weld nugget morphology is as follows Figure 6 shown. Depend on Figure 6 It can be seen that the cross-section shape of the obtained nugget area is approximately a regular rectangle, the width is slightly larger than the diameter of the stirring needle 2 , and the height is slightly longer than the length of the stirring needle 2 .

Embodiment 6

[0038] Example 6, using the stirring head in Example 3 to weld a 5083 aluminum alloy plate with a thickness of 5 mm. Set the diameter of the stirring head shoulder 1 to D=10mm, the diameter of the stirring needle 2 to d=7.5mm, α=60°, and the length of the stirring needle 2 to h=3.8mm. The rotation speed of the stirring head is 800 rpm, and the travel speed is 60 mm / min. The obtained weld nugget morphology is as follows Figure 7 shown. Depend on Figure 7 It can be seen that the cross-sectional shape of the obtained nugget area is approximately a regular rectangle, the width is slightly larger than the diameter of the stirring pin 2 , and the height is equivalent to the length of the stirring pin 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com