A friction stir welding tool for lap joints

A technology of friction stir welding and lap joints, which is used in manufacturing tools, welding equipment, non-electric welding equipment and other directions. The effect of reducing the size of the defect and reducing the tendency of vertical migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

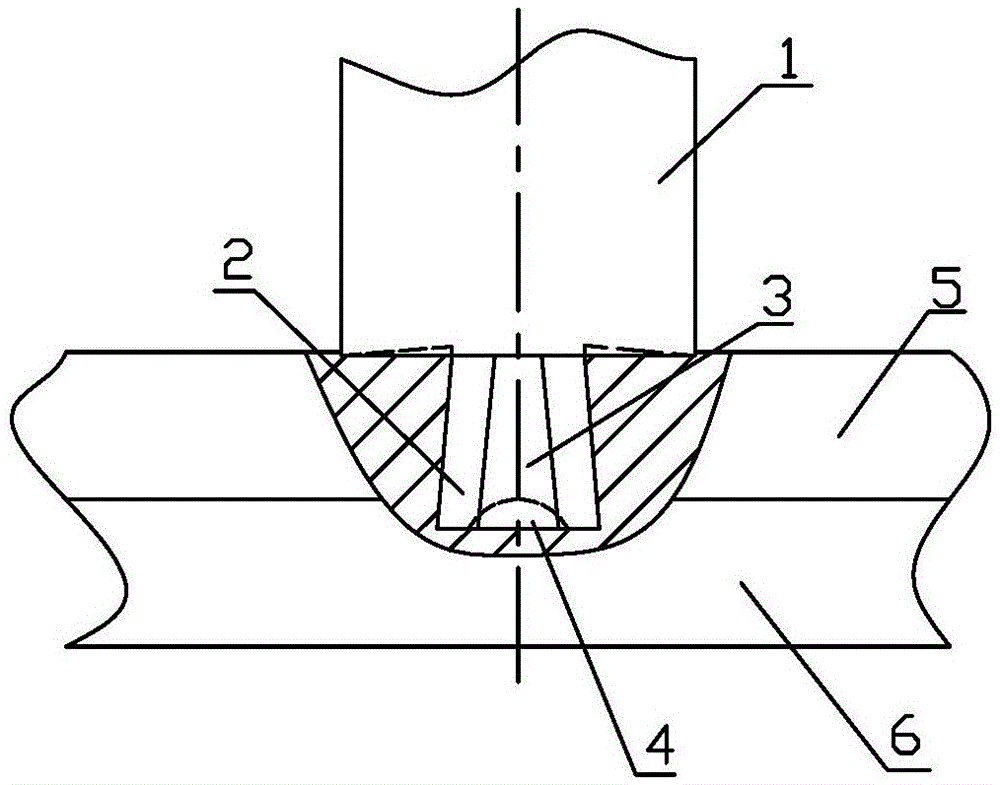

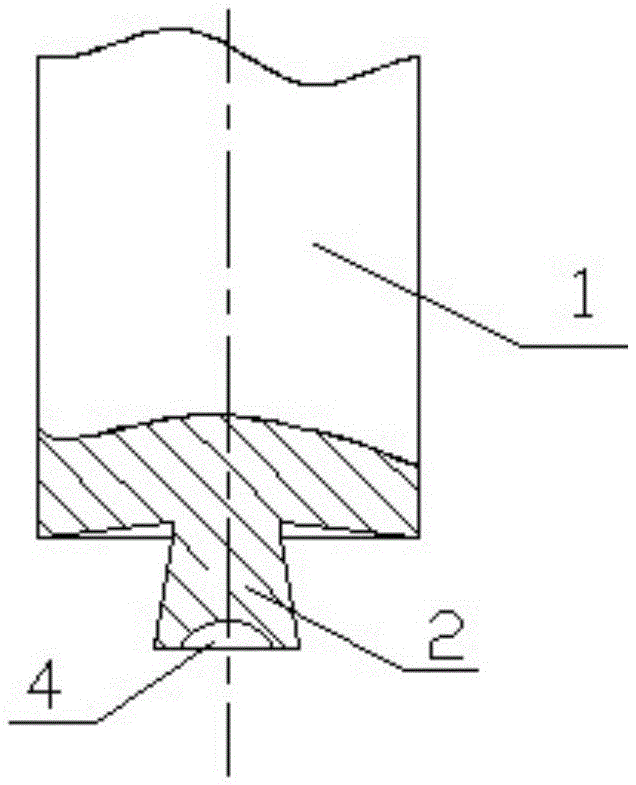

[0021] An aerospace structural part needs to involve lap joints of 5mm thick 2024 and 7075 dissimilar aluminum alloy plates. When welding the joints with ordinary cylindrical or conical threaded friction stir welding tools in the prior art, there are serious hooks in the joints. defect. Now according to the technical scheme provided by the present invention, a stirring tool suitable for this lap joint is processed.

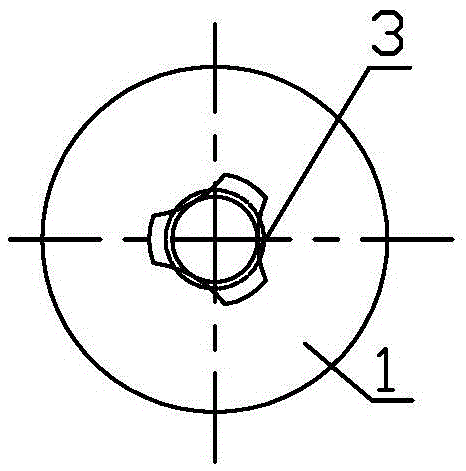

[0022] The length of setting stirring pin 2 is h=6mm, the cone angle 2α=16 ° of its truncated cone, and the (small bottom) top diameter of the truncated cone is D 2 =6mm, the diameter of the bottom (big bottom) is D 1 =2h*tanα+D 2 ≈7.7mm, the diameter of the circular concave hole 4 on the large bottom end face of the truncated cone is D 3 =0.75D 1 ≈5.8mm, depth h 1 = 1.5mm, the three arc-shaped grooves on the side of the stirring needle 2 are evenly distributed along the circumference, satisfying that the diameters of the three arc-shaped grooves 3 and the ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com