Patents

Literature

30results about How to "Uniform pressure transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

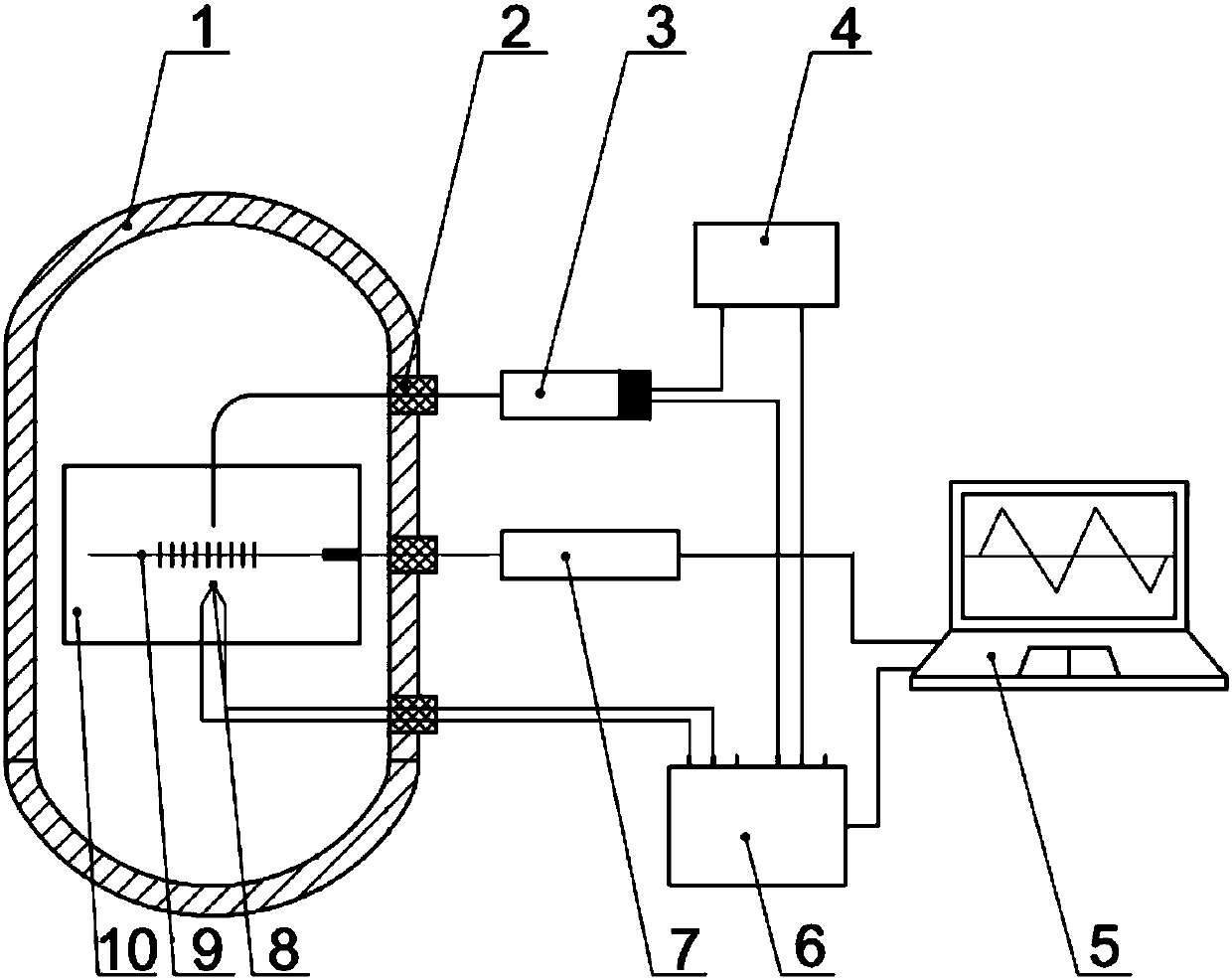

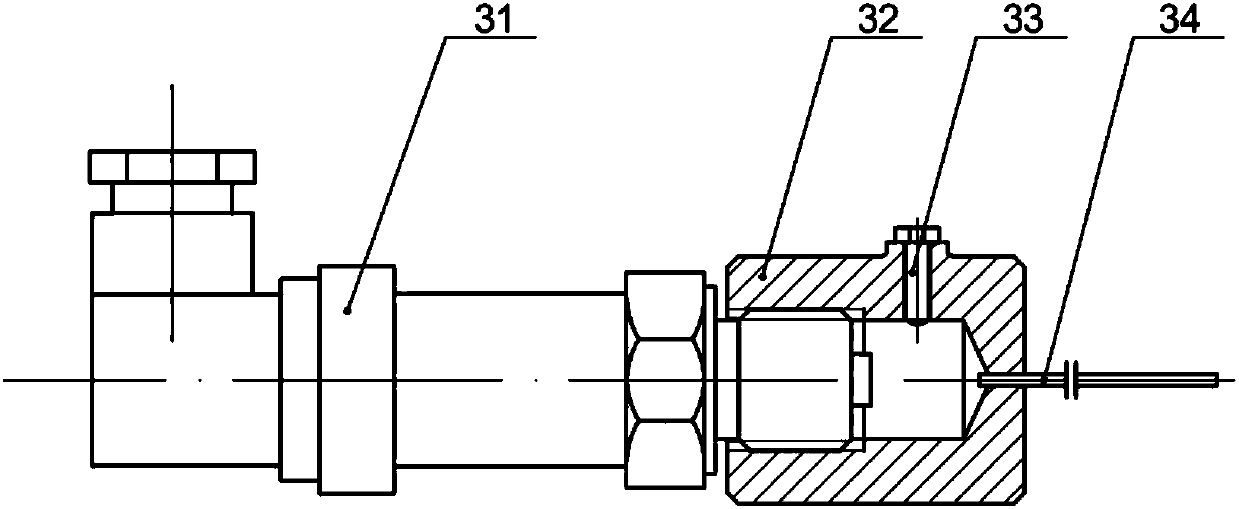

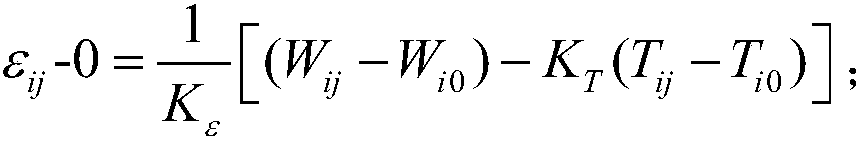

Multi-parameter online monitoring system and method for hot-pressing solidification process of composite material

The invention provides a multi-parameter online monitoring system and method for a hot-pressing solidification process of a composite material, and the system comprises a temperature sensor, an FBG (fiber bragg grating) sensor, an FBG demodulation instrument, a pressure sensor, a data recorder, and an upper computer. A multi-parameter monitoring module operating in the upper computer executes themonitoring. The monitoring method comprises a step of temperature measurement, a step of pressure monitoring, a step of strain monitoring, and a step of stress monitoring. The system and method can achieve the multi-parameter real-time coordinative online monitoring, is high in accuracy, is high in sensitivity, and can continuously and truly reflect the actual conditions of various parameters of the composite material in the hot-pressing solidification process.

Owner:CENT SOUTH UNIV

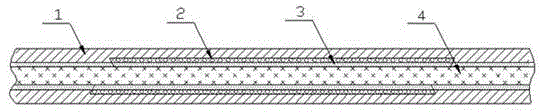

Straight conveyor belt finger-model connector and preparation method thereof

ActiveCN103072786AIncreased warp strengthHigh warp strengthConveyorsBeltsAdhesive cementStructural engineering

The invention belongs to the technical field of a rubber conveyor belt product, and particularly relates to a straight conveyor belt finger-model connector and a preparation method thereof. The straight conveyor belt finger-model connector comprises a straight finger-model skeleton structure, wherein the straight finger-model skeleton structure comprises a straight canvas layer; a rubberizing layer is arranged on the surface of the straight finger-model skeleton structure; a textile layer playing a reinforcement effect is arranged on the rubberizing layer; and a coverage rubber layer is arranged on the textile layer. The preparation method of the straight conveyor belt finger-model connector comprises the following steps of (1) stripping coverage adhesive; (2) removing residual adhesive; (3) cutting a finger model; (4) coating adhesive cement; (5) splicing the finger model; (6) forming a finger-model connector; and (7) vulcanizing the finger-model connector. Due to the adoption of the straight conveyor belt finger-model connector, the strength of the connector is improved; and the preparation method is simple and easy to operate.

Owner:YANKUANG GRP CO LTD +1

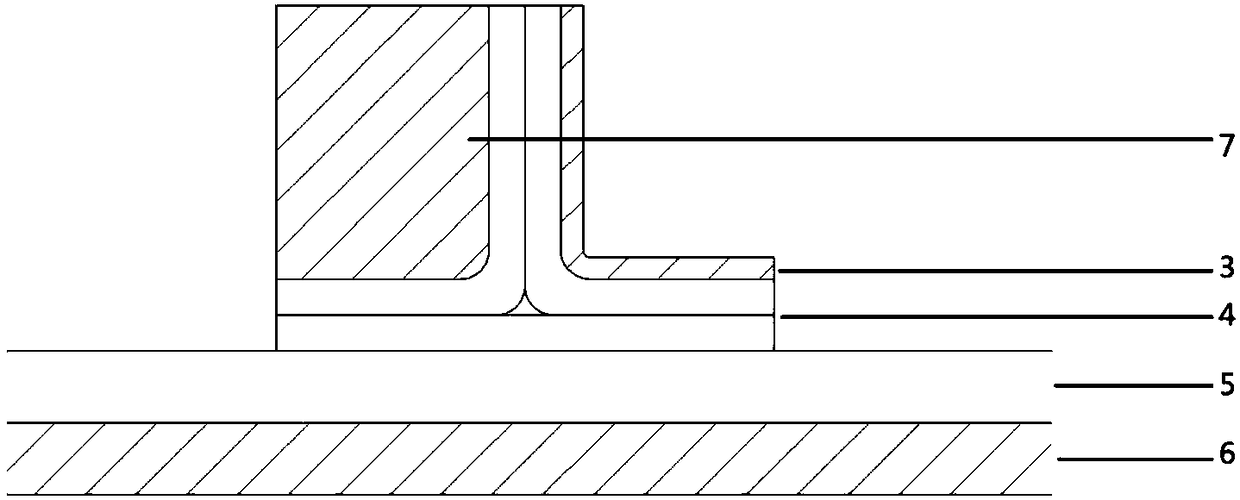

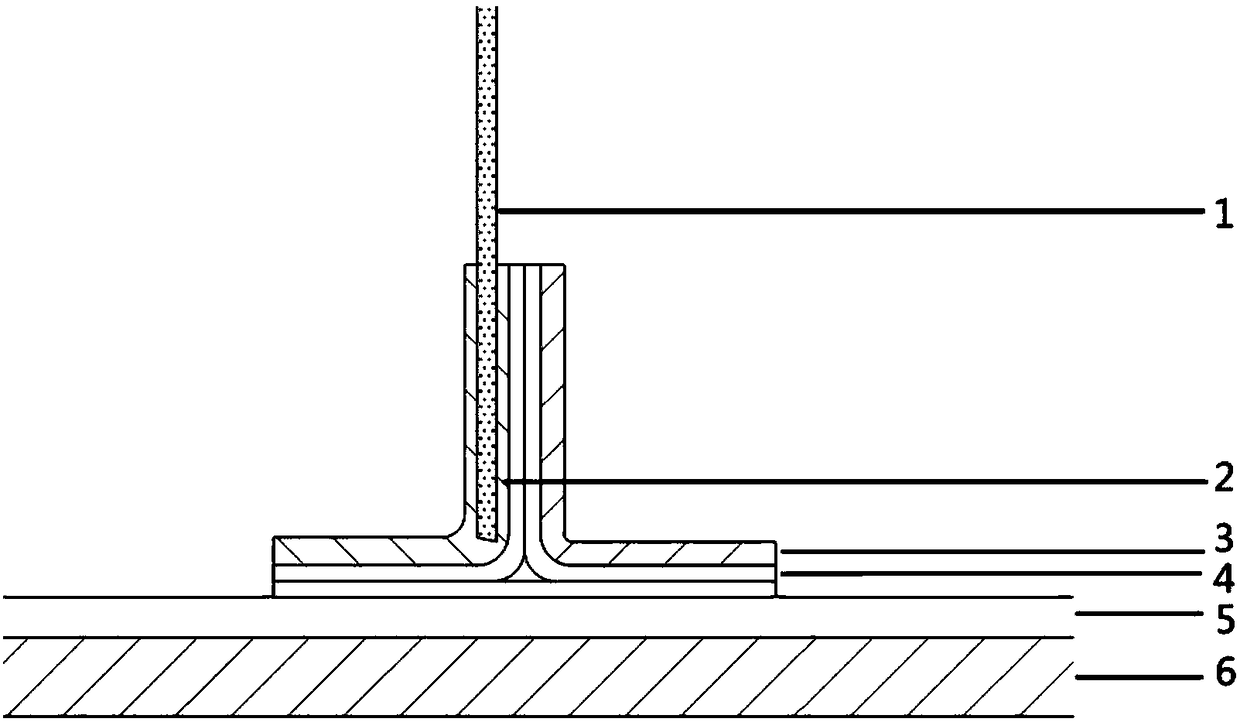

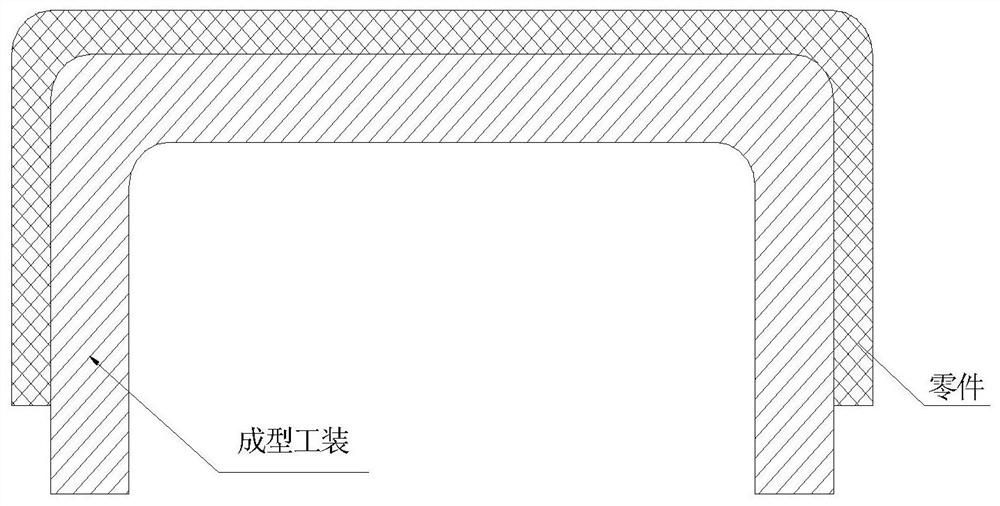

Forming method suitable for T-shaped and L-shaped composite material wall plates

The invention belongs to the technical field of forming of composite materials, and relates to a forming method suitable for T-shaped and L-shaped composite material wall plates. A forming mode combining a soft film positioning plate and a soft film is adopted, a fit clearance does not exist, pressure transmission is uniform, and the internal quality of formed wall plates is good. There are only afew molds in a vacuum bag, heat transferring is uniform, and the uniformity of a temperature field is good. The number of molds entering a tank is small, a soft film forming mold is low in precisionand does not need to enter the tank, and the overall mold cost is low. The assembling clearance is small, the forming quality is good, and the forming method is suitable for wall plates with large skin thickness change or large skin shape change. By means of the forming method suitable for T-shaped and L-shaped composite material wall plates, the internal quality of composite material wall platesformed through the method is high, studs are high in position precision, and the forming method is particularly suitable for forming wall plates with complex surfaces and many variable-thickness areas, and lays a certain technical foundation for development of composite materials.

Owner:AVIC COMPOSITES

Wall board structure of fixed hydraulic balance extra large storage tank

ActiveCN102229377ASolve the problem of running down rainwaterReduce construction costsLarge containersEngineeringBoard structure

The invention relates to a wall board structure of a fixed hydraulic balance extra large storage tank. The structure comprises an inner tank and an outer tank, wherein the inner tank is used for storing materials; the outer tank is wrapped by the inner tank; a distance is arranged between the outer side wall of the inner tank and the inner side wall of the outer tank so as to form an annular space for containing liquid for balancing pressure; and the structure is characterized in that a plurality of structural steel connecting pieces for improving the bearing capability of the side wall of the inner tank are arranged between the inner side wall of the outer tank and the outer side wall of the inner tank. Compared with the prior art, the invention really realizes the manufacturing of an extra storage tank, has the advantages of low the manufacturing cost, and ensures the welding quality.

Owner:CHINA PETROLEUM & CHEM CORP +2

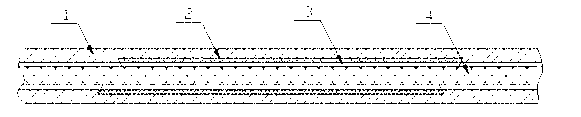

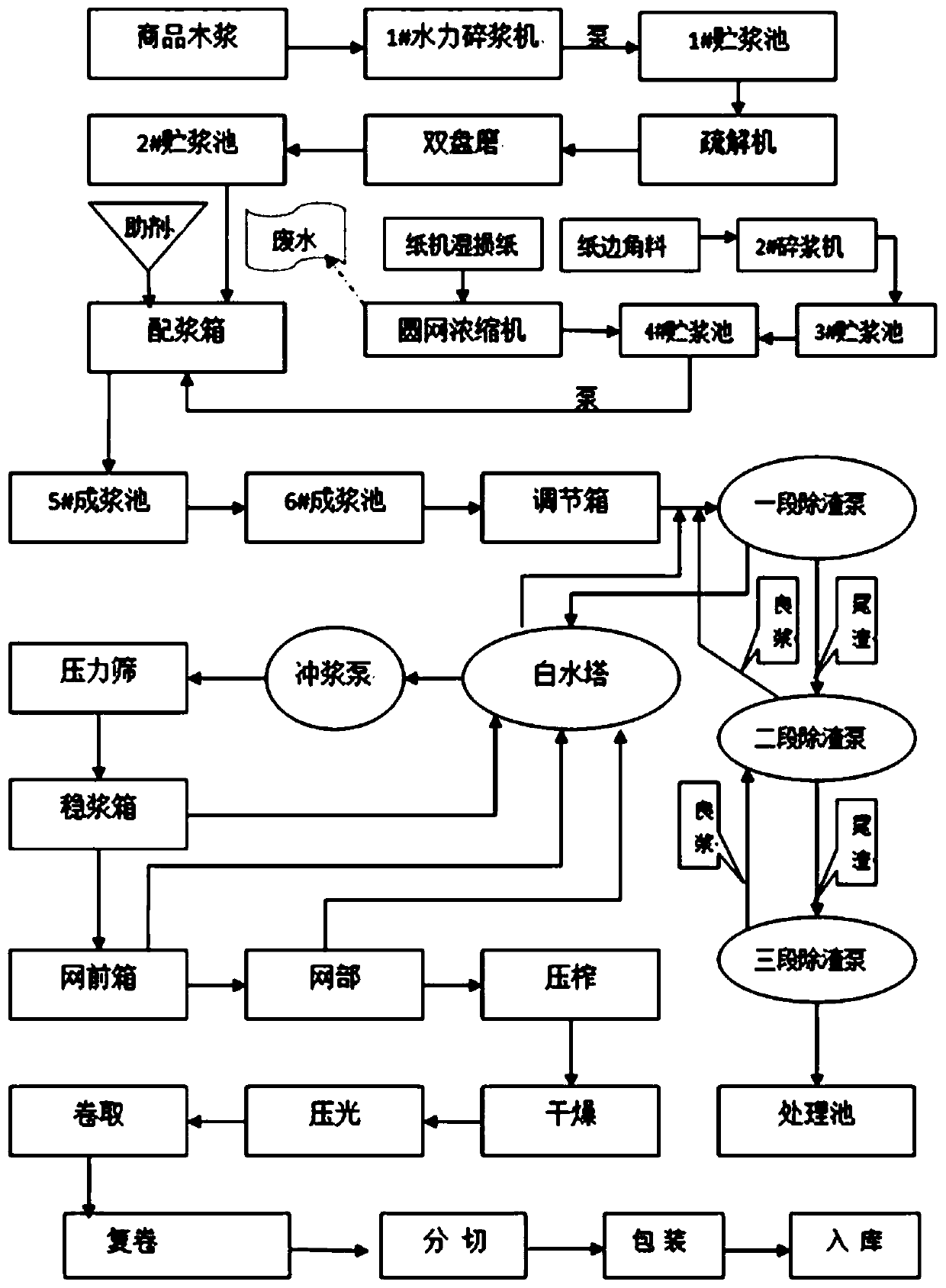

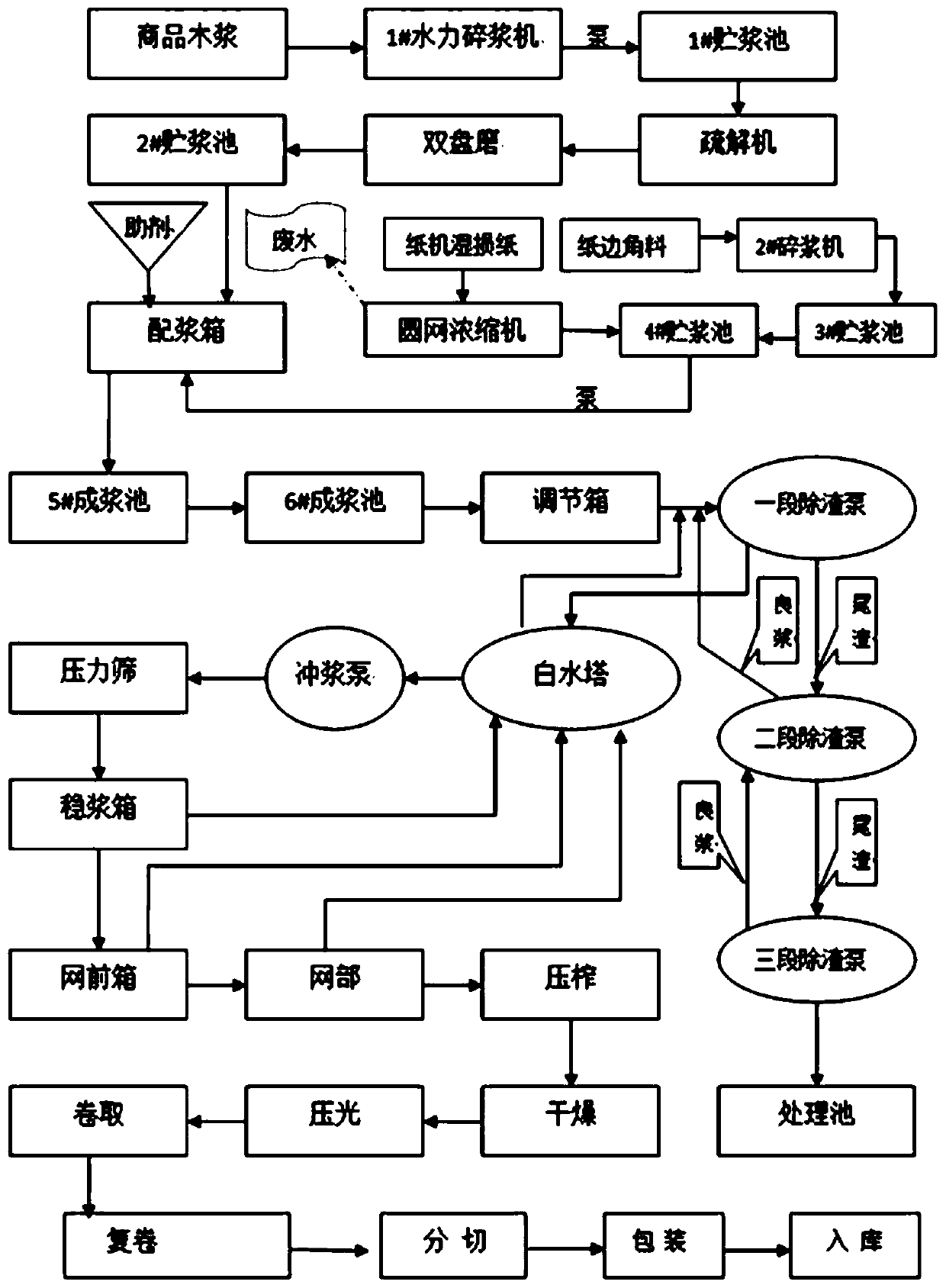

Production process of hot-pressing tympan paper taking pressing copper-clad plate as cushion layer as well as application of hot-pressing tympan paper

Hot-pressing tympan paper taking a pressing copper-clad plate as a cushion layer takes natural-color needlebush pulp, natural-color broadleaf wood pulp and kraft paper leftover materials as fiber rawmaterials; short fiber free pulping is adopted; the current of a pulping machine, the beating degree and the wet weight are controlled; finally, the quantity is 192+ / -4 g / m<2>, the thickness is 0.320+ / -0.02 mm, the tensile strength is more than or equal to 10 KN / m, the air permeability is more than or equal to 10 [mu]m / pa*s, the folding resistance is more than or equal to 10 times, the water-absorbing property is more than or equal to 100 mm / min, and the tightness is controlled to 550 to 600 kg / m<3>. Through cell cavity filling, on one hand, the fiber raw materials are reduced and the cost isgreatly saved; and on the other hand, fillers are added into the cell cavities, so the paper strength is not influenced. Therefore, the hot-pressing tympan paper has double advantages of improving theproperties of the tympan paper and reducing the cost.

