A method for preparing a high-strength single-layer aramid conveyor belt joint structure

A joint structure and conveyor belt technology, applied in conveyors, belt fasteners, mechanical equipment, etc., can solve the problems of difficulty in using joint methods, low joint strength retention rate, etc., and achieve high meridional strength and smooth transition of stress. , the effect of good bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

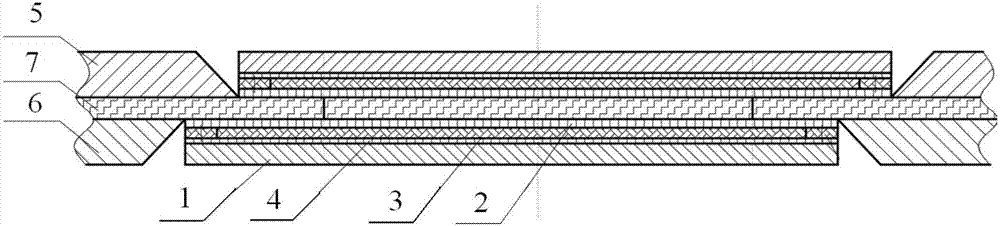

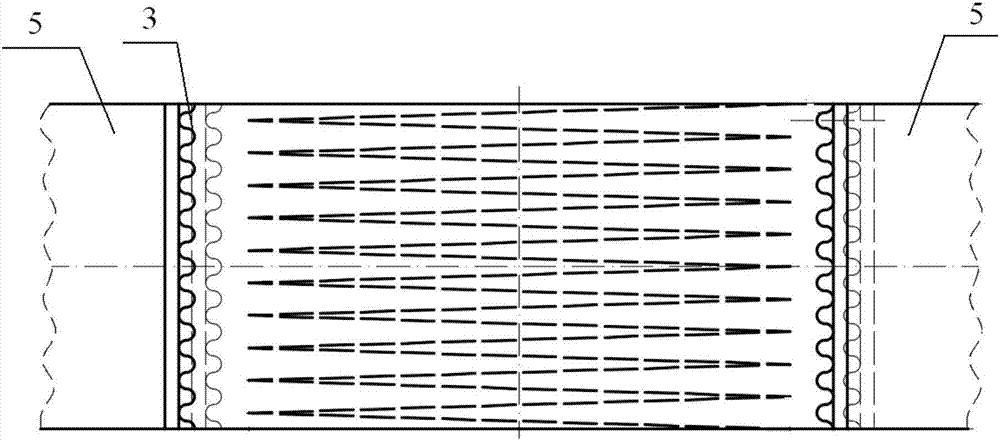

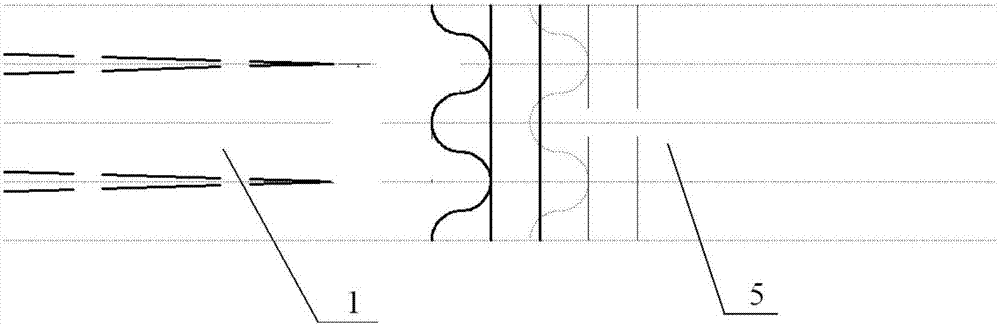

[0034] Such as Figure 1-3 Shown: A high-strength single-layer aramid conveyor belt joint structure, including a single-layer aramid straight warp and straight weft canvas conveyor belt, the single layer aramid straight warp and straight weft canvas conveyor belt consists of a skeleton material in the middle and covers the upper and lower The two ends of the upper belt body cover glue and the lower belt body cover glue; the two ends of the skeleton material of the single-layer aramid straight warp and straight weft canvas conveyor belt are spliced with each other to form a ring; the upper and lower sides of the skeleton material are covered with a layer cladding;

[0035] The cladding layer sequentially includes a cover film, a first adhesive layer, a fabric reinforcement layer and a second adhesive layer from top to bottom; the second adhesive layer is directly bonded to the skeleton material; The splicing of the skeleton material of the straight weft canvas conveyor belt ...

Embodiment 2

[0045] The preparation method of the high-strength single-layer aramid conveyor belt joint structure, the steps are:

[0046] (1) Peel off the rubber material: take the single-layer aramid straight warp and straight weft canvas conveyor belt to be connected, and peel off the upper belt body covering glue and the lower belt body covering glue in the joint area at both ends; the remaining upper belt body covering after stripping Trim the end surface of the glue and the covering glue of the lower belt body into a 45° groove, and the slope width is 50mm; cut off the remaining glue on the surface of the skeleton material, and pay attention to avoid scratching the canvas surface of the skeleton material;

[0047] (2) Grinding excess glue: Grind the surface of the single-layer aramid straight warp and straight weft canvas conveyor belt skeleton material obtained in step (1) with glue, and pay attention to avoid damage to the surface of the skeleton material to prevent polishing or sco...

Embodiment 3

[0055] The preparation method of the high-strength single-layer aramid conveyor belt joint structure, the steps are:

[0056] (1) Peel off the rubber material: take the single-layer aramid straight warp and straight weft canvas conveyor belt to be connected, and peel off the upper belt body covering glue and the lower belt body covering glue in the joint area at both ends; the remaining upper belt body covering after stripping Trim the end surface of the glue and the covering glue of the lower belt body into a 45° groove, and the slope width is 50mm; cut off the remaining glue on the surface of the skeleton material, and pay attention to avoid scratching the canvas surface of the skeleton material;

[0057] (2) Grinding excess glue: Grind the surface of the single-layer aramid straight warp and straight weft canvas conveyor belt skeleton material obtained in step (1) with glue, and pay attention to avoid damage to the surface of the skeleton material to prevent polishing or sco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com