Patents

Literature

51results about How to "Fully fill the gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

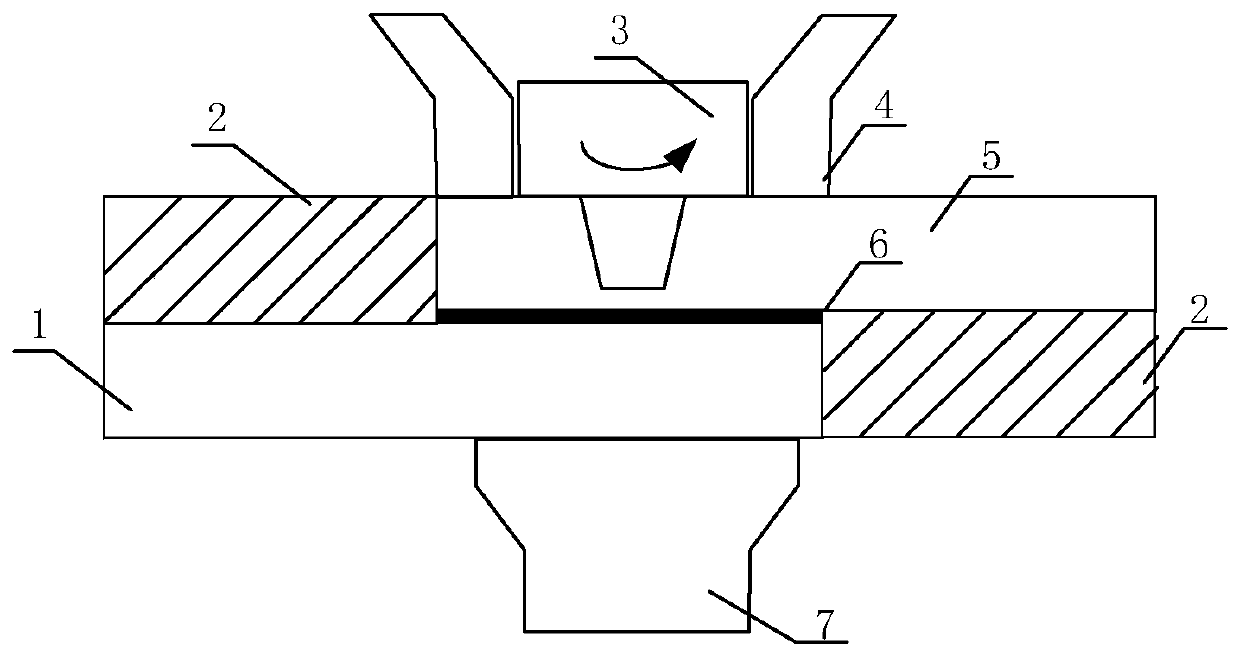

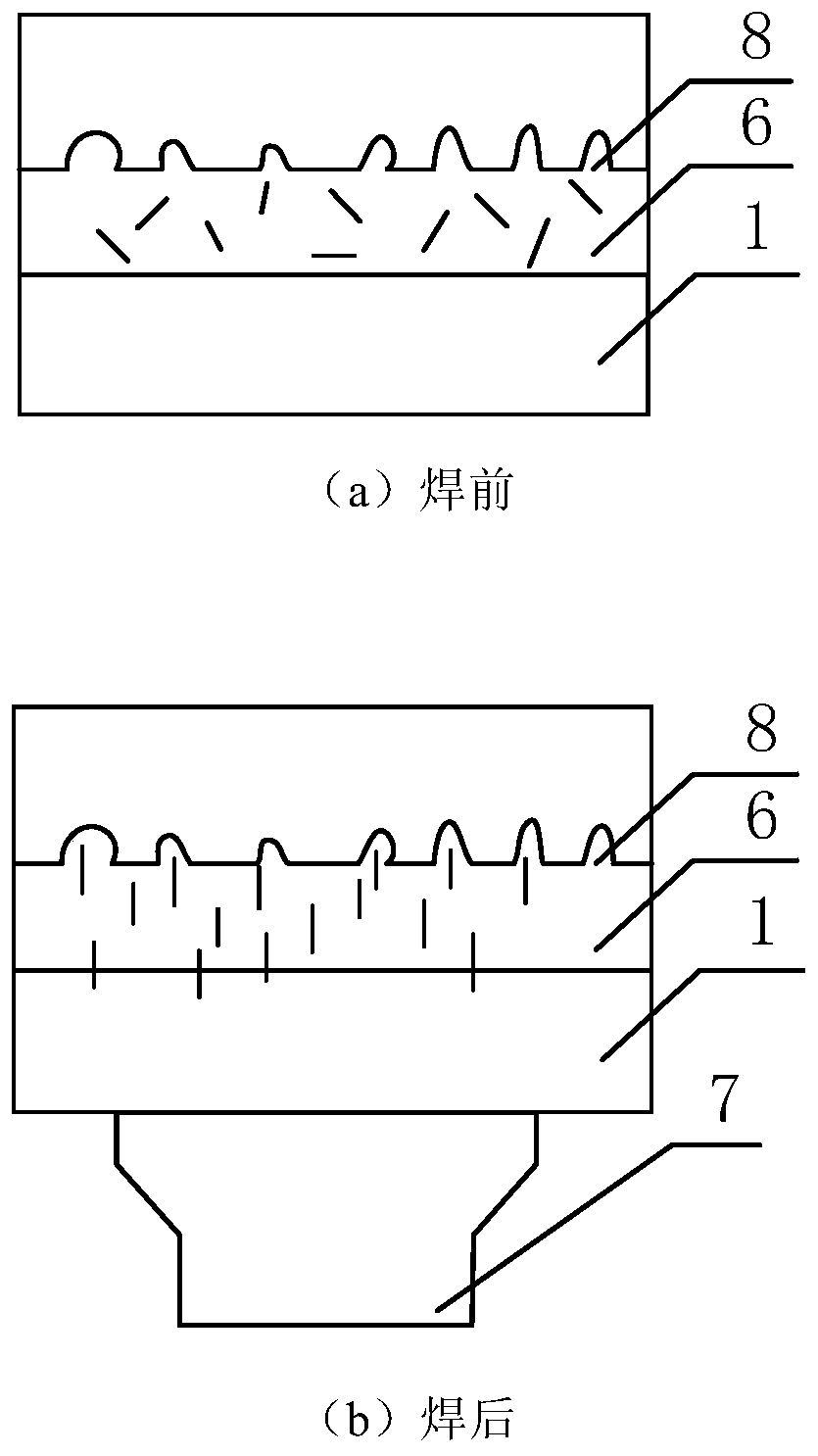

Friction stir and ultrasonic compound welding method of light alloy and resin-based composite

ActiveCN110653479AImprove shear resistanceEasy to moveWelding/soldering/cutting articlesNon-electric welding apparatusInter layerCarbon nanotube

The invention relates to a friction stir and ultrasonic compound welding method of light alloy and a resin-based composite. The method comprises the steps that firstly, the surface, making contact with the resin-based composite, in the light alloy is subjected to mechanical processing or electrochemical processing; secondly the light alloy serves as an upper plate, the resin-based composite servesa lower plate, a carbon nano tube composite thin film serves as a middle layer, and the upper plate, the lower plate and the middle layer are placed on a worktable and fixed; thirdly, an ultrasonic system is connected; fourthly, a stirring head is rotated and carries out downward pricking; fifthly, the ultrasonic system is started; and sixthly, after the shaft shoulder of the stirring head and the upper plate are in contact, the stirring head stays for 3 to 120 s, and then, the stirring head moves in the welding seam direction at the speed of 5 to 1000 mm / min until welding is finished. The welding seam width can be increased, the microcosmic mechanical interlocking capacity in the joint is increased, and the joint anti-shearing and stretching property can be improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

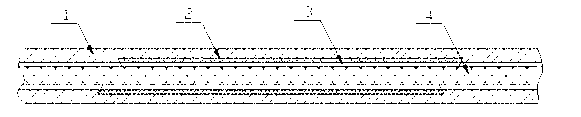

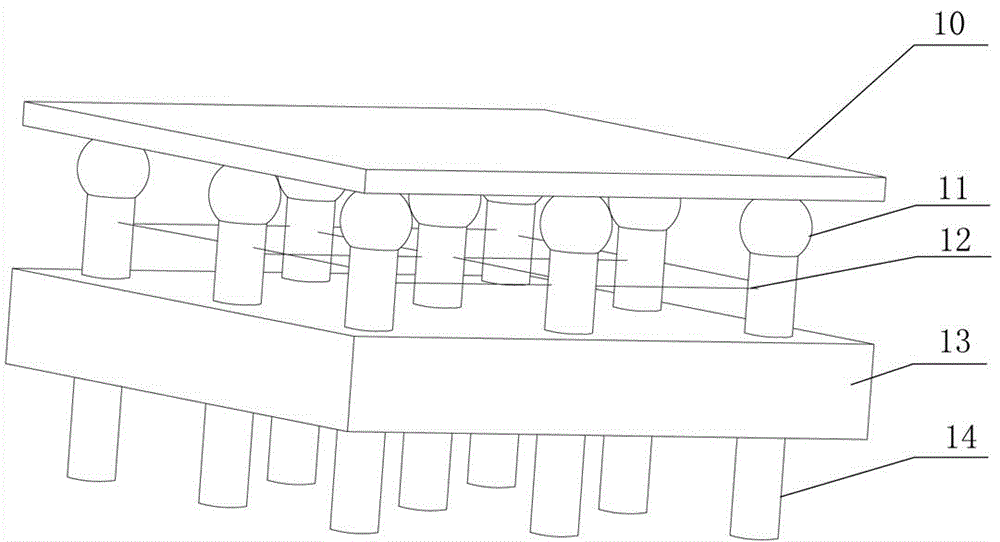

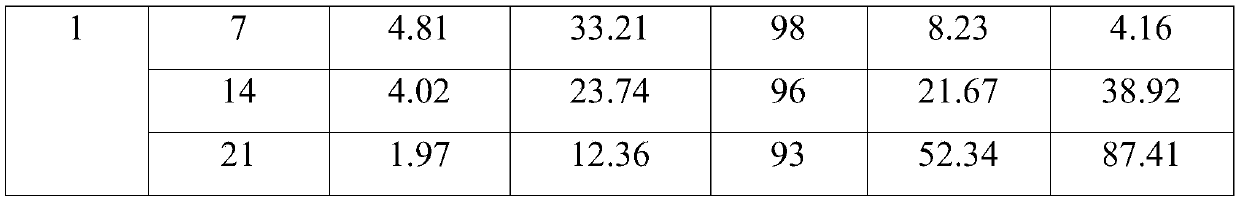

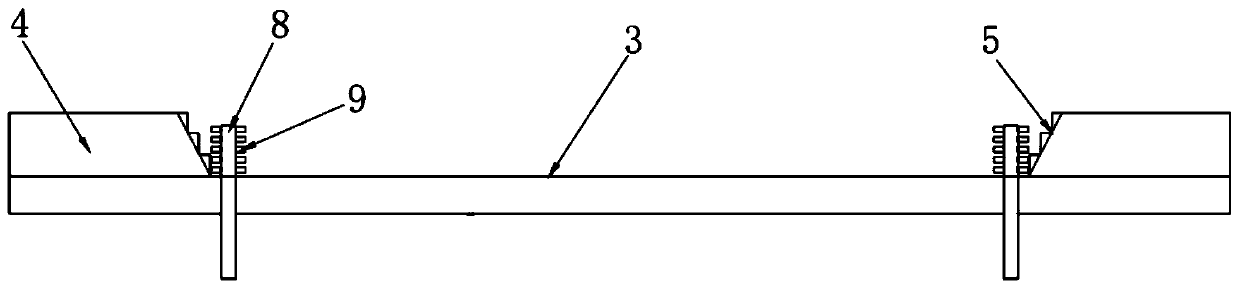

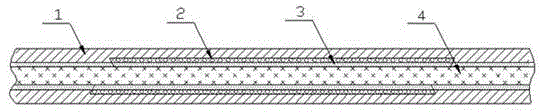

Straight conveyor belt finger-model connector and preparation method thereof

ActiveCN103072786AIncreased warp strengthHigh warp strengthConveyorsBeltsAdhesive cementStructural engineering

The invention belongs to the technical field of a rubber conveyor belt product, and particularly relates to a straight conveyor belt finger-model connector and a preparation method thereof. The straight conveyor belt finger-model connector comprises a straight finger-model skeleton structure, wherein the straight finger-model skeleton structure comprises a straight canvas layer; a rubberizing layer is arranged on the surface of the straight finger-model skeleton structure; a textile layer playing a reinforcement effect is arranged on the rubberizing layer; and a coverage rubber layer is arranged on the textile layer. The preparation method of the straight conveyor belt finger-model connector comprises the following steps of (1) stripping coverage adhesive; (2) removing residual adhesive; (3) cutting a finger model; (4) coating adhesive cement; (5) splicing the finger model; (6) forming a finger-model connector; and (7) vulcanizing the finger-model connector. Due to the adoption of the straight conveyor belt finger-model connector, the strength of the connector is improved; and the preparation method is simple and easy to operate.