Owner:建滔(佛冈)绝缘材料有限公司

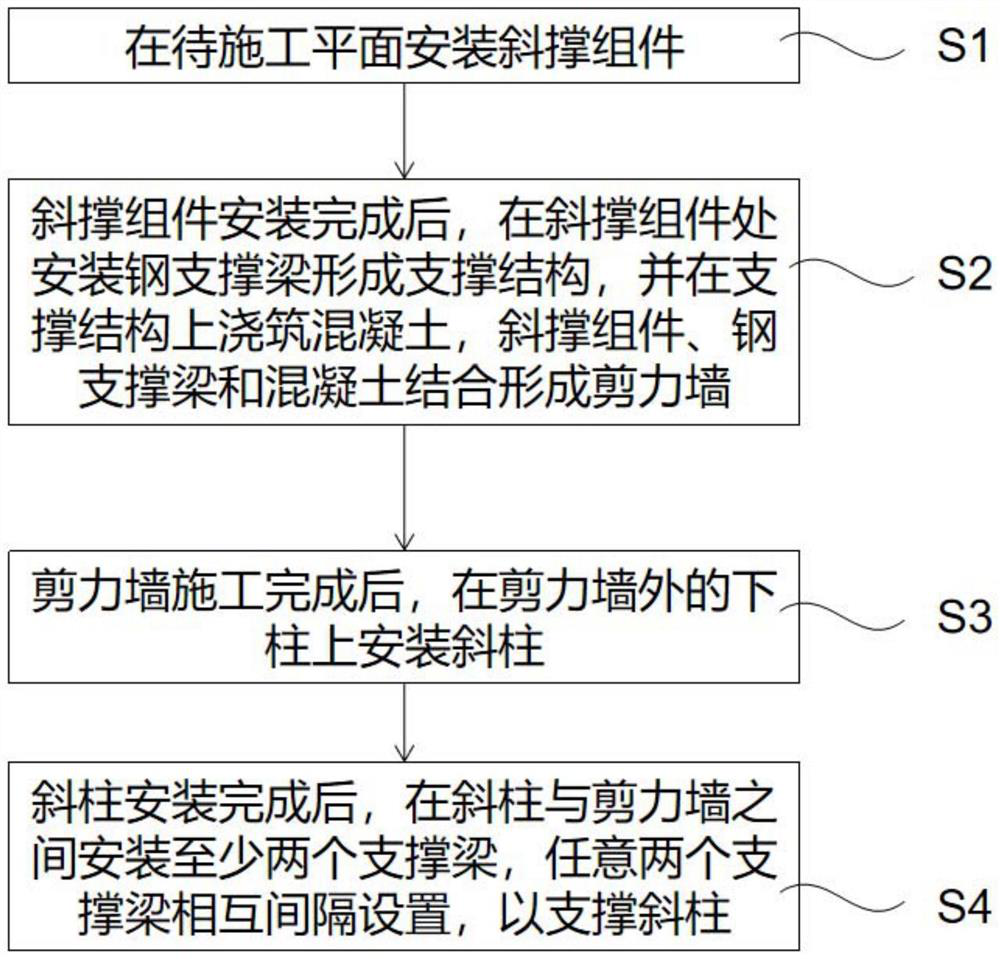

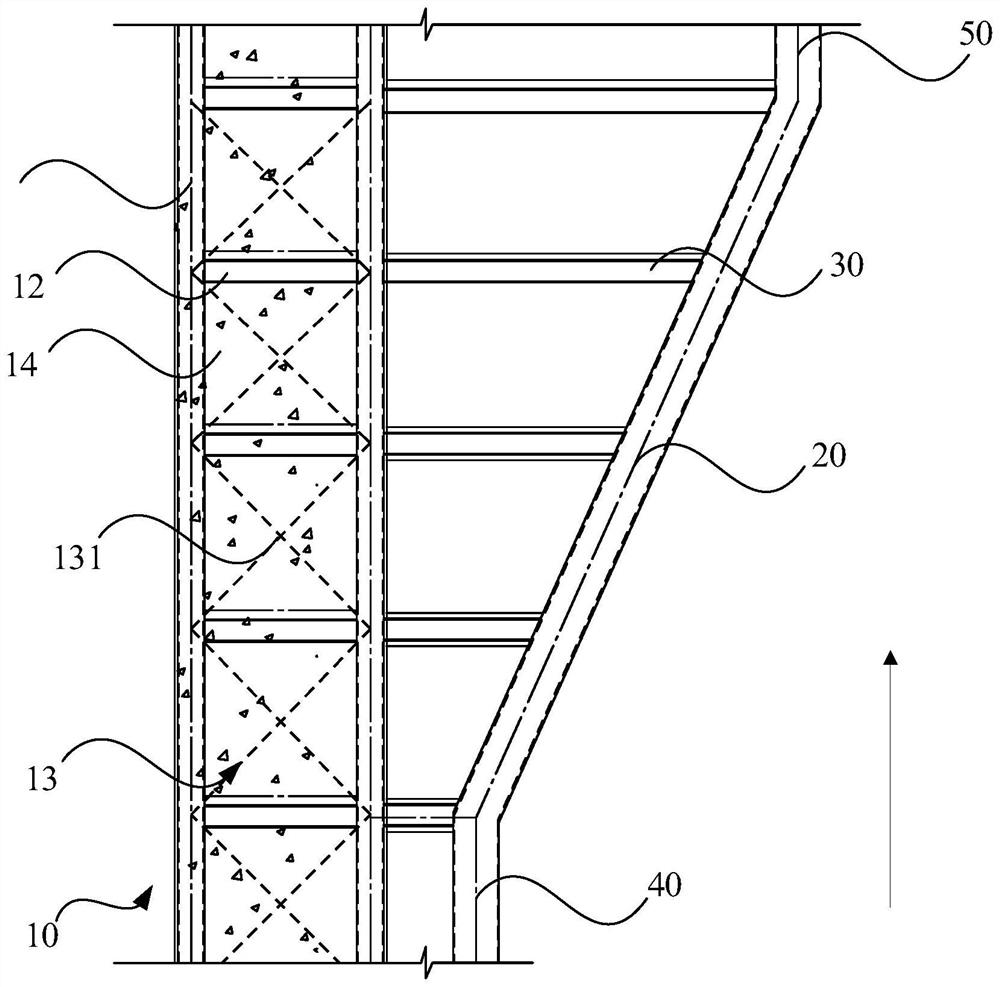

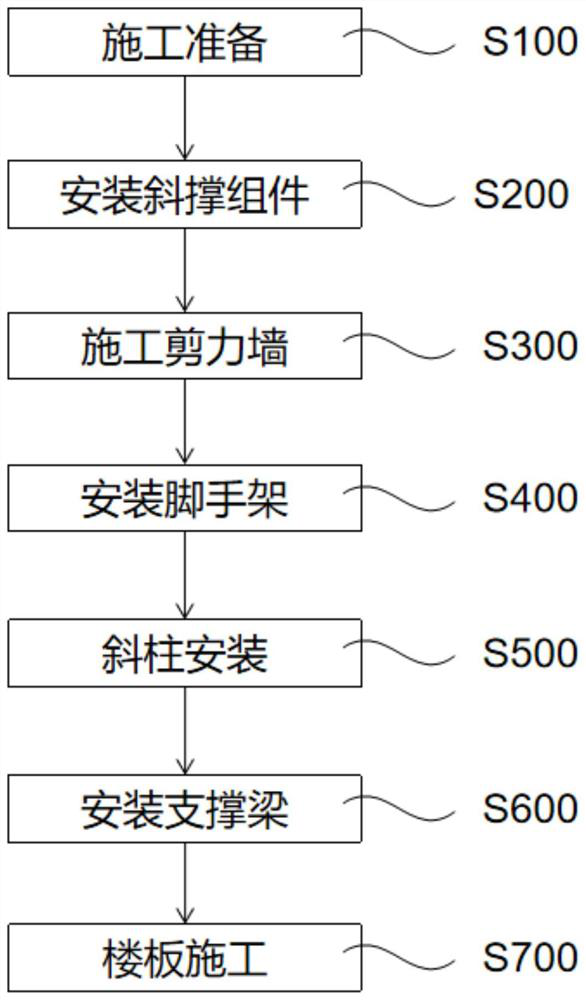

Construction method of inclined column conversion frame shear wall structure

PendingCN114232841AEasy to installStable construction platformWallsBuilding material handlingArchitectural engineeringStructure support

The invention discloses a construction method of an inclined column conversion frame shear wall structure. The construction method comprises the following steps that inclined strut assemblies are installed on a to-be-constructed plane; after the inclined strut assemblies are installed, steel supporting beams are installed at the inclined strut assemblies to form a supporting structure, concrete is poured on the supporting structure, and the inclined strut assemblies, the steel supporting beams and the concrete are combined to form a shear wall; after construction of the shear wall is completed, inclined columns are installed on the lower columns outside the shear wall; after the batter post is installed, at least two supporting beams are installed between the batter post and the shear wall, and any two supporting beams are arranged in a spaced mode so as to support the batter post. And the diagonal bracing assembly improves the shear bearing capacity of the shear wall. The bearing force transmitted by the upper column is transferred into the force in the horizontal direction through the inclined column, the force is transmitted into the shear wall through the supporting beam, the force is transmitted and dispersed in cooperation with the inclined strut assembly, the overall structure is simple and reasonable, the shear bearing capacity is high, the connection reliability is ensured, and the problem that concrete cracks are caused by large horizontal force generated by inclination of the inclined column is solved.

Owner:广州市设计院集团有限公司

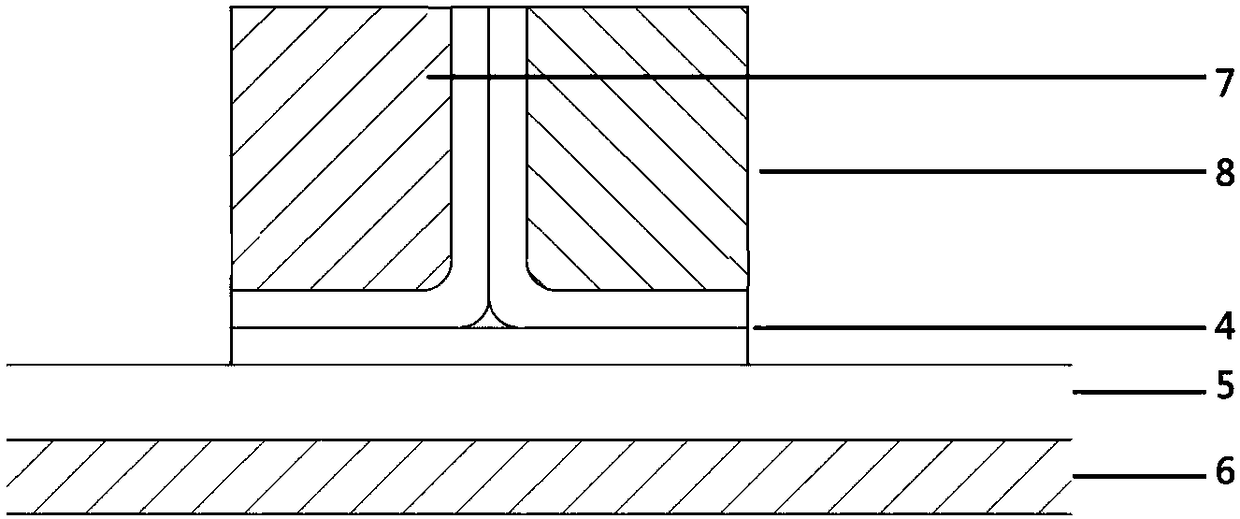

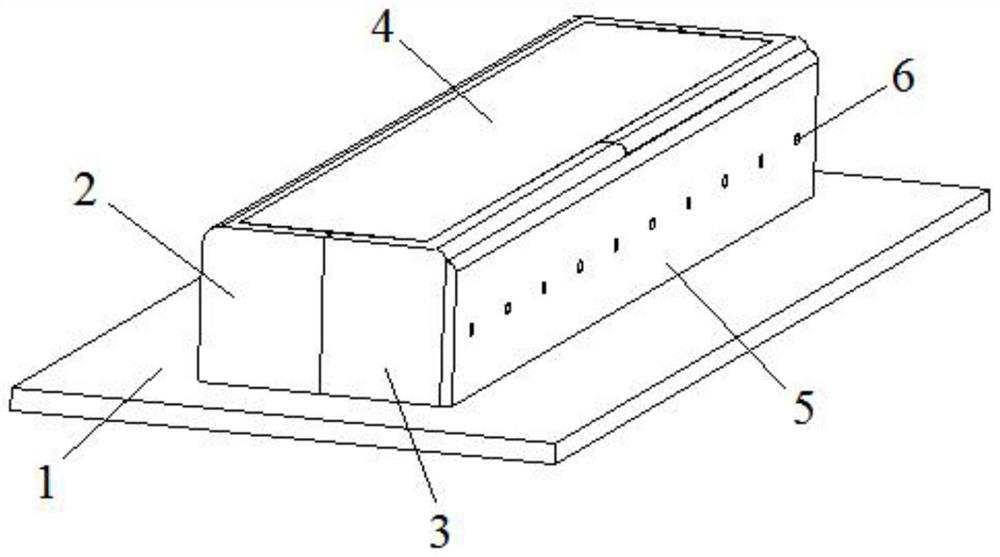

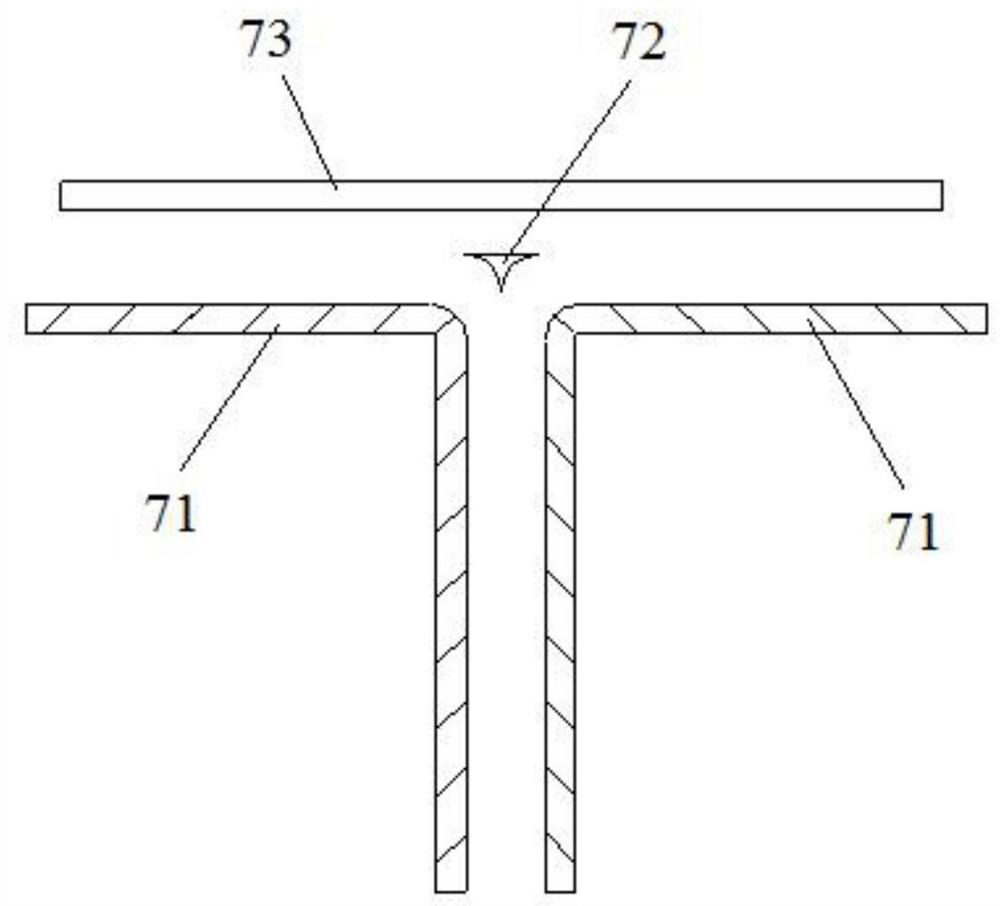

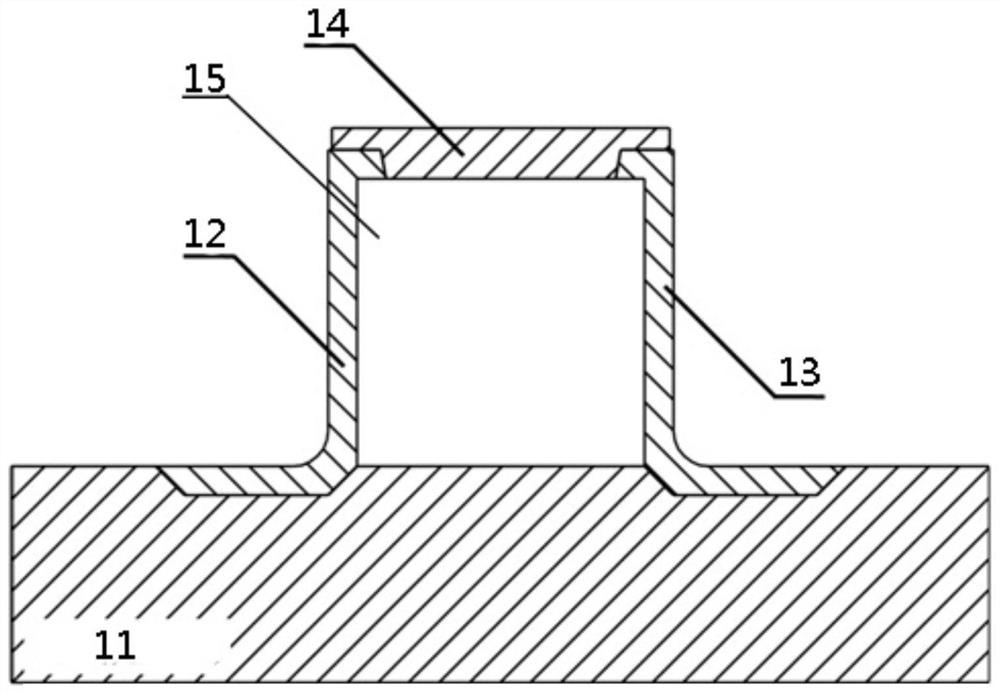

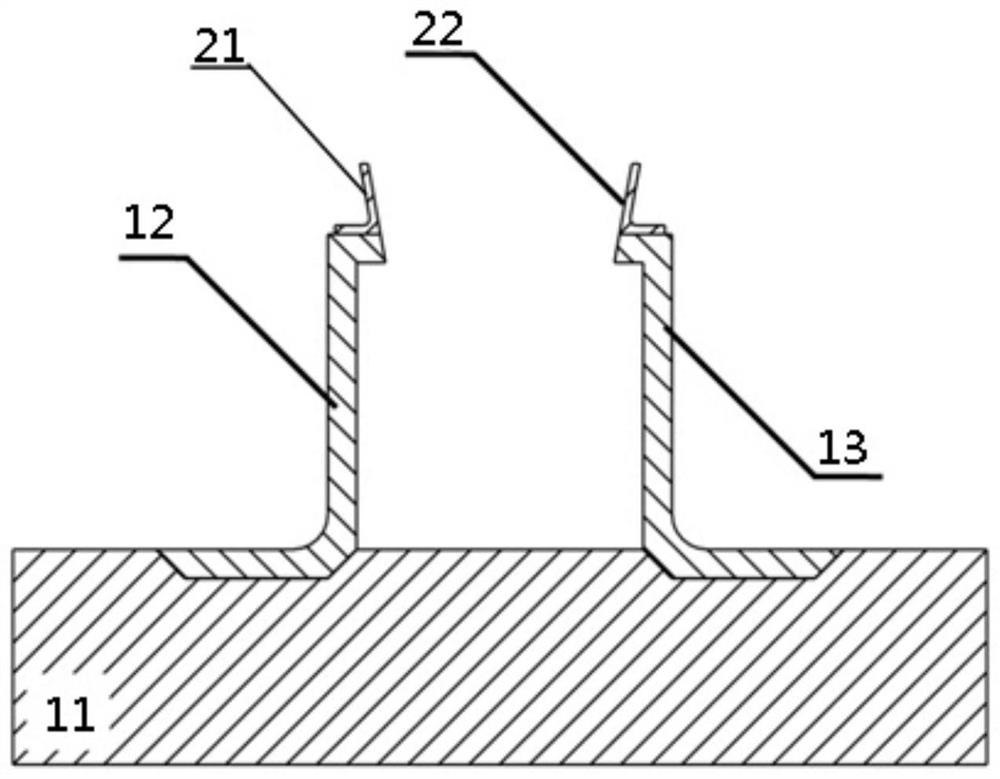

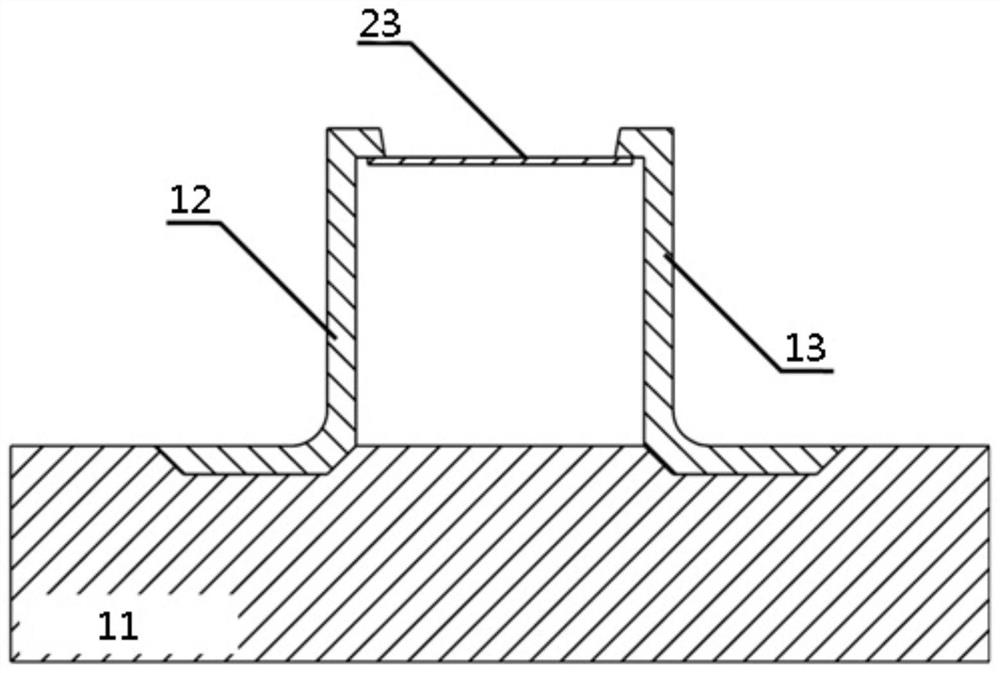

Forming device and forming method for T-shaped composite material part with high resin fluidity

ActiveCN112895510AControl flow behaviorPrecise alignmentWeight reductionDomestic articlesMechanical engineeringMold removal

The invention discloses a forming device and method for a T-shaped composite material part with high resin fluidity, and relates to the field of composite material part manufacturing. The forming device comprises a bottom plate, a fixed core mold, a movable core mold, a uniform pressing plate, a positioning adjusting assembly and a plurality of sealing rubber strips, the fixed core mold is fixed on the bottom plate, the movable core mold is movably installed on the bottom plate through the positioning adjusting assembly, a first inverted-L-shaped groove is formed in the side, close to the movable core mold, of the fixed core mold, a second inverted-L-shaped groove is formed in the side, close to the fixed core mold, of the movable core mold, the first inverted-L-shaped groove and the second inverted-L-shaped groove are symmetrically formed and are the same in structure, the multiple sealing rubber strips are used for being arranged on the bottom of the vertical section and the periphery of the horizontal section of the T-shaped composite material part with high resin fluidity, and the uniform pressing plate is used for being placed on the top of the T-shaped composite material part with high resin fluidity. The forming device and the forming method can effectively control the flowing behavior of the resin in the curing process, ensure the internal quality, and are simple to use, convenient to demold and low in cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Co-curing molding process for double-sided reinforced fuselage frame of composite materials

The invention provides a co-curing forming technological method for a composite fuselage frame body with ribs added to the two sides. The method comprises the steps of 1, manufacturing a soft mould forming tool; 2, manufacturing a soft mould; 3, laying, attaching and assembling the T-shaped ribs; 4, positioning the ribs of a first side; 5, laying and attaching a laminated board; 6, conducting overturning and positioning; 7, positioning the ribs of a second side; 8, making vacuum bags; 9, overturning and fixing a rigid forming tool; 10, conducting curing; and 11, conducting demoulding. By means of the co-curing forming technological method, the laminated board and the ribs at the two sides can be co-cured; curing of all components can be completed through one-step potting; manufacturing cost is lowered; the manufacturing process is simplified; and product quality can also be guaranteed.

