A kind of woven bag and its weaving process

A woven bag and process technology, which is applied in the direction of textile, fabric, textile and papermaking, etc., can solve the problems of poor surface effect, flat yarn discount, rough surface, etc., achieve smooth surface, enhanced shrinkage rate, and improve surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

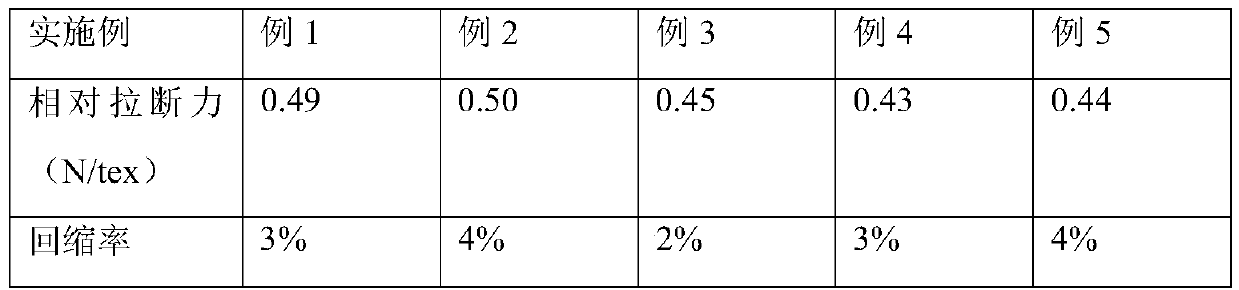

Examples

Embodiment 1

[0033] A woven bag, woven through the following process: using flat yarn as raw material, dividing the flat yarn into vertical warp flat yarn and horizontal weft flat yarn, weaving warp flat yarn and weft flat yarn to obtain weaving Cloth, the woven cloth can be cut into a certain length and width and then sewn into a woven bag. The width of the warp flat yarn is smaller than the width of the weft flat yarn.

[0034] The weaving density of the warp flat yarns and weft flat yarns is that the ratio of the number of warp flat yarns to the number of weft flat yarns per unit area of 10cm*10cm is 48-49:41-42.

[0035] The width ratio of the warp flat yarn and the weft flat yarn is 2.00:2.40. The width of the warp flat yarn is 2.00mm, and the width of the weft flat yarn is 2.40mm.

[0036] Described flat silk comprises the raw material of following weight percent:

[0037] PP 100%

[0038] The flat yarn comprises the following preparation steps: (1) drying PP at 90°C for a certai...

Embodiment 2

[0042] A woven bag, woven through the following process: using flat yarn as raw material, dividing the flat yarn into vertical warp flat yarn and horizontal weft flat yarn, weaving warp flat yarn and weft flat yarn to obtain weaving Cloth, the woven cloth can be cut into a certain length and width and then sewn into a woven bag. The width of the warp flat yarn is smaller than the width of the weft flat yarn.

[0043] The weaving density of the warp flat yarns and weft flat yarns is that the ratio of the number of warp flat yarns to the number of weft flat yarns per unit area of 10cm*10cm is 49-50:40-41.

[0044] The width ratio of the warp flat yarn and the weft flat yarn is 1.80:2.40, the width of the warp flat yarn is 1.80mm, and the width of the weft flat yarn is 2.40mm.

[0045] Described flat silk comprises the raw material of following weight percent:

[0046] Masterbatch 15%

[0047] PP 75%

[0048] Recycled 10%.

[0049] The masterbatch is prepared by the followi...

Embodiment 3

[0054] A woven bag, woven through the following process: using flat yarn as raw material, dividing the flat yarn into vertical warp flat yarn and horizontal weft flat yarn, weaving warp flat yarn and weft flat yarn to obtain weaving Cloth, the woven cloth can be cut into a certain length and width and then sewn into a woven bag. The width of the warp flat yarn is smaller than the width of the weft flat yarn.

[0055] The weaving density of the warp flat yarns and weft flat yarns is that the ratio of the number of warp flat yarns to the number of weft flat yarns in a unit area of 10cm*10cm is 49-50:39-40.

[0056] The width ratio of the warp flat yarn and the weft flat yarn is 1.95:2.45, the width of the warp flat yarn is 1.95mm, and the width of the weft flat yarn is 2.45mm.

[0057] Described flat silk comprises the raw material of following weight percent:

[0058] Masterbatch 10%

[0059] PP 85%

[0060] Recycled 5%.

[0061] The masterbatch is prepared by the followi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com