Owner:YANKUANG GRP CO LTD +1

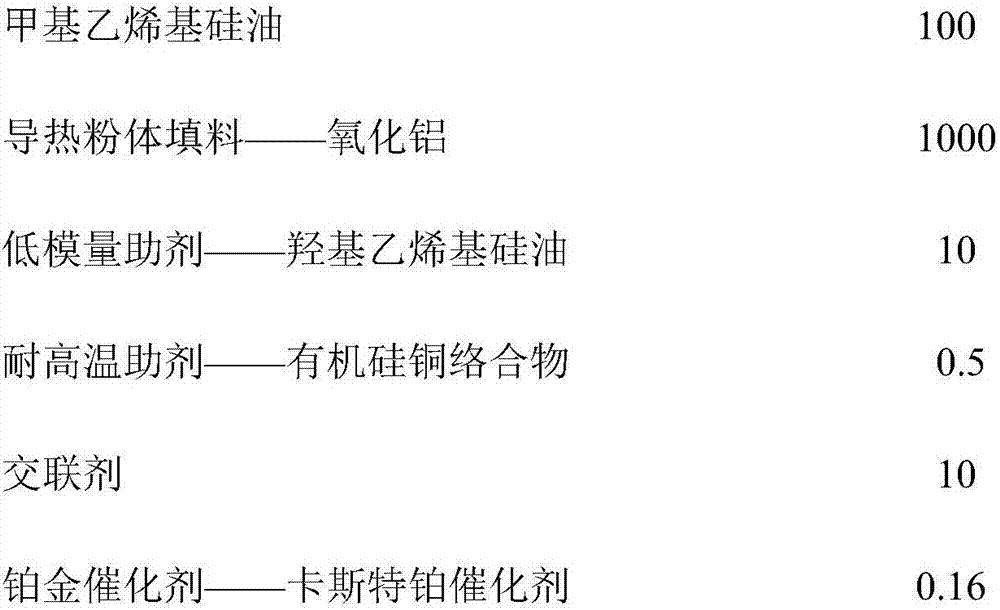

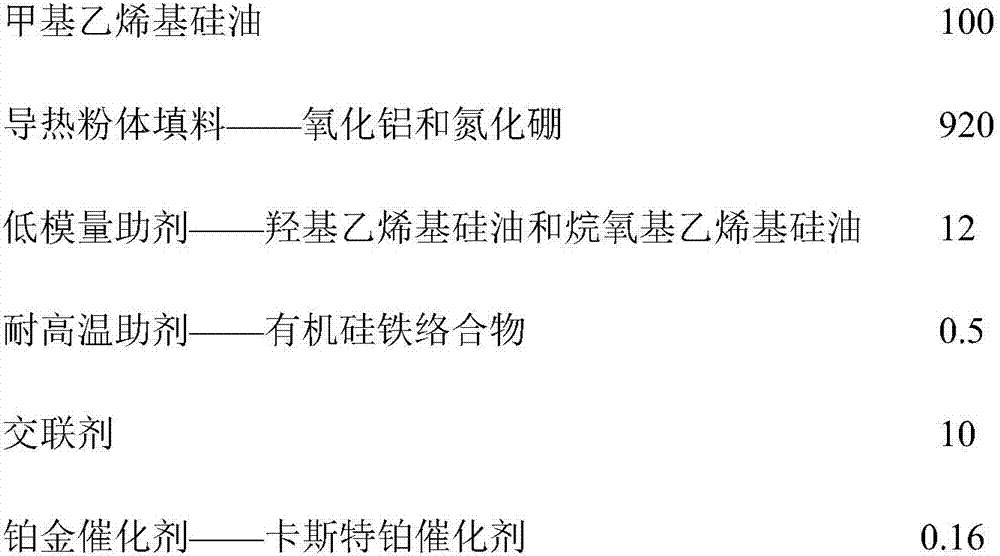

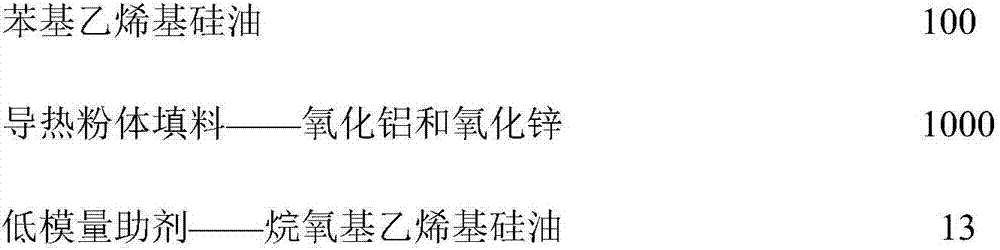

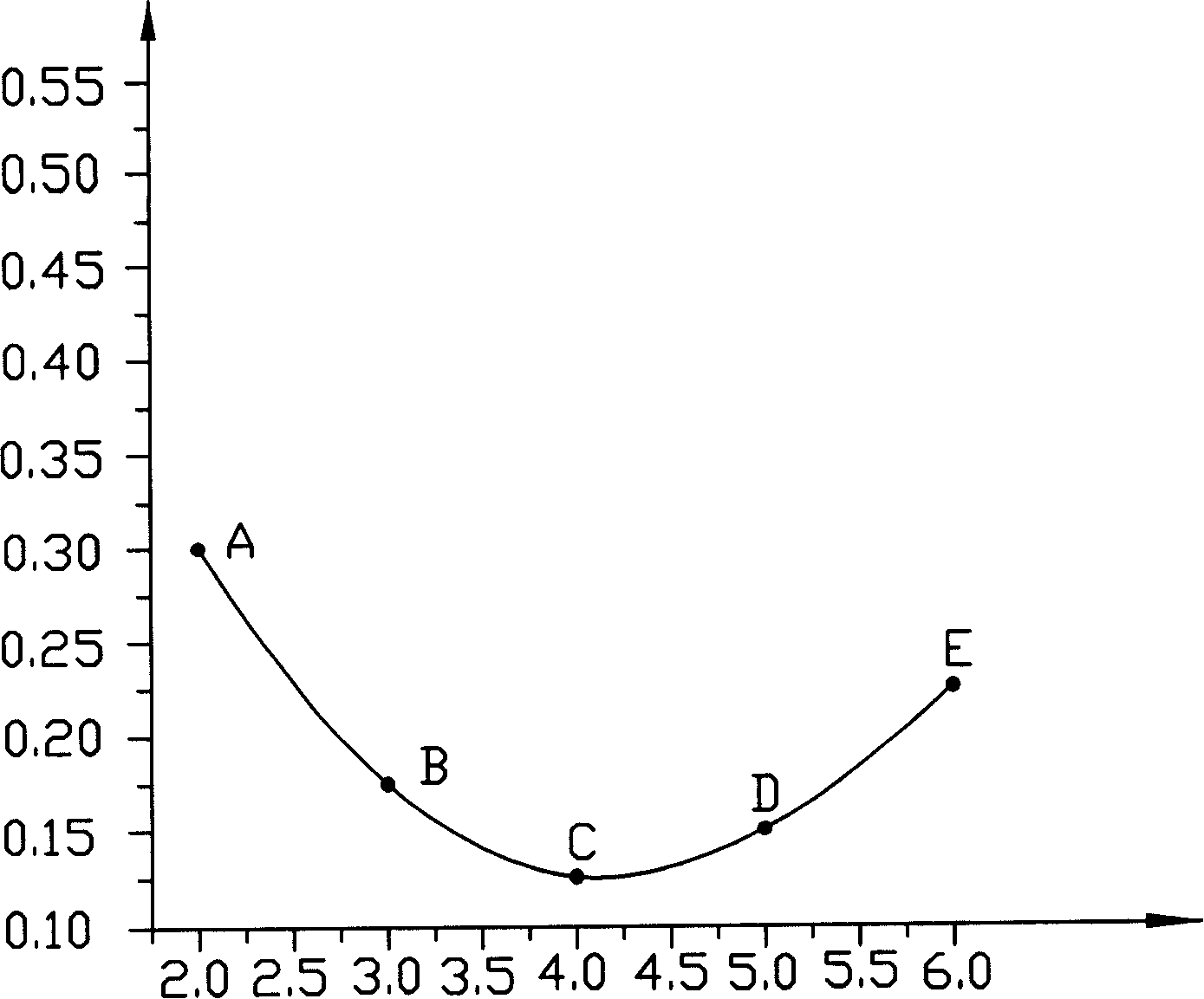

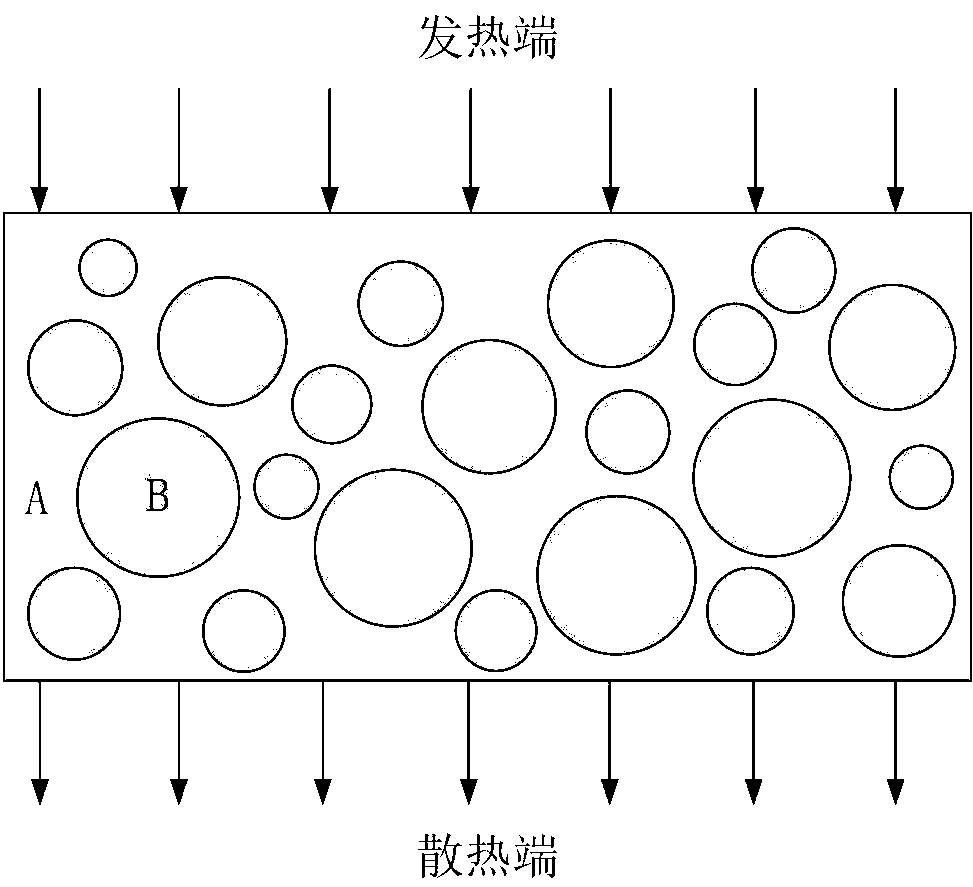

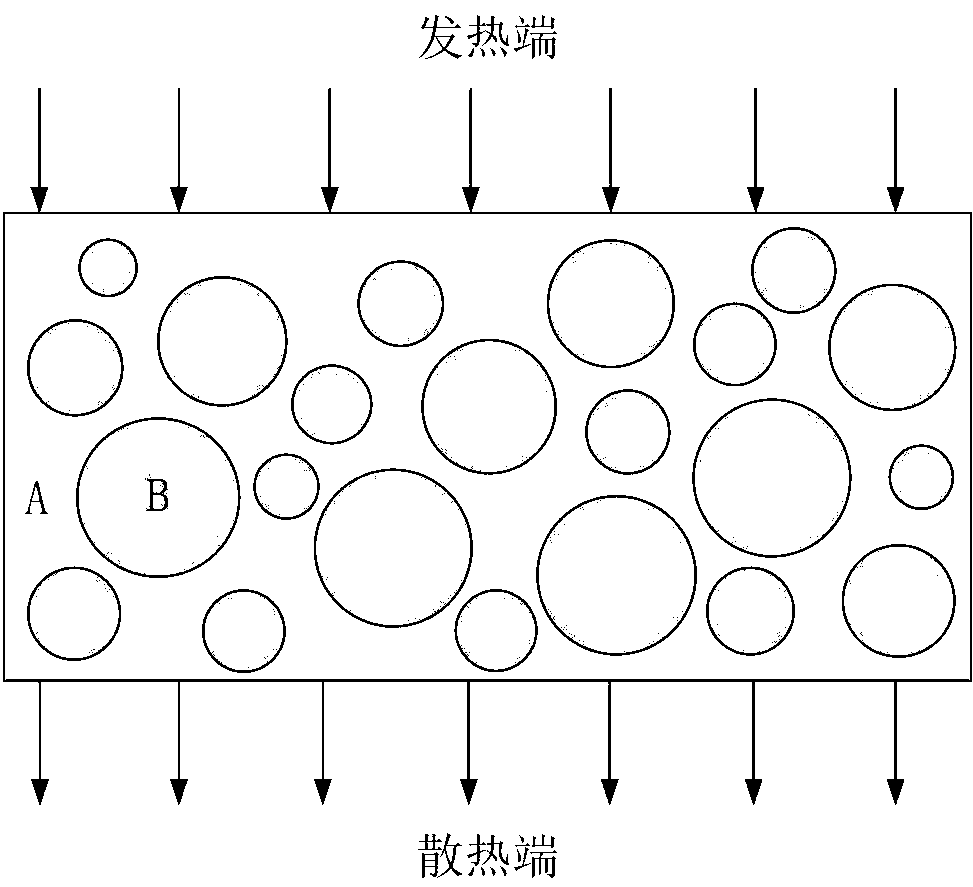

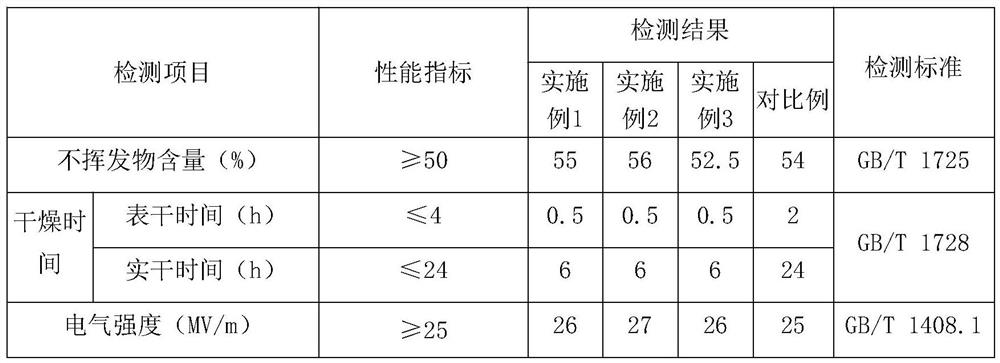

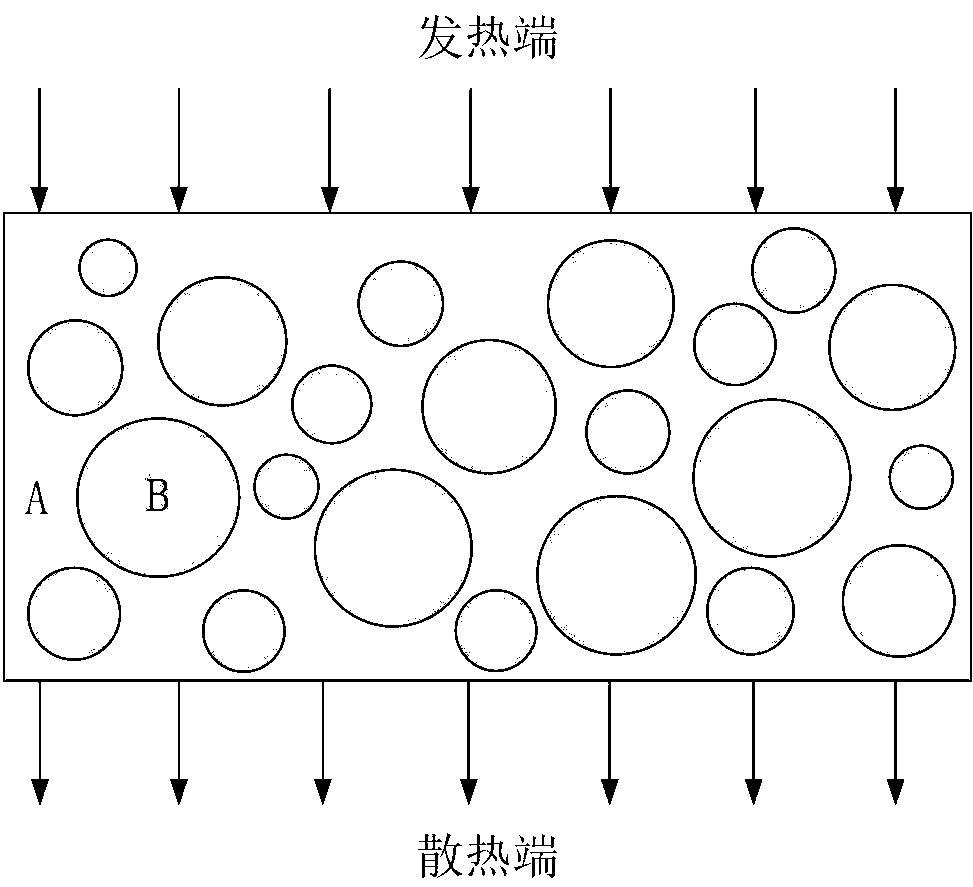

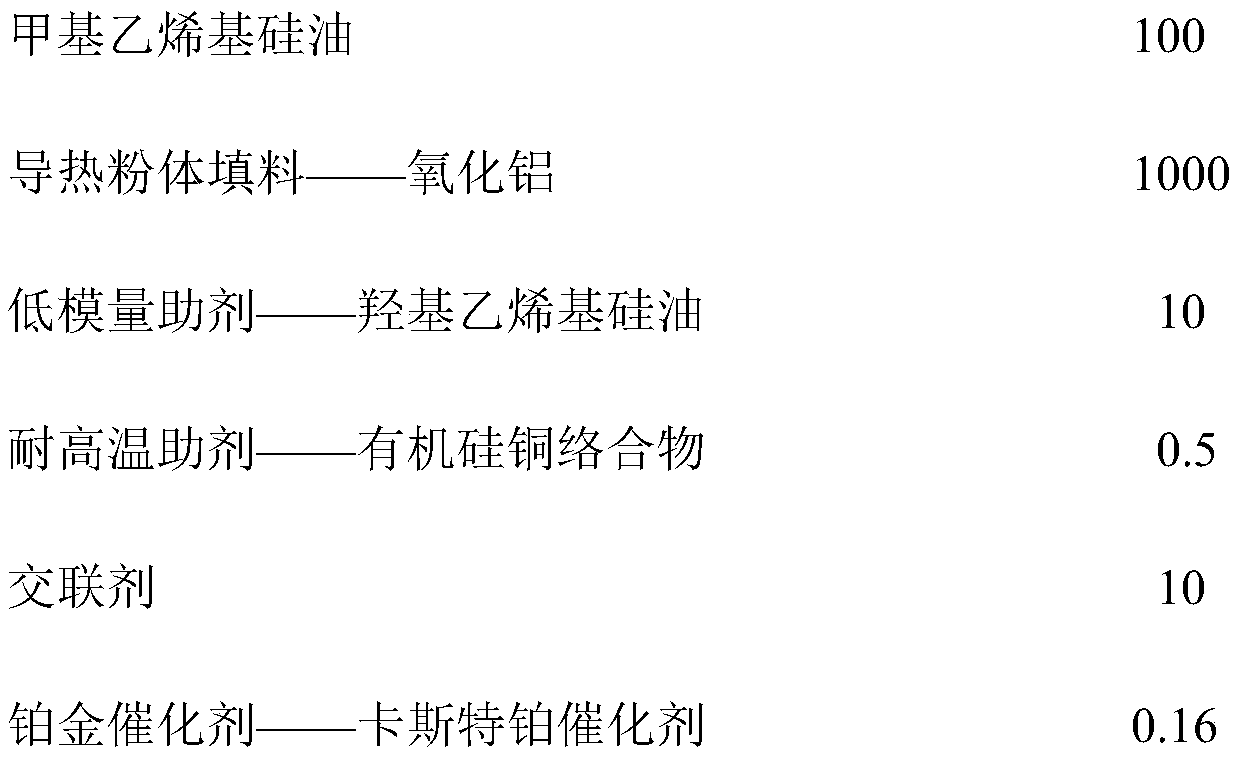

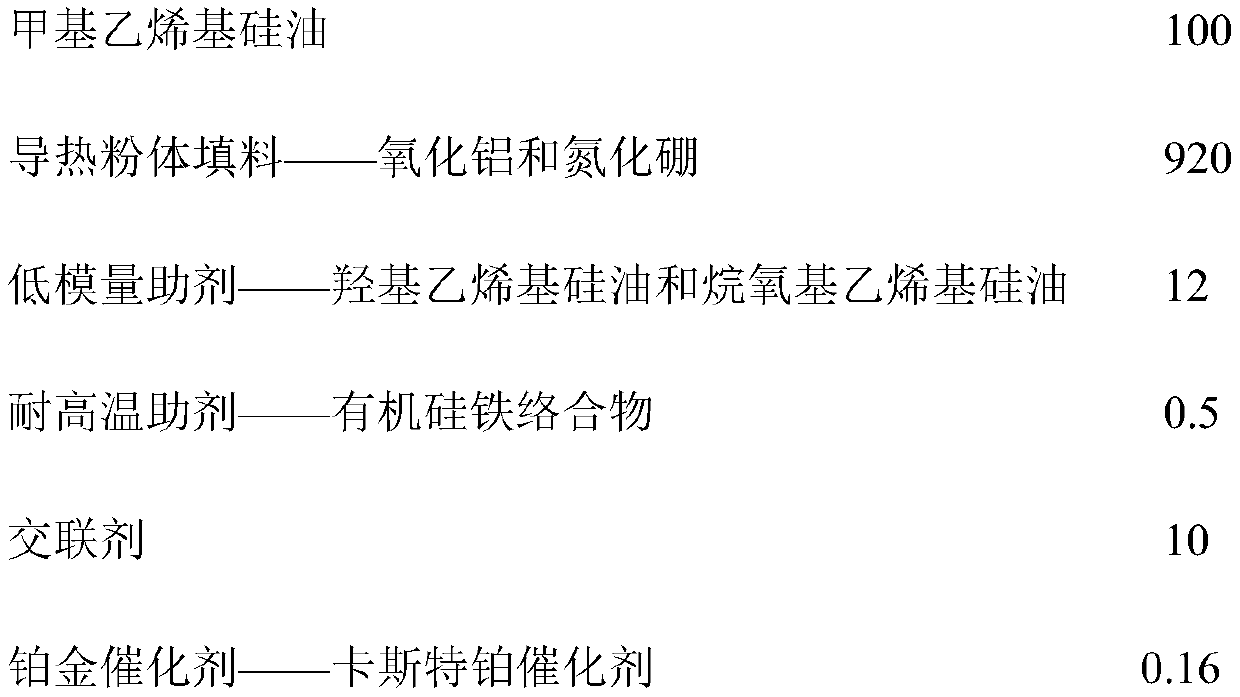

High temperature resistant and low-modulus heat conducting organic silicon material and preparation method thereof

ActiveCN107141815AChange surface polarityImprove compatibilityHeat-exchange elementsAdhesiveHeat conducting

The invention provides a high temperature resistant and low-modulus heat conducting organic silicon material which is prepared from the following raw materials: silicone oil, heat conducting powder filler, a low-modulus auxiliary, a high temperature resistant auxiliary, a crosslinking agent and a platinum catalyst, wherein the mass ratio of the silicone oil to the heat conducting powder filler is (90-110):(900-1,100); the mass ratio of the heat conducting powder filler to the low-modulus auxiliary is 100:(0.5-2); the mass ratio of the silicone oil, the high temperature resistant auxiliary, the crosslinking agent and the platinum catalyst is 100:(0.1-1):(5-15):(0.1-0.2) in turn. The invention belongs to the technical field of organic silicone. The heat conducting organic silicon material provided by the invention has the advantages of high long-term stability of heat dissipation in a high-temperature condition, low modulus, easy gap fitting, low thermal resistance and no oil leakage or volatilization; automatic adhesive dispensing construction can be realized; a better interface heat conducting material is provided between a heating component of an electronic appliance and a heat dissipation device or apparatus.