Owner:COMAC +1

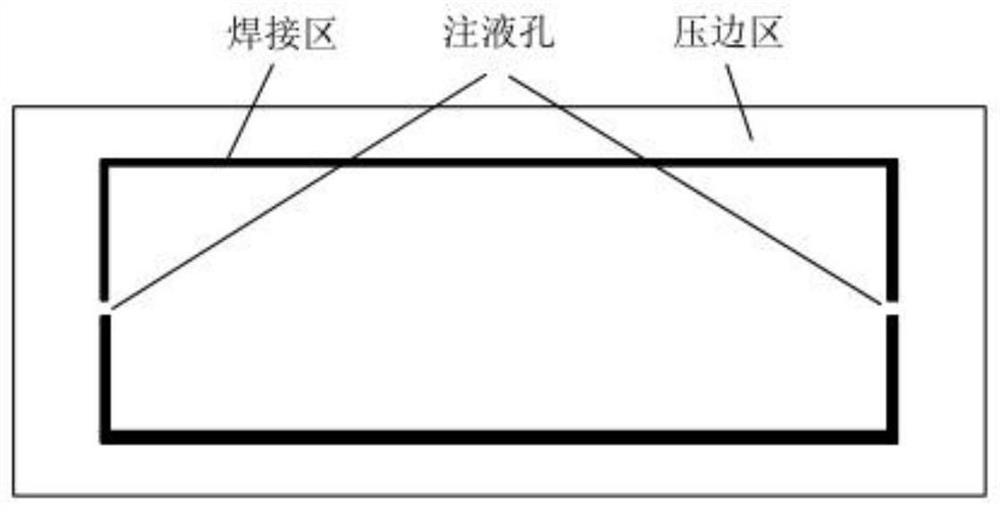

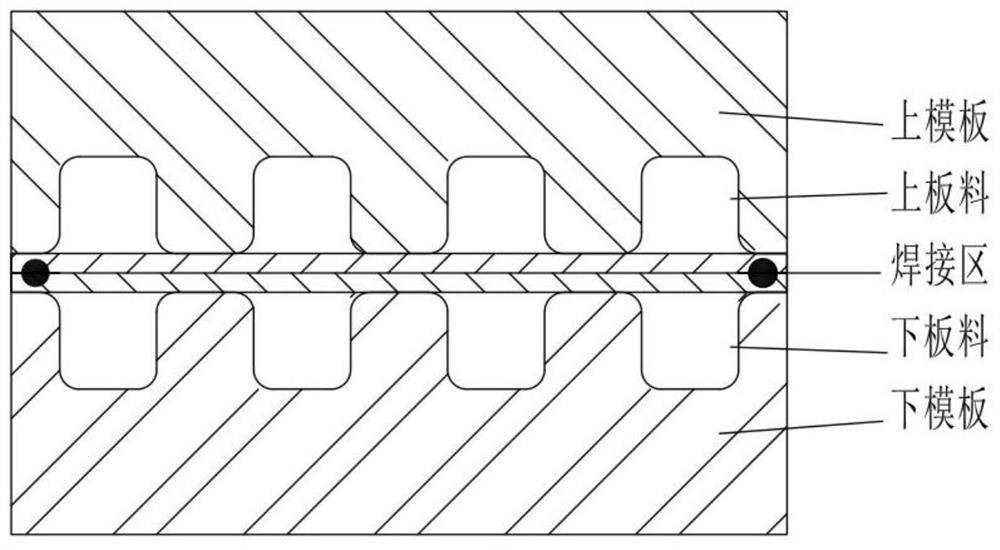

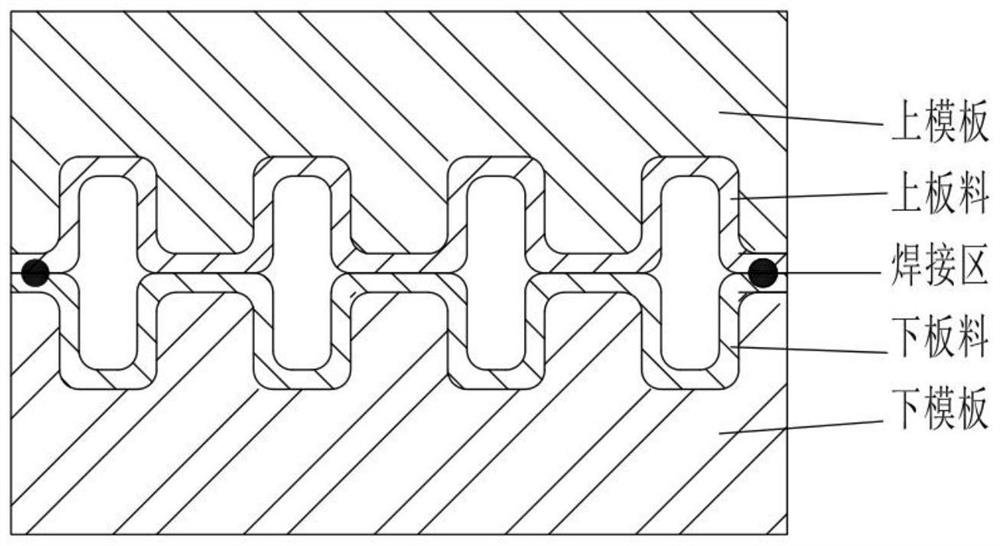

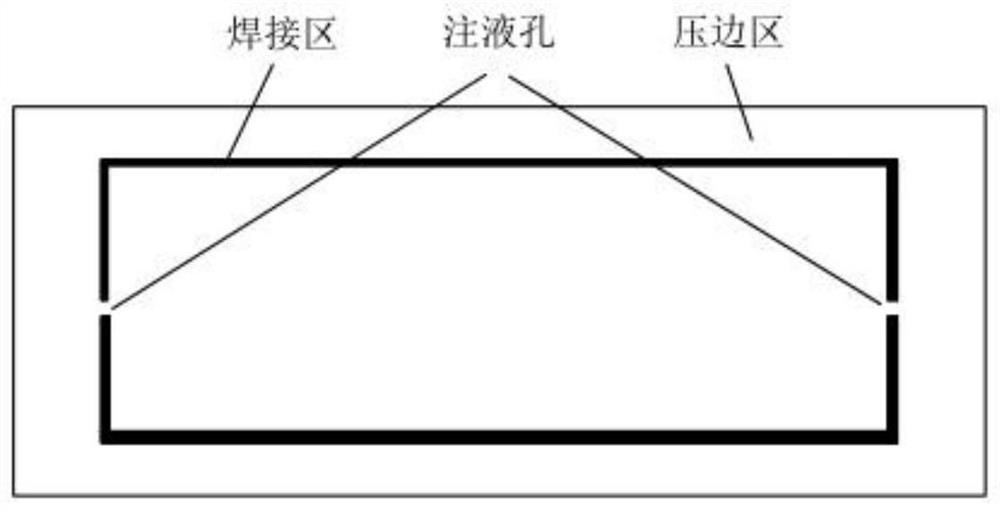

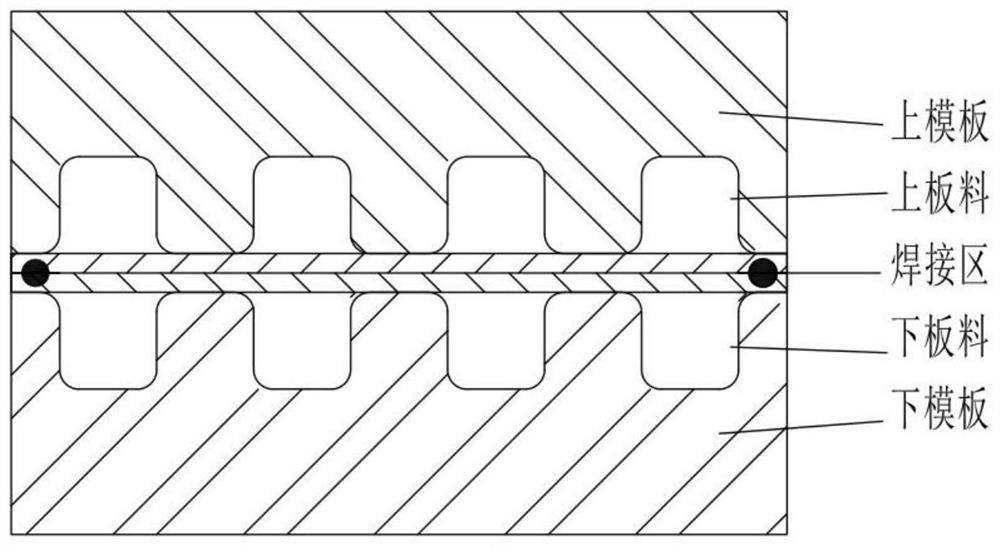

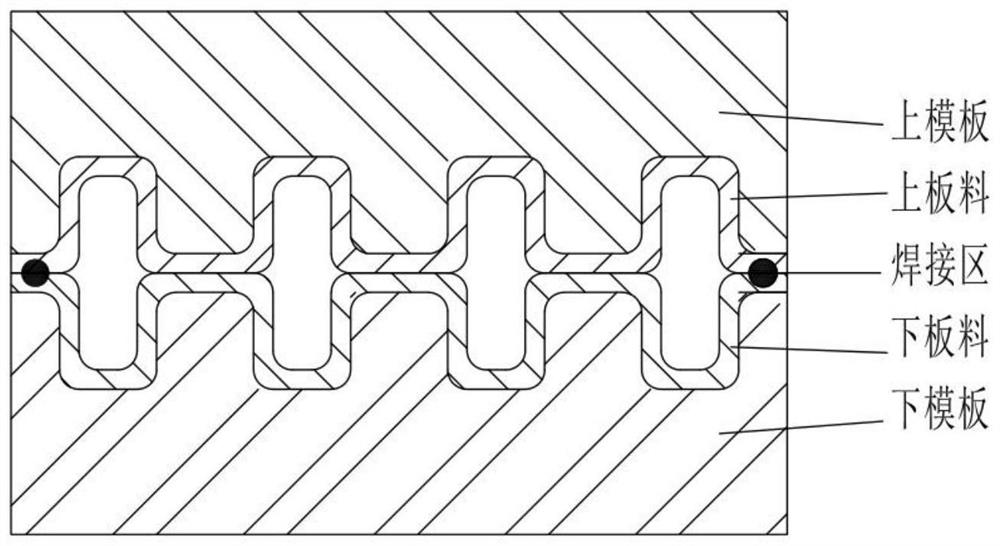

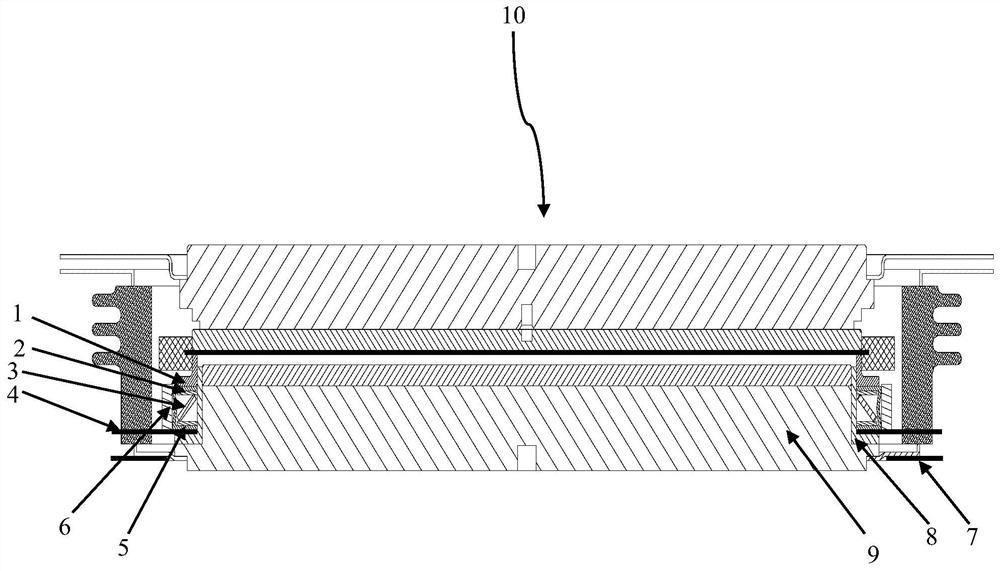

Preparation method of metal bipolar plate of proton exchange membrane fuel cell

ActiveCN112993301AGuaranteed CorrosionEnsure consistencyCollectors/separatorsHydroformingProton exchange membrane fuel cell

The invention relates to the technical field of fuel cells, and provides a preparation method of a metal bipolar plate of a proton exchange membrane fuel cell. According to the invention, the metal bipolar plate is prepared by adopting a method of firstly coating, then welding and finally hydroforming, so that the uniform thickness of the coating can be ensured, and the consistency of corrosion resistance and contact resistance of each part of the bipolar plate is ensured; and when the two layers of metal plates are welded, one non-welding area is reserved on each of the two sides, during hydraulic forming, the non-welding areas serve as liquid injection holes to inject high-pressure liquid between the two layers of metal plates, under the action of hydraulic pressure, the upper layer of metal plate is attached to the cavity wall of an upper mold plate, and the lower layer of metal plate is attached to the cavity wall of a lower mold plate, so a cathode plate and an anode plate are formed at the same time. When the method is adopted for hydraulic forming, the coating cannot be damaged, the formed runner is high in precision, the product percent of pass is high, and simultaneous forming of the cathode plate and the anode plate is achieved for the first time.

