Ultra thin-wall high-temperature alloy lamination laser welding technology and clamp thereof

A high-temperature alloy and laser welding technology, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as large welding deformation, welding penetration not meeting the requirements, and welding technology not meeting the technical requirements of new structures. To achieve the effect of widening the weld width, controlling the welding penetration and reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

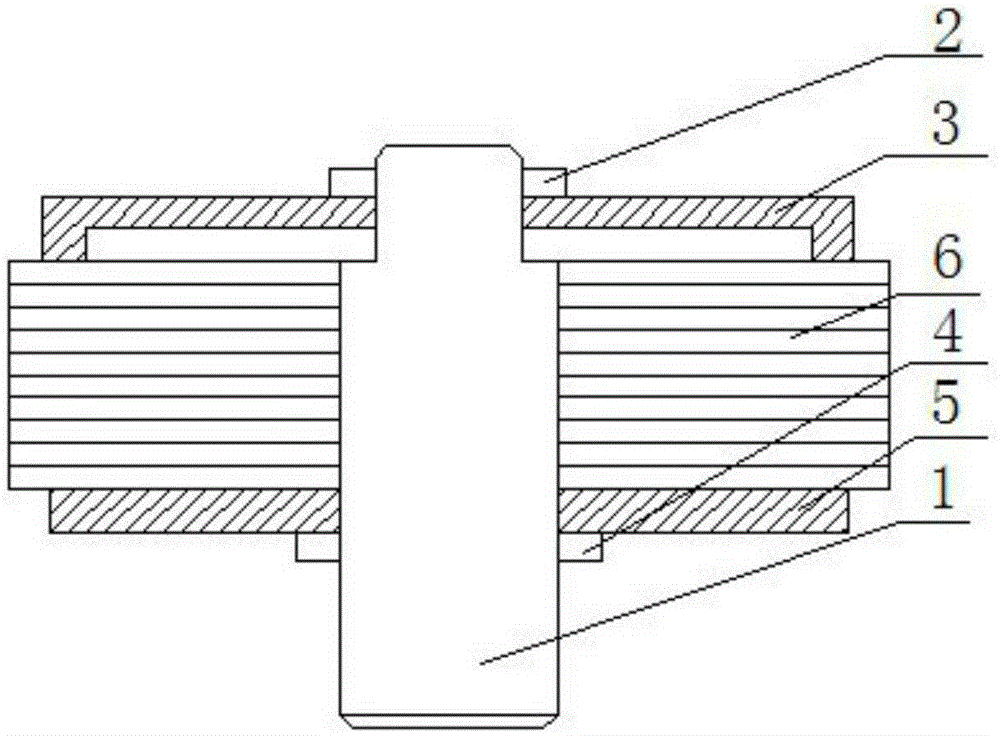

Embodiment 1

[0021] Example 1: A certain type of GH4648 high-strength superalloy has a thickness of 0.1mm and a diameter of 100mm with leaf-shaped grooves and finger pieces in the middle. After removing oil and dirt, 10 pieces are stacked together in groups. Assemble the laminations on the fixture and tighten the locking nut 2 to ensure that each lamination is tightly fitted, then use 40% of the normal welding power, and the spot diameter is 0.1mm to locate an area with an arc of 5°, each time In the positioning area, the workpiece is rotated by 1° to be a tack welding spot for 8 uniform tack welding in the circumferential direction, and then the laser power is 75W, the welding speed is 800m / min, and the laser defocus is used to increase the spot diameter to 0.4mm. Process parameters The rotary table is used to scan and weld once every rotation of 0.4°, and finally, laser repair is performed on the part with local unwelded fusion with a laser power of 90W. After welding, the welding meltin...

Embodiment 2

[0022] Example 2: A certain type of GH4648 high-strength superalloy has a thickness of 0.1mm and a diameter of 100mm with leaf-shaped grooves and fingers in the middle. After removing oil and dirt, 10 pieces are stacked together in groups. Assemble the laminations in the fixture and tighten the locking nut 2 to ensure that each lamination is tightly fitted, then use 40% of the normal welding power, and the spot diameter is 0.2mm to locate an area with an arc of 7°, each time In the positioning area, the workpiece is rotated by 1° to be a tack welding spot, and 8 positions are uniformly positioned in the circumferential direction, and then the spot diameter is increased to 0.4mm with a laser power of 85W, a welding speed of 800m / min and laser defocusing. Process parameters The rotary table is used to scan and weld once every rotation of 0.4°, and finally the local unwelded parts are repaired with laser power of 95W. After welding, the welding melting depth is 0.2mm, the outer c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com