Owner:广东皓明有机硅材料有限公司

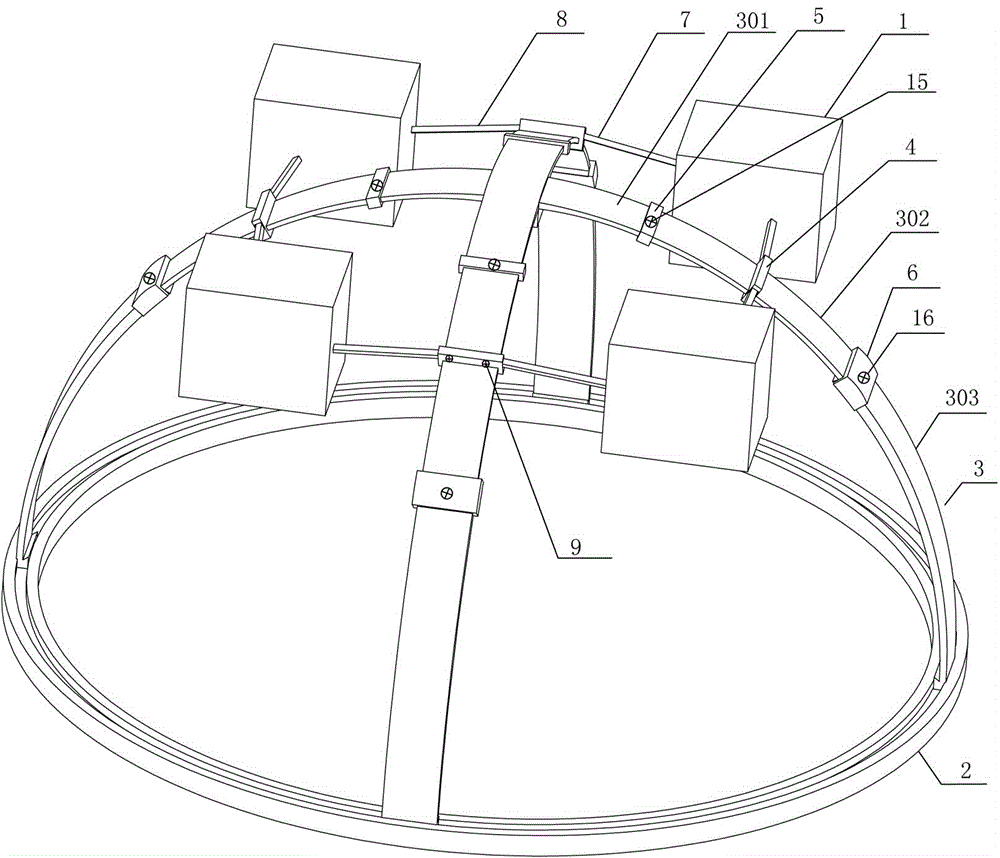

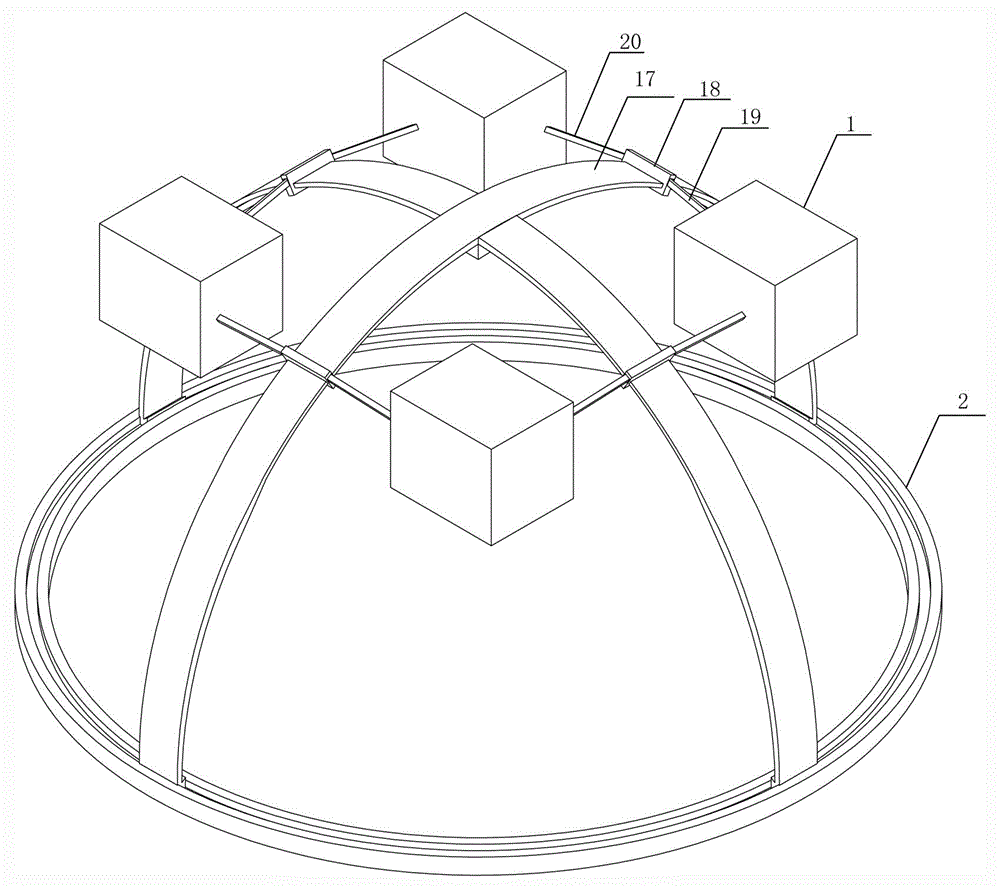

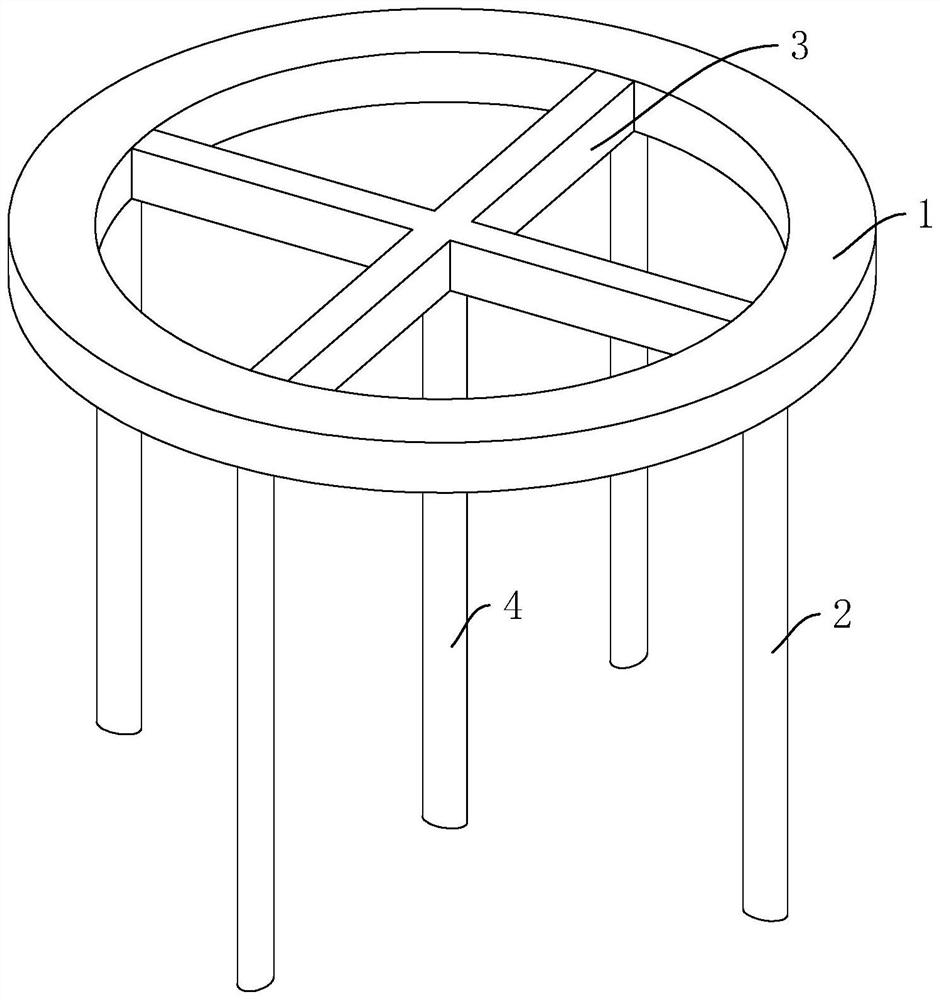

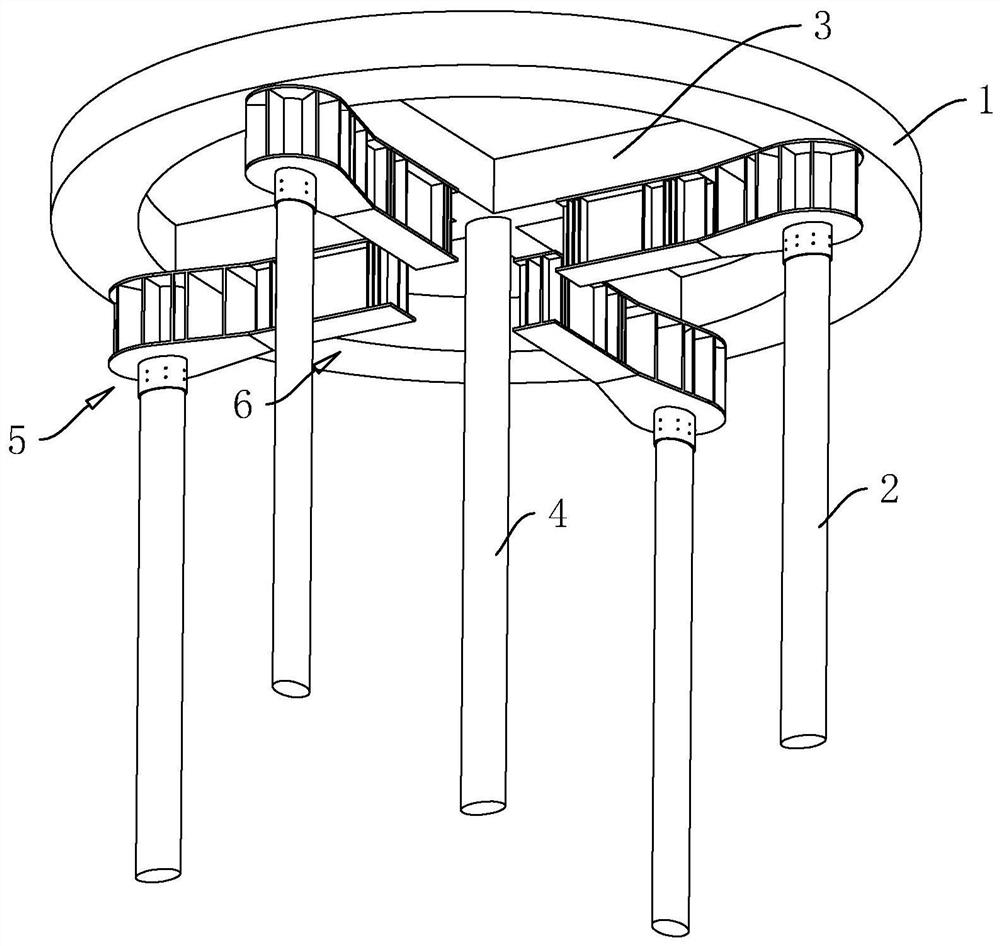

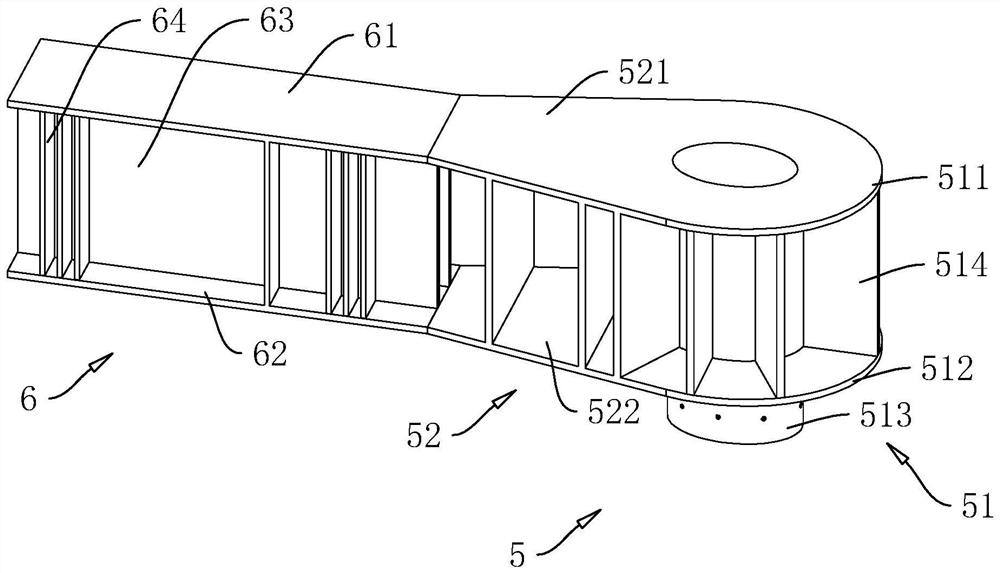

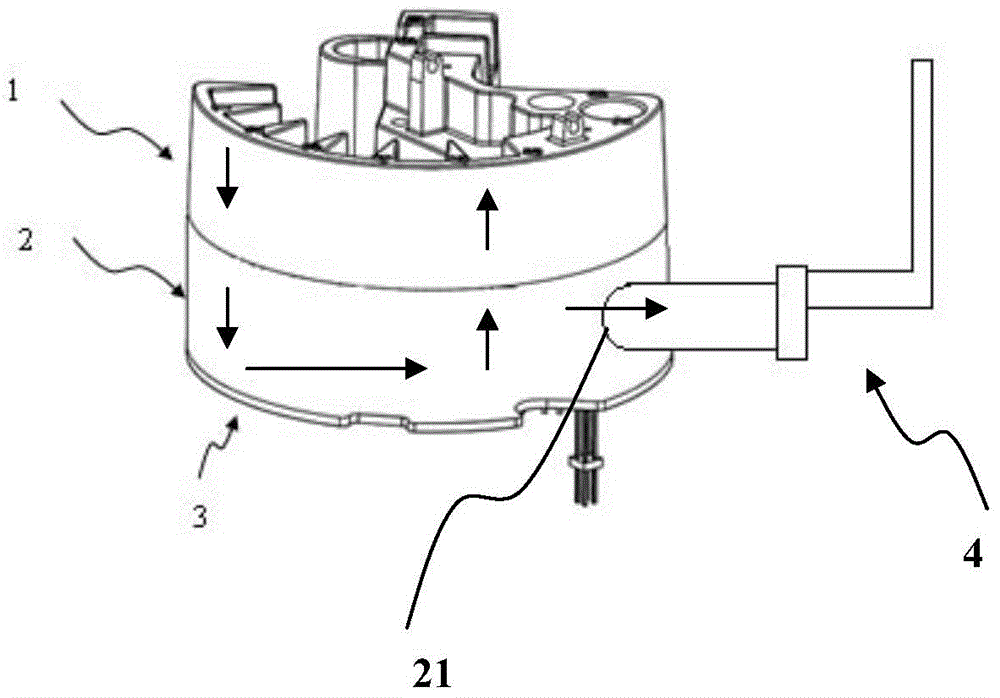

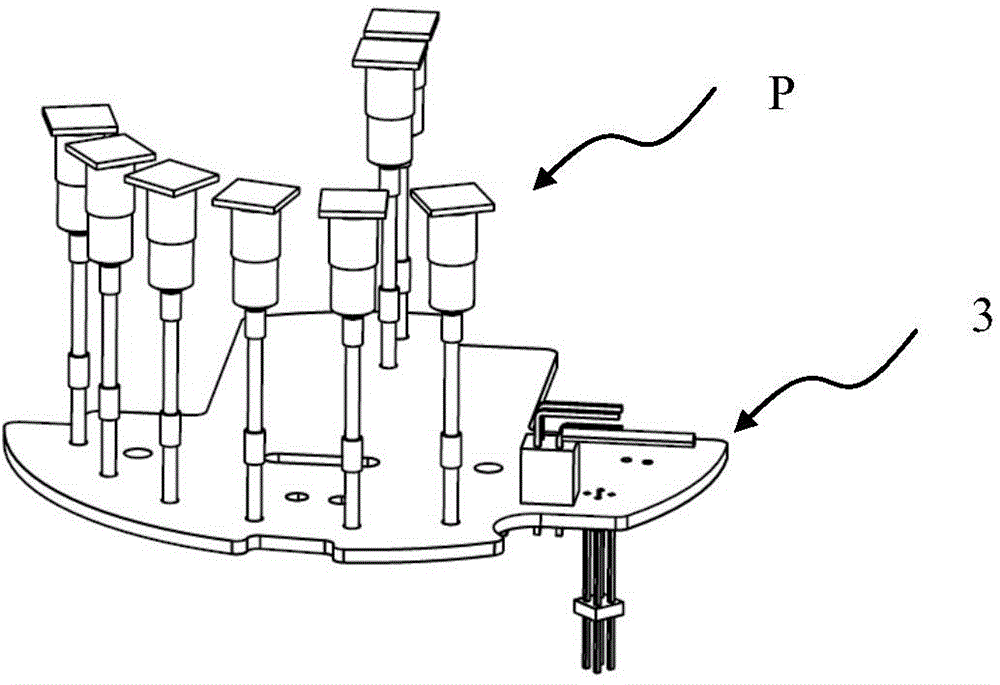

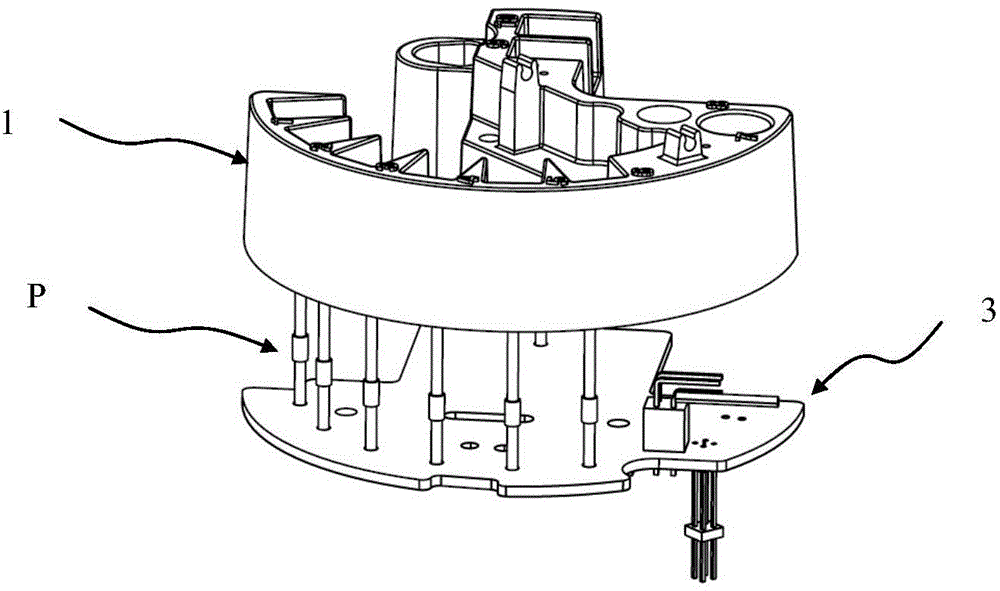

EEG collection device

ActiveCN104783789AEasy to fixIncrease frictionDiagnostic recording/measuringSensorsFixed frameEngineering

The invention provides an EEG collection device which comprises an EEG collection electrode and an electrode fixing frame used for fixing the EEG collection electrode. The EEG collection electrode comprises a fixing plate, a thrusting needle set, a squeezing plate and a power source. The electrode fixing frame comprises a head loop and four fixing arc plates. Each fixing arc plate is provided with an elastic installation plate. The elastic installation plates are perpendicular to the corresponding fixing arc plates and extend downwards and obliquely. The outer ends of the elastic installation plates of the adjacent fixing arc plates are fixed to the same fixing plate. According to the EEG collection device, conductive needles are pressed on the scalp by penetrating through hair under the elastic effect of the elastic installation plates, and therefore the poor contact phenomenon is avoided. Through the cooperative effect of the EEG collection electrode and the electrode fixing frame, EEG can be stably and accurately detected, the requirement for a detector is greatly lowered, and the detector even can freely move.

Owner:HENAN RYAN MEDICAL INSTR

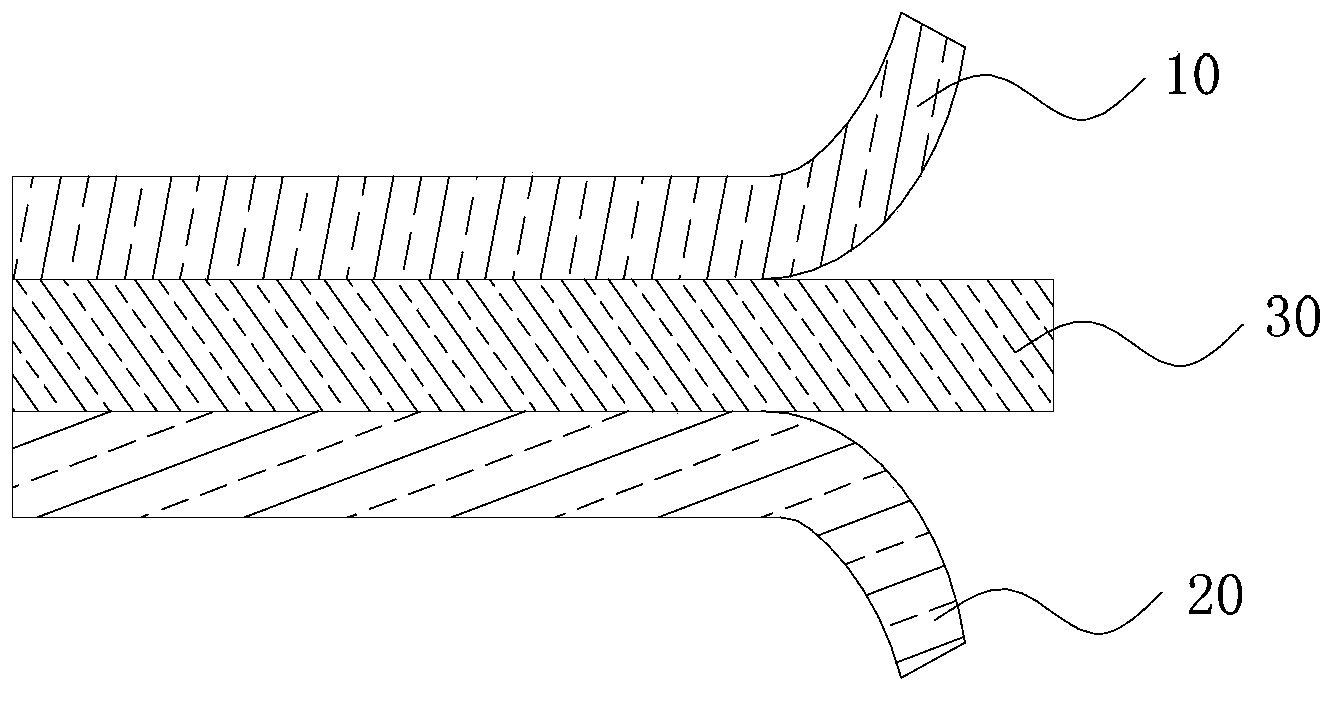

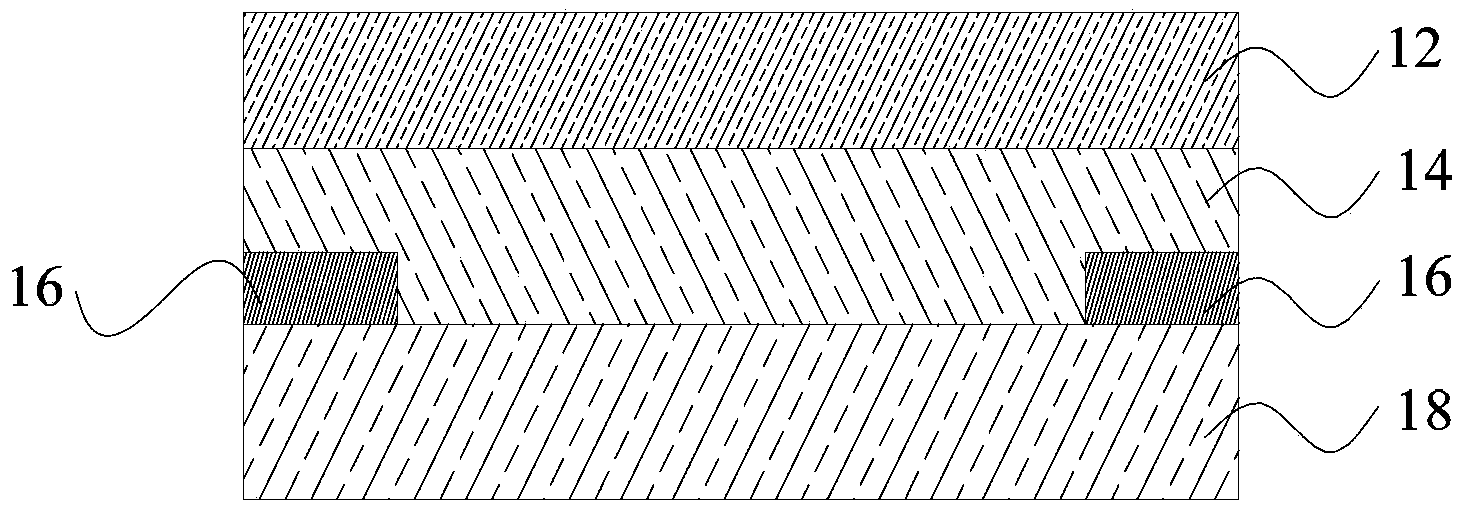

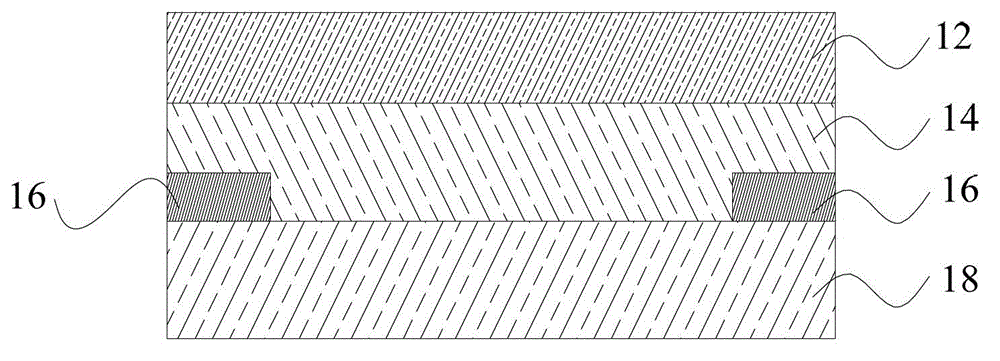

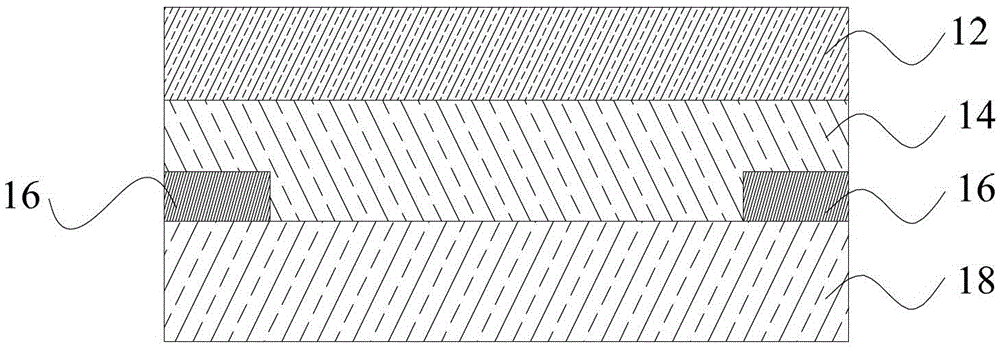

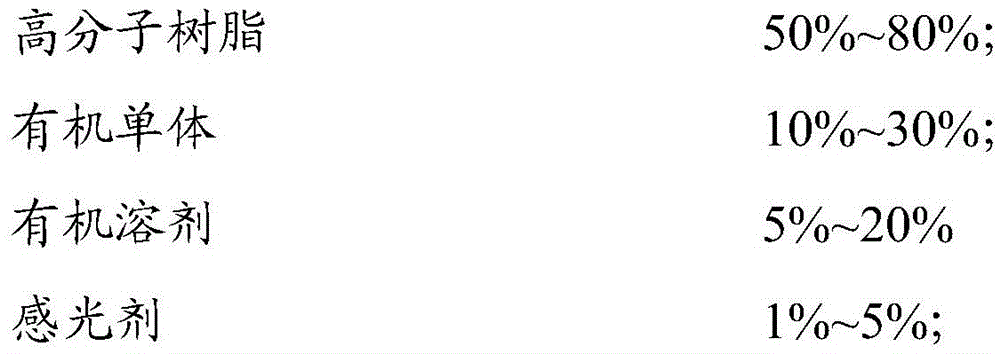

Adhesive and application thereof as well as adhesive film component and application thereof

InactiveCN103360958ASolve the bubblesLiquidFilm/foil adhesivesOrganic non-macromolecular adhesiveChemistryAdhesive

The invention discloses an adhesive which comprises the following ingredients in percentage by weight: 50-80% of a high-molecule resin, 10-30% of an organic monomer, 5-20% of an organic solvent and 1-5% of a photosensitizer. The adhesive has certain mobility after being heated and softened, gaps among adhered articles can be sufficiently filled, through vacuum defoaming treatment, bubbles among the adhesive and the adhered articles are completely eliminated, furthermore through ultraviolet radiation, a transparent optical cement can be hardened, the bonding property of the adhesive is sufficiently realized, and gas molecules inside the hardened optical cement are unlikely aggregated to form visible aggregated bubbles, so that the problem of bubbles of an adhered component is effectively solved. In addition, the invention further provides an application of the adhesive, an adhesive film component and an application of the adhesive film component.