Owner:UNIV OF JINAN +1

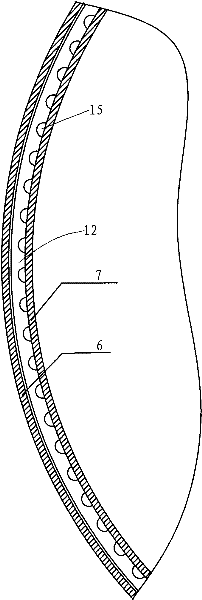

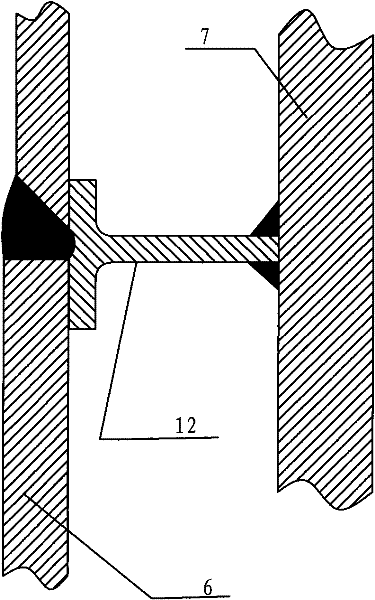

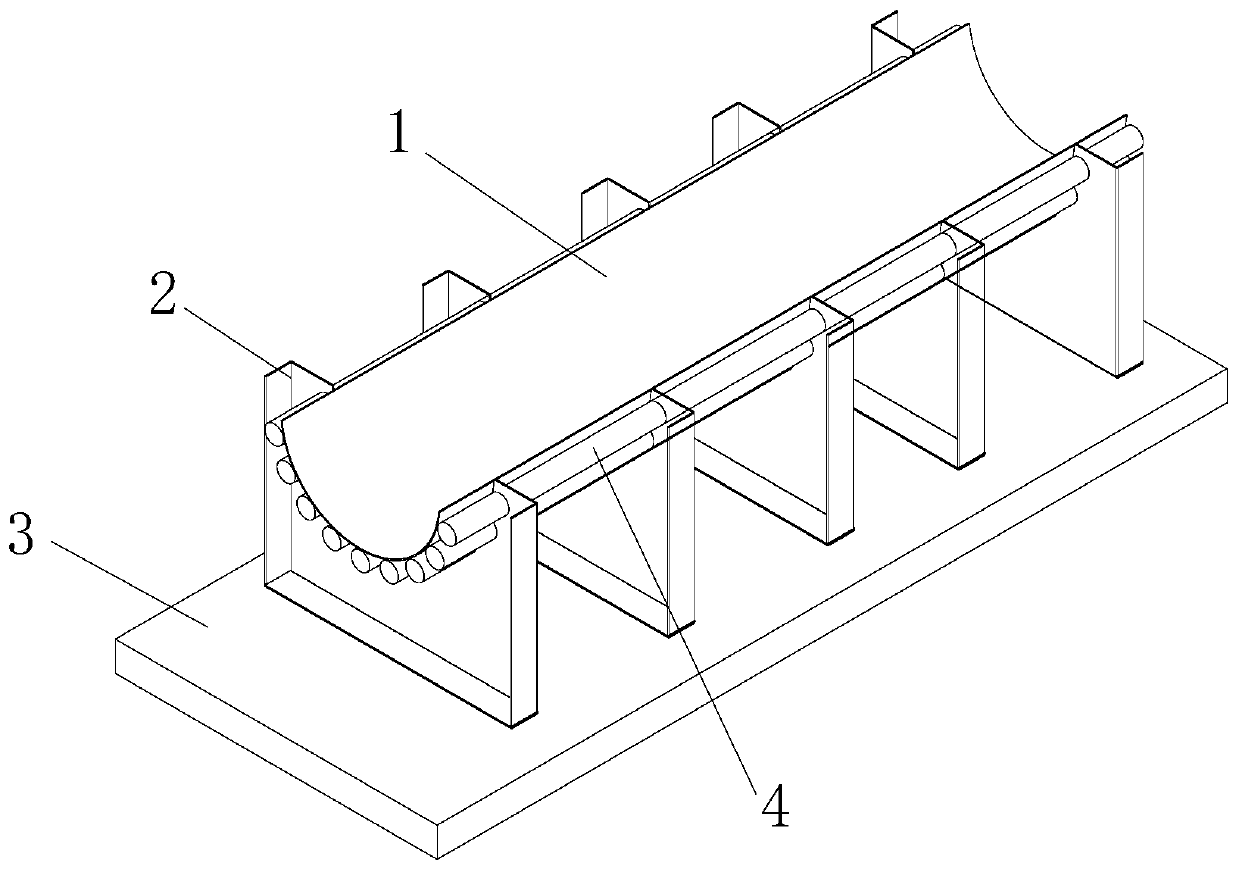

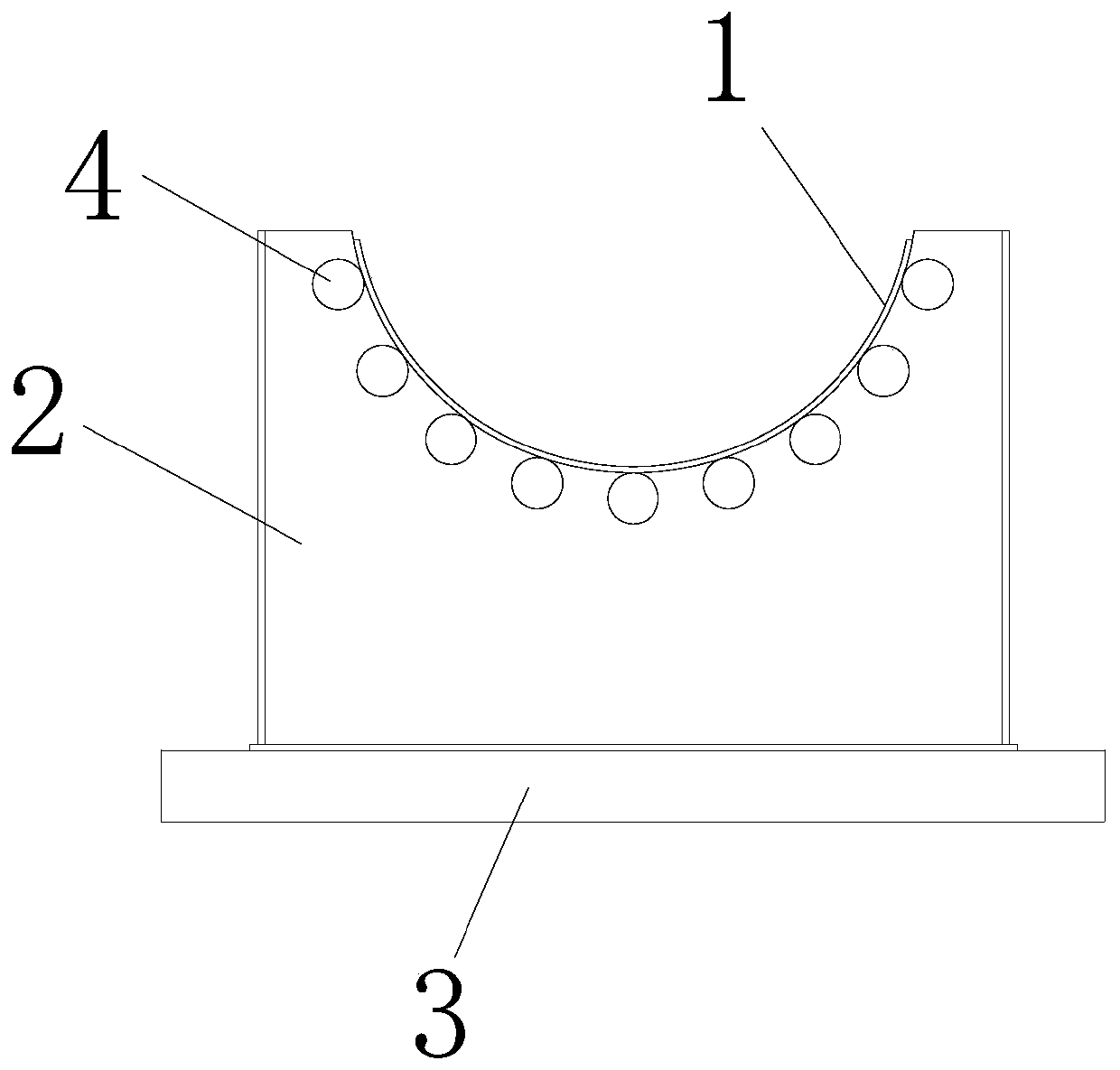

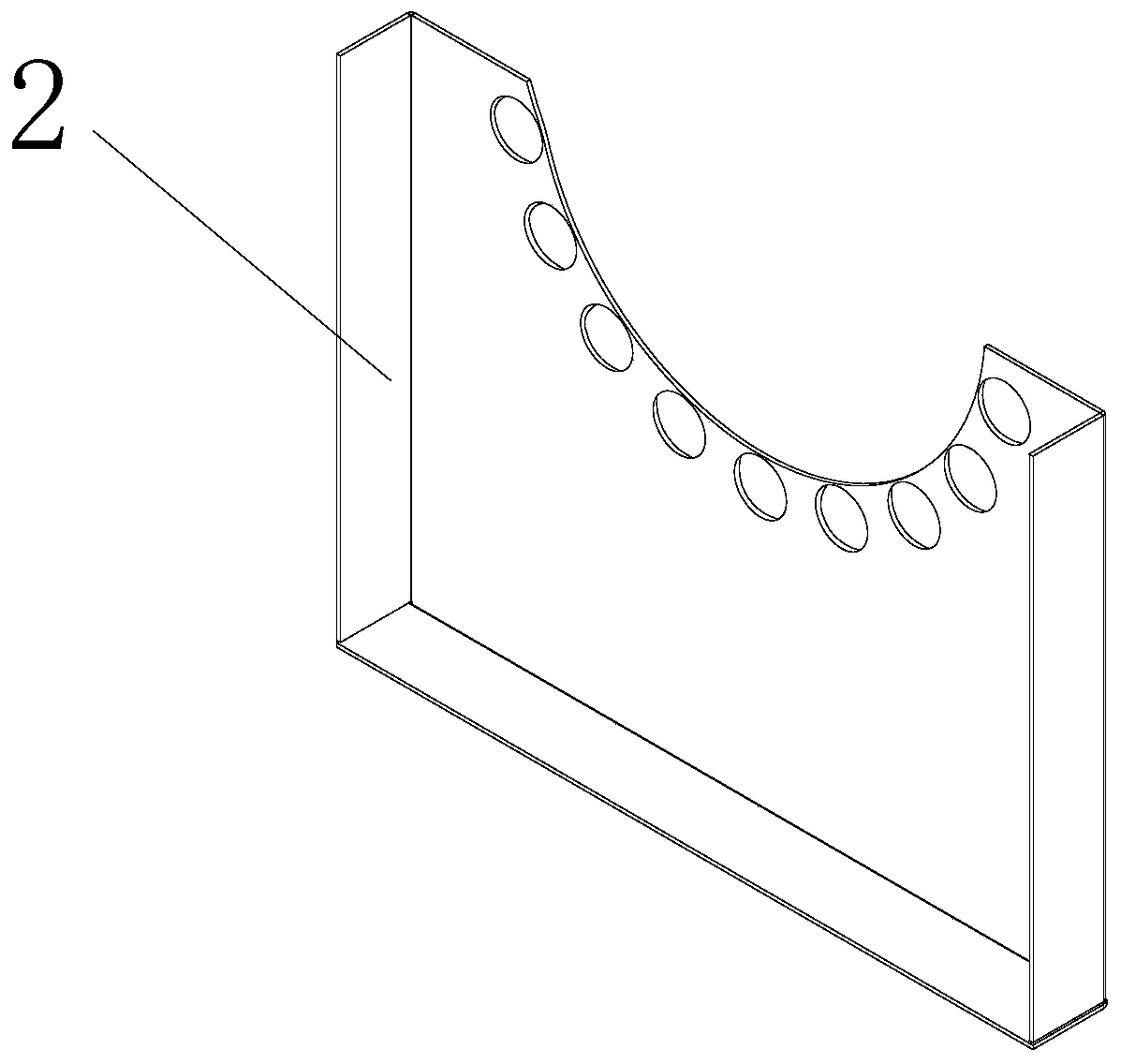

Mold and thermal compounding process used for arc-shaped plate of metal composite curtain wall

ActiveCN110142338AGuaranteed not to deformHigh bonding strengthShaping toolsLayered product treatmentThermal expansionAssembly line

The invention discloses a mold used for an arc-shaped plate of a metal composite curtain wall. The mold comprises an arc mold surface, bearing platform supports, a mold base and a mold surface bearingplatform. The invention further discloses a thermal compounding process used for the arc-shaped plate of the metal composite curtain wall. According to the mold and the thermal compounding process used for the arc-shaped plate of the metal composite curtain wall, the mold is designed to be small, exquisite and flexible, so that automatic production assembly line work is achieved cooperatively, and the automation degree is effectively improved; the whole mold is convenient to assemble and disassemble,90% ore more of materials can be used repeatedly, and the rest of the materials can be used again after being processed for the second time, so that material waste of the mold is minimized, and the manufacturing cost is reduced; the whole mold is made from metal materials, so that the heat conductivity is good, the unique cavity design ensures direct conduction of the temperature, it is guaranteed that heat is efficiently transferred onto products from a heating device through a hot-pressing compounding device, and the pressing time of the products is shortened; and through the structure of the mold and the point-type fixing mode of the edges, uniform release of stress during thermal expansion and cold contraction is guaranteed, and local deformation is avoided.

Owner:SHANDONG HONGXING NEW MATERIAL TECH CO LTD

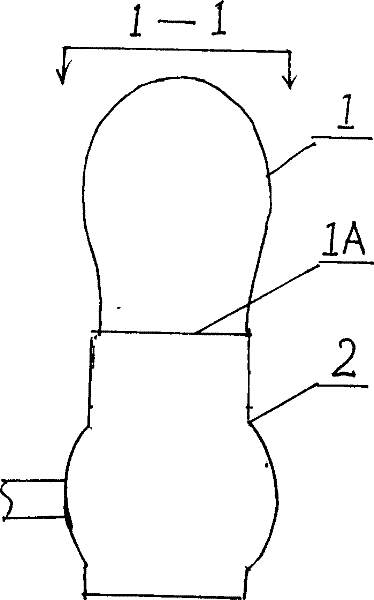

Forming tool and method for preparing rectangular hollow composite tubular member by using forming tool

ActiveCN111873478ARealize pavementAvoid manufacturing processTubular articlesStructural engineeringMechanical engineering

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

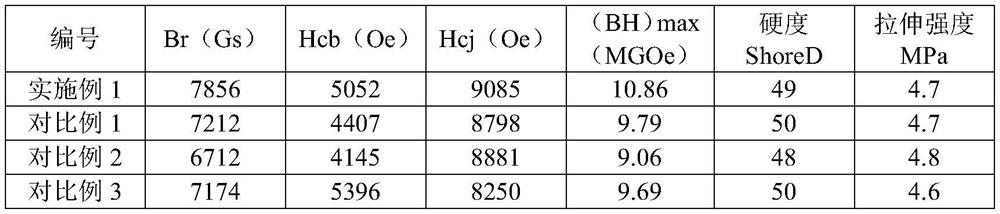

Flexible neodymium-iron-boron magnet as well as preparation method and application thereof

PendingCN112563011AEasy to fillImprove magnetic propertiesMagnetic materialsPermanent magnet manufactureVulcanizationMixed materials

The invention discloses a flexible neodymium-iron-boron magnet as well as a preparation method and application thereof. The preparation method of the flexible neodymium-iron-boron magnet comprises thefollowing steps: mixing neodymium-iron-boron magnetic powder, rubber and auxiliary materials; crushing and tabletting the mixed material to obtain a sheet; carrying out heating and magnetic field orientation on the sheet; and calendering, vulcanizing and carrying out surface treatment to obtain the flexible neodymium-iron-boron magnet. Magnetic field orientation is carried out on the high-temperature neodymium-iron-boron sheet by heating the sheet, the magnetic performance of the flexible neodymium-iron-boron magnet can be effectively improved, and the obtained flexible neodymium-iron-boron magnet has good magnetic performance, mechanical performance and corrosion resistance.

