Argon arc welding method suitable for self connection of TiAl-based alloy material

A base alloy, argon arc welding technology, applied in arc welding equipment, welding/cutting medium/material, welding medium, etc., to achieve fast speed, high efficiency, and the effect of suppressing welding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Below in conjunction with embodiment technical solution of the present invention will be described in further detail:

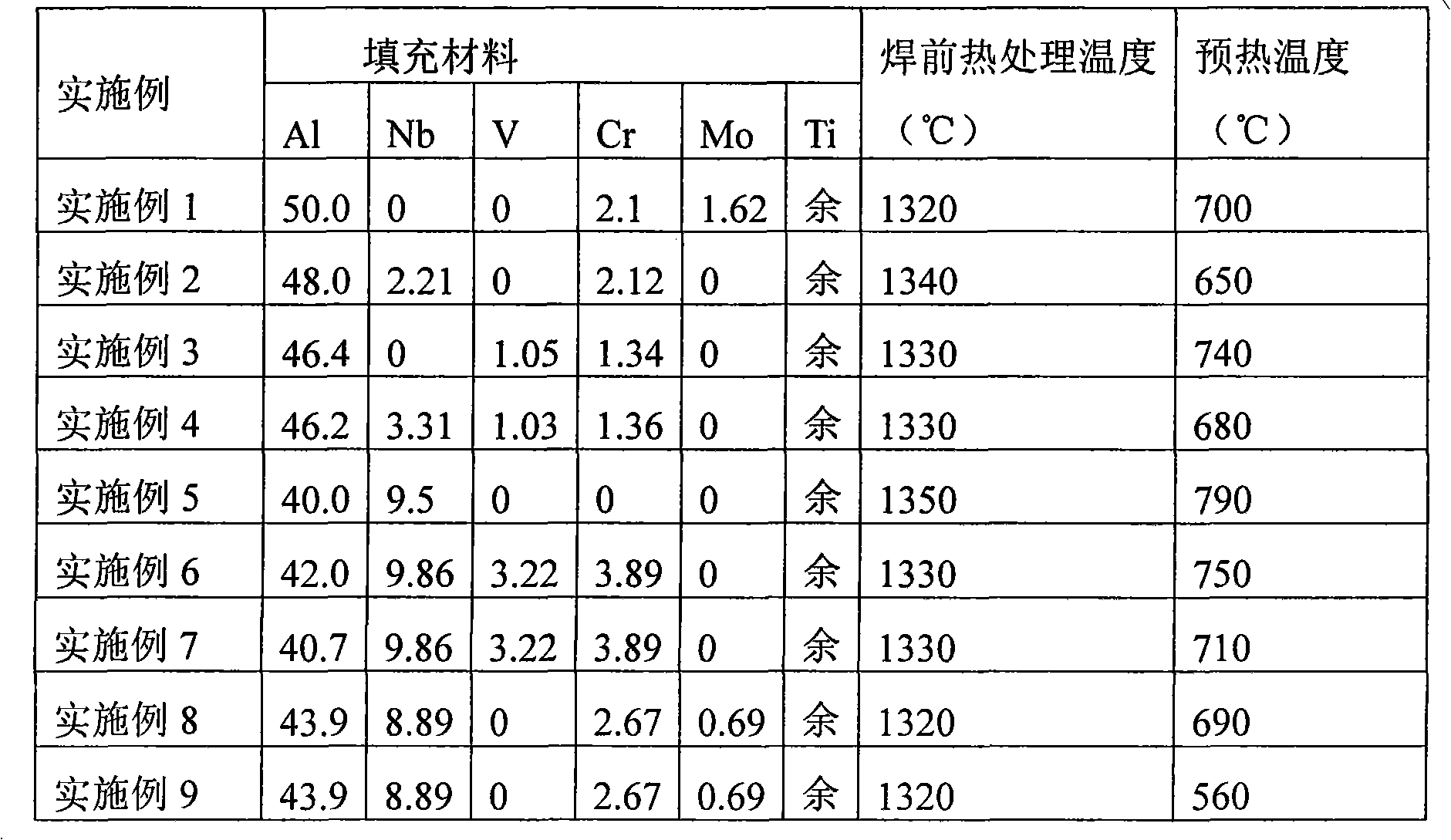

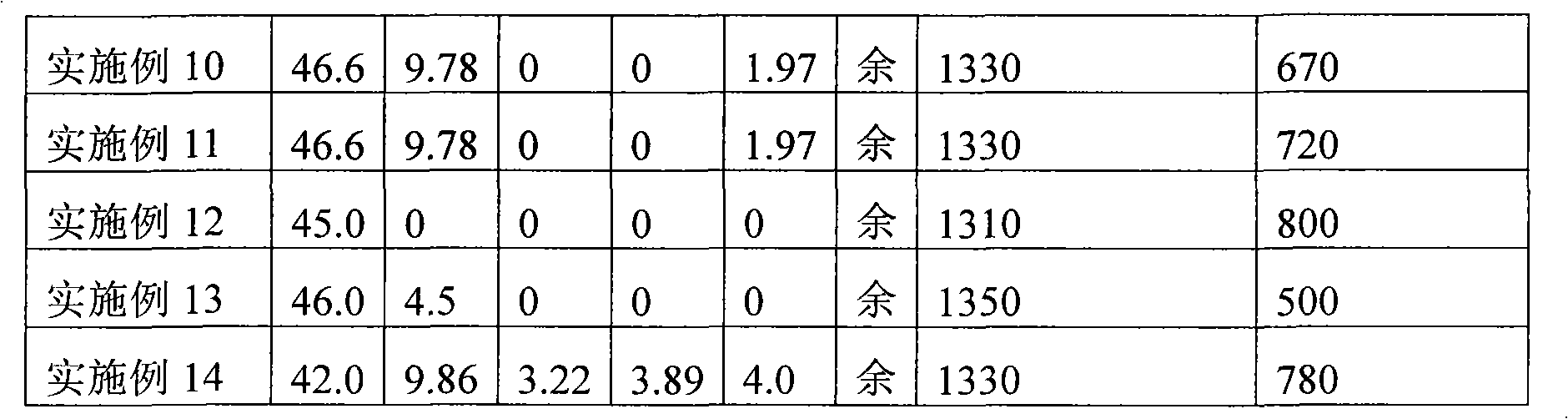

[0028] The filling material that each embodiment of table 1 uses

[0029]

[0030]

[0031] Argon arc welding of TiAl-based alloy itself, the steps of the method are:

[0032] (1) Preparation of filler material for self-welding of TiAl-based alloy, the filler material for self-welding of TiAl-based alloy is: Ti-Al-Nb based filler material, the chemical composition is shown in Table 1, prepared by the following method:

[0033] ①Raw material configuration, the matrix elements are added in the form of 0-grade sponge titanium and titanium-based master alloy, and the alloying elements Al, Nb, V, Cr are added in the form of titanium-based, aluminum-based master alloy or pure metal, and are formulated by weight percentage;

[0034]②Smelting the alloy, in order to ensure the uniformity of the alloy composition, repeatedly smelting and casting into rods...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com