Owner:NANCHANG O FILM TECH CO LTD +2

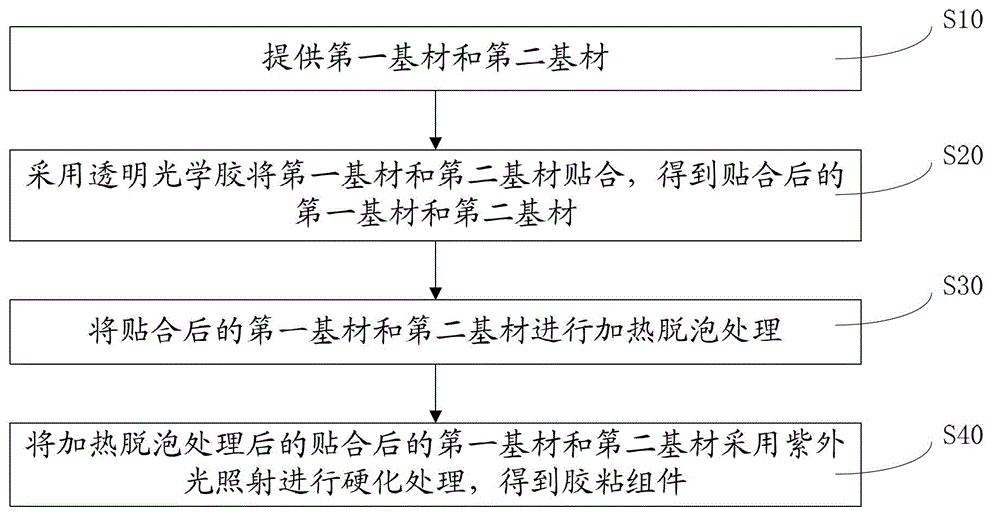

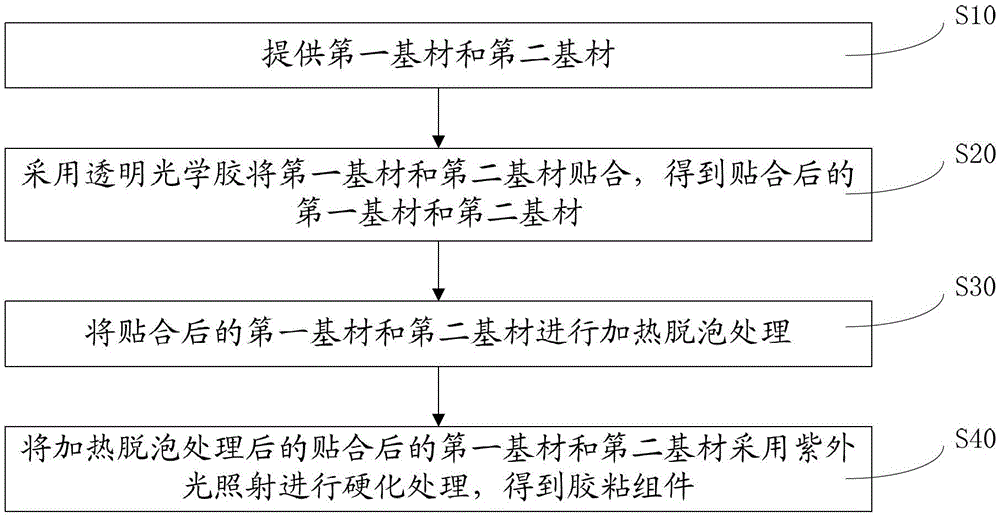

Method for preparing gluing component

ActiveCN103333620ASolve the bubblesNot easy to gatherAdhesive processes with adhesive heatingOrganic non-macromolecular adhesiveUltraviolet lightsIrradiation

A method for preparing a gluing component comprises the following steps: providing a first base material and a second base material; adopting transparent optical cement to glue the first base material and the second base material; heating and debubbling the first base material and the second base material which are glued; and adopting ultraviolet light to irradiate and harden the first base material and the second base material which are heated, debubbled and glued, and obtaining the gluing component. According to the method for preparing the gluing component, the transparent optical cement is softened and has a certain fluidity through the heating and debubbling, so that a gap between glued objects can be sufficiently filled; meanwhile, bubbles between the transparent optical cement and the glued objects are removed completely through the vacuum debubbling treatment; and then the transparent optical cement is hardened through ultraviolet light irradiation, so that a gluing property is sufficiently achieved, gas molecules in the hardened optical cement has low possibility of accumulation, then visually visible accumulated bubbles are not formed, and accordingly, the problem of bubbles of the gluing component can be effectively solved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Thermolysis cream, and prepartion method

InactiveCN1916105ASimple preparation processSmall particle sizeSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceHeat conducting

This invention relates to a method for preparing heat-dissipation grease, which comprises a polymer matrix and a heat-conducting filler at a weight ratio of (3-7): 1. The thermal conductivity coefficients of the polymer matrix and the heat-conducting filler are 0.1-0.2 W / mK and 20-1000 W / mK, respectively. The method comprises: providing a polymer matrix and a heating-conducting filler, and mixing at a weight ratio of (3-7): 1 to obtain the heat-dissipation grease.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

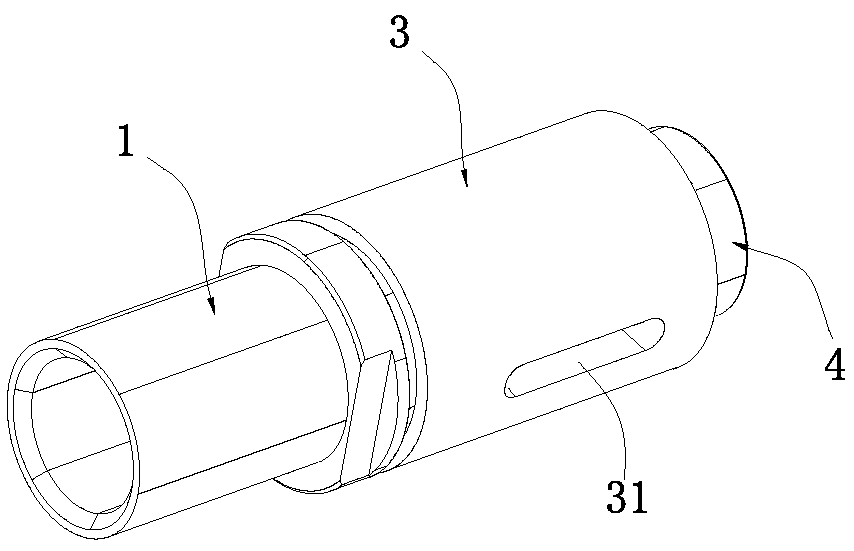

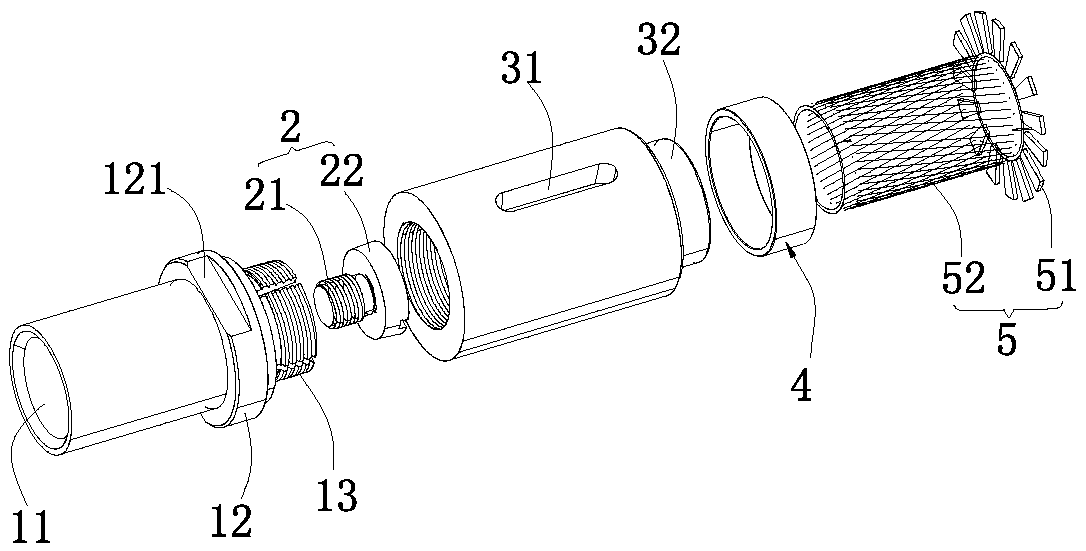

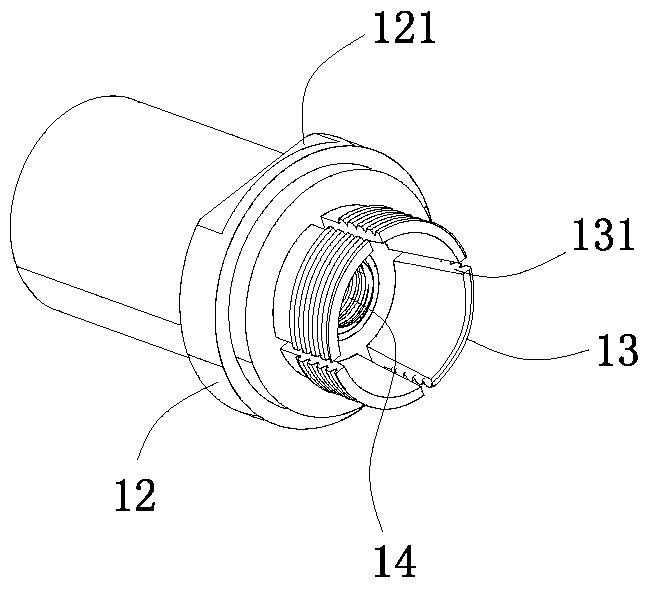

Quick-change type electric automobile charging base female terminal

PendingCN108879163AImprove wear resistanceFully fill the gapVehicle connectorsCouplings bases/casesEngineeringElectrical and Electronics engineering

The invention discloses a quick-change type electric automobile charging base female terminal. The quick-change type electric automobile charging base female terminal comprises a terminal crimping part, a rotation stopping part, a female end sleeve shell, a fixed sleeve and a contact spring piece; a wire core is inserted into a wire pressing hole, and then by extruding the terminal crimping part,the wire pressing hole is deformed to tightly clamp the wire core; the assembly mode is simple and rapid, and the connection is firm. When a male terminal is plugged, the contact spring piece is reasonably arranged, so that the male terminal can be guided to be inserted into the female end sleeve shell quickly and accurately; in addition, the contact spring piece is soft, so that the gap between the male terminal and the female end sleeve shell can be fully filled, the male terminal can be tightly pressed, and the tightness of the matching between the male terminal and the female end sleeve shell can be effectively improved; meanwhile, the abrasion-resistant effect of the contact spring piece is high, so that the number of times of plugging can be effectively increased, and the service life is prolonged; and in replacement, only the male terminal needs to be pulled out, and then the rotation stopping part is unscrewed, and at the moment, the terminal crimping part can be screwed and extruded, so that a sleeve connecting cylinder and the female end sleeve shell 3 are separated from each other, and the whole replacement process is convenient and rapid.

Owner:GUANGZHOU ZHICHONG AMPEREX TECH CO LTD

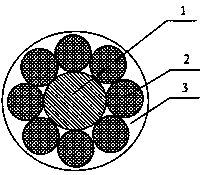

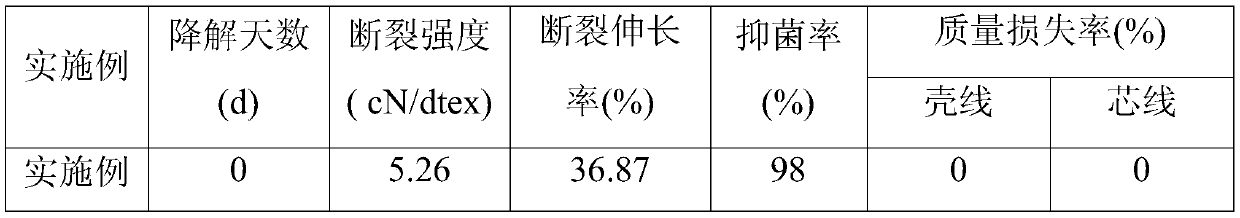

Strile absorbent sutures for gynaecology and obstetrics and preparation method of strile absorbent sutures

ActiveCN110665045AHigh strengthGood biocompatibilitySuture equipmentsPharmaceutical delivery mechanismSilk suturesAbsorbable suture

The invention discloses strile absorbent sutures for gynaecology and obstetrics and a preparation method of the strile absorbent sutures. The strile absorbent sutures for the gynaecology and obstetrics are prepared by taking chitosan silk threads as core threads, taking modified polylactic acid silk threads as shell threads, after stranding braiding, immersing the chitosan silk threads and the modified polylactic acid silk threads into coating liquid containing calcium stearate and polylactic acid and drying the liquid. Through the preparation method, the mechanical properties and hydrophilicproperties of the polylactic acid can be improved, and the prepared sutures have high strength and good biocompatibility; chitosan in the inner part of the sutures degrades slowly, while long-term antibacterial action is achieved, the sutures can further gradually form a hollow structure, thus ingrowth and healing of tissue is promoted, and the effect of accelerating the healing of the tissue is achieved; and the overall preparation process is simple and convenient to control, and needs of practical production and application can be met.