Owner:GUANGZHOU GOLDEN SOUTH MAGNETIC MATERIAL

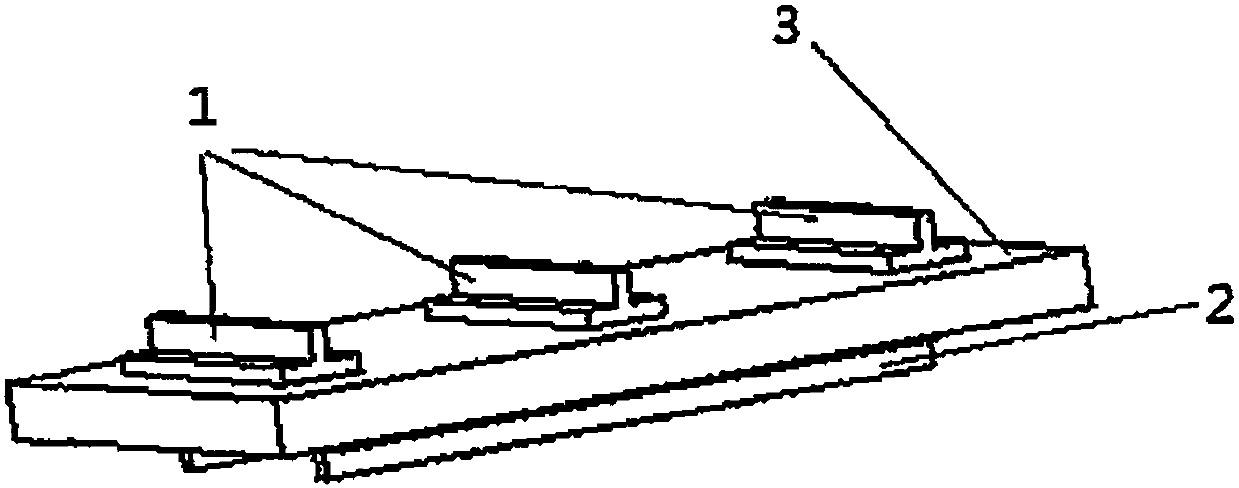

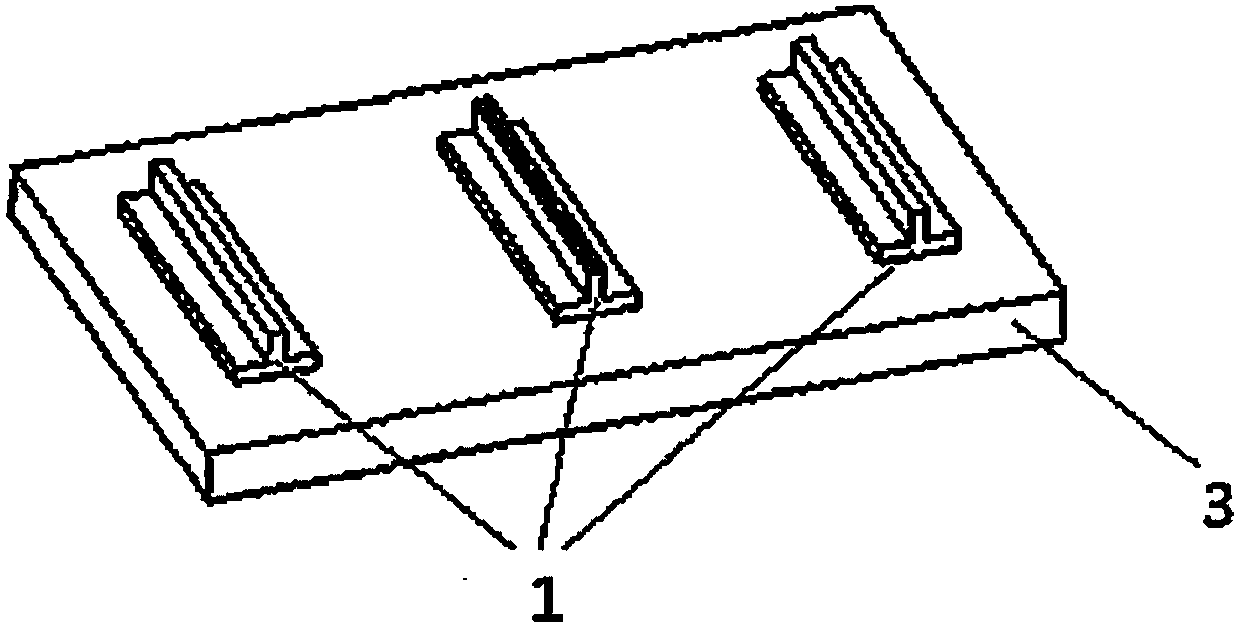

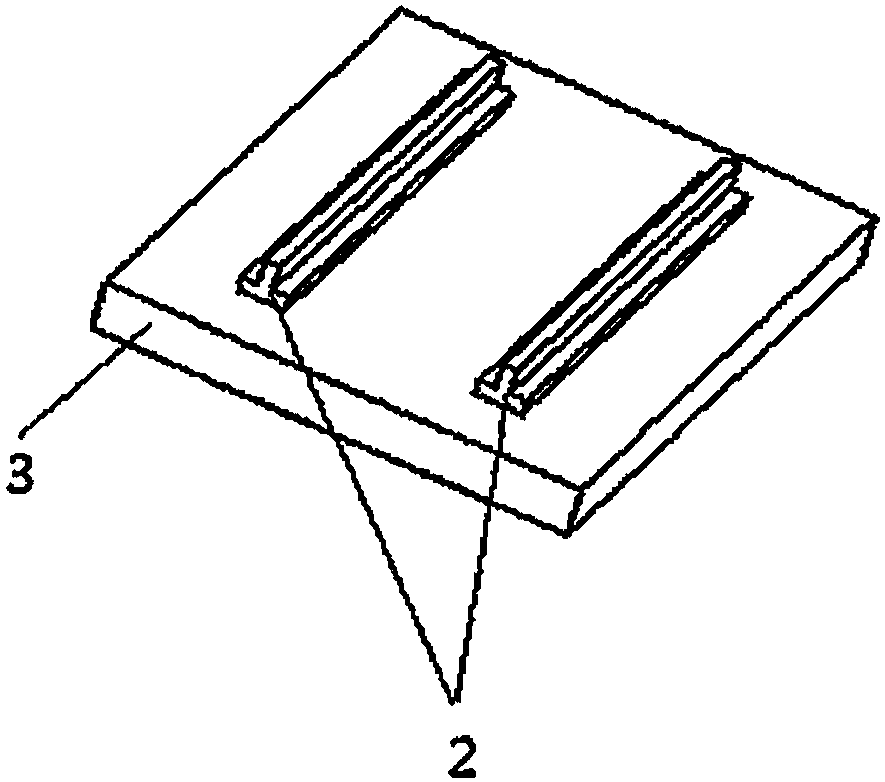

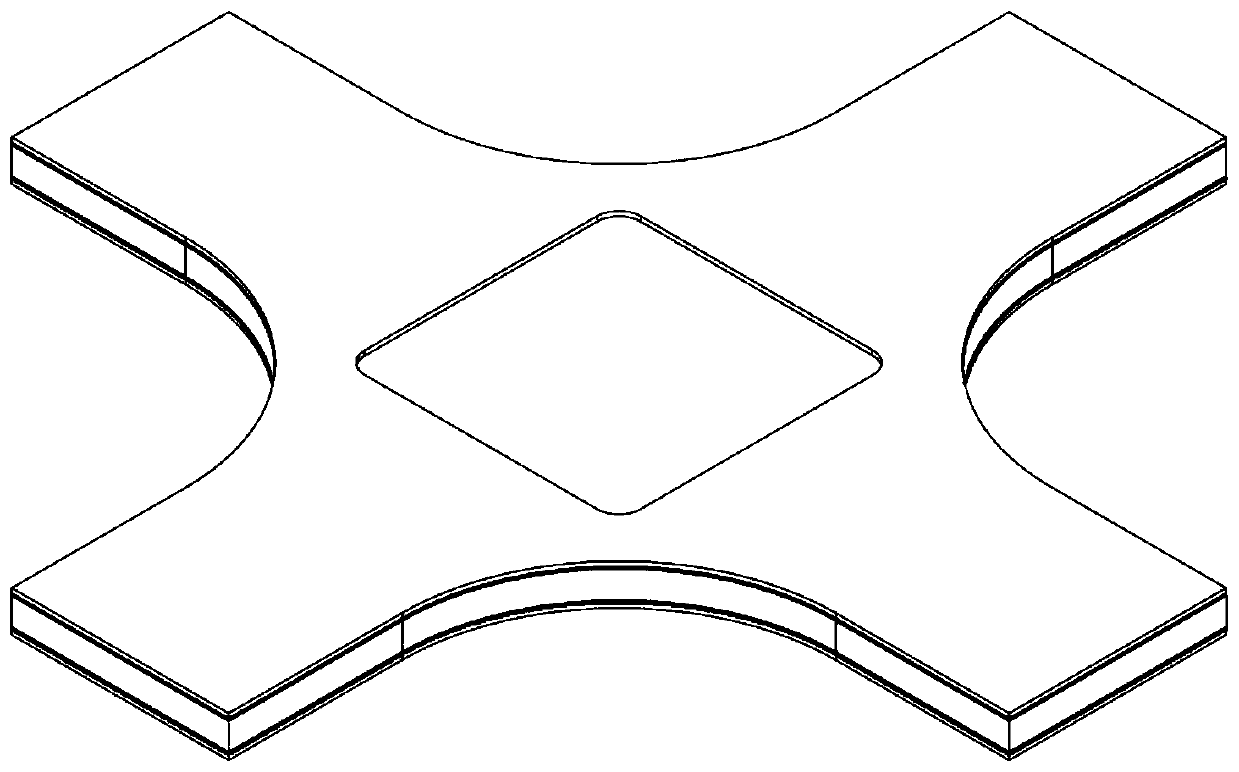

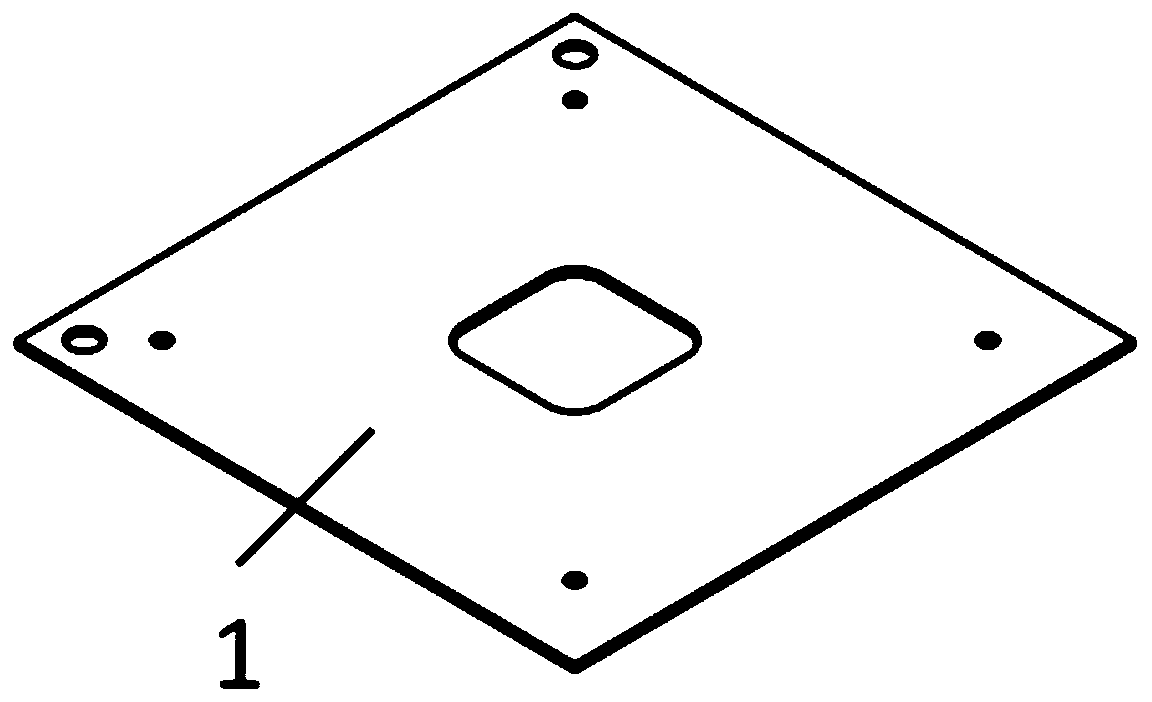

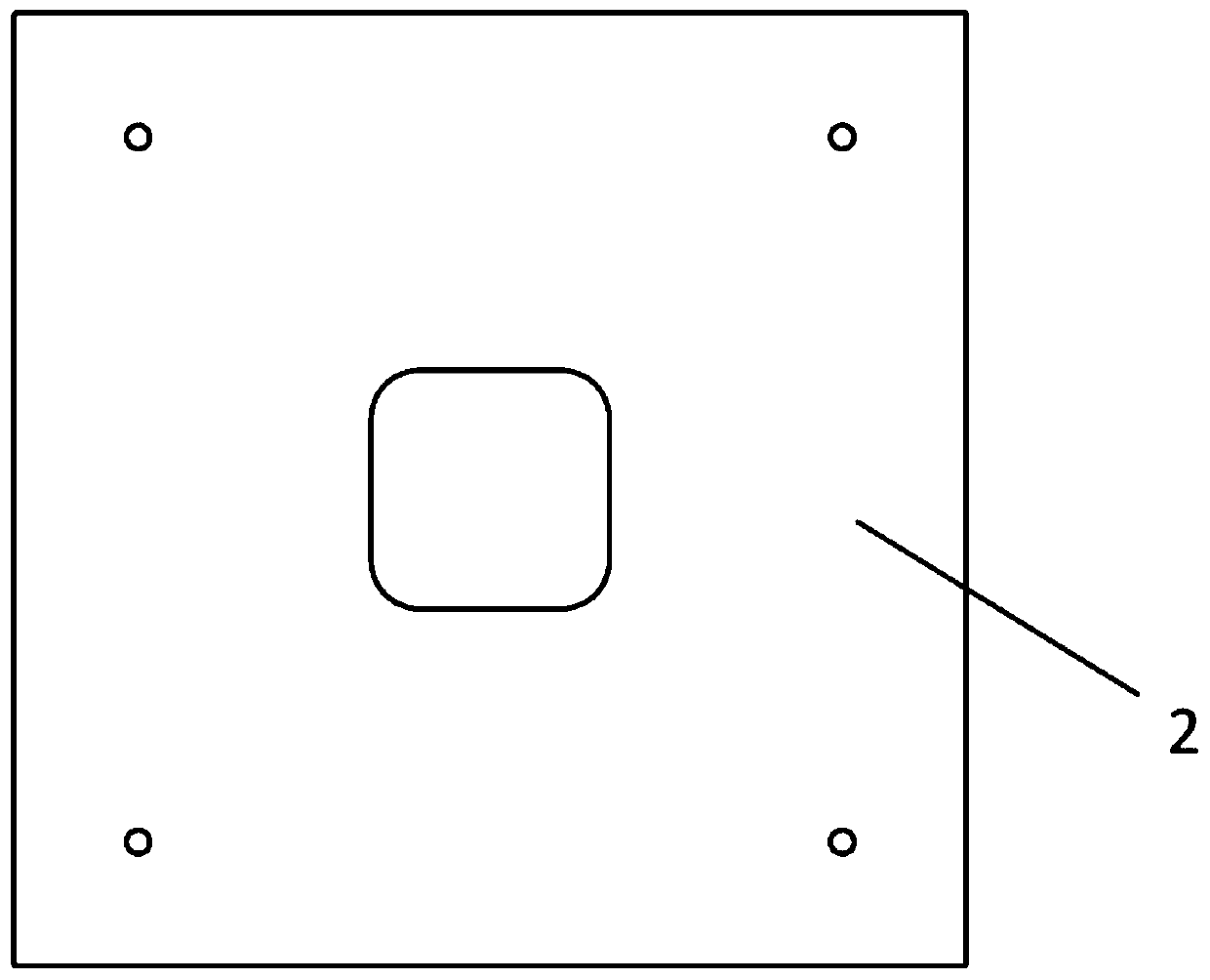

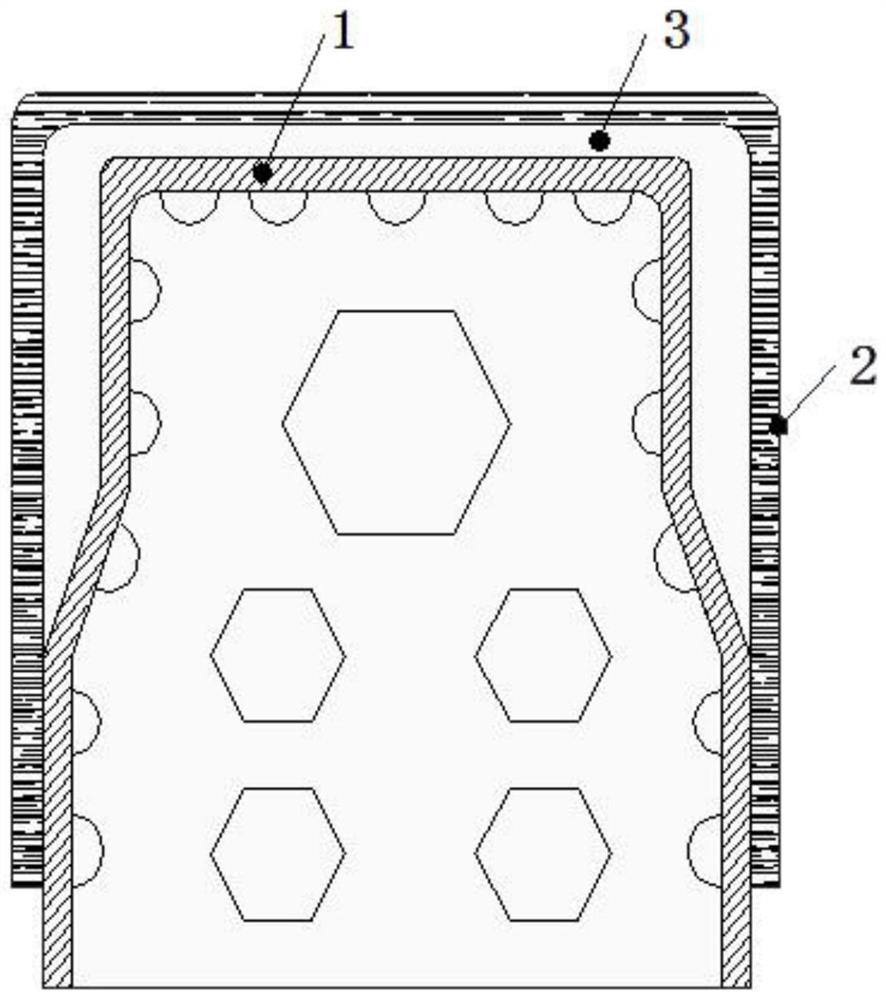

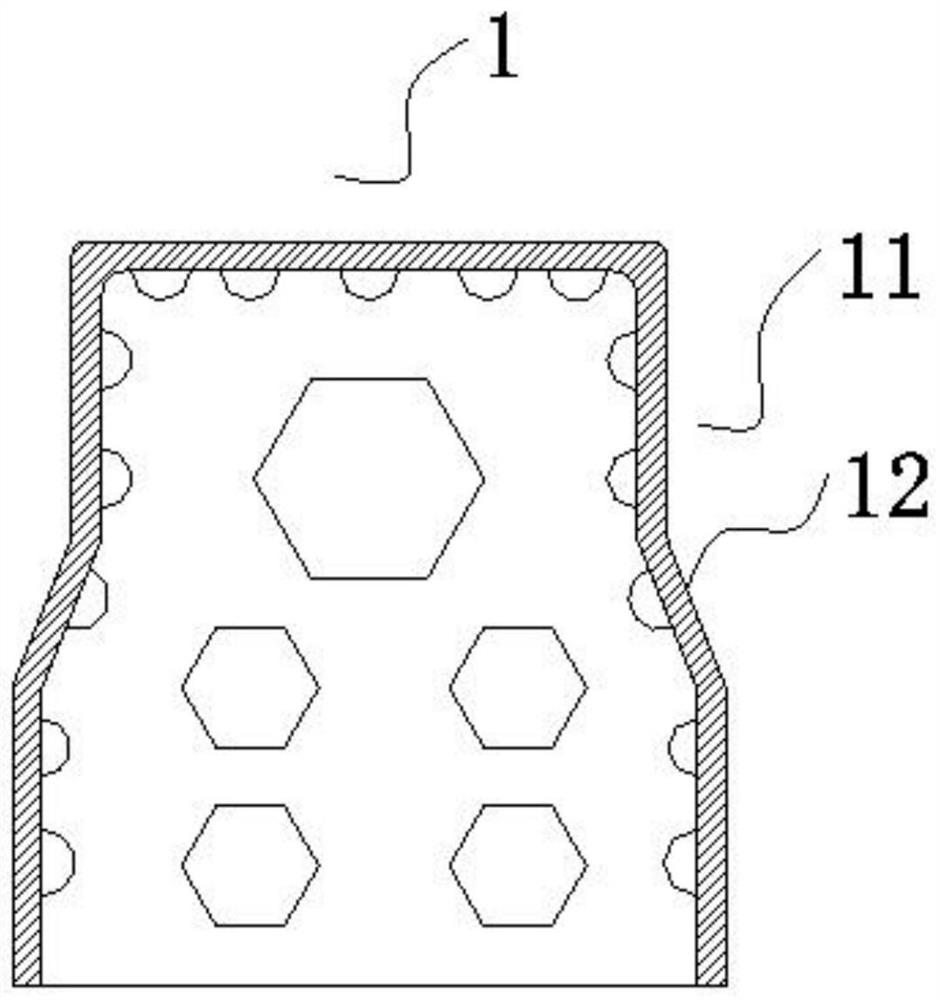

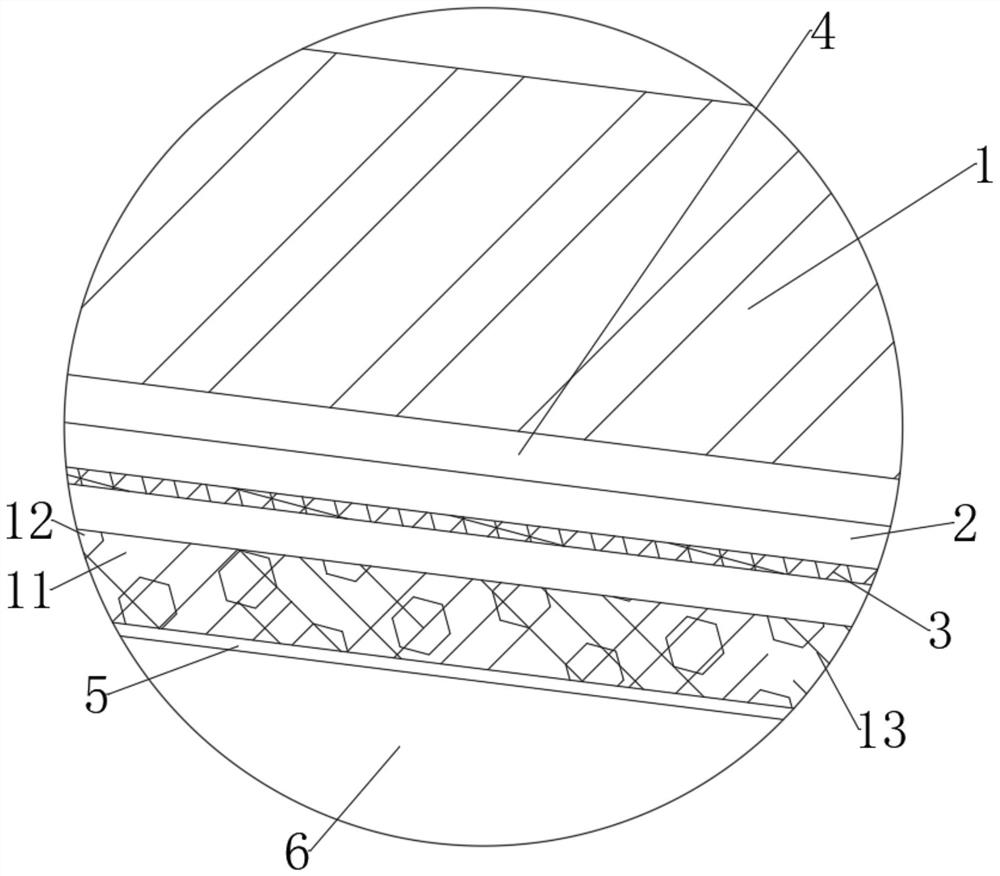

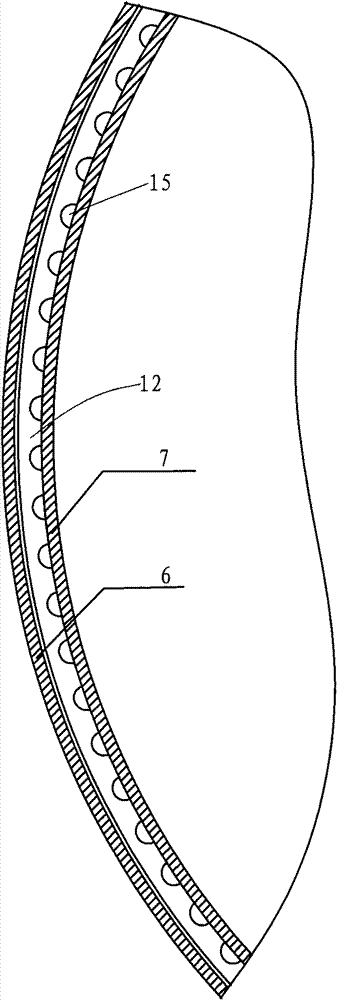

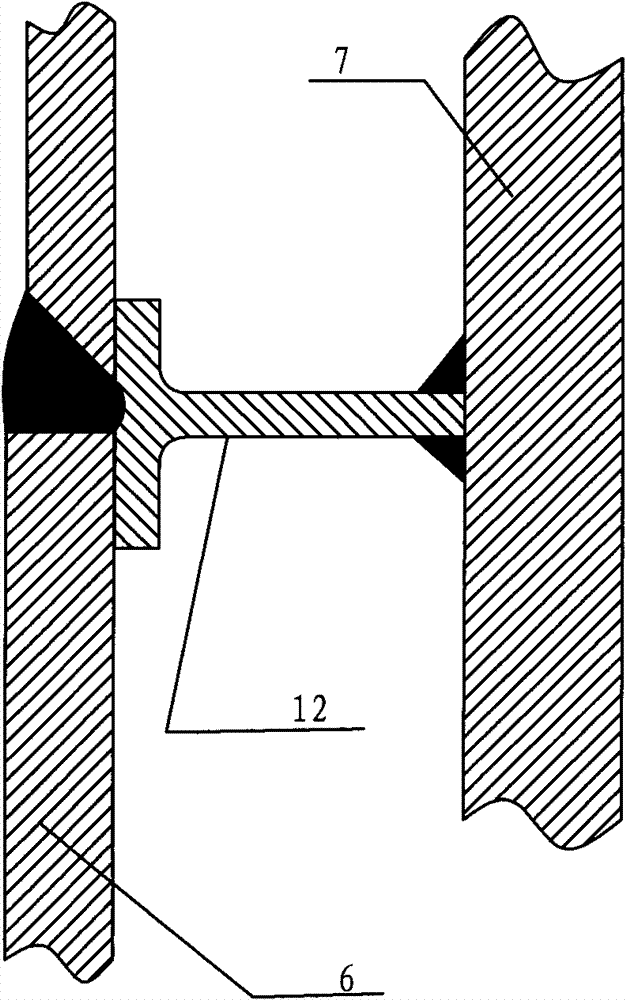

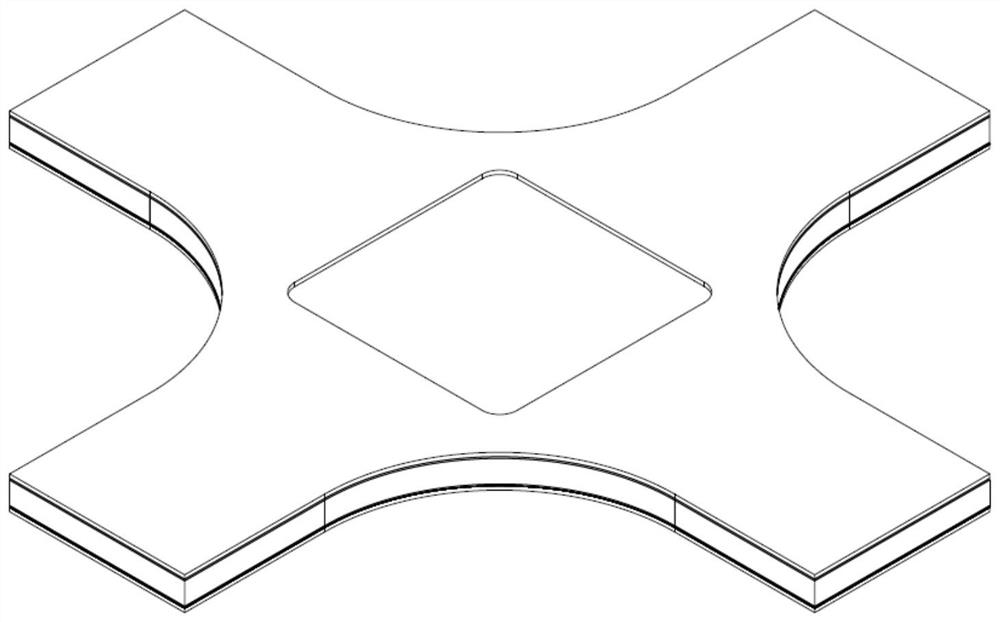

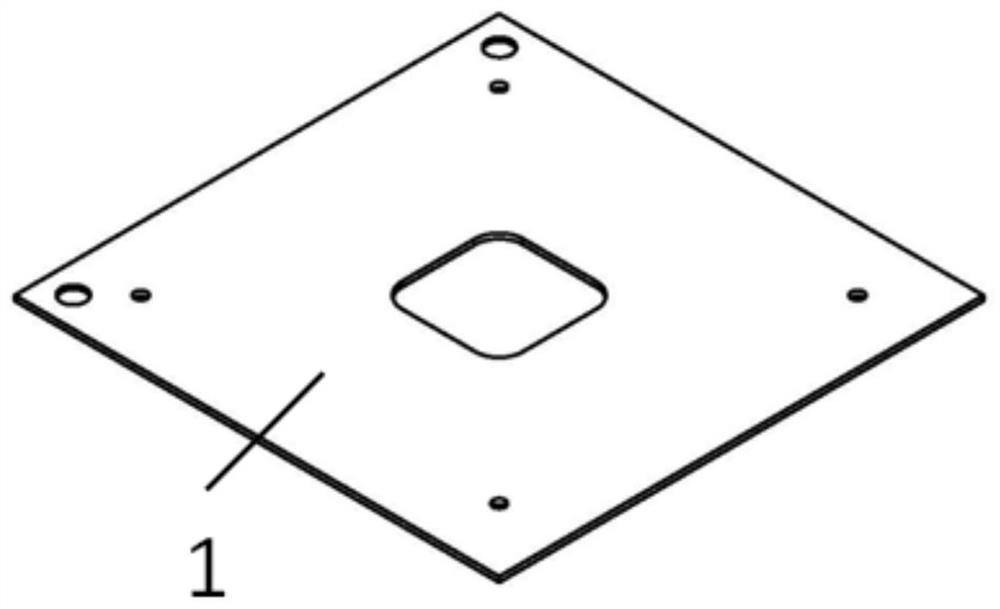

Machining method of butterfly-shaped composite material sandwich part

ActiveCN110626043AReduce manufacturing costUniform pressure transmissionLamination plant layoutLamination ancillary operationsNumerical controlEngineering

The invention discloses a machining method of a butterfly-shaped composite material sandwich part. The butterfly-shaped composite material sandwich part is composed of an upper base plate, a lower base plate, an upper panel, a lower panel, a core material and a filling block; the above five-membered structure is positioned and fixed through appearance design and pin rods; the upper base plate, thelower base plate and a composite material process base plate are formed by milling a same composite material blank plate, numerical control datum holes and positioning holes are adopted for milling forming at the same time, the relative positions are accurate, and the secondary positioning and milling precision is high after part gluing is completed.

Owner:XIAN AIRCRAFT IND GROUP

A molding tool and a method for preparing a rectangular hollow composite material tubular member using the molding tool

ActiveCN111873478BRealize pavementAvoid manufacturing processTubular articlesStructural engineeringMechanical engineering

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

C-beam composite material forming tooling and composite material C-beam forming method

ActiveCN108688192BQuality assuranceGuaranteed thickness accuracyDomestic articlesShaped beamEngineering

Owner:深圳市泰格尔航天航空科技有限公司

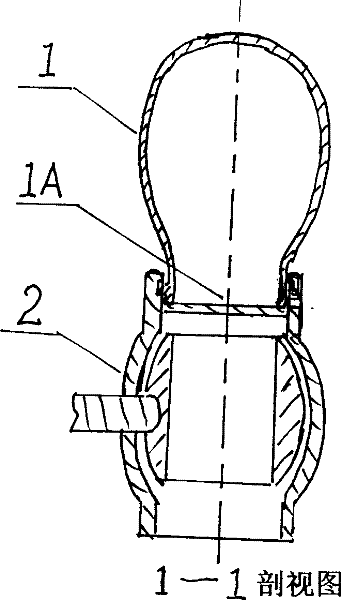

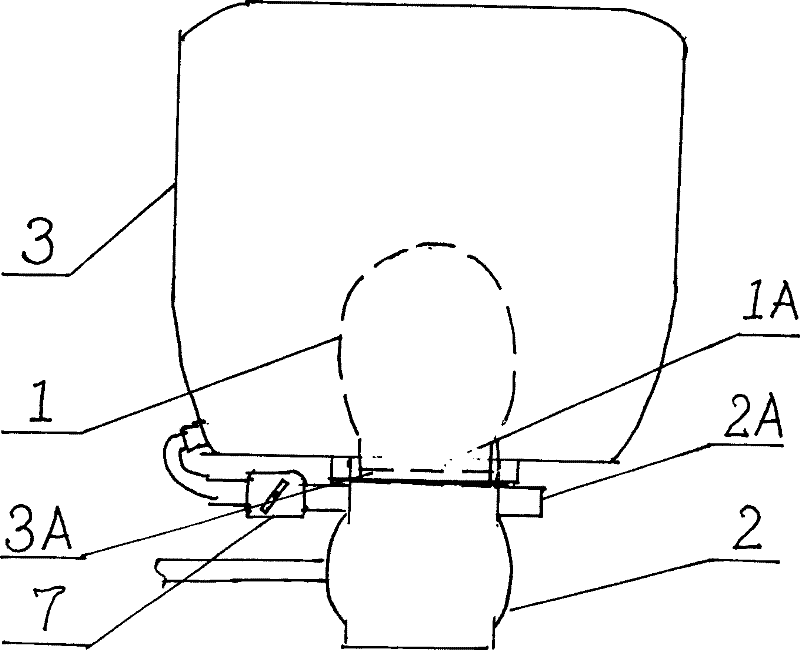

Multipurpose liquid pressure discharge device and suppress discharge method

InactiveCN101140049BReduce volumeEasy to carryPressure vesselsContainer discharging from pressure vesselsFire extinguisherEngineering

The invention discloses a multipurpose fluid pressing and discharging device and a pressing and discharging method; wherein an elastic bag is sealed in a fluid charging and discharging valve, or sealed on a fluid charging and discharging port of an outer box body, and the fluid charging and discharging valve is arranged on the fluid charging and discharging port of the outer box body. The upper end of the outer box body is provided with an air hole or an air adjusting valve and a cleaner. The device and the pressing and discharging method utilizes the expansion and rebound extrusion force of an elastic body as well as the stored fluid and the fluid pressure to facilitate the pressure not reduced with the reduction of capacity when discharging fluid, which solves the problems existing in the prior art. The invention is widely used in sanitary wares, fire fighting, sprinklers, automobile washing, sanitation and cleanness, fire extinguishers, water consumption electric appliances, various cylinders, pressure power drive, storage and transportation of fluid and other fields. The invention has the advantages of simple structure, small volume, light weight, low cost and convenient use, etc.

