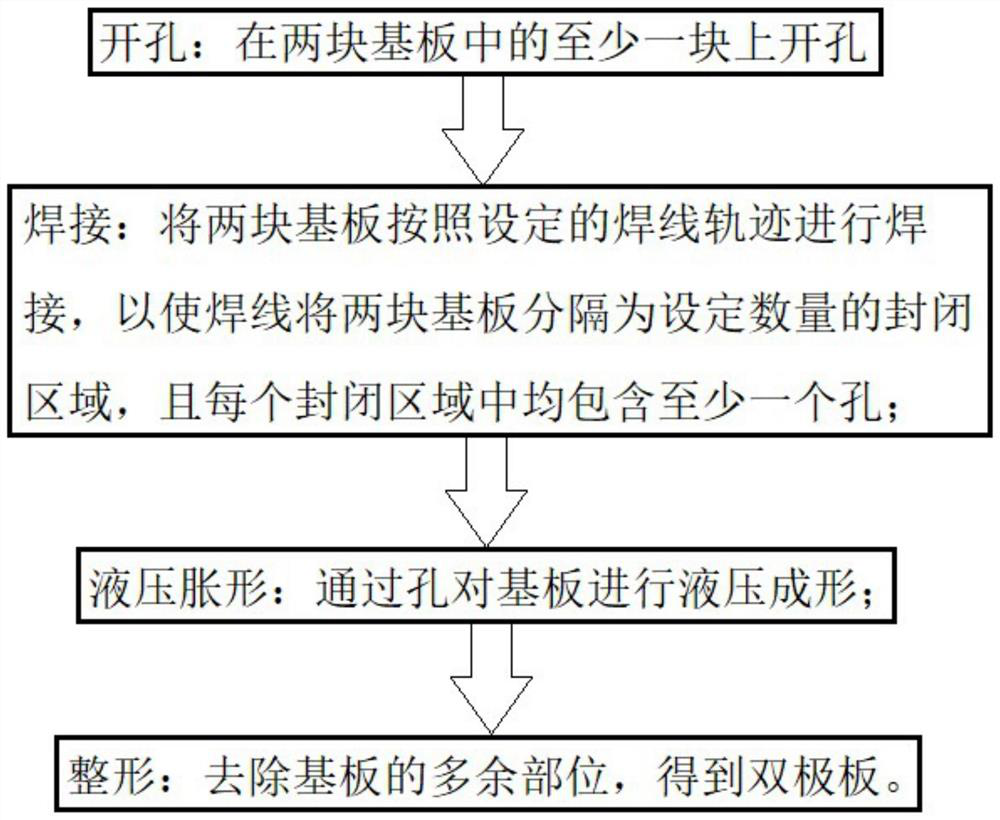

Fuel cell bipolar plate production method

A fuel cell and production method technology, applied in the direction of fuel cells, electrochemical generators, circuits, etc., can solve the problems of high production cost, poor molding precision, and large number of molds, achieve sufficient plastic deformation, reduce welding difficulty, and pressure Delivers an even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

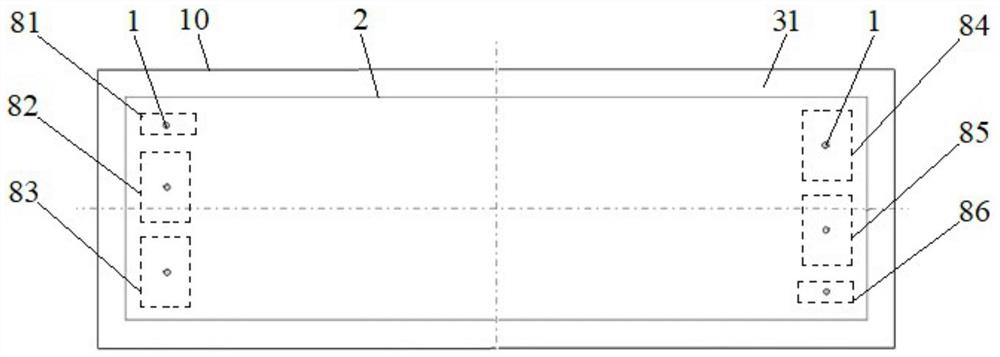

[0042] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0043] The traditional bipolar plate manufacturing process is: stamping → laser welding → coating → sealing. Usually, the raw materials are stamped and formed into cathode plates and anode plates with fine flow channels, and the two unipolar plates are welded together by laser to form a bipolar plate structure of "two plates and three fields", and then the bipolar plates are coated. Layer treatment to improve its corrosion resistance, and then fill the sealing material in the designed sealing line on the bipolar plate. The forming accuracy of the bipolar plate is affected by factors such as plate springback, the forming accuracy is poor, and the entire production cycle is long.

[0044]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com