Owner:刘金娥 +2

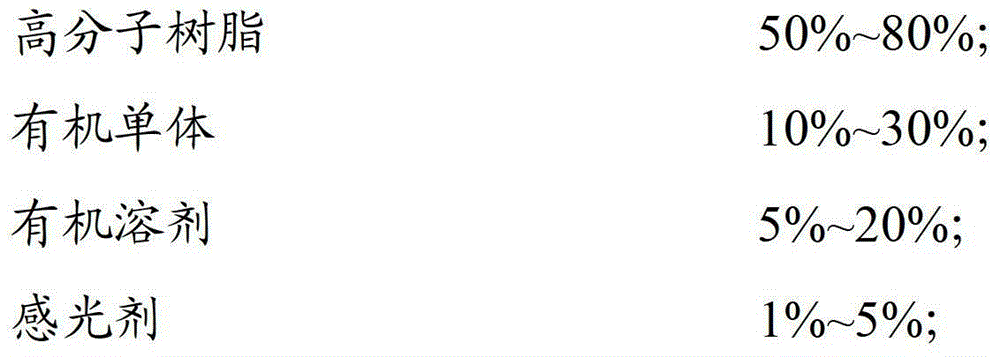

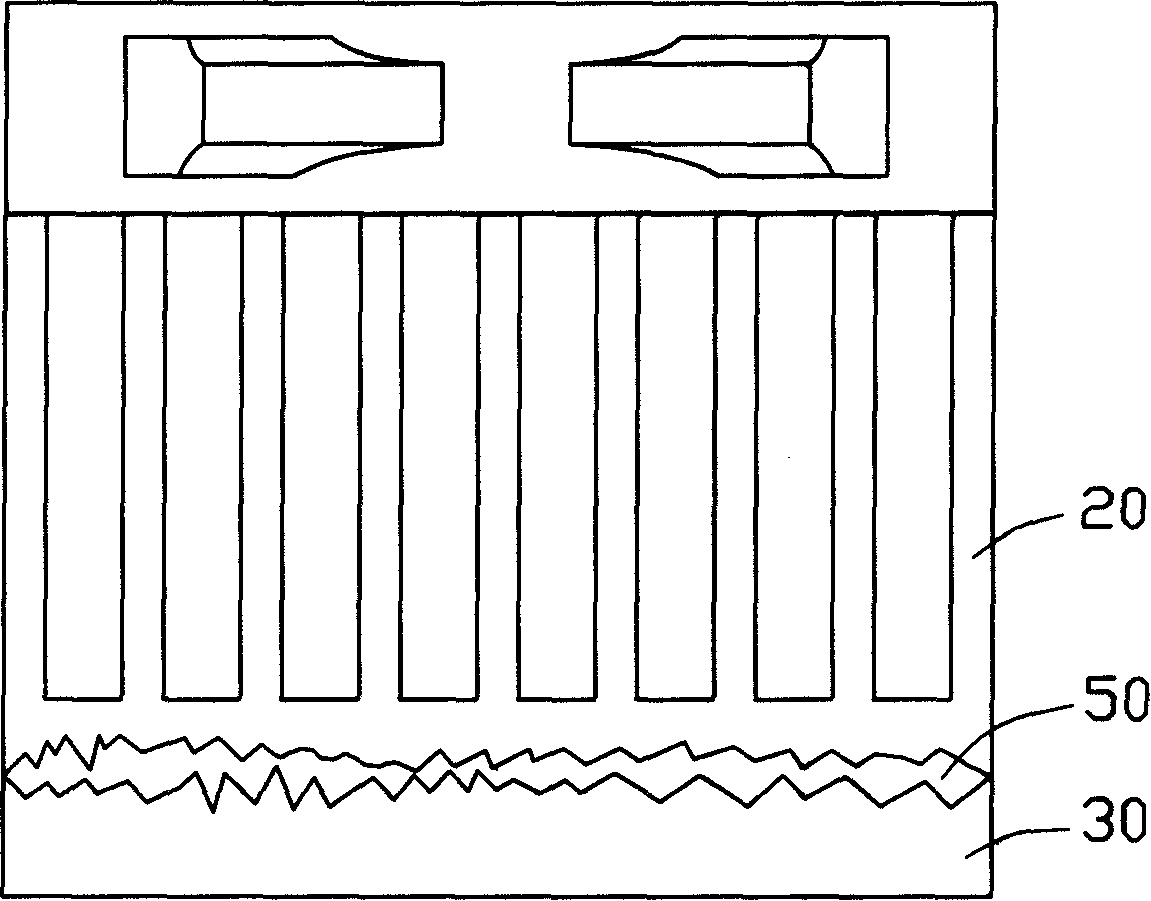

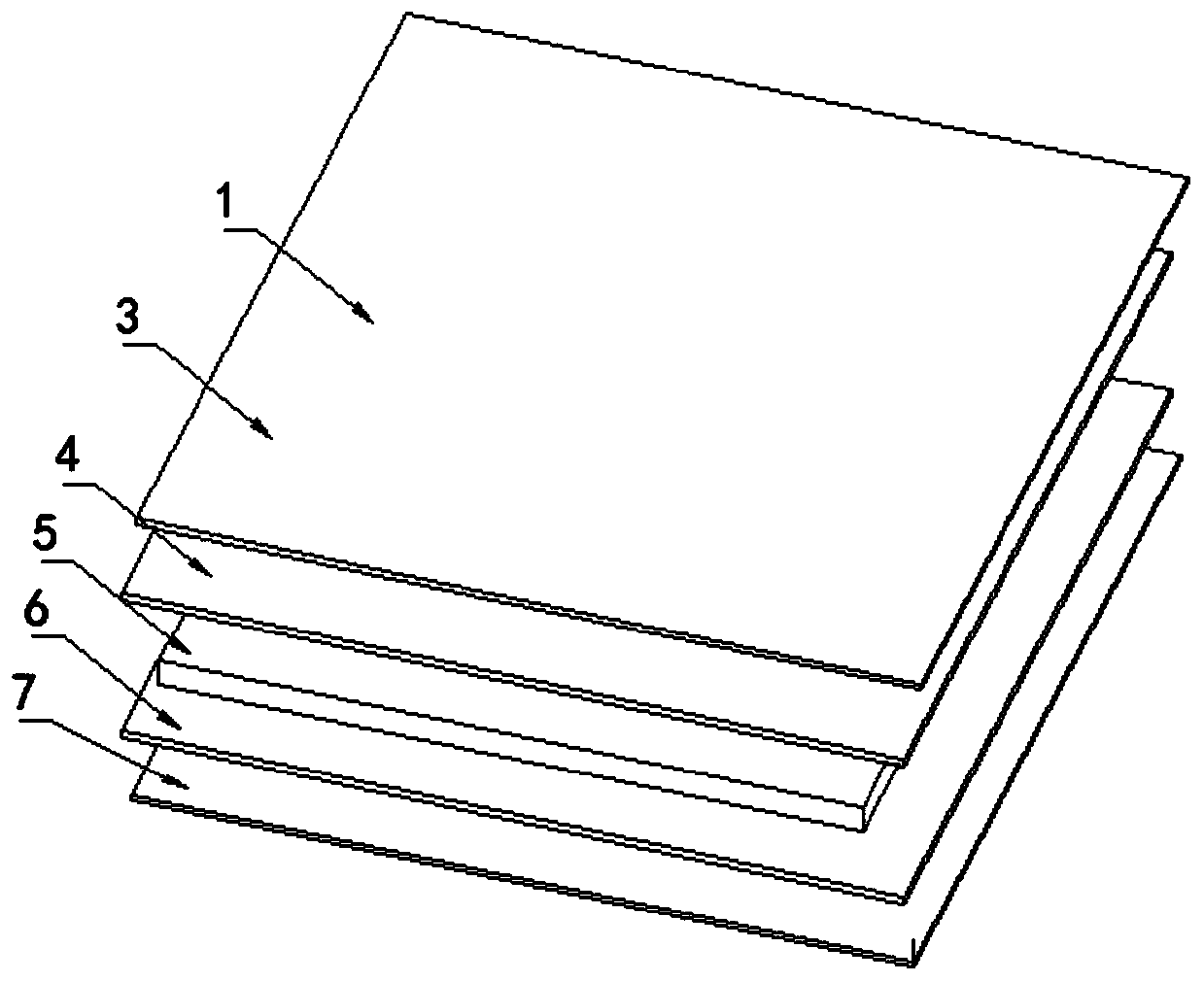

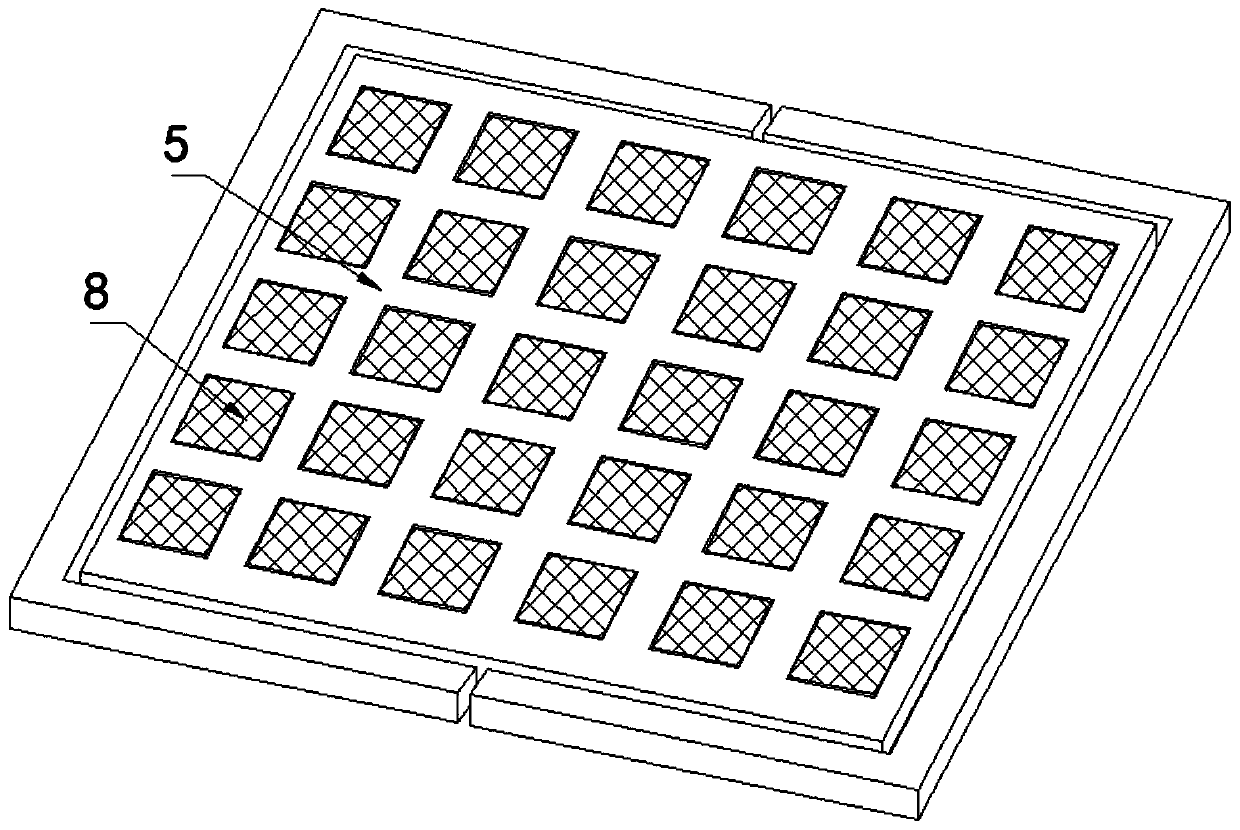

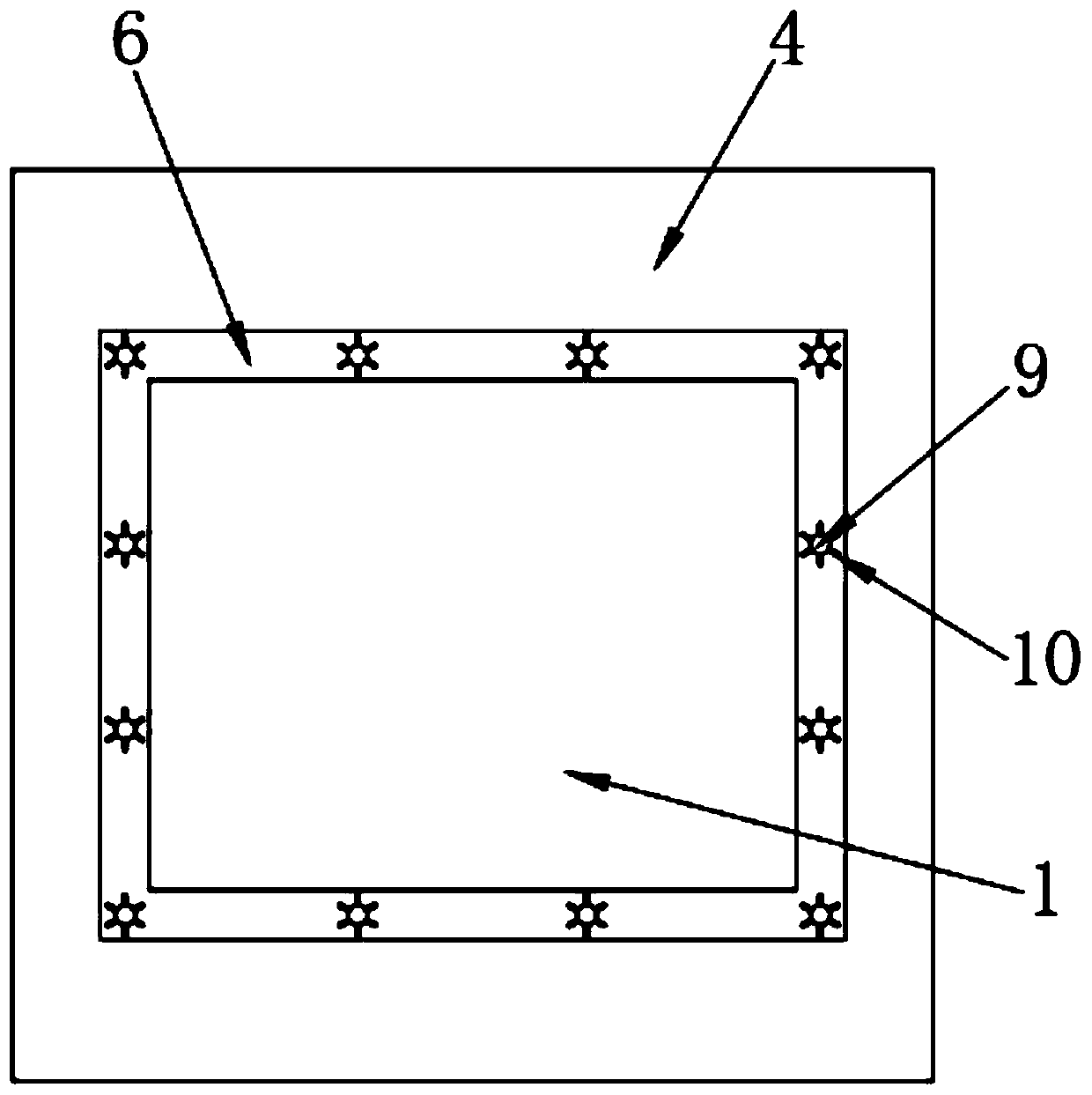

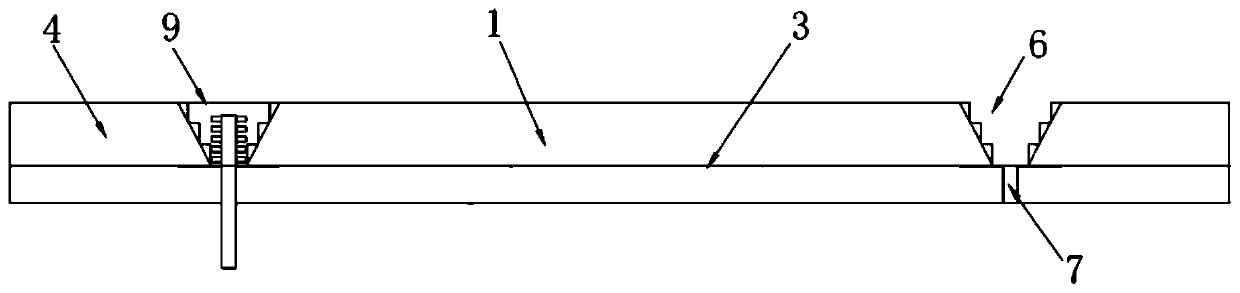

Solar panel and processing method

InactiveCN109713993AImprove photoelectric conversion rateFully fill the gapPhotovoltaicsPhotovoltaic energy generationPhotoelectric conversionEngineering

The invention discloses a solar panel and a processing method. The solar panel comprises a body, an AS resin frame and a junction box. The AS resin frame is disposed outside the body. A side of the body is provided with the junction box. The body is composed of tempered Glass, a front EVA film, a PCB, a rear EVA film, a backplane and a crystalline silicon battery sheet. The top of the backplane isconnected with the rear EVA film. The top of the rear EVA film is connected with the PCB. The crystalline silicon battery sheet is uniformly welded to the top of the PCB. The top of the crystalline silicon battery sheet is connected with the front EVA film. The solar panel replaces an aluminum alloy frame with the AS resin frame so that the light inclined at a large angle can also fully irradiatethe surface of the battery, thereby improving the photoelectric conversion rate of the solar panel. Further, sealing is achieved by injection molding the AS resin frame. In cooperation with the frontEVA film and the rear EVA film, a gap between the tempered glass and the PCB can be fully filled, thereby achieving a good sealing effect.