Owner:陈广丰

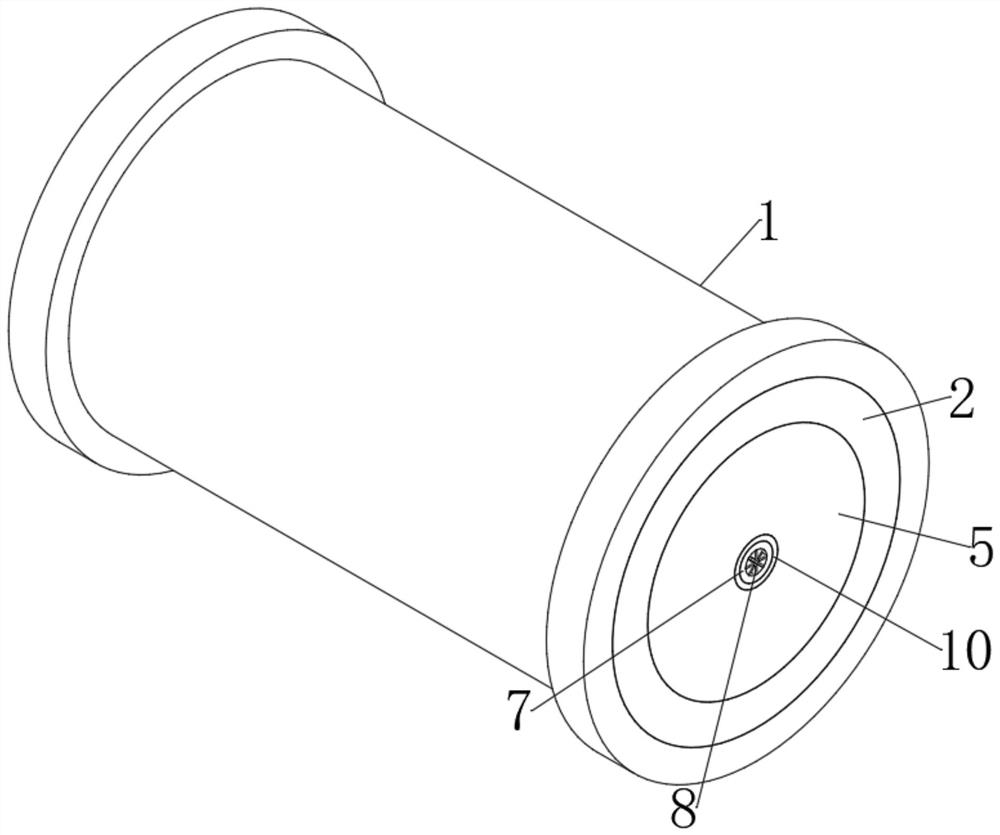

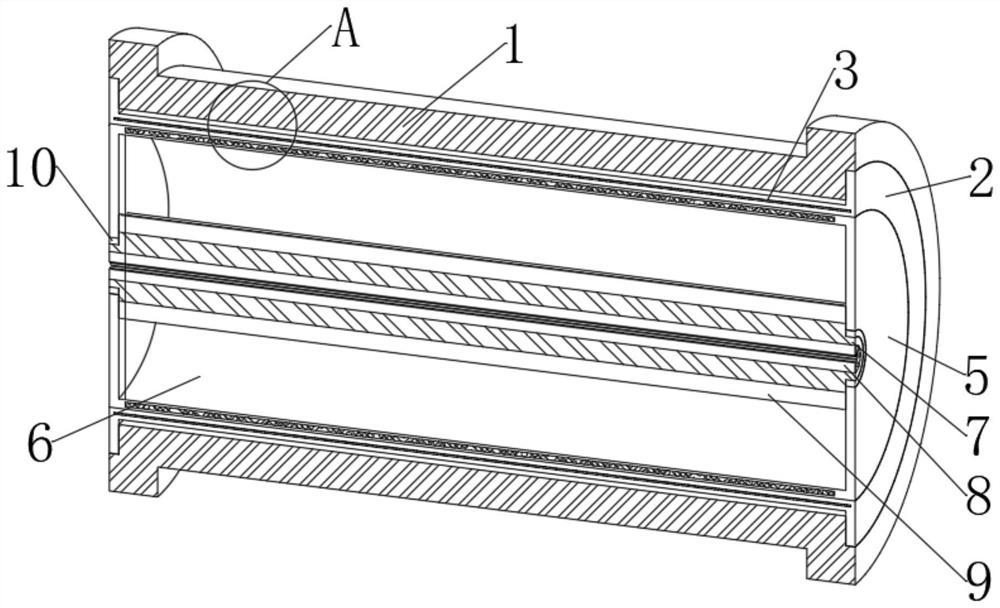

An automated equipment for culvert pipe production

Owner:张家界涵睿新材料科技有限公司

A kind of preparation method of straight conveyor belt finger joint

ActiveCN103072786BIncreased warp strengthHigh warp strengthConveyorsBeltsAdhesive cementVulcanization

The invention belongs to the technical field of a rubber conveyor belt product, and particularly relates to a straight conveyor belt finger-model connector and a preparation method thereof. The straight conveyor belt finger-model connector comprises a straight finger-model skeleton structure, wherein the straight finger-model skeleton structure comprises a straight canvas layer; a rubberizing layer is arranged on the surface of the straight finger-model skeleton structure; a textile layer playing a reinforcement effect is arranged on the rubberizing layer; and a coverage rubber layer is arranged on the textile layer. The preparation method of the straight conveyor belt finger-model connector comprises the following steps of (1) stripping coverage adhesive; (2) removing residual adhesive; (3) cutting a finger model; (4) coating adhesive cement; (5) splicing the finger model; (6) forming a finger-model connector; and (7) vulcanizing the finger-model connector. Due to the adoption of the straight conveyor belt finger-model connector, the strength of the connector is improved; and the preparation method is simple and easy to operate.

Owner:YANKUANG GRP CO LTD +1

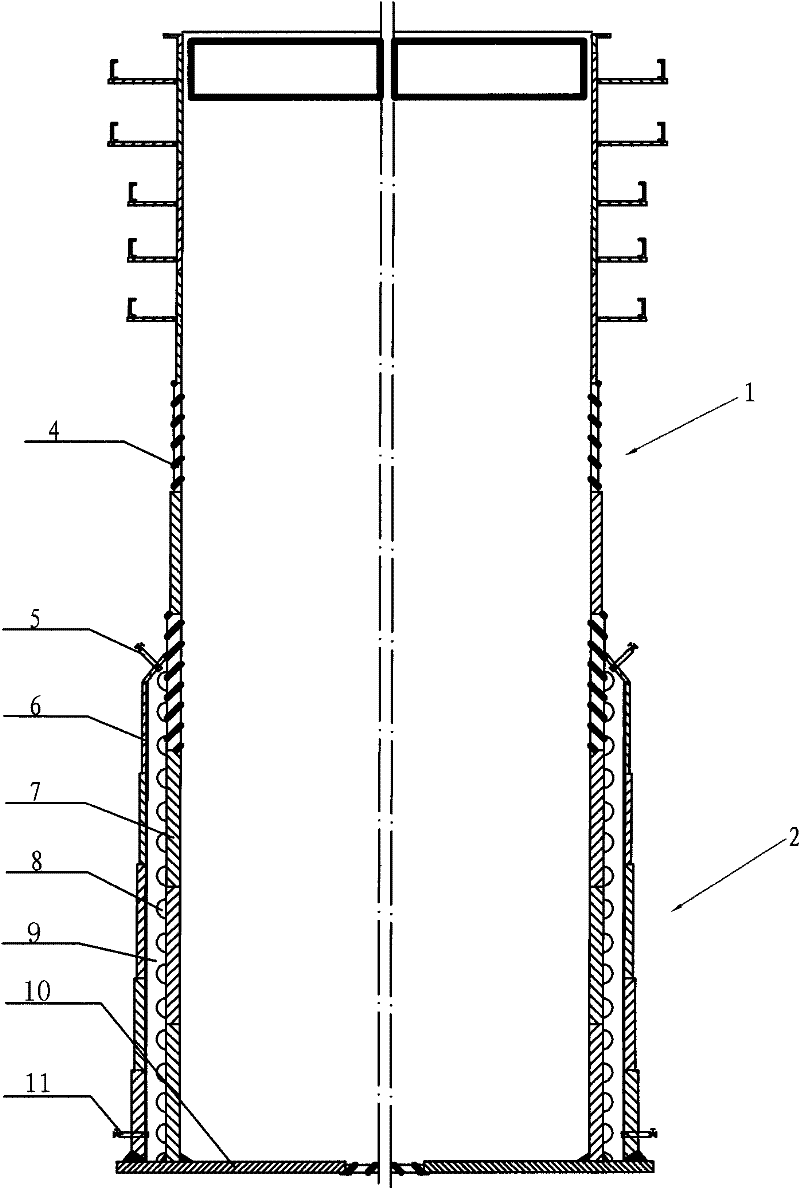

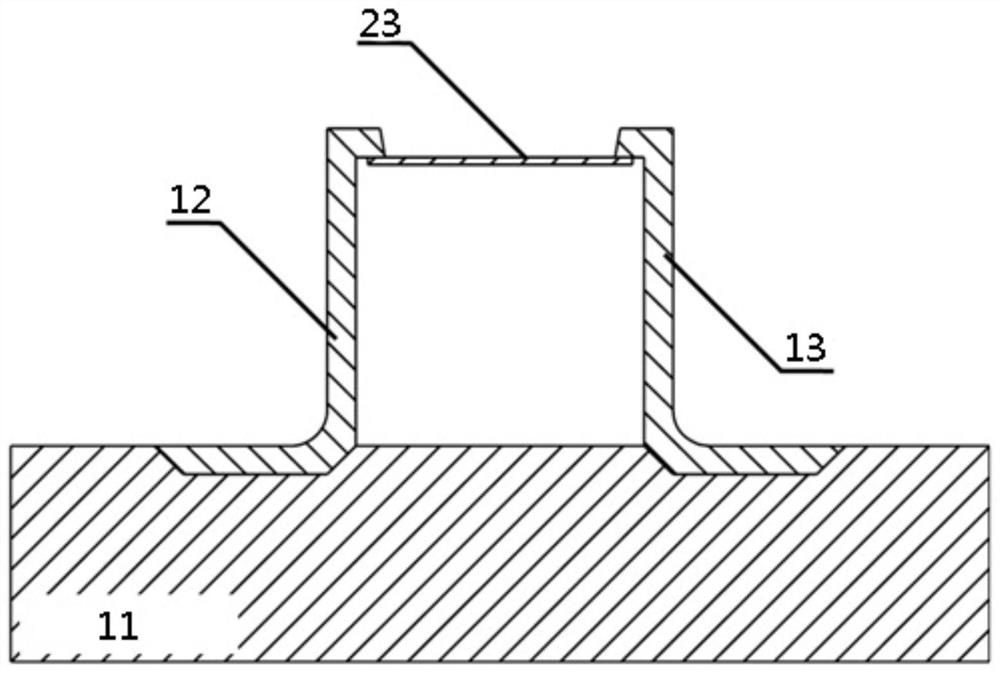

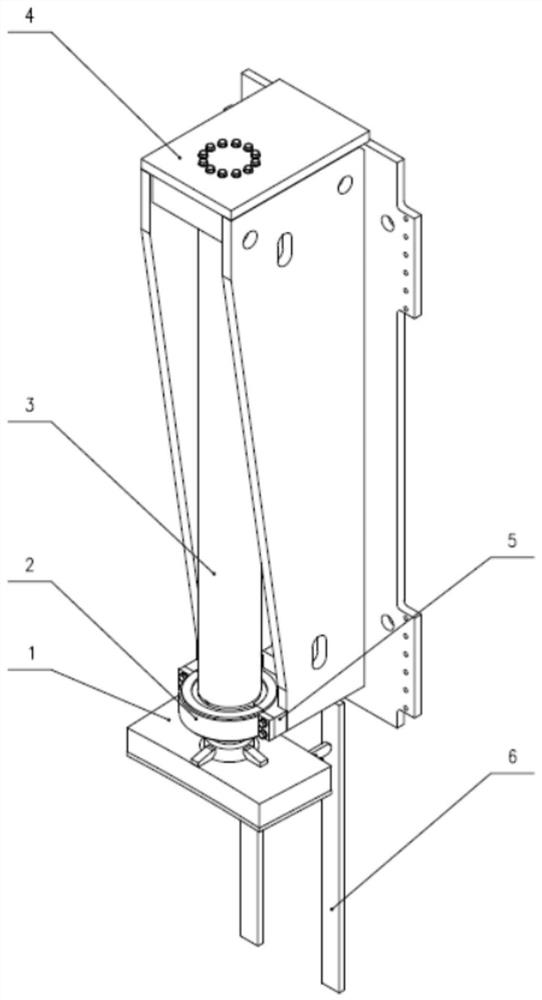

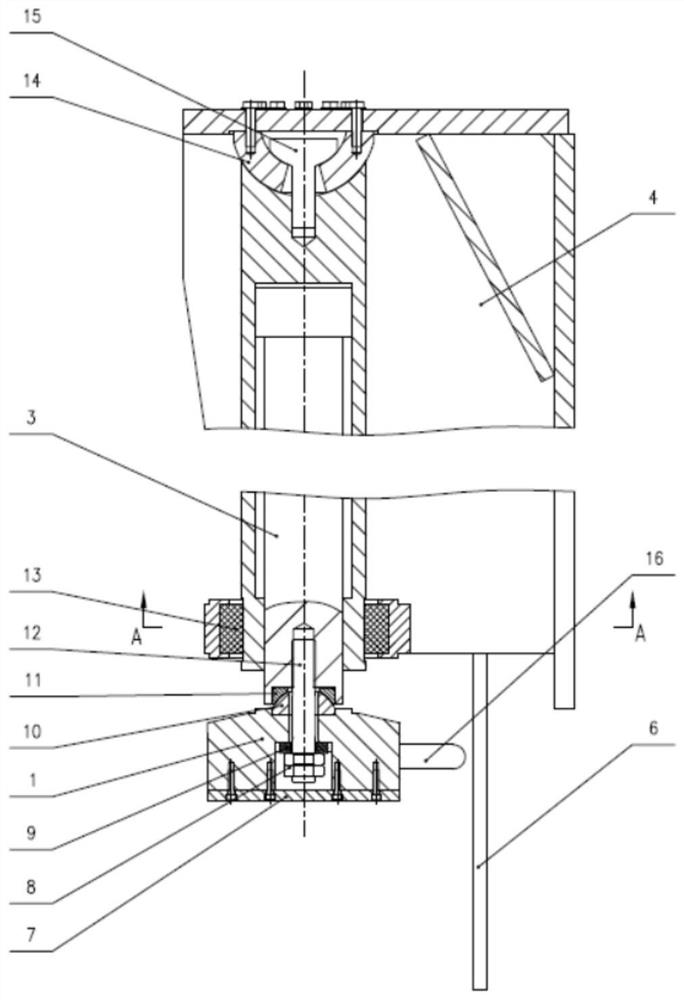

Pushing device for sunken vertical shaft

The invention discloses a pushing device for a sunken vertical shaft, relates to the technical field of vertical shaft construction equipment, and aims to solve the problems that in the prior art, a vertical shaft inclines due to non-uniform stress, and even an open caisson cannot sink in a severe condition. According to the technical scheme, the pushing device is characterized by comprising a vertically-arranged oil cylinder and a supporting frame, and the bottom of a piston rod of the oil cylinder is connected with a supporting shoe; a bearing seat is arranged at the bottom end of a piston rod of the oil cylinder, a spherical groove is formed in the bottom wall of the bearing seat, a hemispherical bearing arranged in the spherical groove and in running fit with the bearing seat is connected to the top wall of the supporting shoe, and the piston rod and the supporting shoe are fixed through a double-end stud penetrating through the bearing seat and the hemispherical bearing; and the double-end stud is sleeved with a disc spring located between the supporting shoe and a locking nut, and the locking nut abuts against the supporting shoe through the disc spring. The vertical shaft posture can be adjusted, downward additional force is increased, soil friction force is overcome in an auxiliary mode, and smooth vertical shaft construction is facilitated.

Owner:XCMG KAIGONG HEAVY IND NANJING

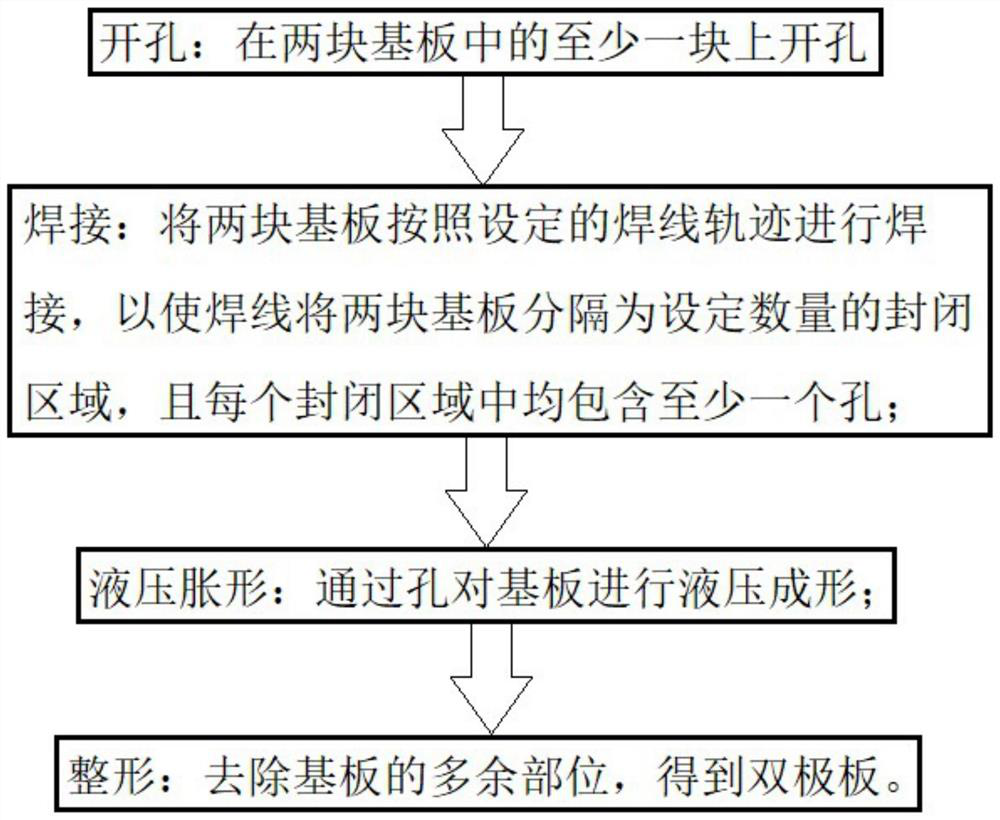

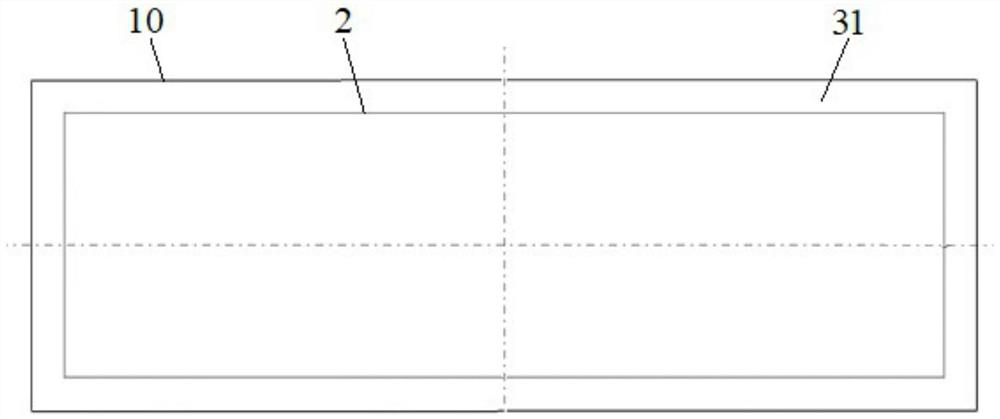

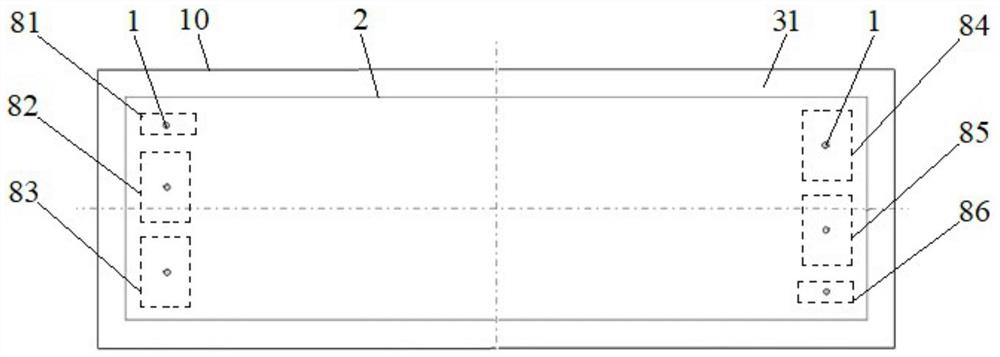

Fuel cell bipolar plate production method

ActiveCN114050288AHydraulic bulging step facilitatesNo deformationFinal product manufactureFuel cellsFuel cellsEngineering

The invention discloses a fuel cell bipolar plate production method, and solves the technical problems of high cost, long period and low bipolar plate forming precision of the existing production method. According to the fuel cell bipolar plate production method, firstly, holes are formed in substrates, and the holes serve as liquid injection holes in a subsequent hydraulic bulging step; the two substrates are welded into a whole according to a set welding track, the welding track completely coincides with a welding line in a bipolar plate, the two substrates are divided into a set number of closed areas by the welding line, and therefore a two-plate three-field structure is formed; and each closed area comprises at least one hole, so that the subsequent hydraulic bulging step can be conveniently carried out. By injecting liquid between the two substrates through the holes, and carrying out hydraulic forming, a flow channel on the bipolar plate and a structure at a fluid inlet and a fluid outlet. are formed. By removing redundant parts of the substrates after hydraulic forming, each fluid inlet / outlet is formed . The integrated forming method is adopted, the production cost is low, the production efficiency is high, and the bipolar plate forming precision is high.

Owner:DONGFENG MOTOR GRP

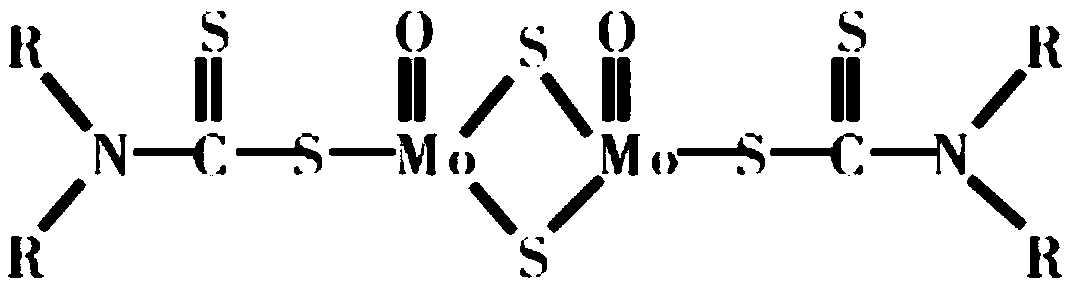

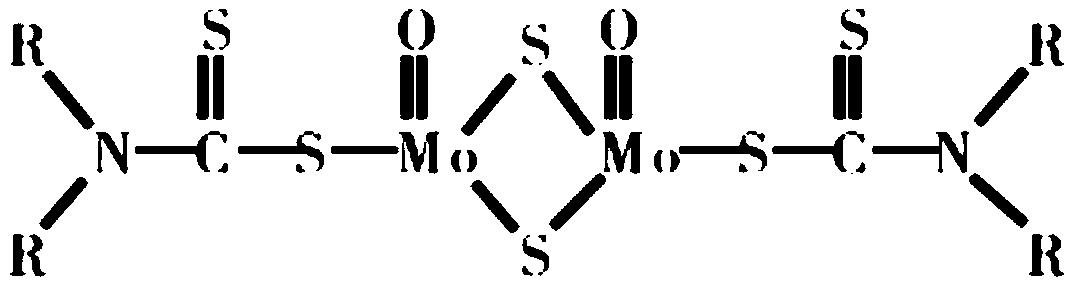

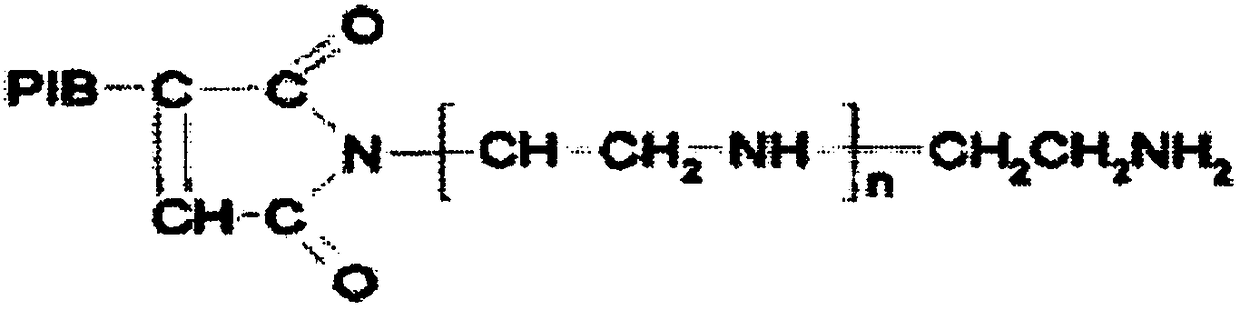

A kind of energy-saving construction machinery hydraulic oil and preparation method thereof

InactiveCN105820860BImprove wear resistanceReduce consumptionLubricant compositionIndustrial equipmentLubrication

The invention discloses energy-saving engineering machinery hydraulic oil. The energy-saving engineering machinery hydraulic oil is prepared from, by weight, 0.2-0.9 part of tricresyl phosphate, 0.8-1.2 parts of antiwear agent, 4-6 parts of benzotriazole octadecylamine salt, 2-4 parts of ethylene glycol oleate, 75-85 parts of hydrogenated styrene isoprene copolymer, 1.5-2.5 parts of monoene succinimide, 1.5-2.5 parts of 2,5-di-tert-butylhydroquinone, 2.5-3.5 parts of 4,4'-dioctyl diphenylamine, 4-8 parts of polymethacrylate, 0.02-0.04 part of dimethicone and 850-950 parts of base oil. The energy-saving engineering machinery hydraulic oil has good wear resistance and can provide a lubrication guarantee in time at different working stages; equipment runs stably, pressure is evenly transferred, friction and abrasion are reduced, temperature rise is low, heat dissipation is rapid, power losses are reduced, energy consumption is reduced, and the oil replacement period is prolonged. The energy-saving engineering machinery hydraulic oil is suitable for hydraulic systems of various kinds of industrial equipment, engineering machinery, metallurgical machinery and the like.

