Electron beam welding method for lock butt joint of large-size thin-wall titanium alloy storage tank

An electron beam welding and butt joint technology, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the gap and dislocation of post-welded butt joints, the influence of electron beam welding parameters on welding results, butt gap and Dislocation sensitivity and other problems, to achieve the effect of reducing production costs, avoiding multiple repairs and product scrap, and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

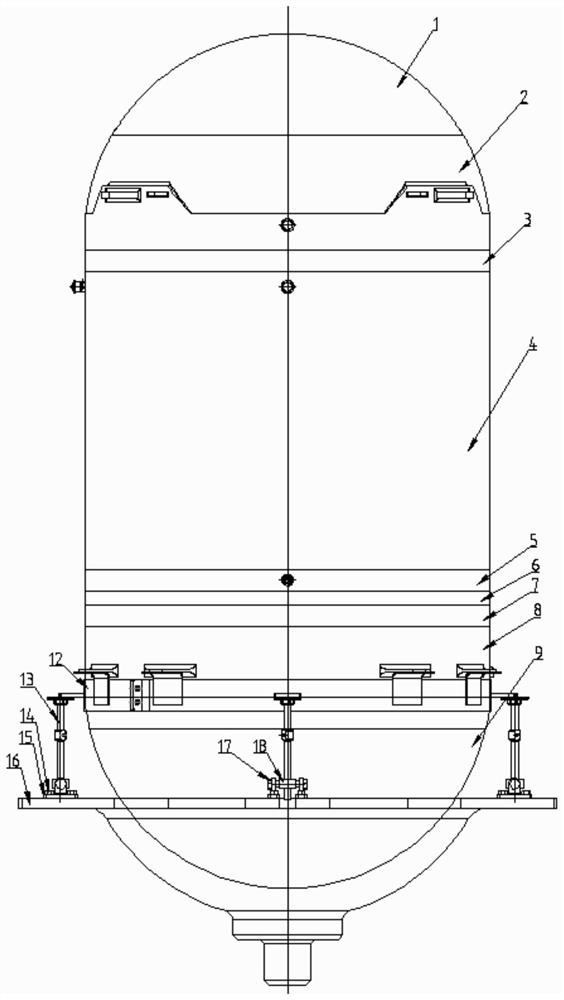

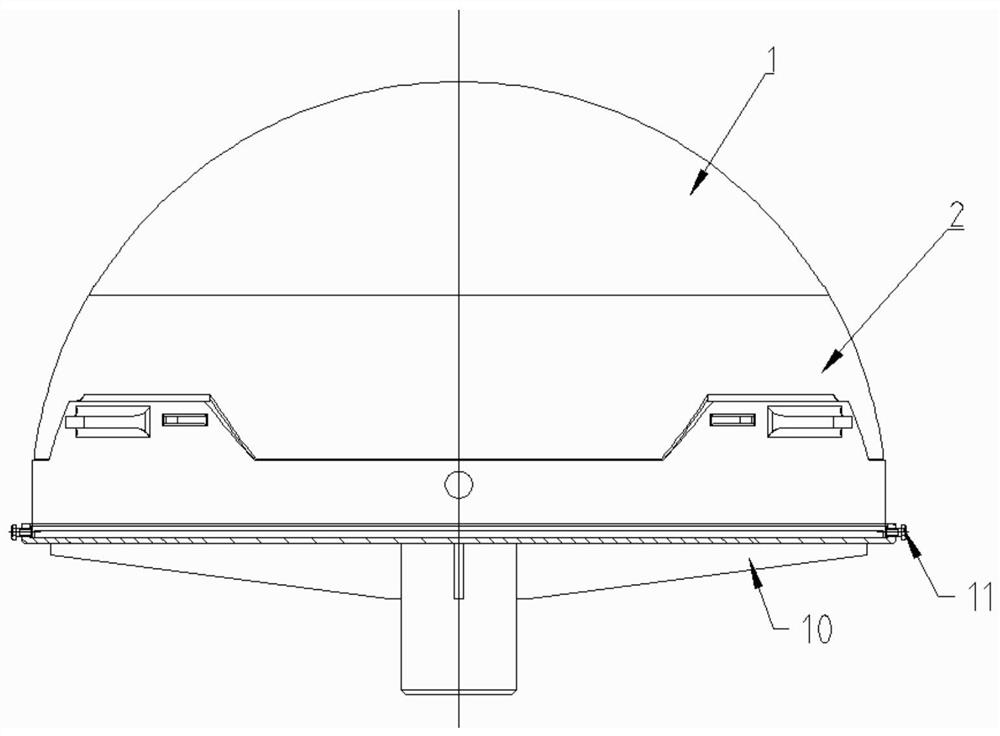

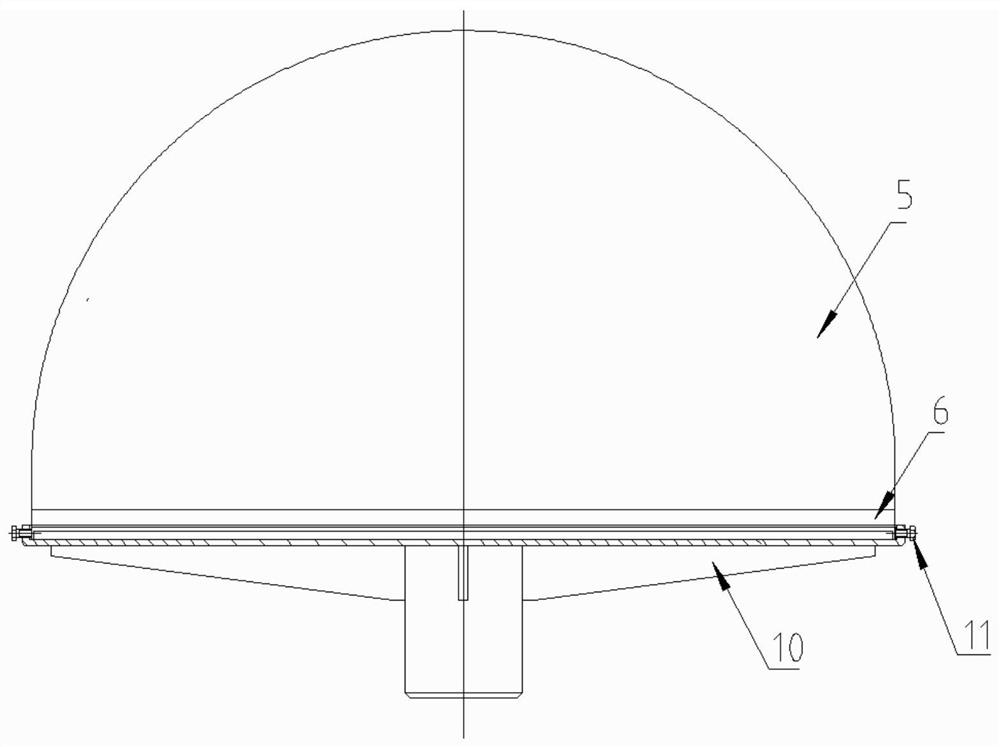

[0051] (1) The diameter of the butt joint of the common bottom partition 5 and the fixed ring 6 is 883.6mm, the diameter of the butt joint of the fuel hemispherical shell 1 and the fuel rear frame 2 is 767mm, and the thickness of the butt joint of the two welds is 2.2mm. The thickness of the bottom is 0.8mm; acid wash the common bottom baffle 5, the fixing ring 6, the fuel rear frame 2, and the fuel hemispherical shell 1, and weld them within 24 hours; assemble the common bottom baffle 5, the fixing ring 6, and the fuel hemispherical shell 1 respectively And the fuel rear frame 2, the butt gap is 0.1mm, the butt dislocation is 0.1mm, the two welds are respectively positioned by manual argon arc welding, no welding wire is added, the distance between the positioning points is 120mm, and the length of the positioning points is 10mm.

[0052] Use the support ring 10 of the first set of tooling to clamp the common bottom partition 5 and the fixed ring 6 that have been positioned, a...

Embodiment 2