Owner:中南新能源技术研究院(南京)有限公司

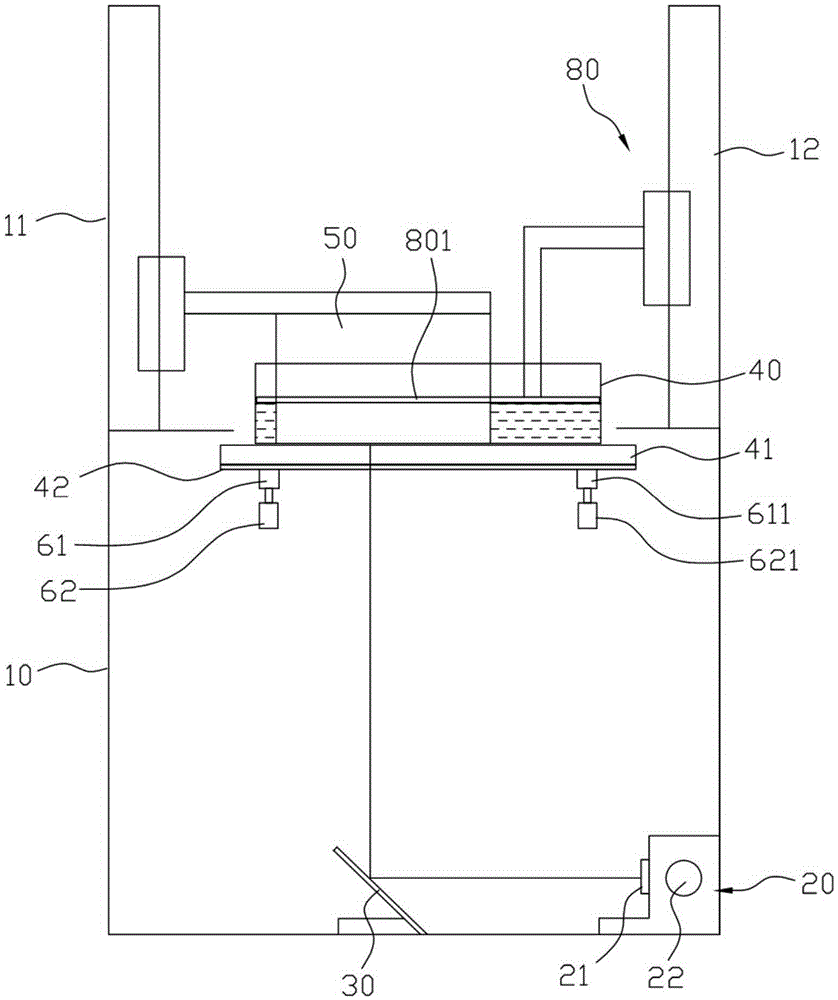

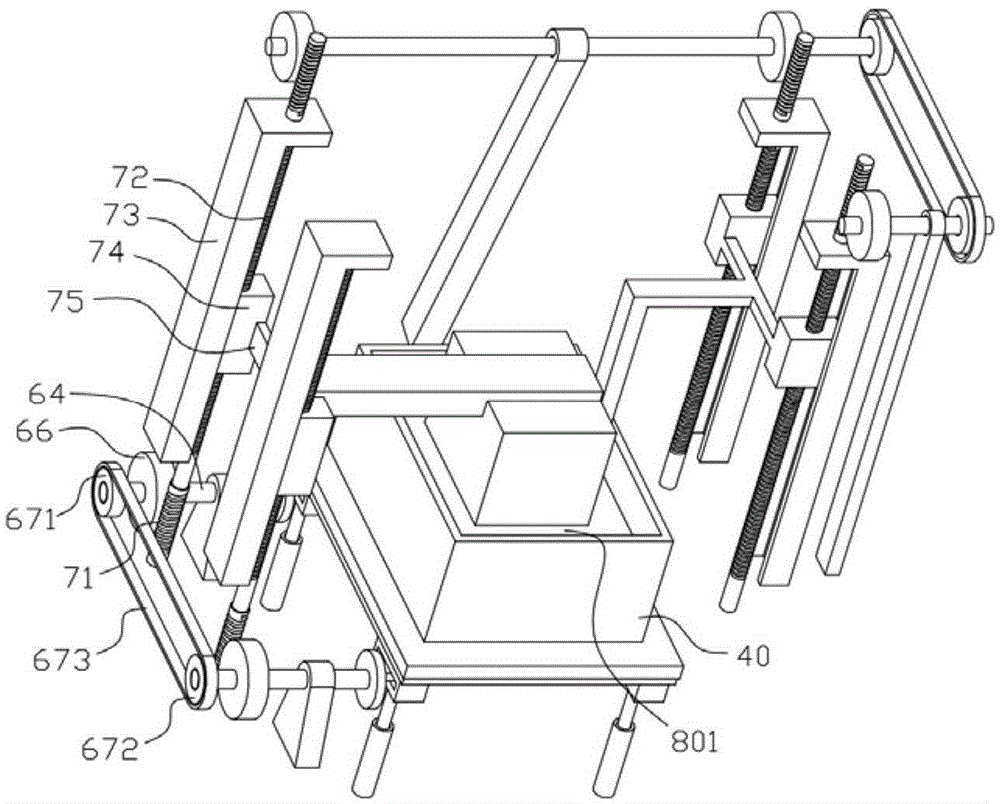

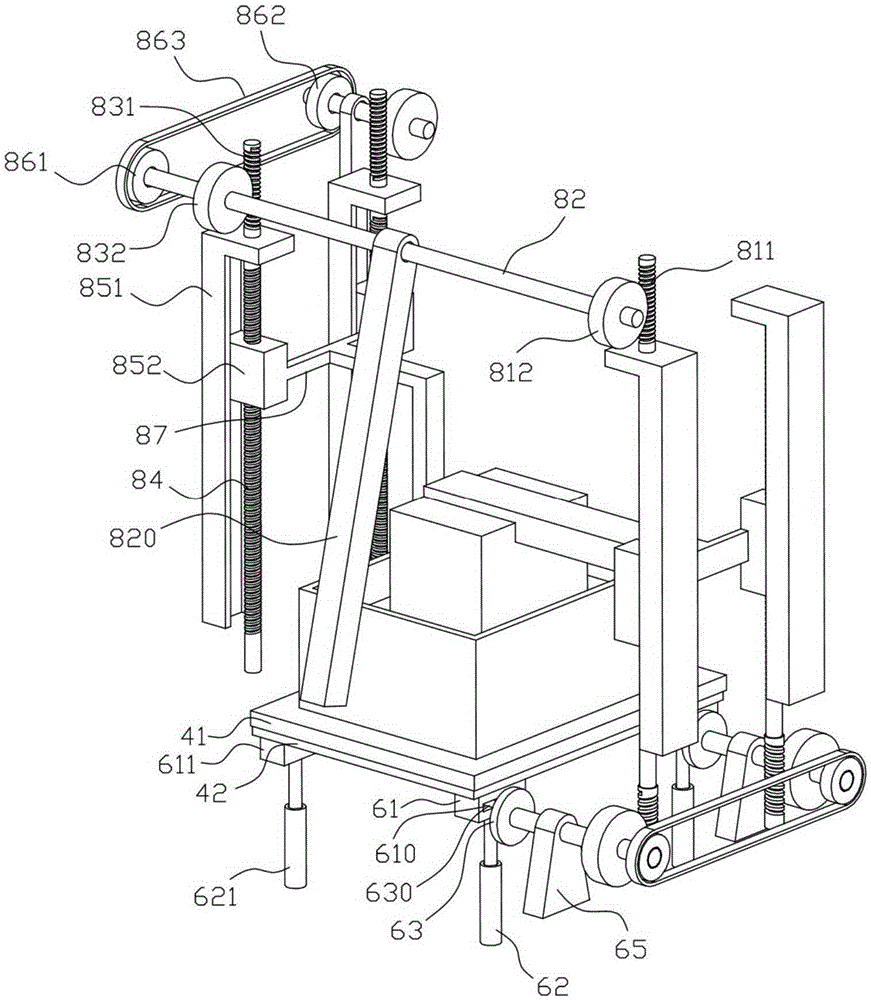

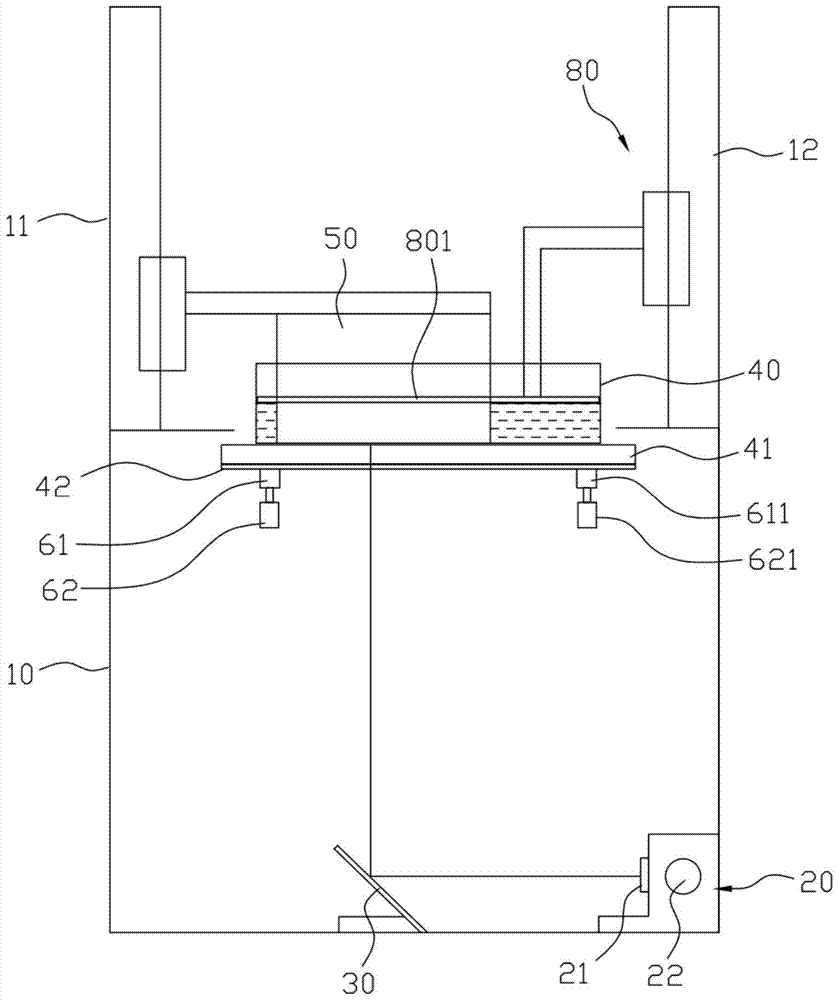

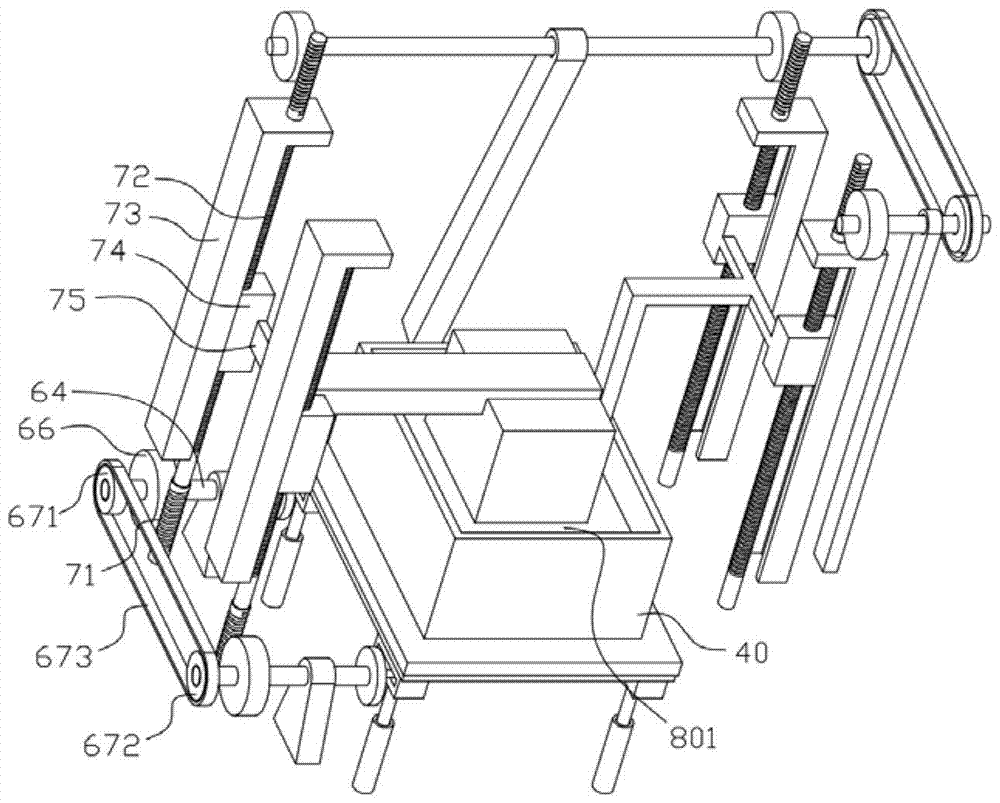

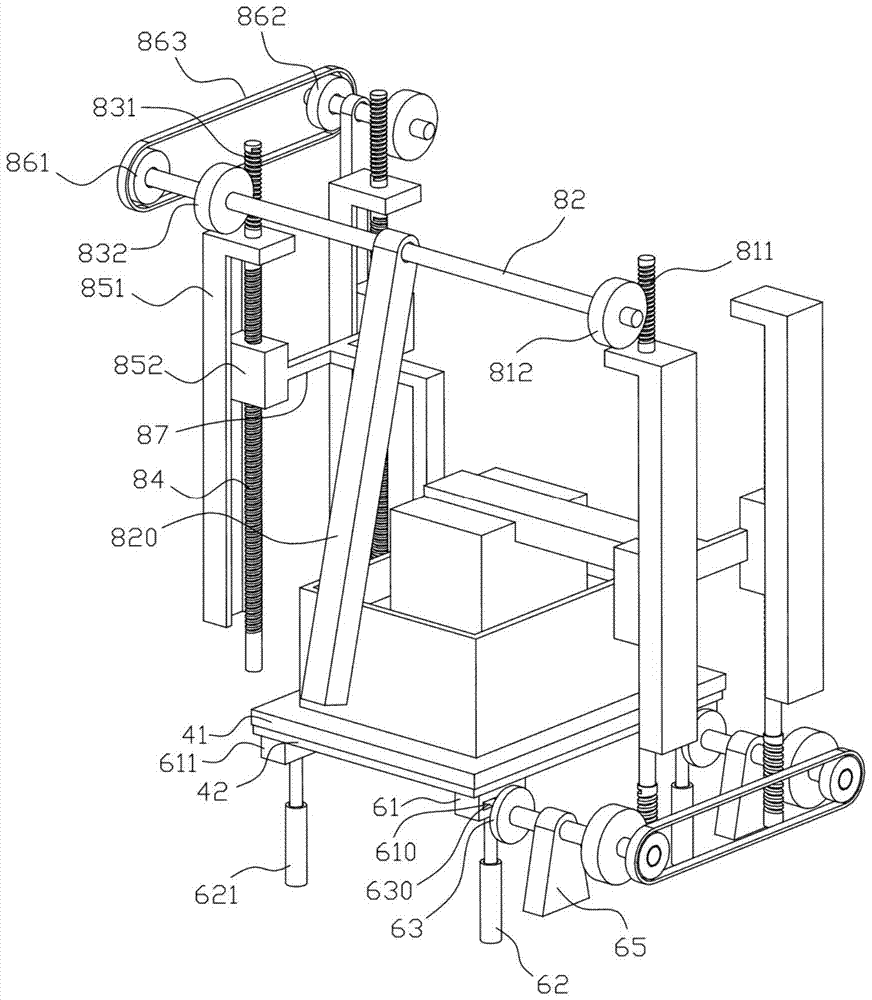

Novel 3D printer and printing process control method thereof

ActiveCN105346084AFully fill the gapImprove printing efficiencyAdditive manufacturing apparatusLaser scanningEngineering

The invention discloses a novel 3D printer and a printing process control method thereof. The novel 3D printer comprises a printer body which comprises a cabinet, a first support and a second support, wherein the first support and the second support are arranged on the two sides of the cabinet; a laser scanning device is arranged on the bottom face of the cabinet, a reflector is arranged in the center of the bottom face of the cabinet, and a resin groove is formed over the reflector; high-transmitting quartz glass is fixedly arranged on the bottom face of the resin groove and fixedly arranged on an iron plate, a lifting table is arranged over the resin groove, and the iron plate is connected with a first lifting device; and the lifting table is connected with a second lifting device which is arranged on the first support, and a resin extrusion mechanism is arranged on the second support. As the first lifting device, the second lifting device and the resin extrusion mechanism are in linkage, the control process is simplified according to the 3D printer and the printing process control method of the 3D printer; and in addition, accurate control over the resin flake thickness of the section profile of a product is facilitated.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

Beam supporting and column pulling construction method

ActiveCN113389406AIncrease beam sectionFully fill the gapBuilding repairsSteel platesClassical mechanics

The construction method comprises the following steps that S1, steel beams are installed, specifically, hoops are installed at the tops of four original structural columns, the steel beams are connected to the ends of the hoops, the ends, away from the hoops, of the steel beams extend to the positions close to the columns to be pulled, and the steel beams are attached to the original structural beams; s2, temporary supporting columns are installed, specifically, the temporary supporting columns are installed on the periphery of the column to be pulled, and the temporary supporting columns bear the steel beam; s3, steel plate wrapping is performed, wherein the outer surface of the original structural beam is wrapped with a steel plate, and the steel plate is connected with the original structural beam through chemical anchor bolts; s4, the to-be-pulled column is cut off, wherein after supporting is stable, a cutting tool is used for cutting off the to-be-pulled column; s5, a cross-shaped steel beam is mounted: after the to-be-pulled column is cut off, mounting the cross-shaped steel beam on the bottom surface of the intersection of the original structural beams; s6, steel pouring glue is injected, specifically, the steel pouring glue is injected between the steel plate and the original structural beam; s7, the temporary supporting columns are dismantled; and S8, the stress and deflection of the composite beam are measured. The method has the advantages of being simple in construction procedure and reducing the workload.

Owner:北京东方悦工程技术有限公司

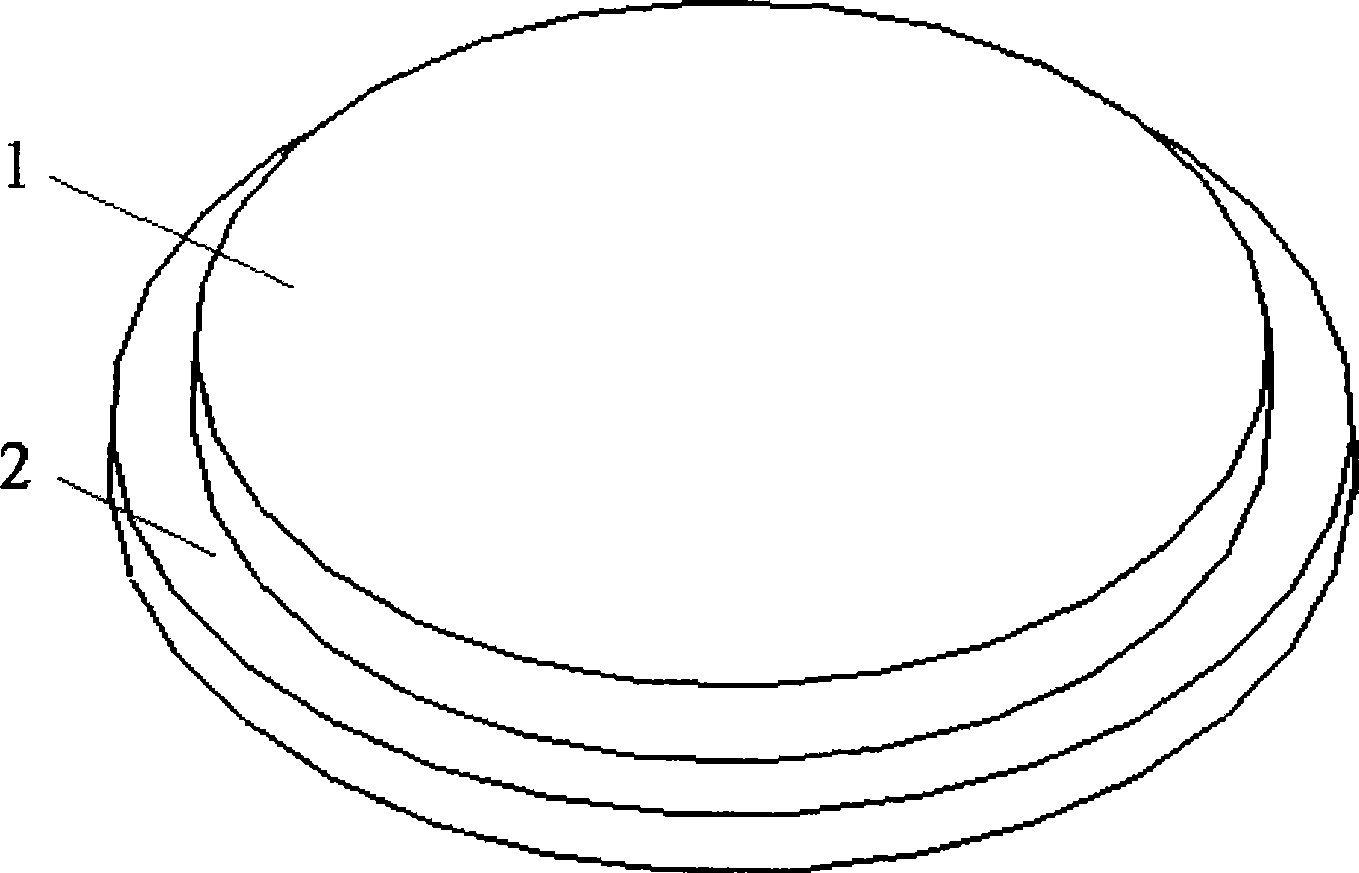

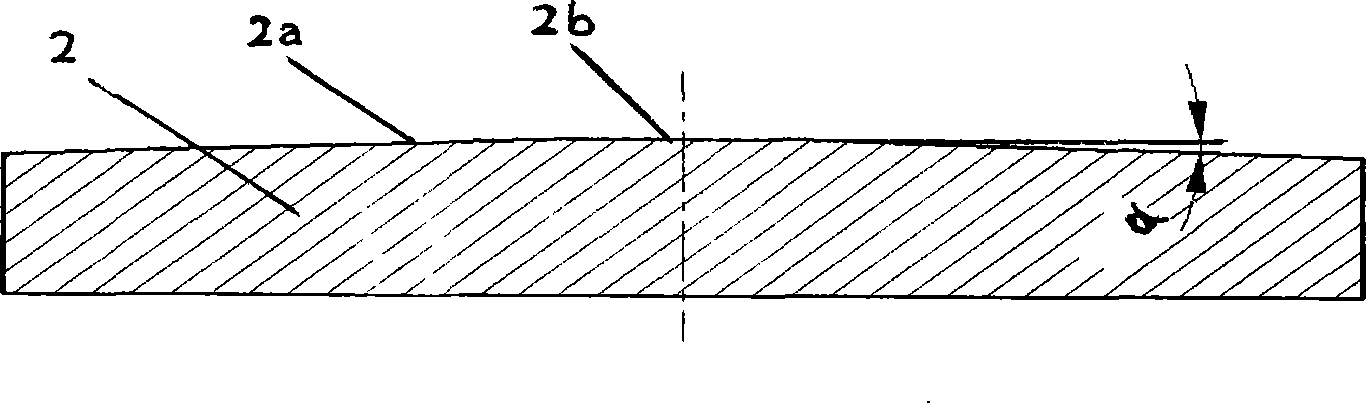

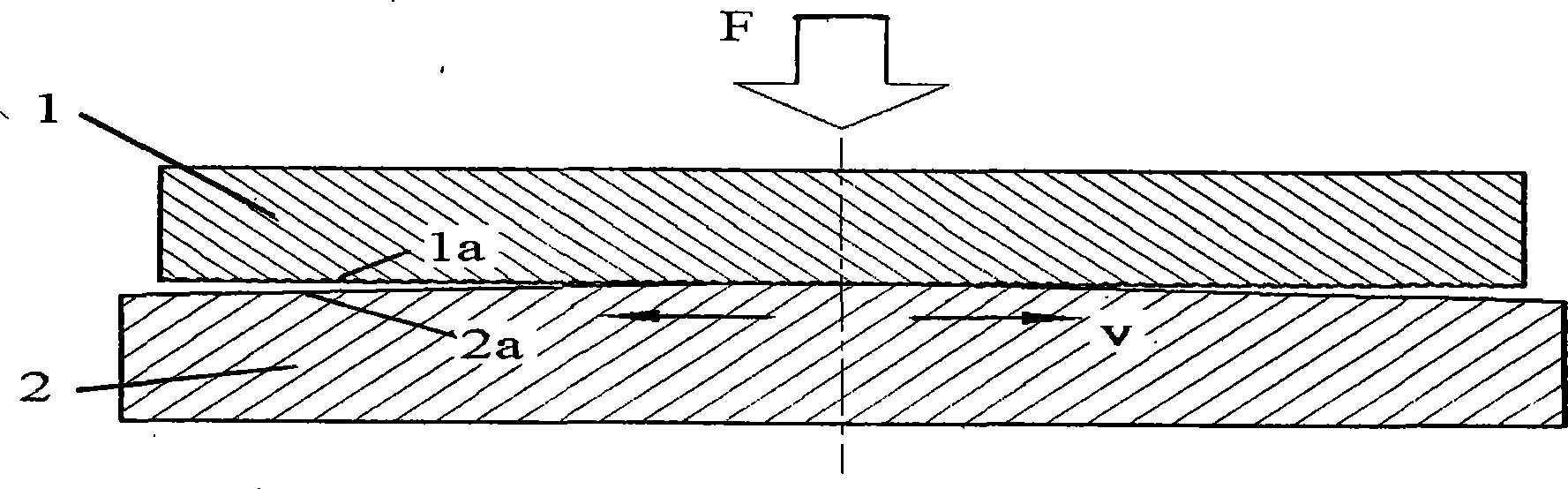

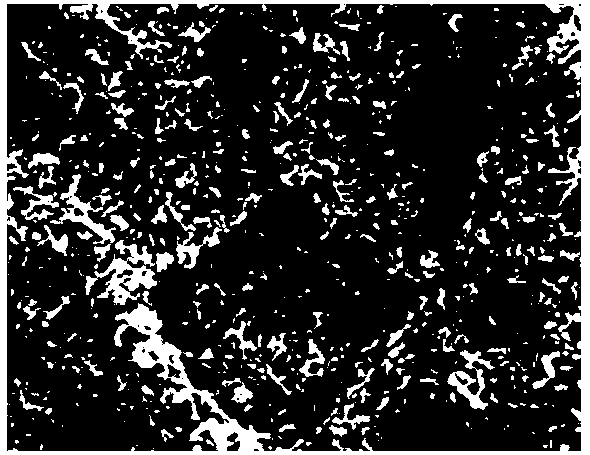

Pressure welding method of large-area target material

ActiveCN101279401BNot easily oxidizedFully fill the gapNon-electric welding apparatusMetallic materialsOxygen

The invention relates to a pressure welding method for large-area target which belongs to the welding field of metallic materials, and the method comprises the following steps that: (1) a roughening treatment is applied to the surface to be welded of the target; (2) the surface to be welded of a backplane is processed into a non-planar structure; (3) the surfaces to be welded of the target and backplane are washed and dried: (4) the backplane is heated and the preheated target or target at normal temperature is placed on the backplane and pressed, so as to deform the curved surface of the backplane till a bonding between two surfaces to be welded is achieved by pressing; (5) the target and the backplane are heated to the temperature which is 0.50 to 0.85 time of the melting point of one with lower melting point in the both and welded under the condition of heat insulation after being clamped tightly. The method has low processing requirement for the equipment and the surface to be welded and can ensure that no oxygen problem exists between the large-area target and the surface to be welded of the backplane, the air around the contacting surface between the target and the backplaneis completely discharged, firm bonding between the target and the backplane is realized in the atmosphere environment, simultaneously the microstructure performance of the target is not affected and problems of severe deformation, etc do not happen to the bonding surface between the target and the backplane.

Owner:GRIKIN ADVANCED MATERIALS

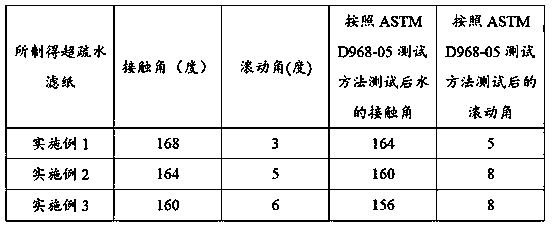

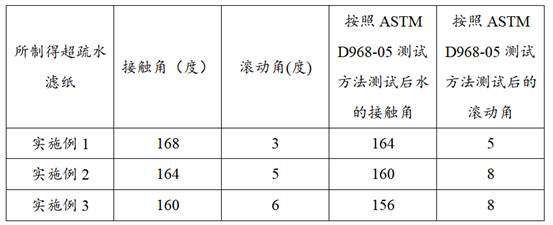

Low-weight superhydrophobic package paper and preparation method thereof

The invention relates low-weight superhydrophobic package paper and a preparation method thereof. The package paper includes: package raw paper, a hydrophobic coating layer made from low-melting-pointwax, a micron structure coating made from high-melting-point wax, and a nano-structure coating made from modified nano-SiO2. The package raw paper is respectively coated with wax emulsion and the modified SiO2 and is calendered by a soft roller. The mixed wax shows a micron-particle appearance and can fully fill the gaps between fibers in the surface of the paper; meanwhile, the hydrophobic nano-SiO2 particles fill the fibers and the mixed wax to form a hydrophobic micron-nano structure. Therefore, the hydrophobicity of the paper is enhanced, the contact angle is increased and rolling angle is reduced. The preparation method is simple in operation, is low in energy consumption and is environment-friendly, is free of fluorine containing compounds or organic solvents, and has great application prospect.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

120-180 degree heat dissipation and non-side-leakage liquid metal heat interface material

The invention discloses a 120-180 degree heat dissipation and non-side-leakage liquid metal heat interface material. The 120-180 degree heat dissipation and non-side-leakage liquid metal heat interface material is prepared from the components in percentage by weight: 0.5-1.0wt.% of Al, 0.2-0.4wt.% of Co, 1.0-1.5wt.% of Ga, 0.2-0.4wt.% of V, 28.0-34.0wt.% of Zn, 1.5-2.0wt.% of Ge, 3.0-4.0wt.% of Sb, and the balance of indium. According to the 120-180 degree heat dissipation and non-side-leakage liquid metal heat interface material, the problem that side leakage can occur in common liquid metalsis solved, and meanwhile, a beneficial liquid metal heat interface material is provided for the field of electronic industry which is in urgent need of efficient heat dissipation. It can be predictedthat great social value and economic value can be certainly obtained through successful industrialization of the 120-180 degree heat dissipation and non-side-leakage liquid metal heat interface material.

Owner:杭州辰卓科技有限公司

Connection terminal frame and flame-proof equipment

ActiveCN106299866AFully pottedImprove the reliability of flameproofElectrically conductive connectionsSecuring/insulating coupling contact membersEngineeringAir bubble

The invention provides a connection terminal frame and flame-proof equipment. The connection terminal frame comprises a first surface and a second surface which are opposite to each other; a first set of contact pin holes and a second set of contact pin holes, wherein each contact pin hole in the first and second sets of contact pin holes penetrates through the first surface and the second surface, and the first set of contact pin holes and the second set of contact pin holes are fluidly separated from each other in the region of the connection terminal frame; and an encapsulating material injection hole arranged to penetrate through the first surface and the second surface and in fluid communication with each contact pin hole in the first set of contact pin holes. According to the connection terminal frame of the invention, the encapsulating material is set to flow along a preset encapsulating path, so that the air in the encapsulating path is discharged favourably. Therefore, the generation of air bubbles in the encapsulating material is avoided. In addition, gaps among relevant structures in the flame-proof equipment provided with the connection terminal frame are fully encapsulated, so that the flame-proof performance of the flame-proof equipment is greatly improved.

