A molding tool and a method for preparing a rectangular hollow composite material tubular member using the molding tool

A composite material and forming tooling technology, applied in the direction of tubular objects, applications, household appliances, etc., can solve problems such as uneven pressure, impact on molding quality, and reduce production costs, so as to avoid uneven expansion pressure, uniform pressure transmission, The effect of simple demoulding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] In general, the preparation method provided by the invention comprises the following steps:

[0085](1) The present invention is a mandrel-free preparation process, which does not require the auxiliary preparation of cavity-type composite products such as silicone rubber mandrels, metal mandrels or foam mandrels, and does not require additional manufacturing of mandrel tooling to avoid the manufacture of mandrels The process not only reduces the cost of tooling and core mold manufacturing, but also has simple mold clamping and demoulding processes, without special equipment, shortening the product preparation cycle and improving production efficiency.

[0086] (2) The present invention transmits the molding pressure through the vacuum bag, which can ensure the uniform pressure transmission of the product during the molding process, ensure the molding quality of the product, and avoid the disadvantage of uneven expansion pressure caused by the expansion mandrel.

[0087]...

Embodiment 1

[0091] Component Product Name: Rectangular Hollow Composite Tube.

[0092] Product dimensions: length 7500mm, square section, side length 200mm.

[0093] The forming tooling is designed as:

[0094] The forming tooling includes a body and auxiliary parts;

