Anti-sagging ceramic-beautifying glue and performance detection method thereof

A detection method and anti-sag technology, applied in the directions of flow characteristics, adhesives, measuring devices, etc., can solve the problems of unfavorable construction stability, poor construction effect, poor anti-sag performance of the porcelain glue, and improve the storage stability. , Good construction effect, the effect of improving waterproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

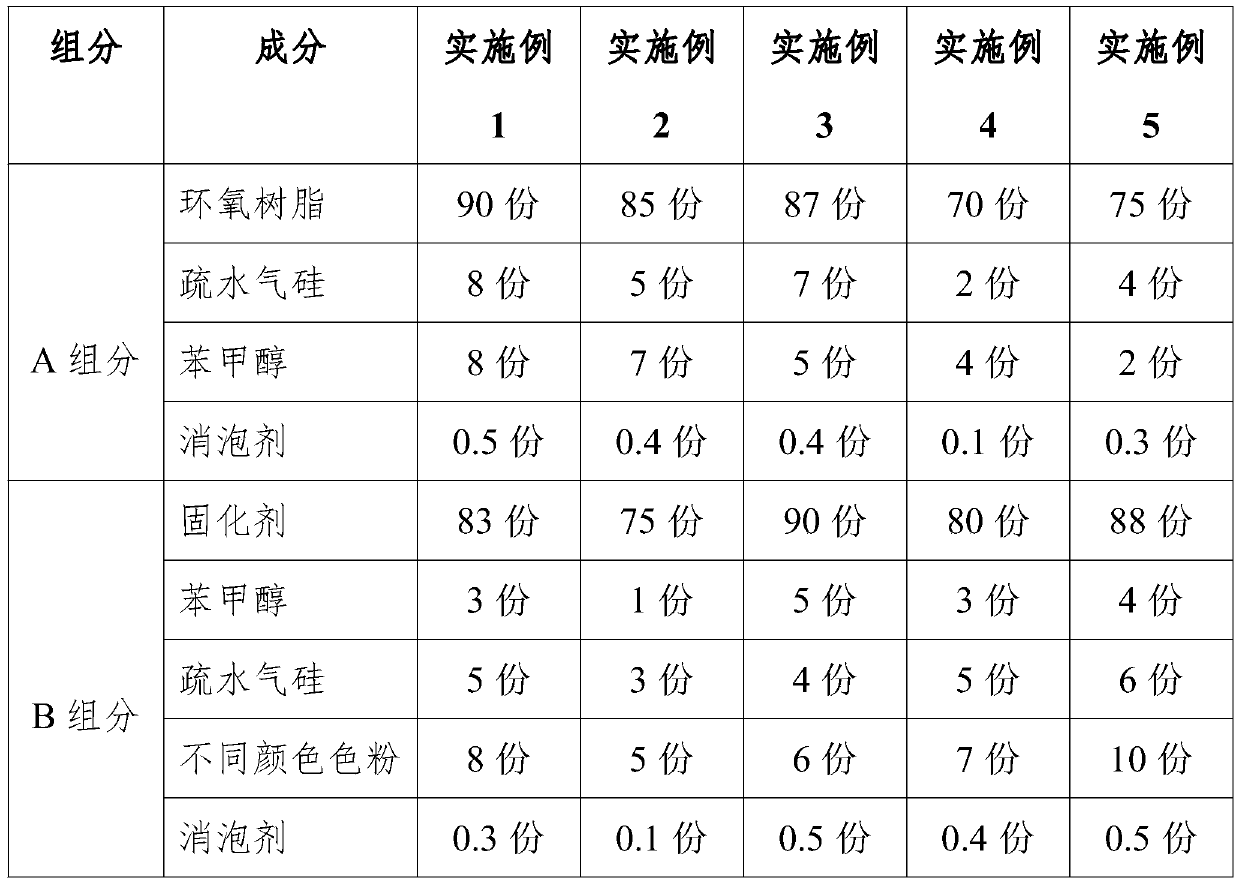

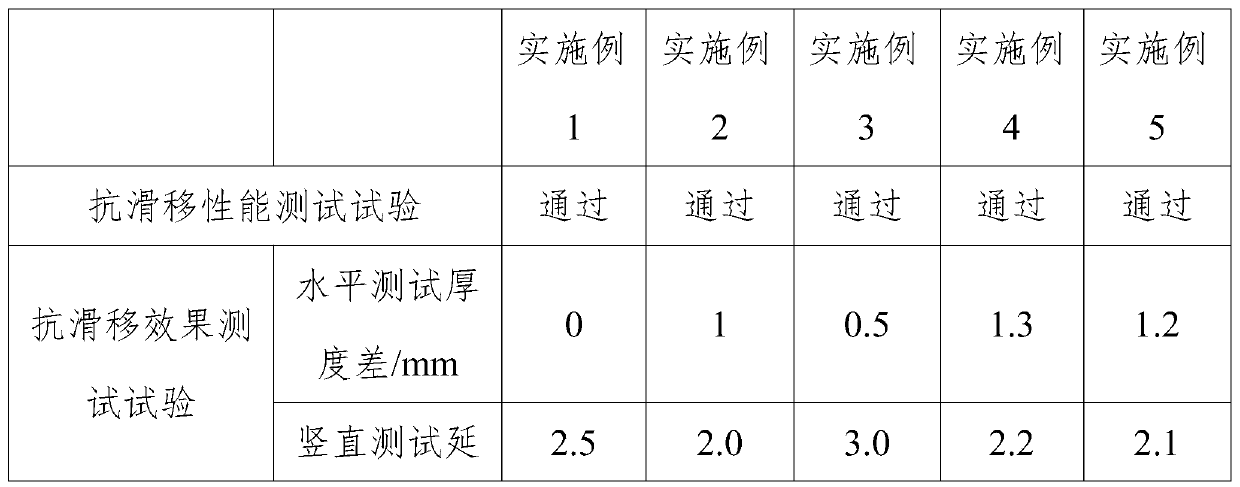

[0027] Embodiments 1 to 5 respectively provide a kind of anti-sag mechatronics, and the components and parts by weight of the anti-sag mechatronics described in each embodiment are shown in Table 1 respectively:

[0028] Table 1 The parts by weight of the anti-sagging mezzanine components of Examples 1 to 5

[0029]

[0030] In Examples 1-5, component A and component B are mixed in a weight ratio of 1:1.

[0031] The curing agent described in Example 1 is m-xylylenediamine; the toner of different colors is gray; the defoamer is a silicone defoamer.

Embodiment 2

[0032] The curing agent described in Example 2 is isophorone diamine; the toner of different colors is gray; the defoamer is a silicone defoamer.

Embodiment 3

[0033] The curing agent described in Example 3 is phenylethylamine; the toner of different colors is gray; the defoamer is a silicone defoamer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com