Owner:MICRO MOTION INC

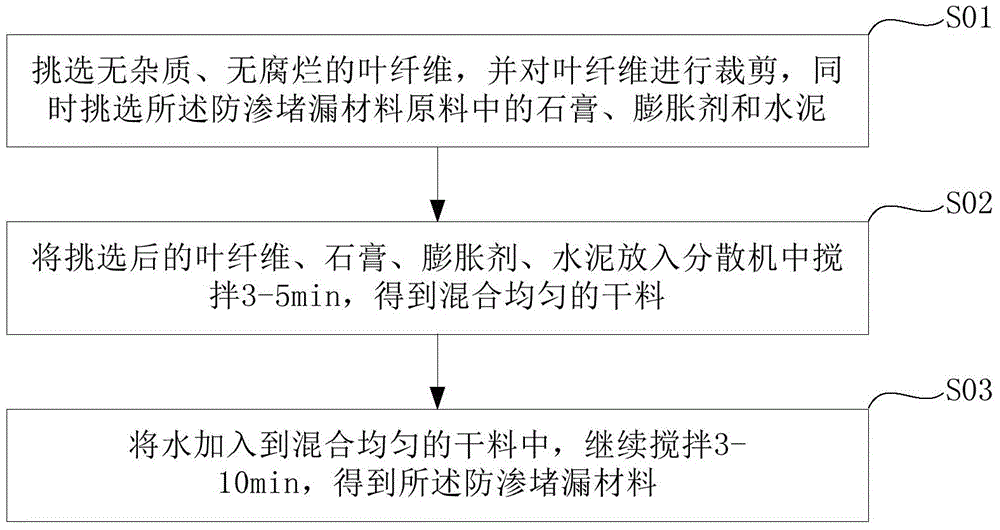

Seepage-proofing leaking-stopping material and preparation method thereof

The invention provides a seepage-proofing leaking-stopping material and a preparation method thereof. The seepage-proofing leaking-stopping material comprises leaf fibers, gypsum, an expanding agent, cement and water. The leaf fibers are added to the cement, so that the tensile strength of cement mortar is improved. Meanwhile, the cost of the seepage-proofing leaking-stopping material can be greatly reduced through the leaf fibers, and the seepage-proofing leaking-stopping material can be widely applied to the fields of tunnels and underground structures, mine excavation and water conservancy and hydropower foundation reinforcement projects and the like.

Owner:重庆市十八土鑫诚灌浆防水工程有限公司

Liquid metal thermal interface material capable of 50-80 DEG C heat dissipation and without side leakage

The invention discloses a liquid metal thermal interface material capable of 50-80 DEG C heat dissipation and without side leakage. An interlayer alloy is prepared from the compositions in percentageby weight: 0.2-0.4 wt.% of Co, 5.0-6.0 wt.% of Zn, 1.0-2.0 wt.% of Ga, 0.5-0.8 wt.% of Mn, 0.1-0.2 wt.% of Si, 0.8-1.2 wt.% of Ge, and the balance of In. According to the liquid metal thermal interface material, side leakage of common liquid metal is avoided, and meanwhile, the beneficial liquid metal thermal interface material is provided for the field of the electronic industry, wherein the field of the electronic industry is in urgent need of efficient cooling. It can be predicted that the successful industrialization of the liquid metal thermal interface material can obtain the great social value and economic value.

Owner:杭州辰卓科技有限公司

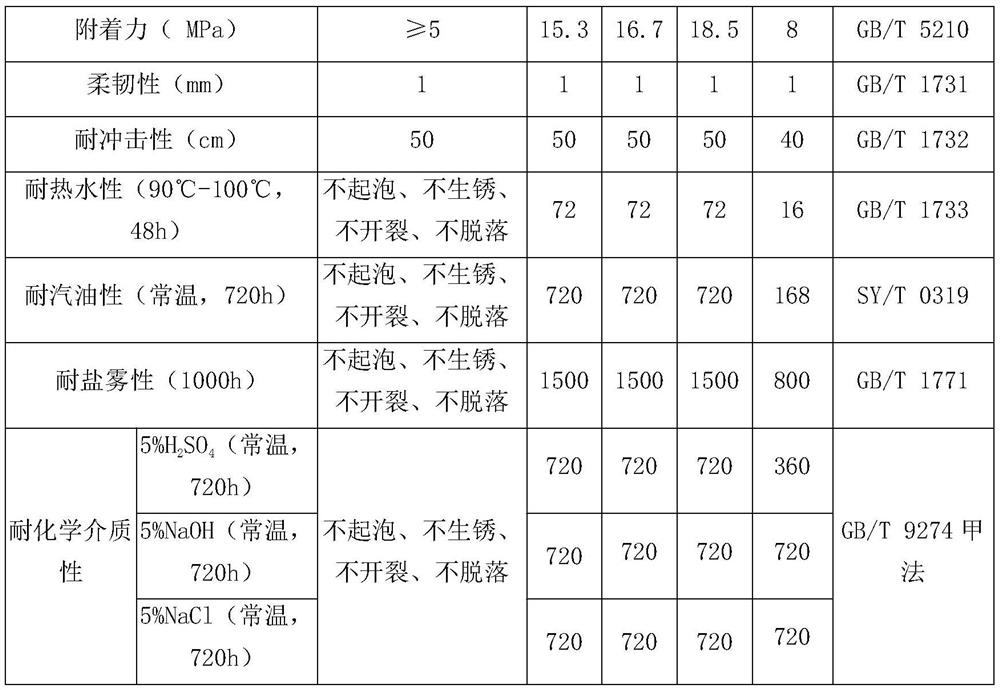

Waterborne epoxy anticorrosive coating for inner wall of petroleum storage tank in medium environment and preparation method of waterborne epoxy anticorrosive coating

ActiveCN113930126AHigh molecular weightReduce crosslink densityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceHexagonal boron nitride

The invention discloses a waterborne epoxy anticorrosive coating for the inner wall of a petroleum storage tank in a medium environment and a preparation method of the waterborne epoxy anticorrosive coating, and belongs to the technical field of petrochemical engineering protection. The coating comprises a component A and a component B; the component A is prepared from the following raw materials in parts by weight: 8 to 13 parts of deionized water, 0.5 to 1.5 parts of a wetting dispersant, 0.1 to 0.3 part of a defoaming agent, 0.1 to 0.5 part of an anti-settling agent, 5 to 10 parts of a pigment, 10 to 20 parts of precipitated barium sulfate, 50 to 60 parts of waterborne epoxy emulsion A, 3 to 5 parts of waterborne epoxy resin B, 3 to 5 parts of modified hexagonal boron nitride, 0.1 to 0.2 part of a defoaming agent, 0.1 to 0.3 part of a flatting agent, 0.1 to 0.3 part of a base material wetting agent, 1-3 parts of an anti-flash rust agent and 0.5-1 part of a thickening agent; the component B is prepared from the following raw materials in parts by weight: 20-35 parts of deionized water, 5-10 parts of propylene glycol butyl ether and 60-70 parts of a waterborne epoxy curing agent; and the mass ratio of the component A to the component B is (4-6):1. The coating disclosed by the invention has excellent hot water resistance, acid and alkali resistance and salt spray resistance, and can form a film at 0 DEG C, so that the use condition of the waterborne epoxy resin coating is improved.

Owner:洛阳双瑞防腐工程技术有限公司

Liquid metal thermal interface material capable of 80-120 DEG C heat dissipation and without side leakage

InactiveCN109957695APrevent side leakageEfficient heat dissipationChemical industryHeat-exchange elementsIndiumAlloy

The invention discloses a liquid metal thermal interface material capable of 80-120 DEG C heat dissipation and without side leakage. An interlayer alloy is prepared from the compositions in percentageby weight: 0.5-0.8 wt.% of Fe, 0.2-0.4 wt.% of V, 2.0-3.0 wt.% of Ga, 0.4-0.5 wt.% of Mn, 7.0-8.0 wt.% of Zn, 4.0-5.0 wt.% of Sb, and the balance of In. According to the liquid metal thermal interface material, side leakage of common liquid metal is avoided, and meanwhile, the beneficial liquid metal thermal interface material is provided for the field of the electronic industry, wherein the field of the electronic industry is in urgent need of efficient cooling. It can be predicted that the successful industrialization of the liquid metal thermal interface material can obtain the great social value and economic value.

Owner:杭州辰卓科技有限公司

Road repairing module and construction method thereof

ActiveCN110195402AWide applicabilityGuaranteed stabilityRoads maintainenceRoad surfaceAsphalt concrete

The invention discloses a road repairing module, which includes a precast block. The precast block is in an prismatic shape and is internally provided with continuous steel reinforcement, irregular folds are arranged on the edge slope of the precast block, the precast block is installed in a roadbed to be filled, a slope extending to the roadbed side is arranged in the road surface edge of the periphery of the roadbed, an connecting area with an inverted trapezoidal section is formed between the road surface and the precast block, positioning holes are uniformly formed in the bottom of the connection area, ground piles are fixed to the positioning holes, the ground piles are located in the connection area, and fixing jaws are fixedly installed on the peripheries of the ground piles. A roadrepairing method is applicable to a cement concrete road and an asphalt concrete road, a connection layer is filled in the connection area, the irregular folds are arranged on a precast block slope and the road slope to ensure connection stability of the connection layer, the construction period of the road surface is shortened, and the financial cost is lowered.

Owner:安徽劲帆建设有限公司

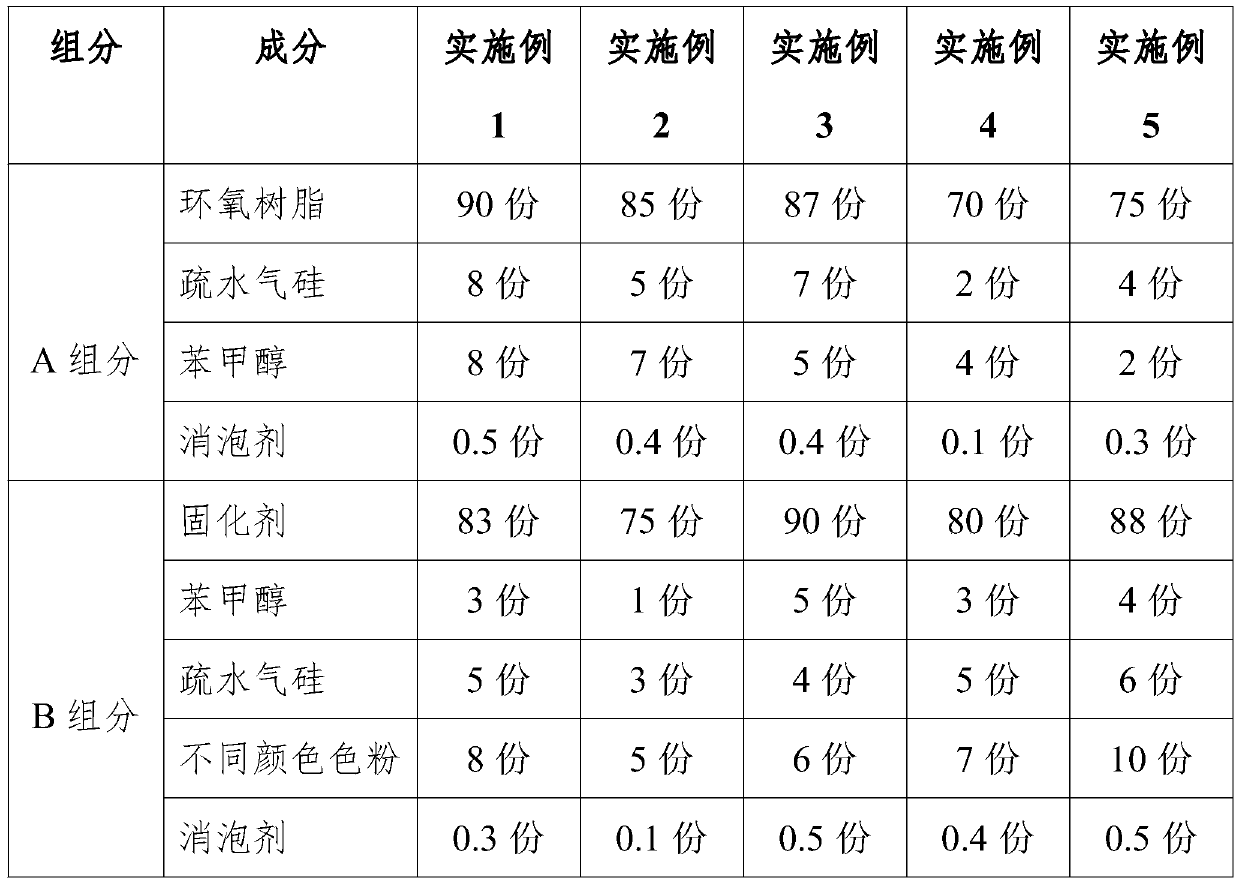

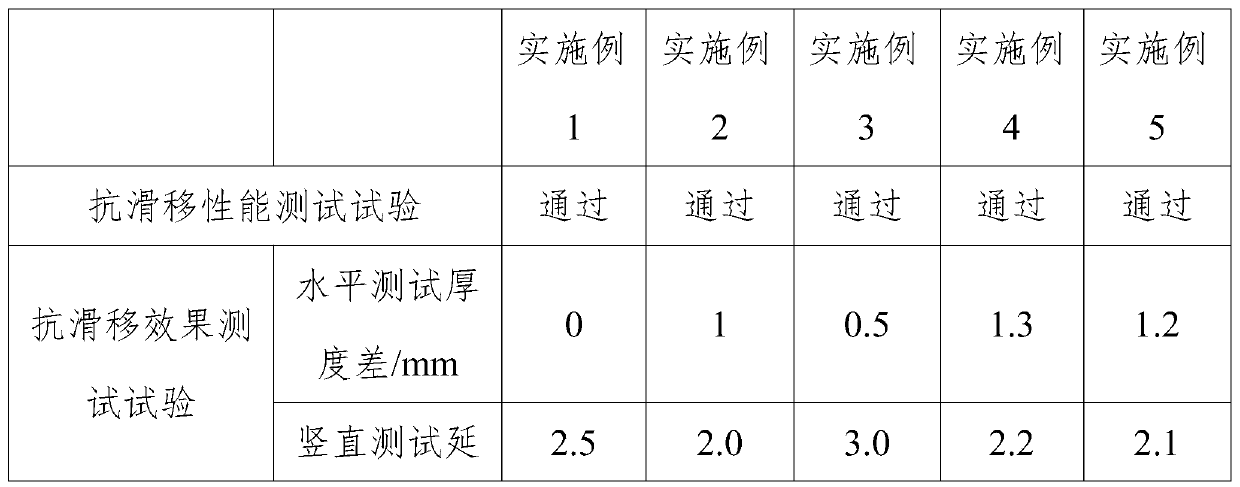

Anti-sagging ceramic-beautifying glue and performance detection method thereof

InactiveCN109868103AHigh viscosityGood storage stabilityNon-macromolecular adhesive additivesFlow propertiesEpoxyBENZYL ALCOHOL/WATER

An anti-sagging ceramic-beautifying glue and a performance detection method thereof are disclosed. The anti-sagging ceramic-beautifying glue is characterized by comprising components A and B, the component A comprises the following components in parts by weight: 70 to 90 parts of epoxy resin, 2 to 8 parts of hydrophobic fumed silica, 2 to 8 parts of benzyl alcohol, and 0.1 to 0.5 part of antifoaming agent; and the component B contains the following components in parts by weight: 70 to 90 parts of curing agent, 1 to 5 parts of benzyl alcohol, 3-6 parts of hydrophobic fumed silica, 5 to 10 partsof toners with different colors, and 0.1 to 0.5 part of antifoaming agent. According to the ceramic-beautifying glue, the hydrophobic fumed silica is selected to be added into the formula, thus the thixotropy of the product is better enhanced, and the sag resistance of the product is significantly improved. The detection method is simple, easy, fast and effective, and an obtained result is clear.When the construction effect and construction efficiency are improved, time and personnel costs are saved to a greatest extent, and a stable construction process is facilitated.

Owner:西卡(上海)管理有限公司

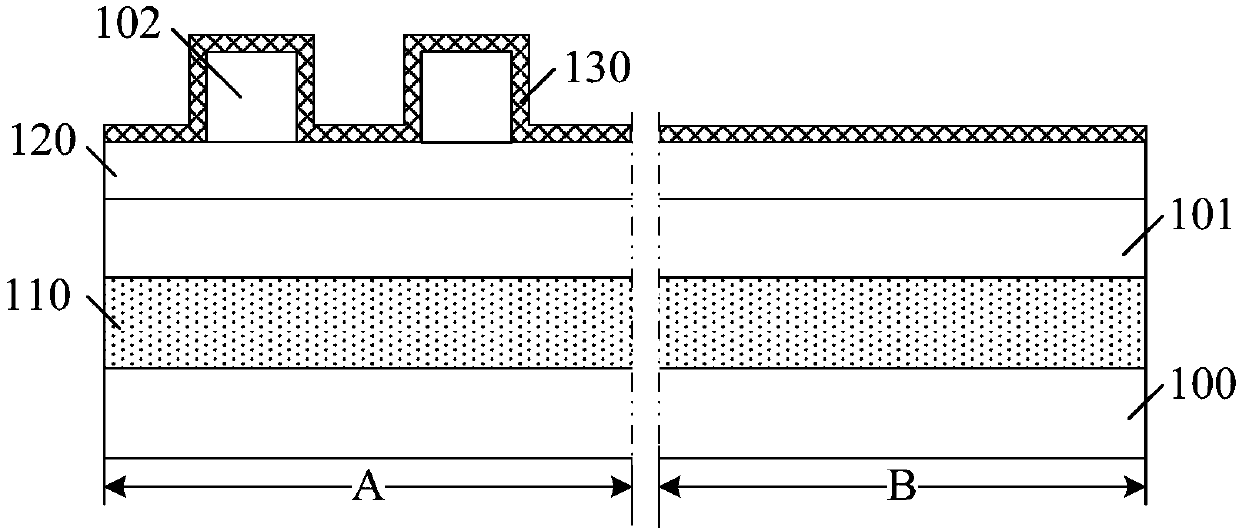

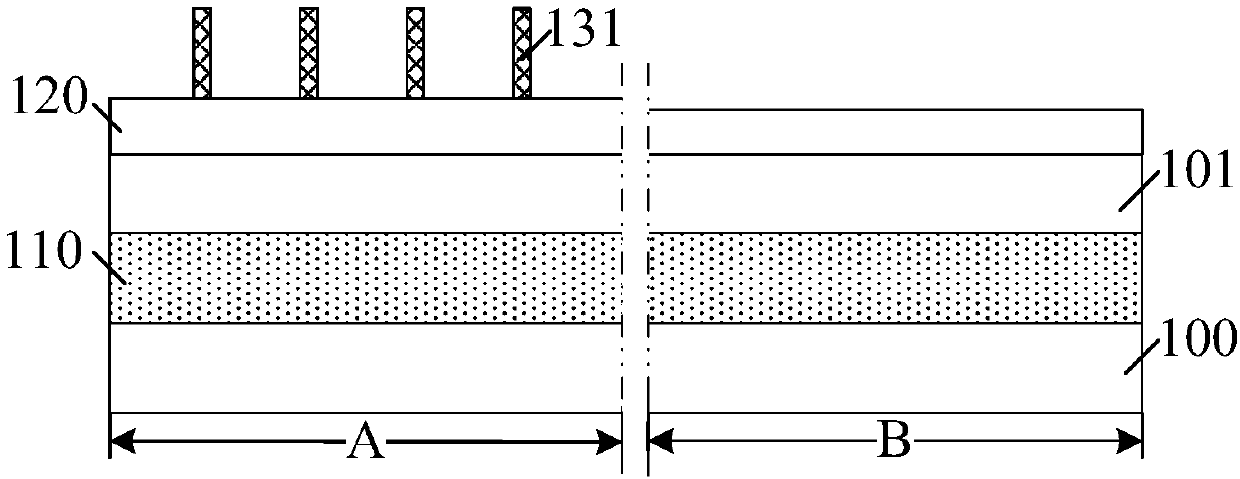

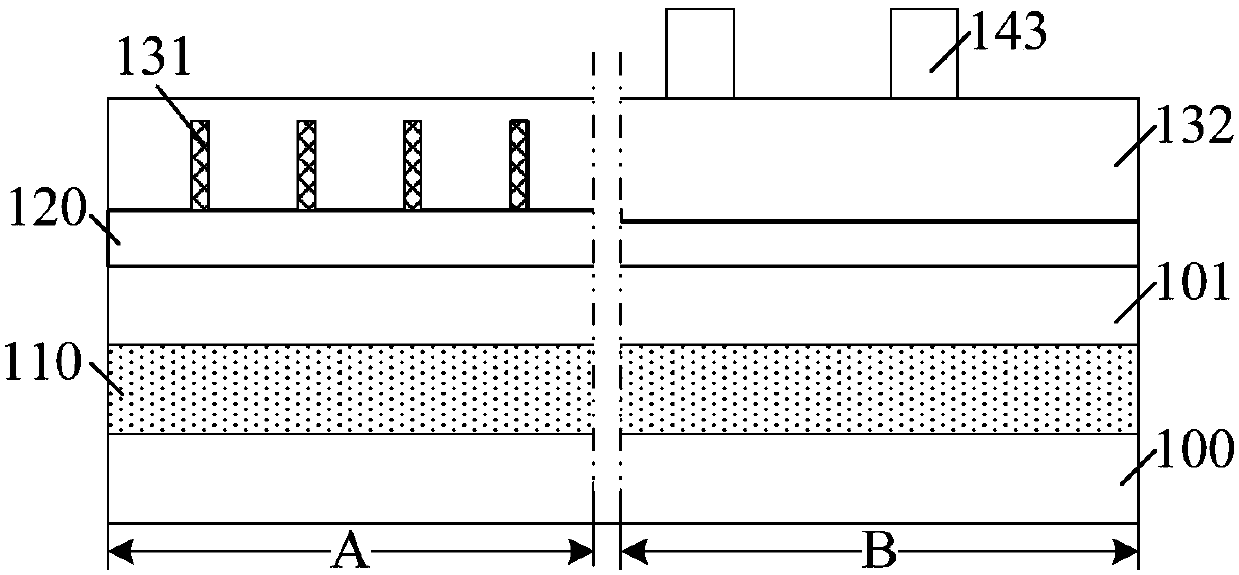

Semiconductor structure and method of forming same

ActiveCN109559978AReduce lossMeet the design requirementsSemiconductor/solid-state device manufacturingSemiconductor structureMask layer

The present invention provides a semiconductor structure and a method of forming the same. The method includes the steps of: forming an initial functional layer on a substrate in a first region and ina second region; forming an initial mask layer on the initial functional layer; forming a plurality of separated graphic layers on the initial mask layer in the first region, and forming second graphic layers on the initial mask layer in a removal region and a remaining region, wherein the dimension of the first graphic layer is a first dimension in a first direction, the dimension of the secondgraphic layer is a second dimension in the first direction, the second dimension is equal to the first dimension, and the distance between the first graphic layers is equal to the distance between theadjacent second graphic layers; performing graph transfer processing to form a plurality of mask layers. The forming method provided by the invention can improve the performances of the formed semiconductor structure and can simplify the process flow.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A high temperature resistant low modulus thermally conductive silicone material and preparation method thereof

The invention provides a high temperature resistant and low-modulus heat conducting organic silicon material which is prepared from the following raw materials: silicone oil, heat conducting powder filler, a low-modulus auxiliary, a high temperature resistant auxiliary, a crosslinking agent and a platinum catalyst, wherein the mass ratio of the silicone oil to the heat conducting powder filler is (90-110):(900-1,100); the mass ratio of the heat conducting powder filler to the low-modulus auxiliary is 100:(0.5-2); the mass ratio of the silicone oil, the high temperature resistant auxiliary, the crosslinking agent and the platinum catalyst is 100:(0.1-1):(5-15):(0.1-0.2) in turn. The invention belongs to the technical field of organic silicone. The heat conducting organic silicon material provided by the invention has the advantages of high long-term stability of heat dissipation in a high-temperature condition, low modulus, easy gap fitting, low thermal resistance and no oil leakage or volatilization; automatic adhesive dispensing construction can be realized; a better interface heat conducting material is provided between a heating component of an electronic appliance and a heat dissipation device or apparatus.