Owner:广州国机润滑科技有限公司

A production process and application of hot-pressed backing paper for pressing copper-clad laminates as a backing layer

Owner:建滔(佛冈)绝缘材料有限公司

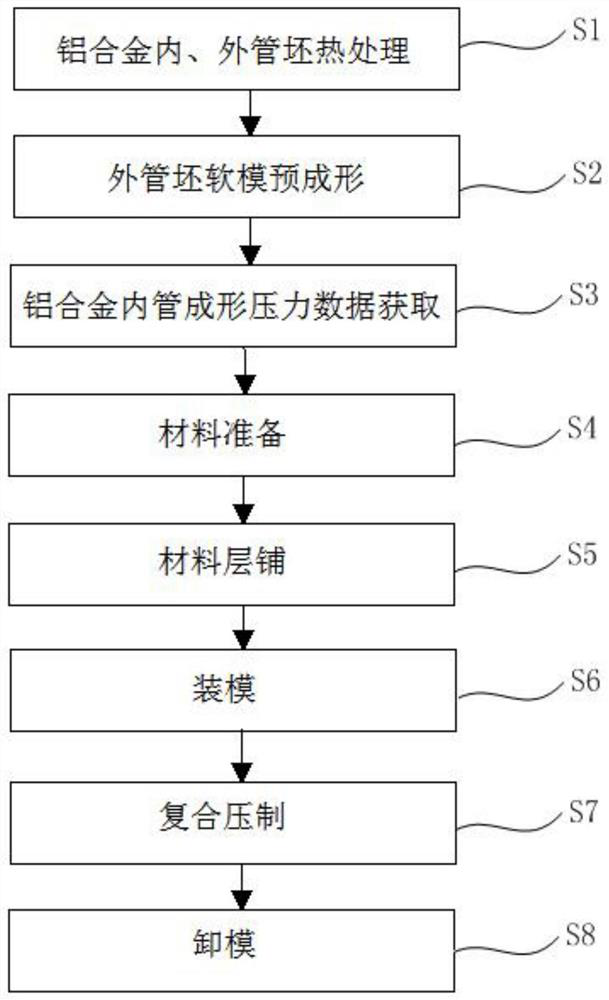

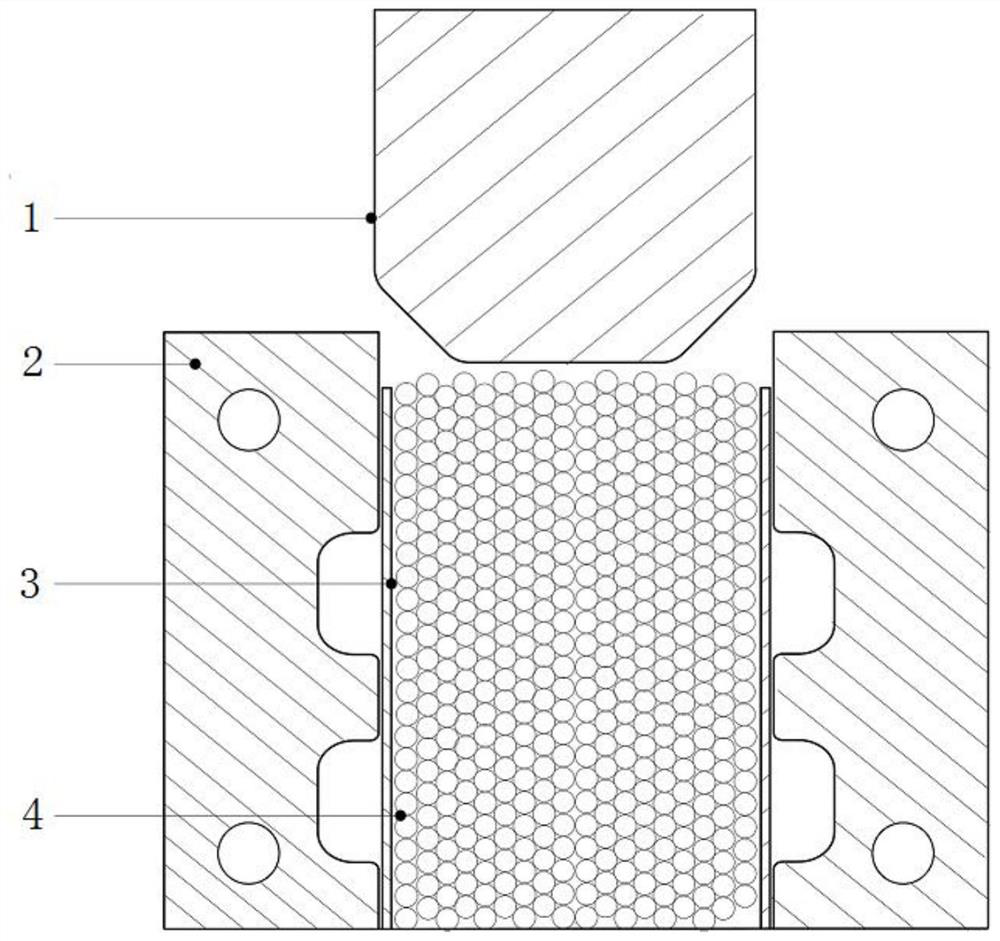

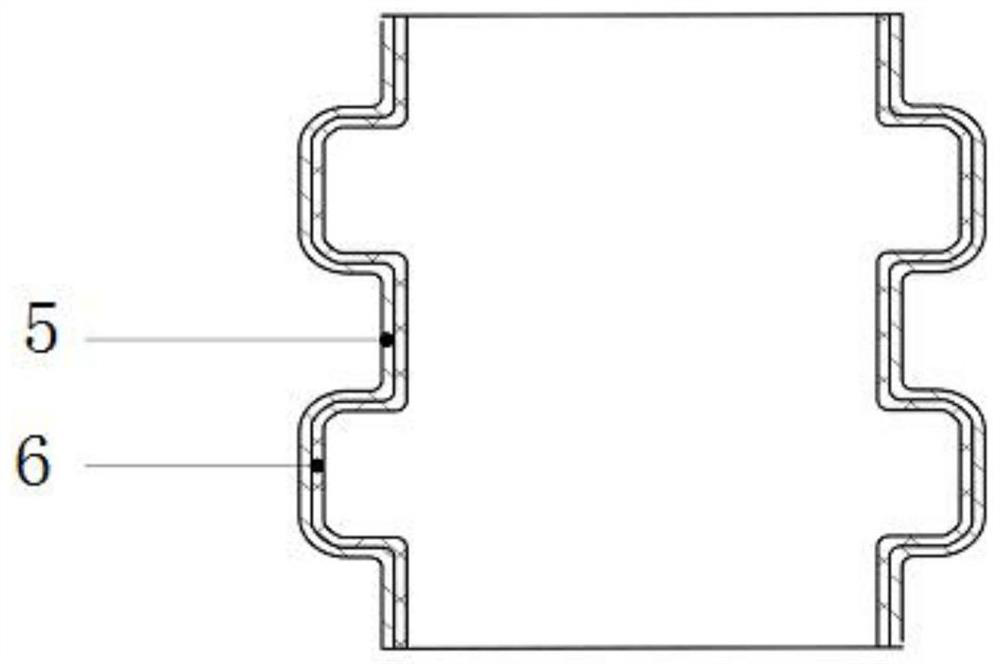

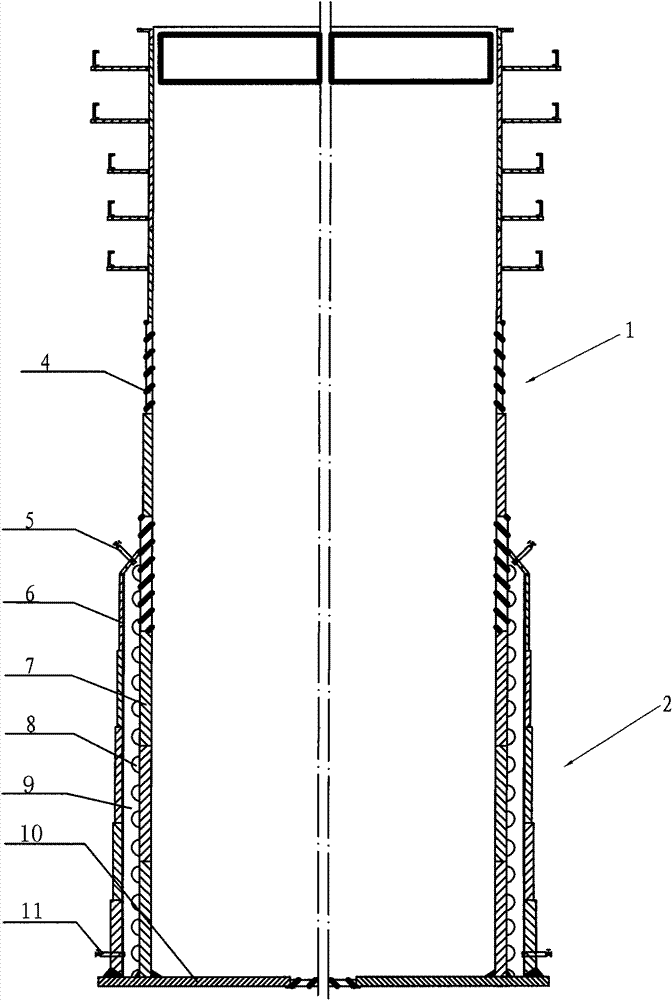

Carbon fiber reinforced aluminum alloy layer pipe component forming process and forming mold

ActiveCN113787733ASolve forming problemsSolve secondary processing difficultiesTubular articlesCarbon fibersMachining

The invention discloses a carbon fiber reinforced aluminum alloy layer pipe component forming process and a forming mold. A process route of 'heat treatment of aluminum alloy inner and outer pipe blanks, forming of an aluminum alloy outer pipe blank soft mold, layered laying of carbon fiber prepreg and outer layer aluminum alloy pipe forming parts, composite pressing of carbon fiber reinforced aluminum alloy layer pipe pre-forming parts, and mold unloading' is provided for fiber metal layer pipe component forming; a delicate composite forming process can be developed according to plastic performances and metallurgical bonding performances of different series of aluminum alloys; a layer pipe component composite forming integrated preparation scheme is realized; the process is particularly suitable for preparing fiber metal layer pipe components with special-shaped sections; the forming problem is solved when parts are compounded; the problem of secondary machining difficulty of fiber metal layer pipes is solved; the application range of fiber metal composite materials is widened; and references are provided for forming of fiber metal layer pipe composite materials in complex shapes.

Owner:YANSHAN UNIV

Wall board structure of fixed hydraulic balance extra large storage tank

ActiveCN102229377BSolve the problem of running down rainwaterReduce construction costsLarge containersEngineeringBoard structure

The invention relates to a wall board structure of a fixed hydraulic balance extra large storage tank. The structure comprises an inner tank and an outer tank, wherein the inner tank is used for storing materials; the outer tank is wrapped by the inner tank; a distance is arranged between the outer side wall of the inner tank and the inner side wall of the outer tank so as to form an annular space for containing liquid for balancing pressure; and the structure is characterized in that a plurality of structural steel connecting pieces for improving the bearing capability of the side wall of the inner tank are arranged between the inner side wall of the outer tank and the outer side wall of the inner tank. Compared with the prior art, the invention really realizes the manufacturing of an extra storage tank, has the advantages of low the manufacturing cost, and ensures the welding quality.

Owner:CHINA PETROLEUM & CHEM CORP +2

A processing method for a butterfly-shaped composite material sandwich part

ActiveCN110626043BReduce manufacturing costUniform pressure transmissionLamination plant layoutLamination ancillary operationsMechanical engineeringMaterials science

The invention discloses a processing method for a butterfly-shaped composite material sandwich part. The part is composed of an upper backing plate, a lower backing plate, an upper panel, a lower panel, a core material and a filling block. The structure of the five parts is fixed by shape and pin positioning. The upper and lower backing plates and the composite material process backing plate are milled from the same composite material wool board. The numerical control reference hole and positioning hole are used to mill and cut at the same time. The relative position is accurate, and the parts The secondary positioning milling after gluing is completed has high precision.

