Low weight superhydrophobic wrapping paper and preparation method thereof

A super-hydrophobic and wrapping paper technology, applied in wrapping paper, wrapping paper, packaging, etc., can solve problems such as difficult to meet waterproof requirements, unstable waterproof performance, limited waterproof performance, etc., to achieve reduced energy consumption, no loss in combination, and reduced pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

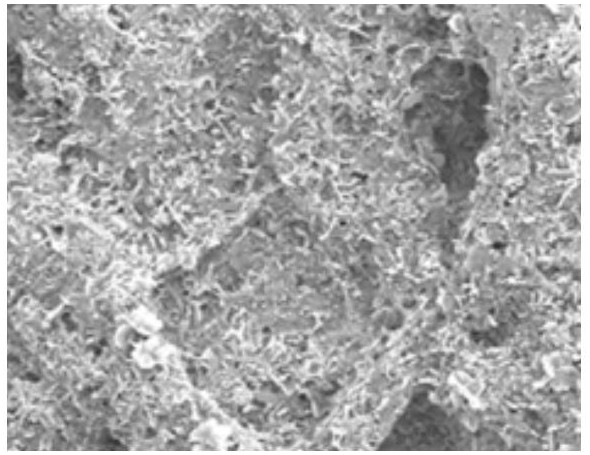

Image

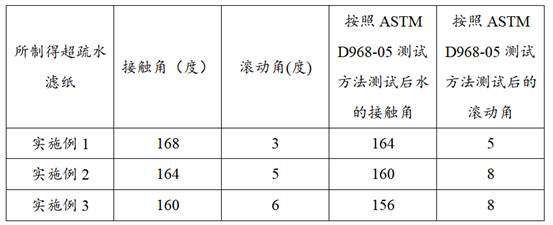

Examples

preparation example Construction

[0029] The preparation method of described low quantitative superhydrophobic wrapping paper, comprises the following steps:

[0030] (1) Preparation of mixed waxy emulsion:

[0031] First prepare 1.0-2.0 g / L CTAB (cetyltrimethylammonium bromide) solution and heat it to 75-85°C, add it to the homogenizer; mix two or more waxes with different melting points Hot-melt mixing, the heating temperature is higher than the temperature of the lowest melting point wax, lower than the temperature of the highest melting point wax, forming a part solid-part liquid state; hot-melt mixed wax is added to the above-mentioned homogenizer, controlled at 75-85 °C, Stirring speed 2000-3000 r / min, stirring time 30-60min, stop heating and continue stirring for 10-20min, stirring speed 500-800 r / min, form micron-sized waxy particle emulsion, concentration is 6-10 wt%, cool to Standby at room temperature;

[0032] (2) Wax emulsion coating:

[0033] Coat the micron-sized wax particle emulsion obtai...

Embodiment 1

[0041] A preparation method for low-weight superhydrophobic wrapping paper, comprising the steps of:

[0042] (1) Preparation of mixed waxy emulsion: first prepare 2.0 g / L CTAB solution and heat it to 85°C, then add it to the homogenizer; heat-melt and mix two or more waxes with different melting points, the heating temperature is high At the temperature of the wax with the lowest melting point, lower than the temperature of the wax with the highest melting point, a part solid-part liquid state is formed; the hot-melt mixed wax is added to the above homogenizer, controlled at 85°C, stirring speed 3000 r / min, stirring time After 60 minutes, stop heating and continue stirring for 20 minutes at a stirring speed of 800 r / min to form a micron-sized wax particle emulsion with a concentration of 10 wt%, and cool to room temperature for later use.

[0043] The wax is vegetable wax, mineral wax or synthetic wax, and the melting point temperature of the wax with the lowest melting poi...

Embodiment 2

[0049] (1) Preparation of mixed wax emulsion: first prepare 1.5 g / L CTAB solution and heat it to 80 ° C, add it to the homogenizer; heat and mix two or more waxes with different melting points, the heating temperature is high At the temperature of the wax with the lowest melting point, which is lower than the temperature of the wax with the highest melting point, a part solid-part liquid state is formed; the hot-melt mixed wax is added to the above homogenizer, controlled at 80°C, stirring speed 2500 r / min, stirring time After 60 minutes, stop heating and continue stirring for 20 minutes at a stirring speed of 650 r / min to form a micron-sized waxy particle emulsion with a concentration of 6 wt%, and cool to room temperature for later use.

[0050] The wax is vegetable wax, mineral wax or synthetic wax, and the melting point temperature of the wax with the lowest melting point is not higher than 70°C.

[0051] (2) Coating of waxy emulsion: apply the waxy emulsion obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com