Owner:广东皓明有机硅材料有限公司

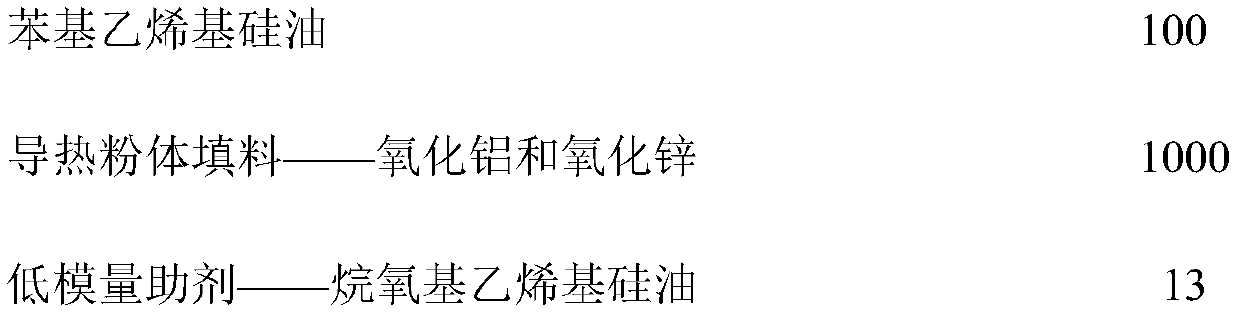

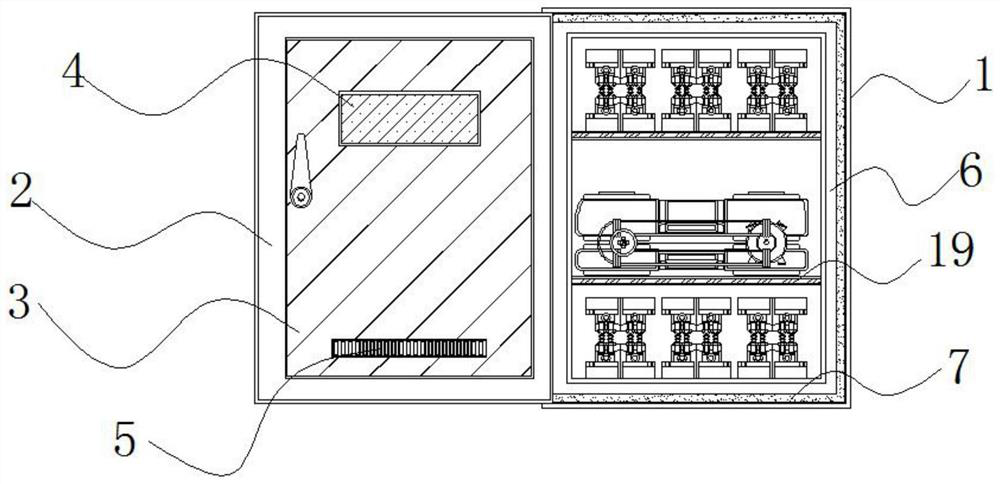

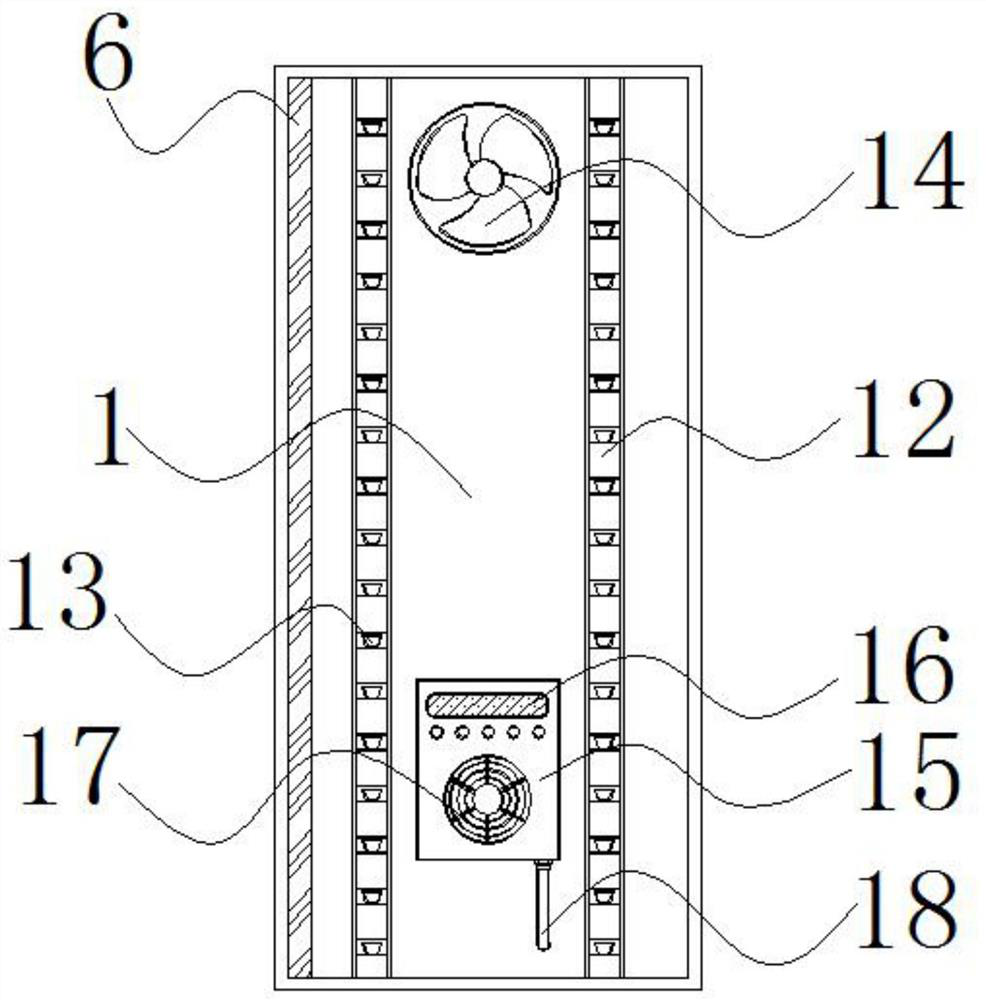

Switch device with layered structure and convenient to assemble

InactiveCN112993787AImprove sealingEliminate potential safety hazardsSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsInterior spaceStructural engineering

The invention discloses a switch device with a layered structure and convenient to assemble, and relates to the technical field of switch devices, in particular to a switch cabinet body, a reinforcing baffle and a mounting support plate, the surface of the switch cabinet body is connected with a protective cabinet door, a protruding door plate is welded to the inner side of the protective cabinet door, and an observation window is embedded in the upper end of the surface of the protective cabinet door. A heat dissipation groove is formed in the lower end of the surface of the protection cabinet door, the reinforcing baffle is fixed to the inner surface of the opening of the switch cabinet body, and the outer side of the reinforcing baffle is connected with a connecting insulation rubber sleeve. The switch device with the layered structure and convenient to assemble is provided with an adjusting positioning plate, the surface of the adjusting positioning plate is provided with a large number of inverted trapezoidal groove openings which are distributed at equal intervals, and the structures of the groove openings are matched with upper inverted hooks at the two sides of a placing bearing plate, so that the placing bearing plate can be buckled and positioned conveniently; and the placing bearing plate can be adjusted and positioned through equidistantly distributed groove openings, so that a user can freely adjust the placement bearing plate to reasonably divide the internal space of the switch cabinet body.

Owner:NANTONG SHENGYANG ELECTRIC CO LTD

A 3D printer and its printing process control method

ActiveCN105346084BFast molding speedImprove yieldAdditive manufacturing apparatus3D object support structuresLaser scanning3d printer

The invention discloses a novel 3D printer and a printing process control method thereof. The novel 3D printer comprises a printer body which comprises a cabinet, a first support and a second support, wherein the first support and the second support are arranged on the two sides of the cabinet; a laser scanning device is arranged on the bottom face of the cabinet, a reflector is arranged in the center of the bottom face of the cabinet, and a resin groove is formed over the reflector; high-transmitting quartz glass is fixedly arranged on the bottom face of the resin groove and fixedly arranged on an iron plate, a lifting table is arranged over the resin groove, and the iron plate is connected with a first lifting device; and the lifting table is connected with a second lifting device which is arranged on the first support, and a resin extrusion mechanism is arranged on the second support. As the first lifting device, the second lifting device and the resin extrusion mechanism are in linkage, the control process is simplified according to the 3D printer and the printing process control method of the 3D printer; and in addition, accurate control over the resin flake thickness of the section profile of a product is facilitated.

Owner:SUZHOU SUNSHINE LASER & ELECTRONICS TECH CO LTD

A kind of preparation method of straight conveyor belt finger joint

ActiveCN103072786BIncreased warp strengthHigh warp strengthConveyorsBeltsAdhesive cementVulcanization

The invention belongs to the technical field of a rubber conveyor belt product, and particularly relates to a straight conveyor belt finger-model connector and a preparation method thereof. The straight conveyor belt finger-model connector comprises a straight finger-model skeleton structure, wherein the straight finger-model skeleton structure comprises a straight canvas layer; a rubberizing layer is arranged on the surface of the straight finger-model skeleton structure; a textile layer playing a reinforcement effect is arranged on the rubberizing layer; and a coverage rubber layer is arranged on the textile layer. The preparation method of the straight conveyor belt finger-model connector comprises the following steps of (1) stripping coverage adhesive; (2) removing residual adhesive; (3) cutting a finger model; (4) coating adhesive cement; (5) splicing the finger model; (6) forming a finger-model connector; and (7) vulcanizing the finger-model connector. Due to the adoption of the straight conveyor belt finger-model connector, the strength of the connector is improved; and the preparation method is simple and easy to operate.

Owner:YANKUANG GRP CO LTD +1

Method of making adhesive components

ActiveCN103333620BSolve the bubblesNot easy to gatherAdhesive processes with adhesive heatingOrganic non-macromolecular adhesiveUltraviolet lightsIrradiation

A method for preparing a gluing component comprises the following steps: providing a first base material and a second base material; adopting transparent optical cement to glue the first base material and the second base material; heating and debubbling the first base material and the second base material which are glued; and adopting ultraviolet light to irradiate and harden the first base material and the second base material which are heated, debubbled and glued, and obtaining the gluing component. According to the method for preparing the gluing component, the transparent optical cement is softened and has a certain fluidity through the heating and debubbling, so that a gap between glued objects can be sufficiently filled; meanwhile, bubbles between the transparent optical cement and the glued objects are removed completely through the vacuum debubbling treatment; and then the transparent optical cement is hardened through ultraviolet light irradiation, so that a gluing property is sufficiently achieved, gas molecules in the hardened optical cement has low possibility of accumulation, then visually visible accumulated bubbles are not formed, and accordingly, the problem of bubbles of the gluing component can be effectively solved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

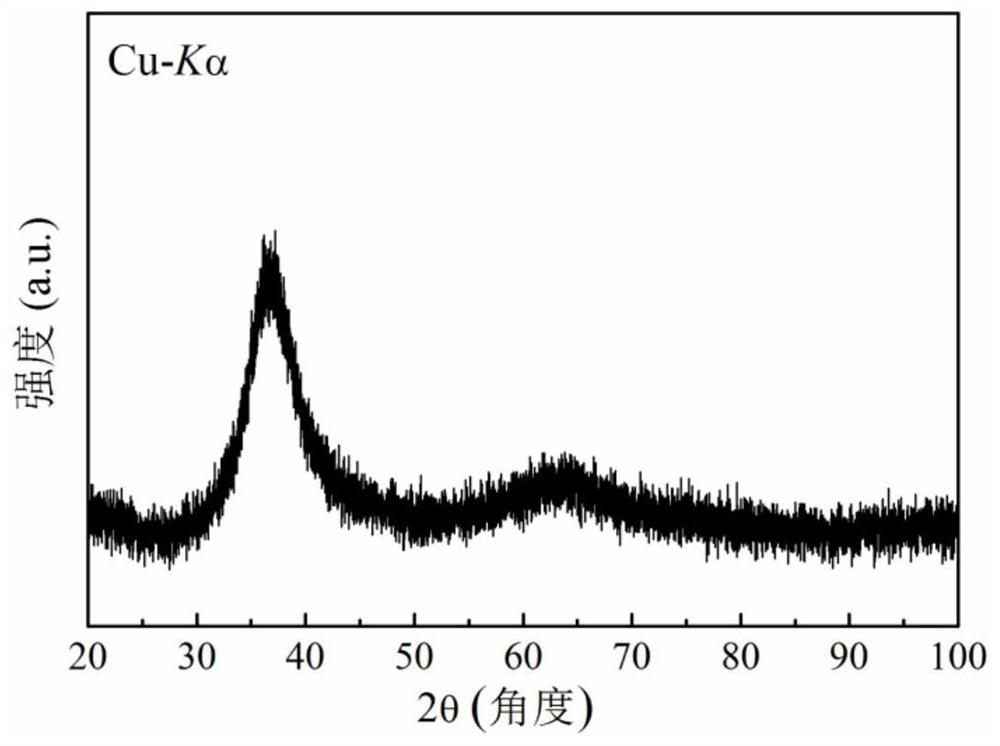

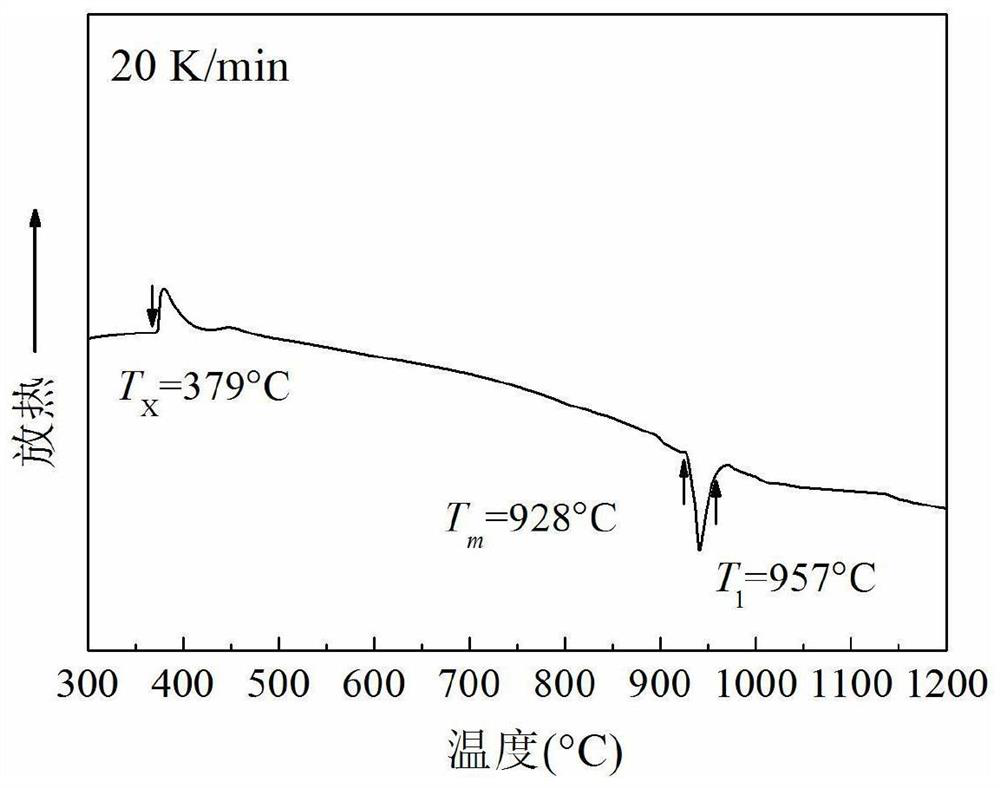

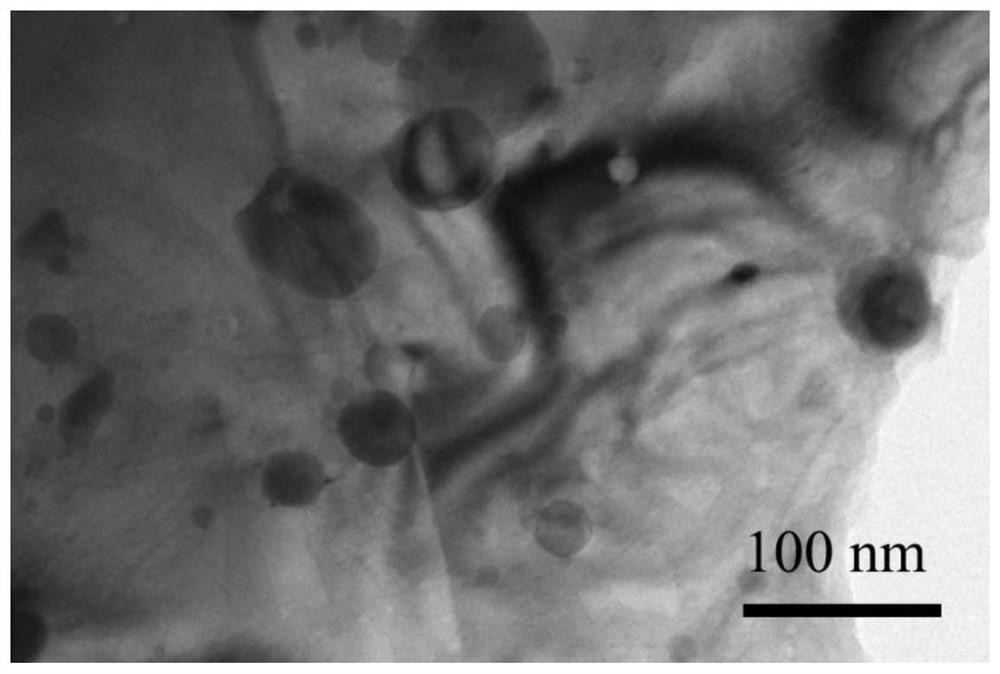

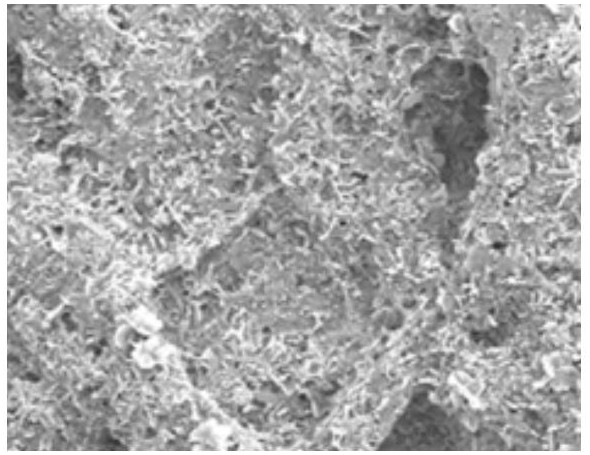

A tungsten-based material with both solid solution and dispersion strengthening and its preparation method

A tungsten-based material with both solid solution and dispersion strengthening and a preparation method thereof belong to the technical field of powder preparation engineering. The preparation method uses industrially pure W powder and Zr and M metals as raw materials. First, ZrM amorphous strips are obtained by arc melting and strip quenching technology; Mixing and preparing materials; finally, the materials are ball milled, pressed and sintered to obtain blocks (W 100‑a Zr a ) 100‑b m b Tungsten-based materials. The tungsten-based material includes W, Zr and M elements, wherein M is one of Fe, Co and Ni elements, a and b are atomic percentages, and their values are 0.5≤a≤8, 0<b≤3. The invention can fully fill the gap between W powder particles to obtain a high-density sintered body of tungsten-based materials; the obtained product has both solid solution and dispersion double strengthening characteristics; it is beneficial to improve the strengthening and toughening effect of tungsten-based materials, and greatly broadens the The preparation of materials controls process parameters, which helps to reduce material production costs and improve material yield and production efficiency.

Owner:DALIAN UNIV OF TECH

Low weight superhydrophobic wrapping paper and preparation method thereof

The invention relates to a low-quantity super-hydrophobic packaging paper and a preparation method thereof, comprising packaging base paper, a hydrophobic coating, a micron-structure coating and a nano-structure coating; the hydrophobic coating is composed of low melting point wax; the micron structure The coating is composed of high melting point wax; the nanostructure coating is composed of modified nano silicon dioxide. The packaging base paper is obtained by wax emulsion coating and modified silica coating, and then soft roll calendering; the mixed wax is in the state of micron particles, which can fully fill the gaps between the fibers on the surface of the paper; at the same time, the hydrophobic nano-silica particles are filled Between the fiber and the micron wax, a hydrophobic micro-nano structure is formed, which can significantly improve the hydrophobicity of the paper, increase the contact angle and reduce the rolling angle; the whole production process is simple to operate, low energy consumption, environmentally friendly, and does not involve fluorine chemicals or organic solvents. It has a good application prospect.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com