Owner:XIAN AIRCRAFT IND GROUP

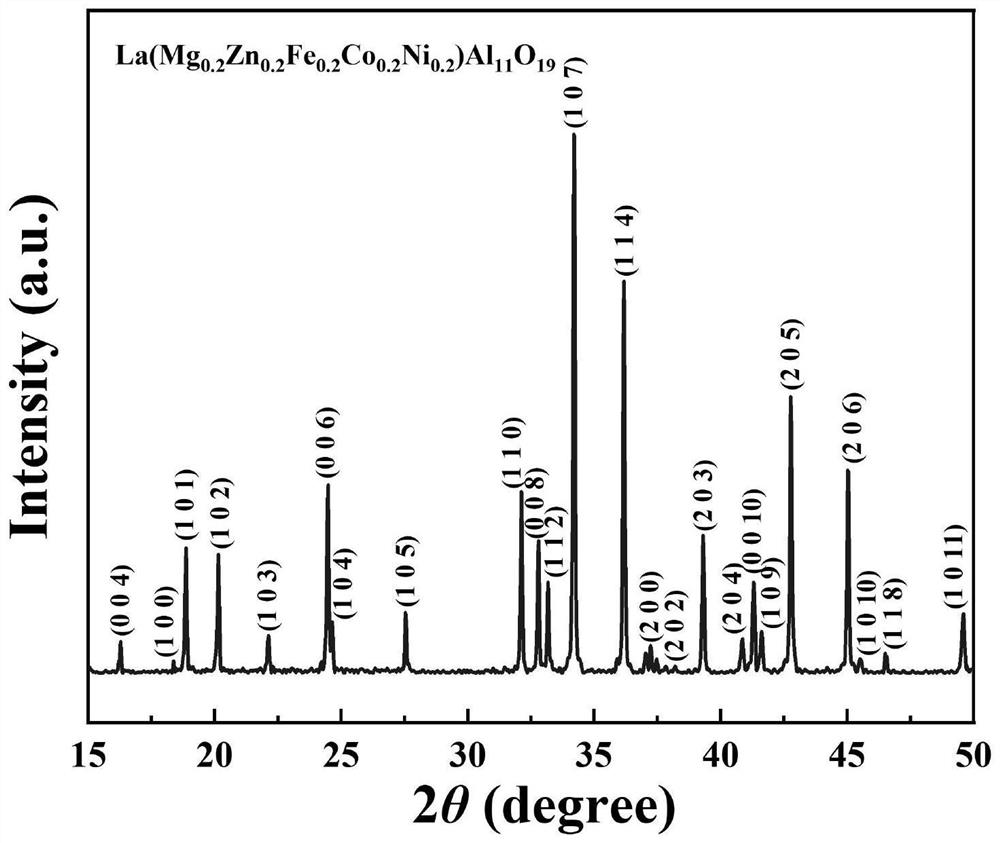

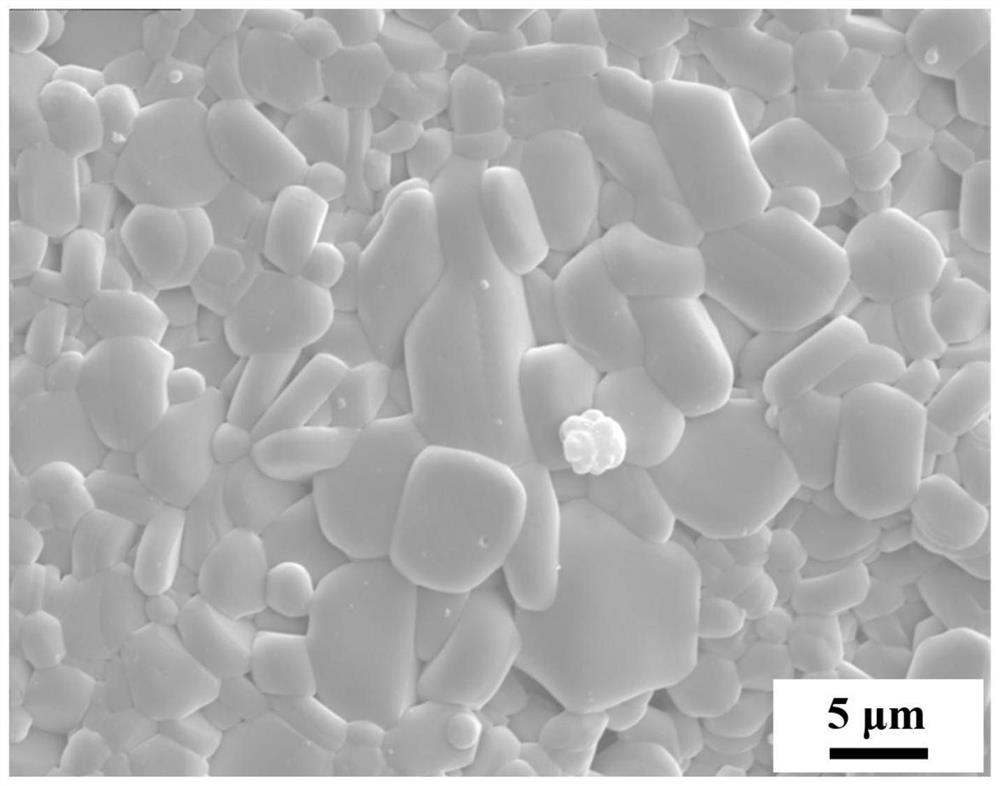

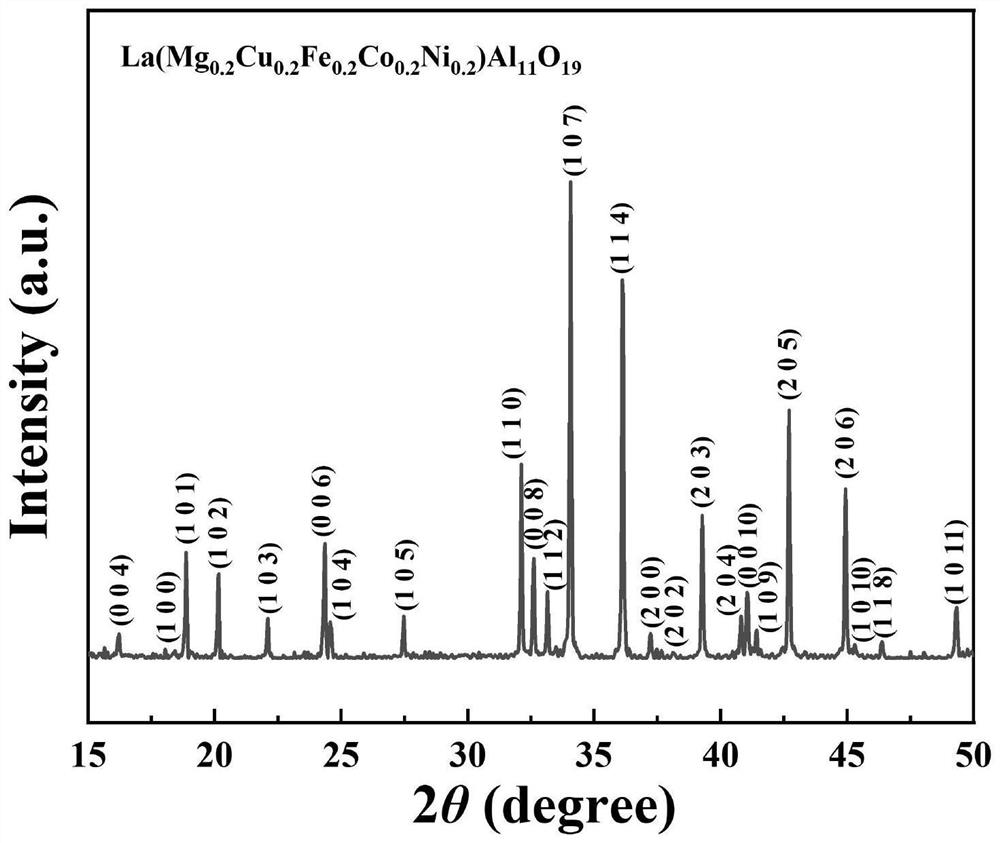

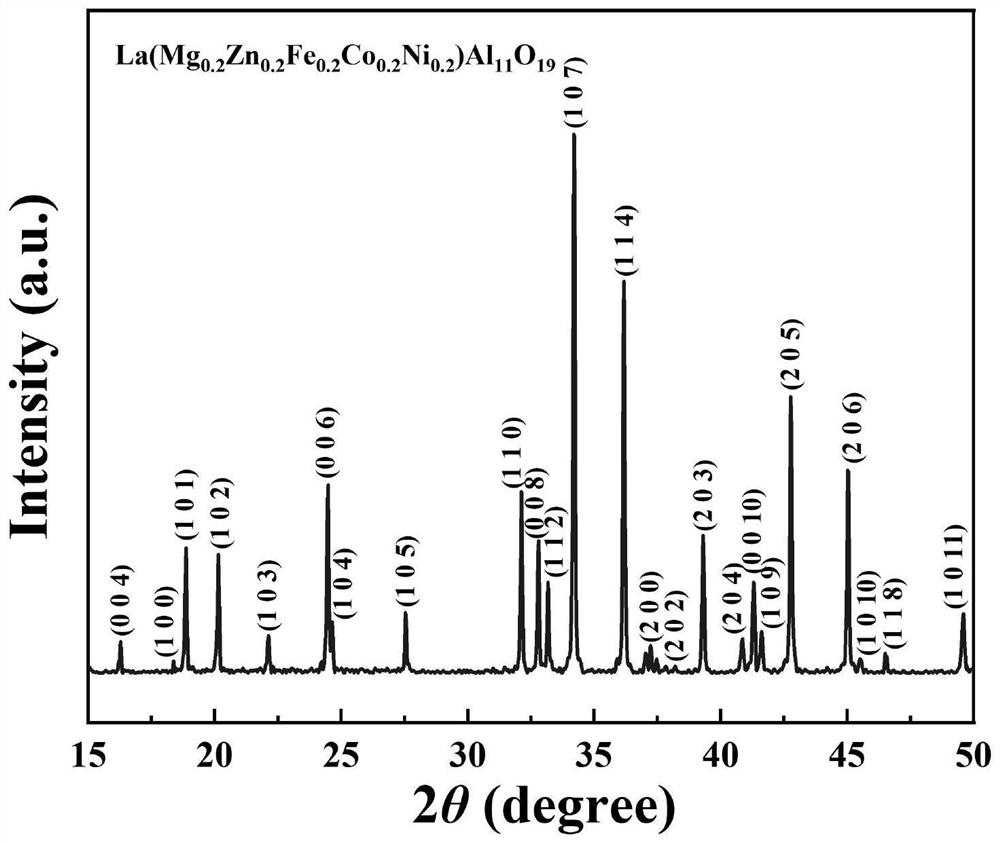

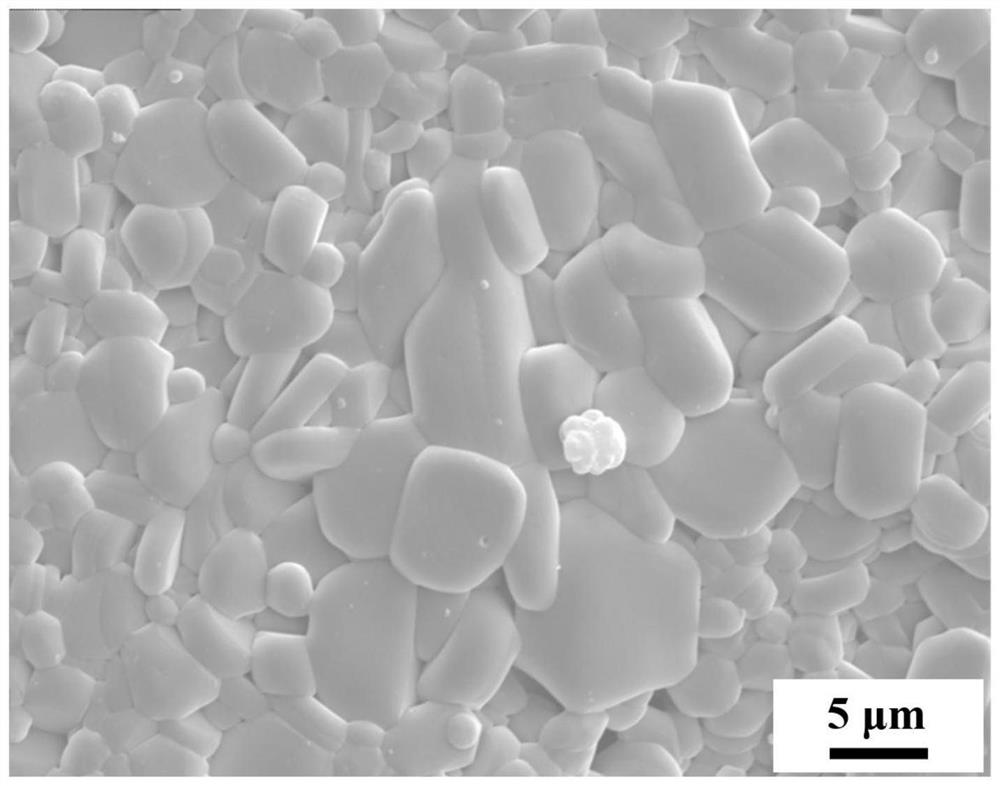

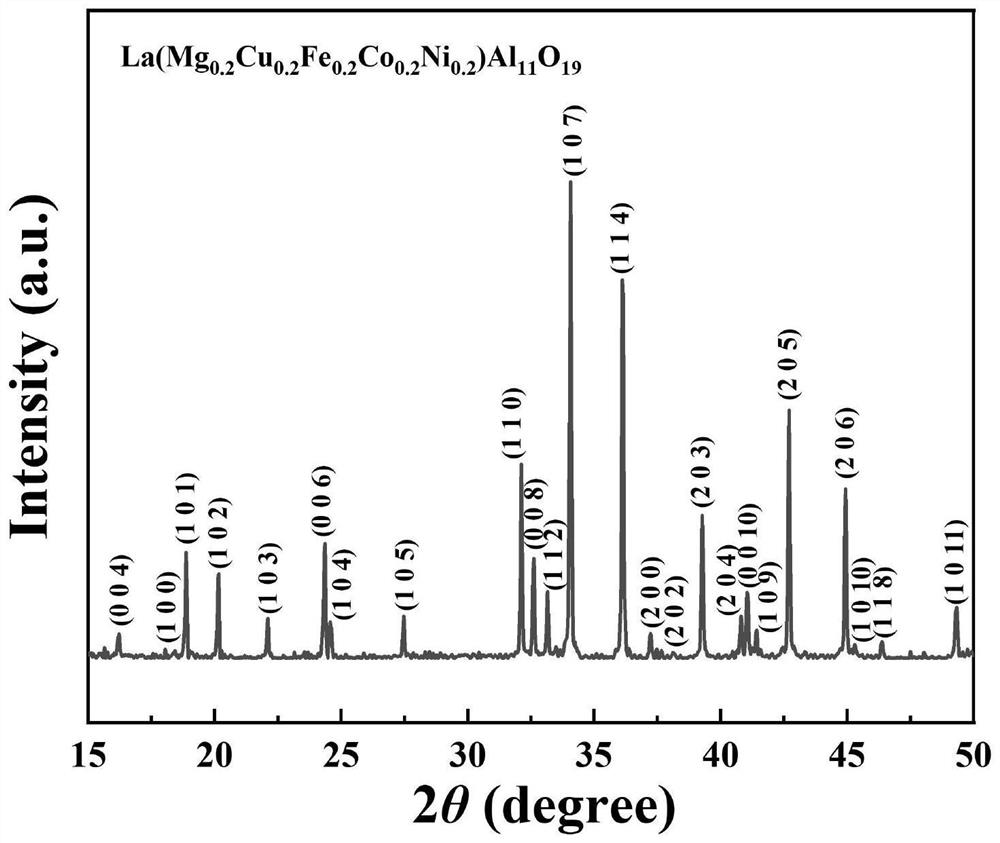

High-density ceramic material as well as preparation method and application thereof

The invention provides a high-density ceramic material as well as a preparation method and application thereof, and belongs to the technical field of ceramic materials. The chemical composition of the high-density ceramic material provided by the invention is La(Mg0.4-xTMxFe0.2Co0.2Ni0.2)Al11O19, and 0 < x < = 0.2. According to the preparation method of the high-density ceramic material, forming is conducted in a staged positive and negative pressure maintaining mode, the density of a green body can be improved, and then the density of a ceramic sample is improved; according to the invention, by adopting a forward and reverse two-way sequential pressurization mode, the non-uniformity of the density of the green body along the vertical direction can be eliminated, so that the density of the green body is further improved; and the ceramic material is pure in phase, the density is higher than 95%, the surface is free of micro cracks, the interior is free of micro holes, and the ceramic material can be widely used as a thermal protection material for aerospace crafts and a lining material for industrial kilns.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A kind of preparation method of metal bipolar plate of proton exchange membrane fuel cell

ActiveCN112993301BGuaranteed CorrosionEnsure consistencyCollectors/separatorsEngineeringHydroforming

The invention relates to the technical field of fuel cells, and provides a method for preparing a metal bipolar plate of a proton exchange membrane fuel cell. The invention adopts the method of first coating, then welding, and finally hydroforming to prepare the metal bipolar plate, which can ensure uniform coating thickness, and ensure the consistency of corrosion resistance and contact resistance in all parts of the bipolar plate; the invention welds two layers of metal Leave an unwelded area on each side of the plate. During hydroforming, the unwelded area is used as a liquid injection hole to inject high-pressure liquid between the two metal plates. Under the action of the hydraulic pressure, the upper metal plate and the upper template The cavity wall is attached, and the lower metal plate is attached to the cavity wall of the lower template, so that the cathode and anode double plates are formed at the same time. Adopting the method of the invention to carry out hydroforming does not cause damage to the coating, the formed flow channel has high precision, and the product qualification rate is high, and the invention realizes the simultaneous forming of the cathode and anode double plates for the first time.

Owner:UNIV OF JINAN +1

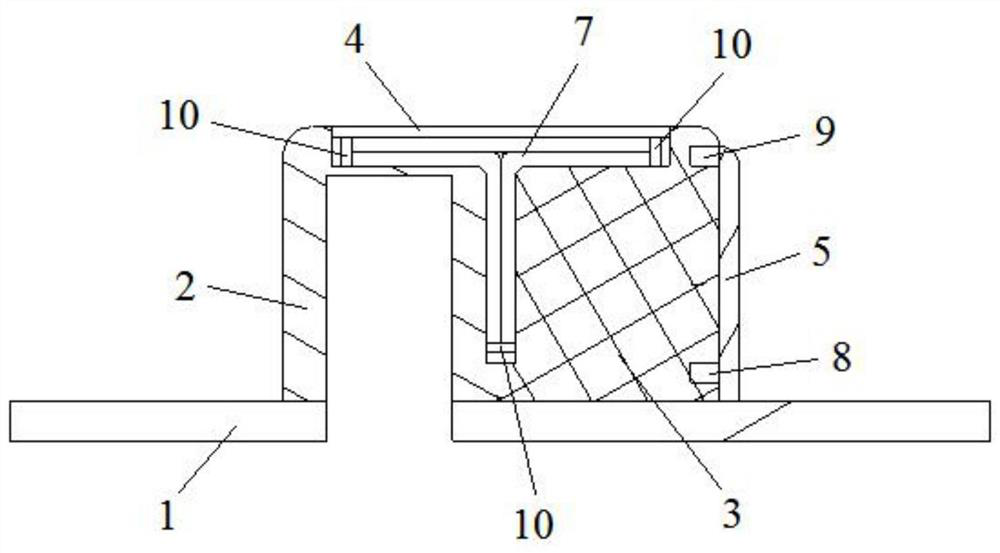

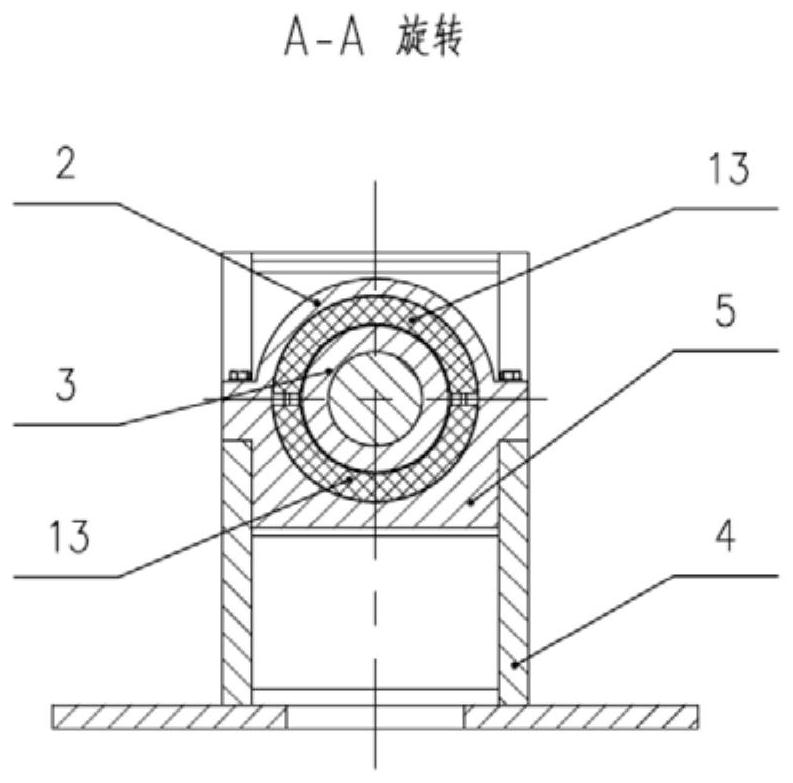

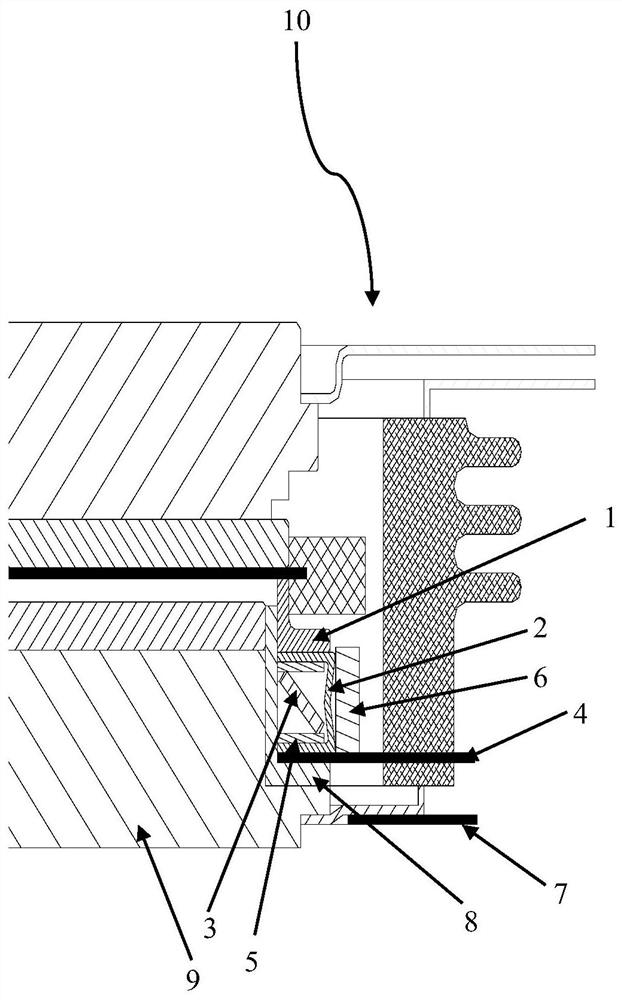

An igct package structure

ActiveCN111933588BAchieve connectionShorten detour lengthThyristorSemiconductor/solid-state device detailsStray inductanceEngineering physics

The invention provides an IGCT packaging structure, which includes a ring-shaped gate, a connecting part, an elastic supporting part and an external connection ring of the gate. Wherein, the top and the bottom of the connection part are respectively connected with the ring-shaped gate electrode and the outer ring of the gate electrode, and the elastic supporting part is located in the connection part. The IGCT packaging structure provided by the present invention can simplify the packaging process while ensuring uniform pressure transmission, improve packaging efficiency, and effectively shorten the detour length of the commutation circuit, thereby effectively reducing the IGCT packaging structure of the stray inductance of the commutation circuit.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

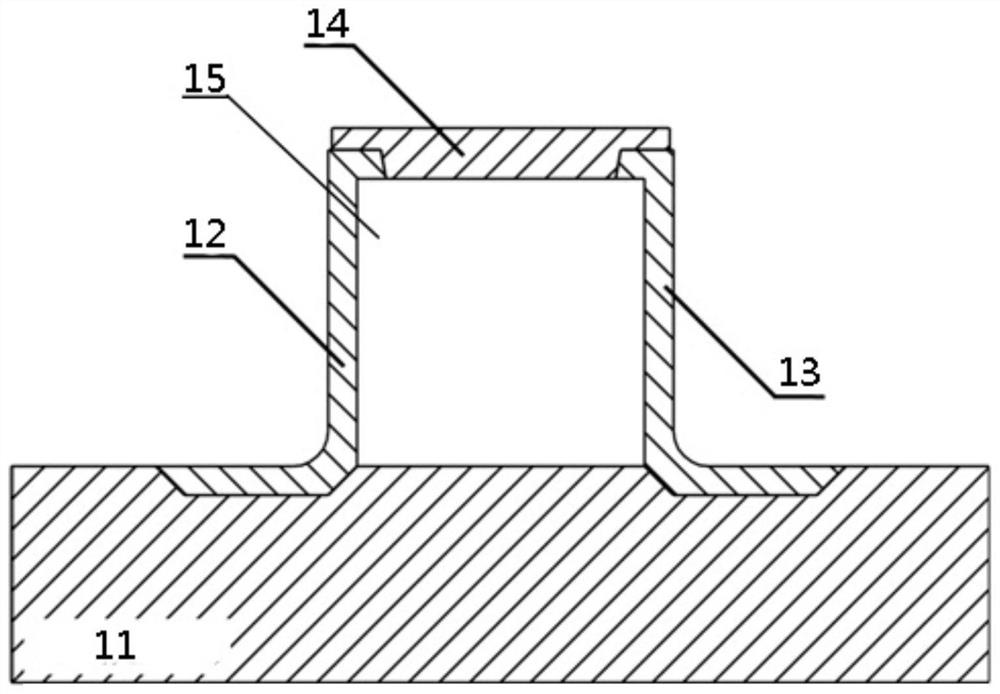

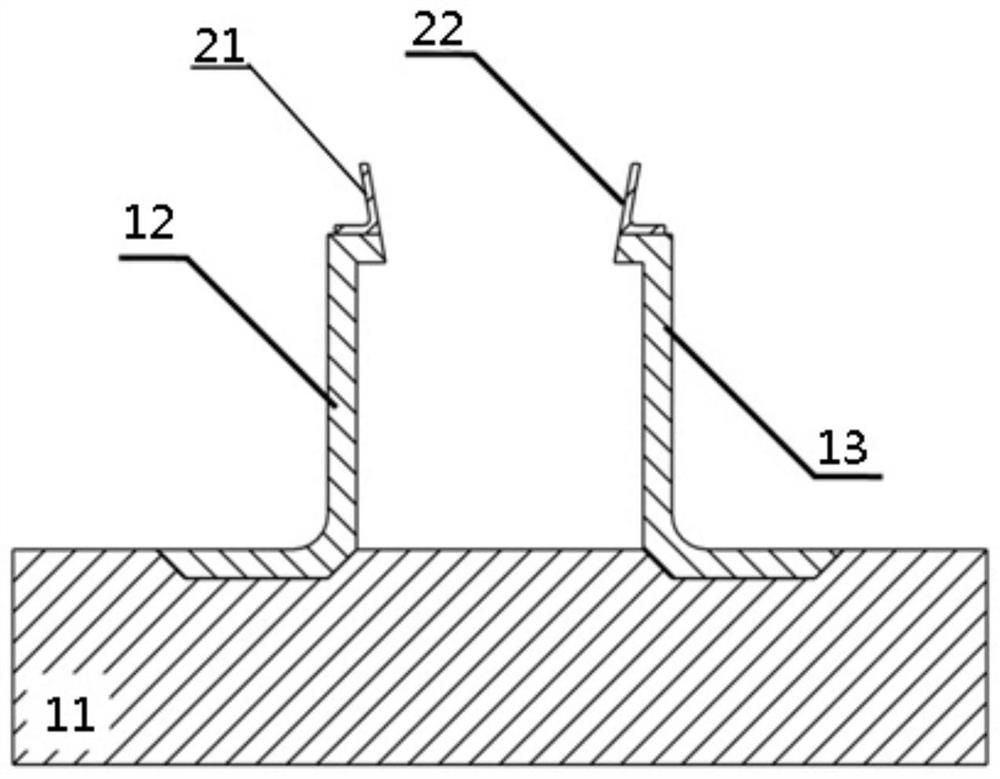

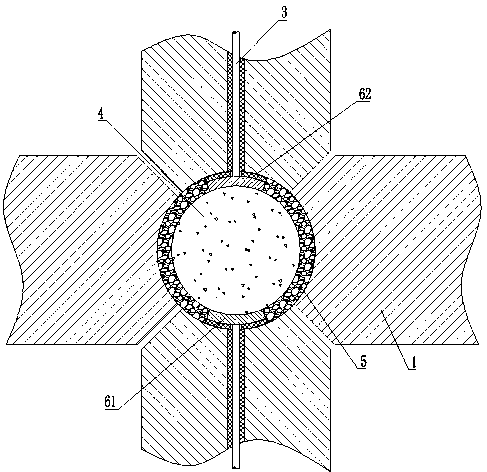

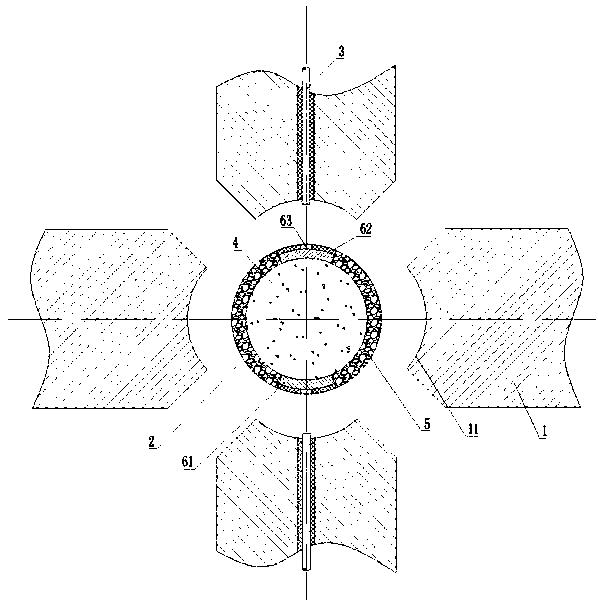

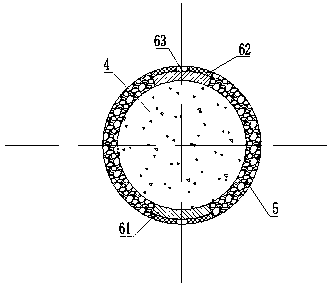

Pressure-equalizing type diamond synthesis device and diamond synthesis method based on device

InactiveCN102658061BKeep shapeRaise the gradeUltra-high pressure processesPyrophylliteSynthesis methods

The invention discloses a pressure-equalizing type diamond synthesis device and a diamond synthesis method based on the device. The pressure-equalizing type diamond synthesis device comprises a cubic apparatus, wherein the concave arc-shaped top pressing surface of each top hammer forms a spherical top pressing cavity; a pair of opposite top hammers is provided with a conductive electrode respectively; and the conductive electrode is isolated from the corresponding top hammer. The pressure-equalizing type diamond synthesis device further comprises a spherical raw material synthesis block made of graphite and a catalyst, wherein a spherical pyrophyllite synthesis bowl matched with the spherical top pressing cavity is arranged on the raw material synthesis block; a conductive communicating device corresponding to the conductive electrode and the raw material synthesis block are arranged on the pyrophyllite synthesis bowl; the raw material synthesis block and the pyrophyllite synthesis bowl are spherical and matched with each other; the top pressing surface of the top hammer has a concave arc shape matched with the top hammer; the top hammers apply pressure to the raw material synthesis block from six directions; the pressure in the spherical top pressing cavity is uniform; any angle of the raw material synthesis block is extruded uniformly; when the raw material synthesis block are electrified and heated, the raw material synthesis block has high resistance value and is heated quickly and uniformly; and the synthesis efficiency of the diamond is improved.

Owner:山东日能超硬材料有限公司

A kind of high density ceramic material and its preparation method and application

The invention provides a high-density ceramic material and its preparation method and application, belonging to the technical field of ceramic materials. The high-density ceramic material provided by the invention has a chemical composition of: La(Mg 0.4‑x tm x Fe 0.2 co 0.2 Ni 0.2 ) Al 11 o 19 , where TM is Cu or Zn; 0

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com