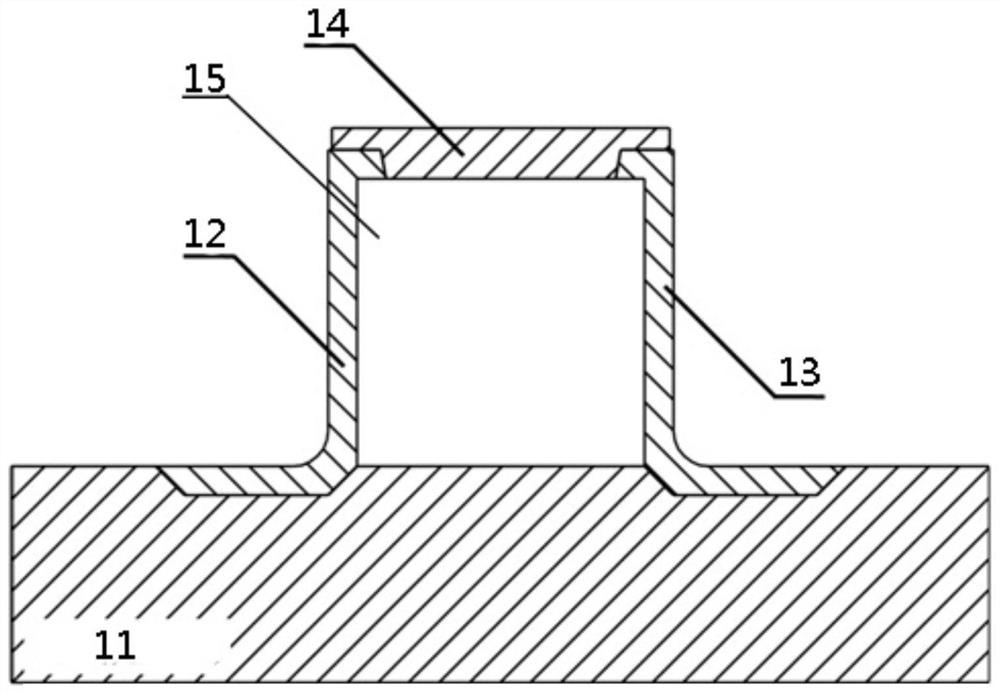

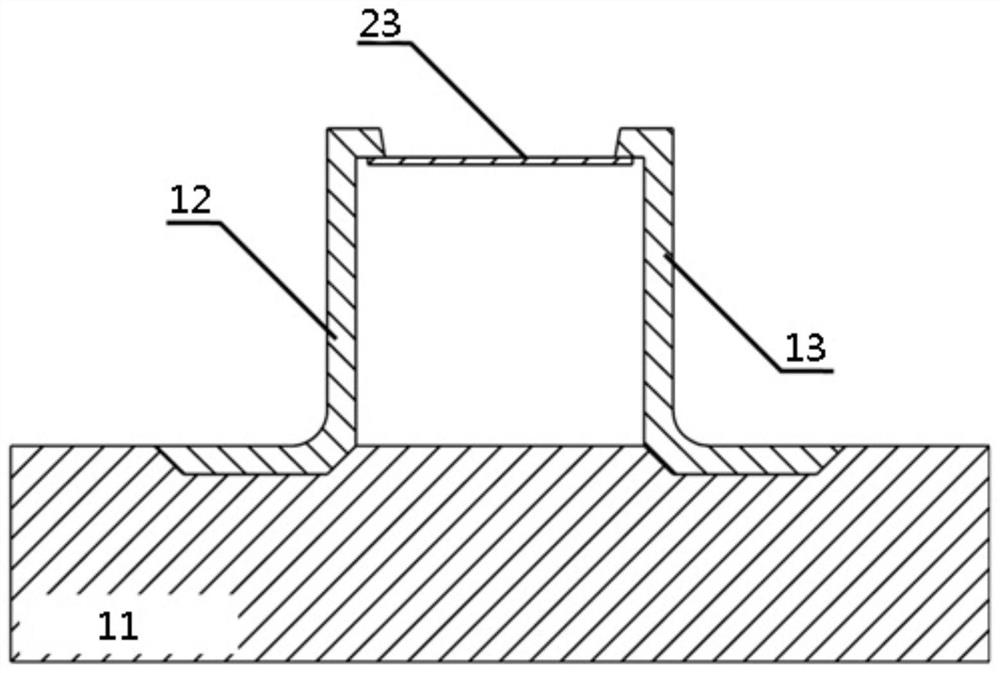

[0095] The body includes a bottom plate, a left side baffle, a right side baffle and an upper baffle, and the four cooperate with each other to form a rectangular cavity. Both the left baffle and the right baffle are detachably connected to the bottom plate, and the upper baffle is detachably connected to the left baffle and the right side baffle. The upper ends of the left side baffle and the right side baffle are designed as corners extending inward, and the corner length is 30 mm (it should be noted that the meaning of the corner length here is the left side baffle and the right side The distance that the baffle extends inward, taking the left baffle as an example, this distance refers to the vertical distance from th...

Embodiment 2

[0114] The dimensions of the rectangular hollow composite material tube provided in Example 2 are the same as those in Example 1.

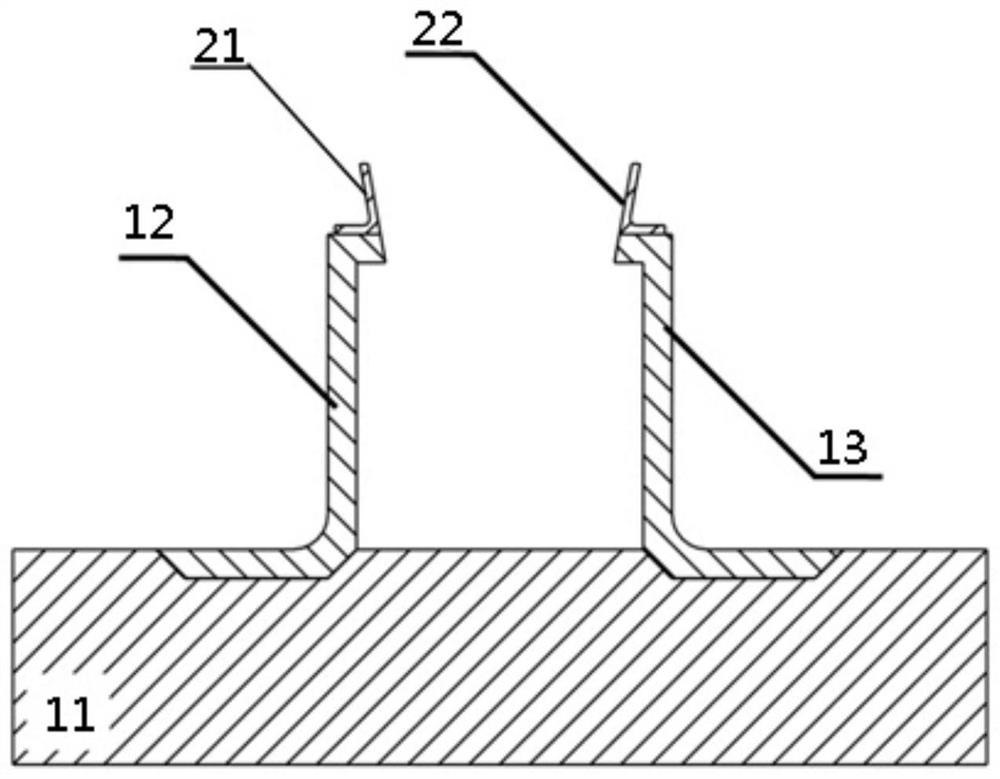

[0115] The design of the molding tool is basically the same as that of Example 1. In order to simplify the text, only the design of the molding tool of Example 2 that is different from that of Example 1 is described here:

[0116] The length of the upper corner of the left baffle and the right baffle are both 20mm, and the length of the lower corner is 110mm;

[0117] The top corners of the left side baffle and the right side baffle are designed to be beveled, and the angle of the bevel is 75°.

[0118] The molding method is the same as in Example 1, and will not be described in detail here.

[0119] The appearance quality of the final formed components is good, and there are no defects such as delamination and debonding inside the non-destructive testing components, and the porosity is qualified, which ensures the appearance quality and internal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com