Pressure welding method of large-area target material

A pressure welding, large-area technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as reducing production costs, and achieve the effects of short welding time, high bonding strength, and low processing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

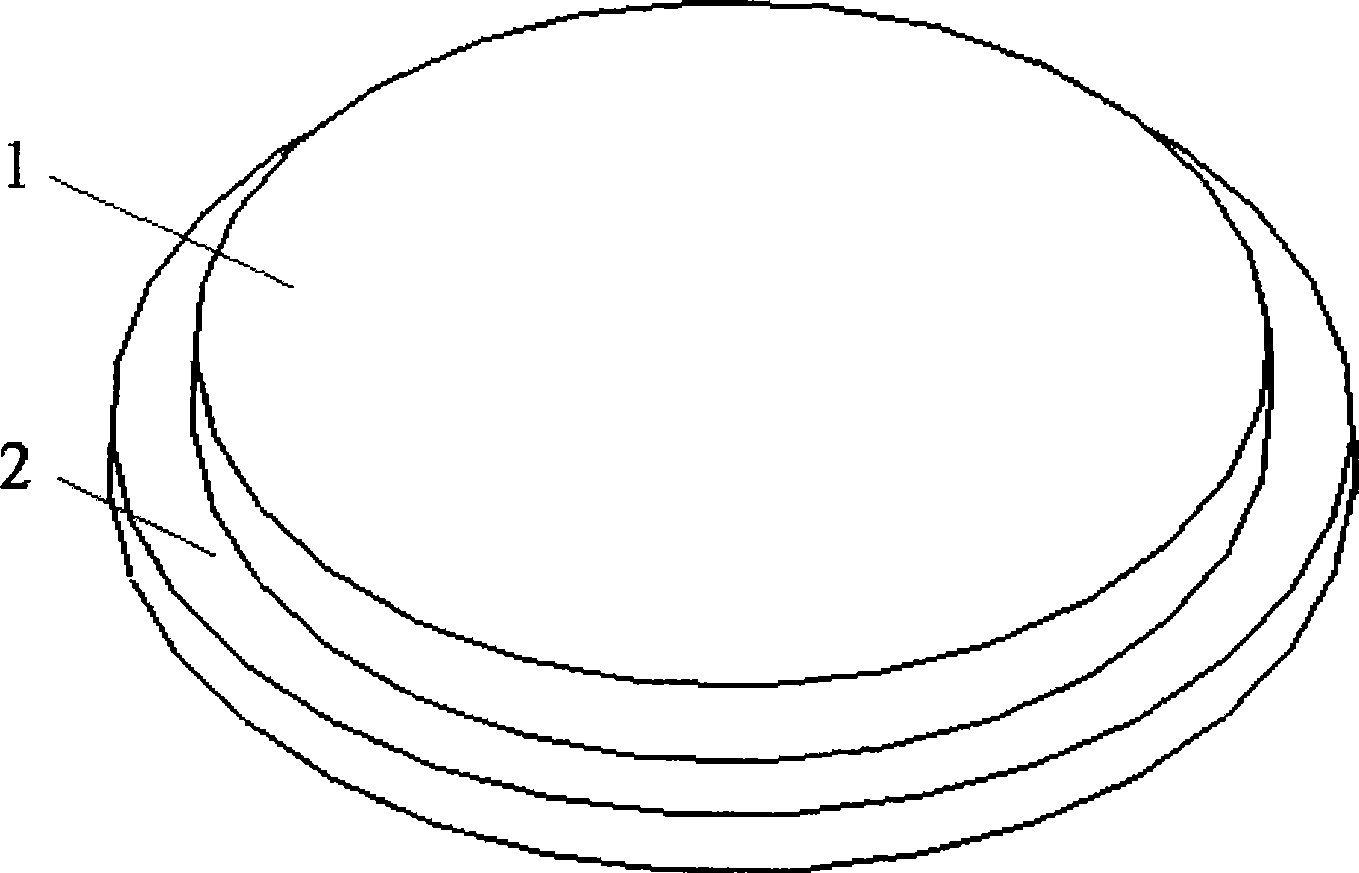

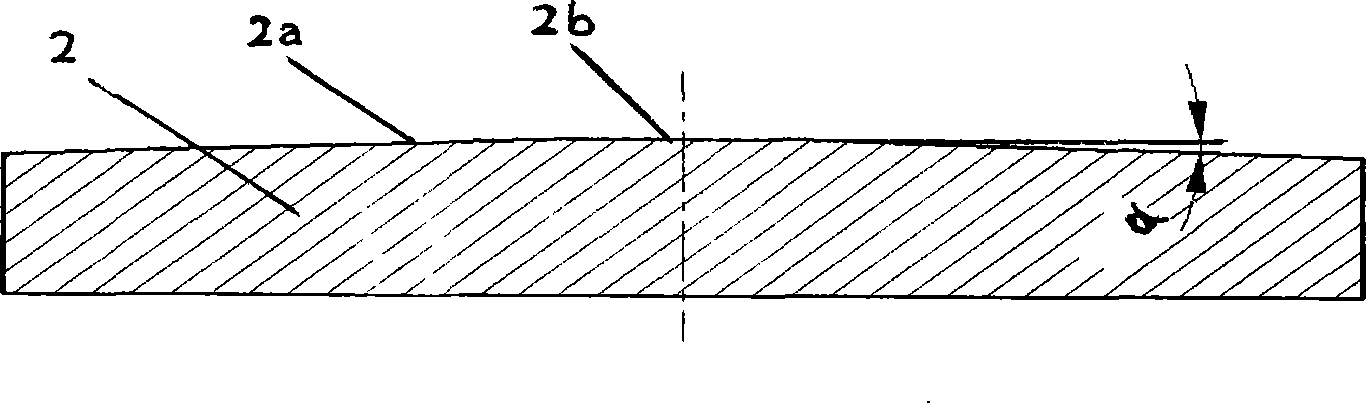

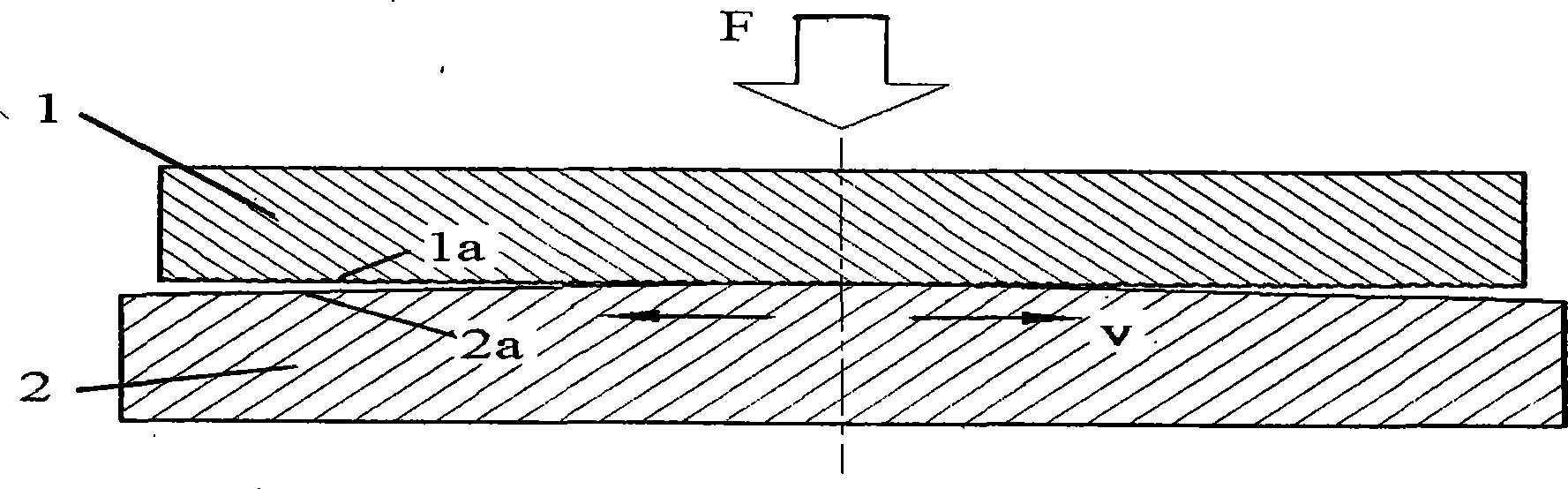

[0033] Welding of high-purity Ti target and 6061Al alloy back plate. The Ti target with a purity of 4N5 has a diameter of 350 mm and a thickness of 15 mm. The surface roughness Rz of the target surface to be welded is about 100 μm by sandblasting. The back plate is made of 6061Al alloy, with a diameter of 380mm and a thickness of 20mm. figure 2 The angle α between the conical surface 2a shown and the horizontal plane is 3°, and 2b is a small platform in the center, which is mainly used to place the target on it; the surface of the target and the back plate is cleaned with clean water with decontamination powder After ultrasonic cleaning to remove oil, clean the surface of the target and the back plate to be welded with absolute ethanol, and finally dry the surface; heat the back plate to 400°C, keep it warm for 30 minutes, and place the unheated target on the heated back On the board, apply a pressure of 100MPa to fully deform the curved surface of the backplane, such as i...

Embodiment 2

[0035] Welding of high-purity Cu target and 6061Al alloy backplane.

[0036] The raw material of the 6N Cu target is a circular plate with a diameter of 350 mm and a thickness of 15 mm. The surface roughness Rz of the target surface to be welded is about 200 μm through turning. The back plate is 6061 Al alloy with a diameter of 380 mm and a thickness of 20 mm. figure 2As shown in the cone surface 2a, the angle α between it and the horizontal plane is 1°, and 2b is the center platform, which is mainly for placing the target on it; the surface of the target and the back plate are cleaned and then dried; the back plate is heated to 450°C, keep warm for 30 minutes, place the unheated Cu target on the heated aluminum backing plate, and apply a pressure of 150 MPa to fully deform the curved surface of the backing plate until the surfaces 2a and 2b of the backing plate and the surface of the target 1a are occluded together; The clamp made of GH130 alloy steel is used to clamp the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com