Friction stir and ultrasonic compound welding method of light alloy and resin-based composite

A light alloy, friction stir technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of changing the microstructure of the base metal, affecting the strength of the joint, reducing the mechanical interlocking ability of the joint, etc. Achieve the effect of increasing temperature and material flow, increasing mechanical interlocking ability, and eliminating the effect of mechanical stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

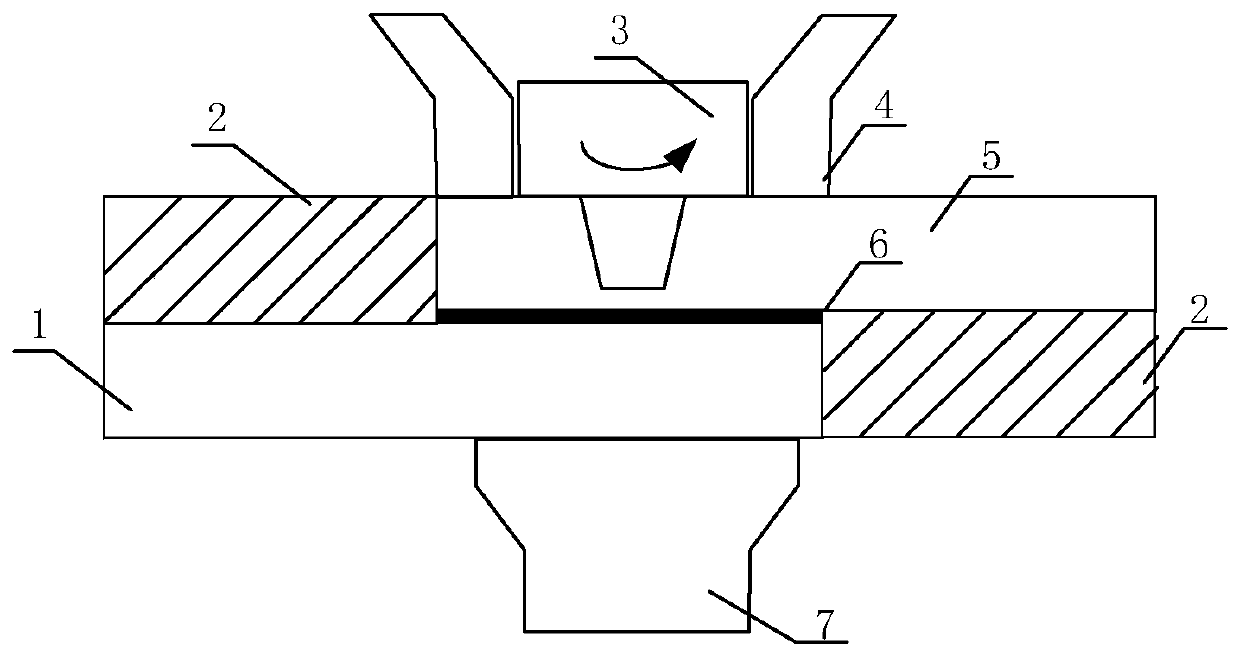

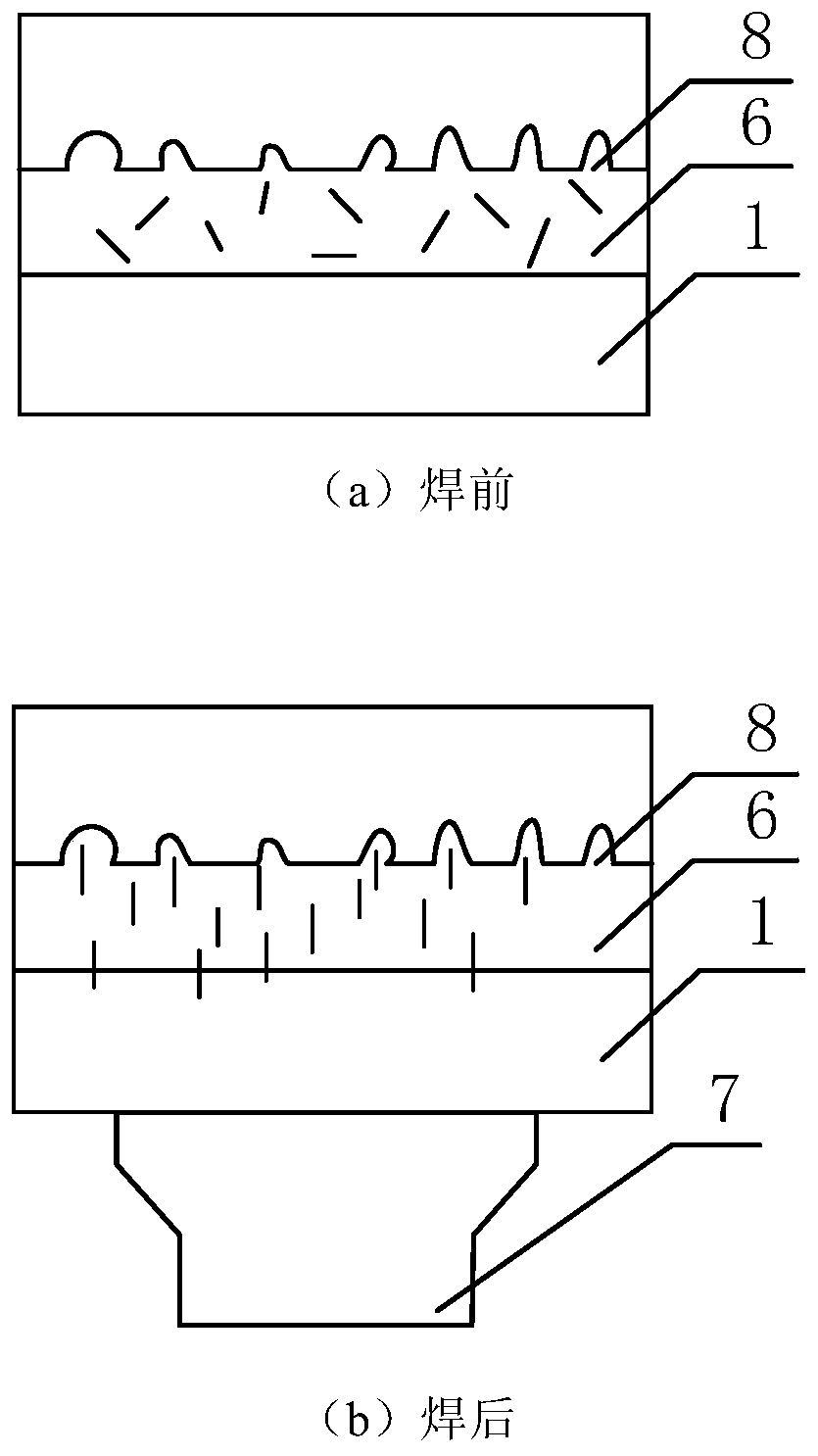

[0034] Such as Figure 1-2 As shown, in this embodiment, the present invention is used to connect the light alloy and the resin-based composite material. The light alloy 5 in this embodiment is 2024 aluminum alloy, and the composite material 1 is a carbon fiber reinforced PEEK composite material, both of which have the same thickness 5mm, the specific steps are as follows:

[0035] Step 1: Anodize the surface of the 2024 aluminum alloy in contact with the carbon fiber reinforced PEEK composite material to form a porous layer structure on the surface;

