A kind of preparation method of straight conveyor belt finger joint

A technology of finger joints and conveyor belts, which is applied in the field of straight conveyor belt finger joints and its preparation, can solve problems such as the difficulty in solving the strength of conveyor belt joints, achieve the effects of reducing capital investment, reducing maintenance, and improving joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

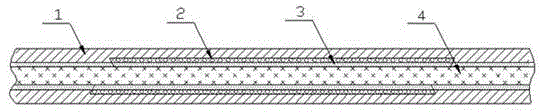

[0028] from figure 1 It can be seen that a straight conveyor belt finger joint of the present invention includes a straight finger skeleton structure 4, which includes a straight canvas layer; There is an adhesive layer 2 on the surface; on the adhesive layer 2 there is a reinforcing fabric layer 3; on the fabric layer 3 there is a covering adhesive layer 1.

[0029] The fabric layer 3 is made of steel screen or aramid mesh cloth. It has high warp strength, small warp density, and obvious gaps between warp threads.

[0030] The length of the fabric layer 3 is 1000mm-3000mm. The strength of the fabric layer 3 is 10%-20% of the strength of the straight conveyor belt.

[0031] The warp direction of the fabric layer 3 is parallel to the warp direction of the straight conveyor belt.

[0032] The thickness of the adhesive layer 2 is 1-2mm.

[0033] The preparation method of described straight through conveyer belt finger joint, comprises the following steps:

[0034] (1) Strip...

Embodiment 2

[0042] from figure 1 It can be seen that a straight conveyor belt finger joint of the present invention includes a straight finger skeleton structure 4, which includes a straight canvas layer; There is an adhesive layer 2 on the surface; on the adhesive layer 2 there is a reinforcing fabric layer 3; on the fabric layer 3 there is a covering adhesive layer 1.

[0043] The fabric layer 3 is made of steel screen or aramid mesh cloth. It has high warp strength, small warp density, and obvious gaps between warp threads.

[0044] The length of the fabric layer 3 is 1500mm-2000mm. The strength of the fabric layer 3 is 10%-20% of the strength of the straight conveyor belt.

[0045] The warp direction of the fabric layer 3 is parallel to the warp direction of the straight conveyor belt.

[0046] The thickness of the adhesive layer 2 is 1-2mm.

[0047] The preparation method of described straight through conveyer belt finger joint, comprises the following steps:

[0048] (1) Strippi...

Embodiment 3

[0056] from figure 1 It can be seen that a straight conveyor belt finger joint of the present invention includes a straight finger skeleton structure 4, which includes a straight canvas layer; There is an adhesive layer 2 on the surface; on the adhesive layer 2 there is a reinforcing fabric layer 3; on the fabric layer 3 there is a covering adhesive layer 1.

[0057] The fabric layer 3 is made of steel screen or aramid mesh cloth. It has high warp strength, small warp density, and obvious gaps between warp threads.

[0058] The length of the fabric layer 3 is 2500mm. The strength of the fabric layer 3 is 10%-20% of the strength of the straight conveyor belt.

[0059] The warp direction of the fabric layer 3 is parallel to the warp direction of the straight conveyor belt.

[0060] The thickness of the adhesive layer 2 is 1-2mm.

[0061] The preparation method of described straight through conveyer belt finger joint, comprises the following steps:

[0062] (1) Stripping of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com