[0058](1) The diameter of the butt joint of the common bottom partition 5 and the fixed ring 6 is 885mm, the diameter of the butt joint of the fuel hemispherical shell 1 and the fuel rear frame 2 is 770mm, and the thickness of the butt joint of the two welds is 2.5mm, and the bottom is locked The thickness is 1.4mm; acid wash the common bottom separator 5, the fixed ring 6, the fuel rear frame 2, and the fuel hemispherical shell 1, and weld them within 24 hours; respectively assemble the common bottom separator 5 and the fixed ring 6, the fuel hemispherical shell 1 and Fuel rear frame 2, the butt gap is 0.2mm, the butt dislocation is 0.2mm, and the two welds are respectively positioned by manual argon arc welding without welding wire. The distance between the positioning points is 180mm, and the length of the positioning points is 20mm.

[0059] Use the support ring 10 of the first set of tooling to clamp the common bottom partition 5 and the fixed ring 6 that have been positio...

Embodiment 3

[0065] (1) The diameter of the butt joint of the common bottom partition 5 and the fixed ring 6 is 850 mm, the diameter of the butt joint of the fuel hemispherical shell 1 and the fuel rear frame 2 is 760 mm, the thickness of the joint of the two welds is 3 mm, and the thickness of the bottom lock 1mm; acid wash the common bottom baffle 5, fixed ring 6, fuel rear frame 2, fuel hemispherical shell 1, and weld them within 24 hours; assemble common bottom baffle 5 and fixed ring 6, fuel hemispherical For frame 2, the butt gap is 0.15mm, and the butt dislocation is 0.15mm. Manual argon arc welding is used to position the two welds separately, without welding wire, the distance between the positioning points is 150mm, and the length of the positioning points is 15mm.

[0066] Use the support ring 10 of the first set of tooling to clamp the common bottom partition 5 and the fixed ring 6 that have been positioned, and tighten and fix them with screws; the axis of the workpiece is in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com