[0036] Step 2: Place the 2024 aluminum alloy as the upper plate and the carbon fiber reinforced PEEK composite material as the lower plate on the workbench. The carbon nanotube composite material film 6 in the middle layer selects a carbon nanotube reinforced PEEK film with a mass fraction of 1%. 0.2mm, with the aid of block 2, fix it with a clamp; choose a suitable external auxiliary heating stationary shoulder 4, and ensure t...

Embodiment 2

[0042] In this embodiment, the present invention is used to connect the light alloy and the resin-based composite material. The light alloy 5 in this embodiment is 2024 aluminum alloy, and the composite material 1 is a carbon fiber reinforced PEEK composite material, both of which have a thickness of 2 mm. Specific steps are as follows:

[0043]Step 1: Texturize the surface of the TC4 titanium alloy that is in contact with the carbon fiber reinforced PEEK composite material to greatly increase the connection area at the interface;

[0044] Step 2: Place the 2024 aluminum alloy as the upper plate and the carbon fiber reinforced PEEK composite material as the lower plate on the workbench. The carbon nanotube composite material film 6 in the middle layer selects a carbon nanotube reinforced PEEK film with a mass fraction of 1%. 1.5mm, with the aid of block 2, fix it with a clamp; choose a suitable external auxiliary heating stationary shoulder 4, and ensure that the distance betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com