Heat exchanging pipe with reinforced heat transfer elements

A technology for enhancing heat transfer and heat exchange tubes, applied in the field of heat exchange tubes, can solve problems such as fouling on the inner wall of the tubes, difficulty in cleaning and maintenance, etc., achieve the possibility of eliminating the dirt layer, easy cleaning and maintenance, and improve heat transfer efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

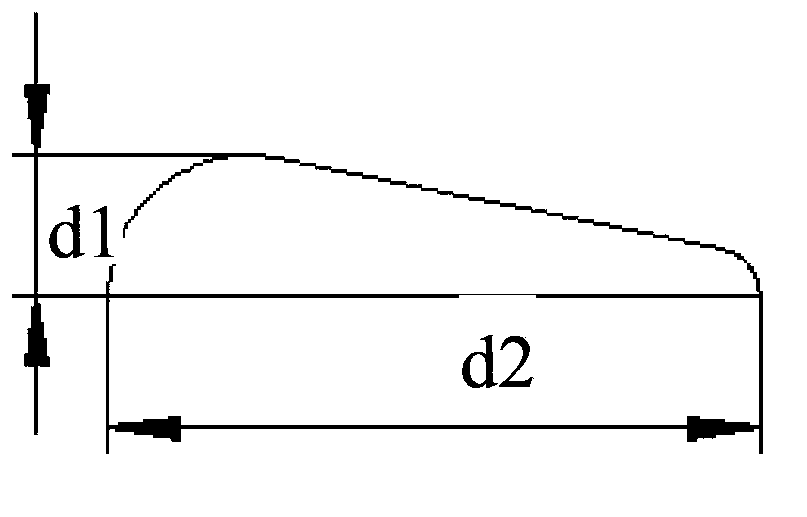

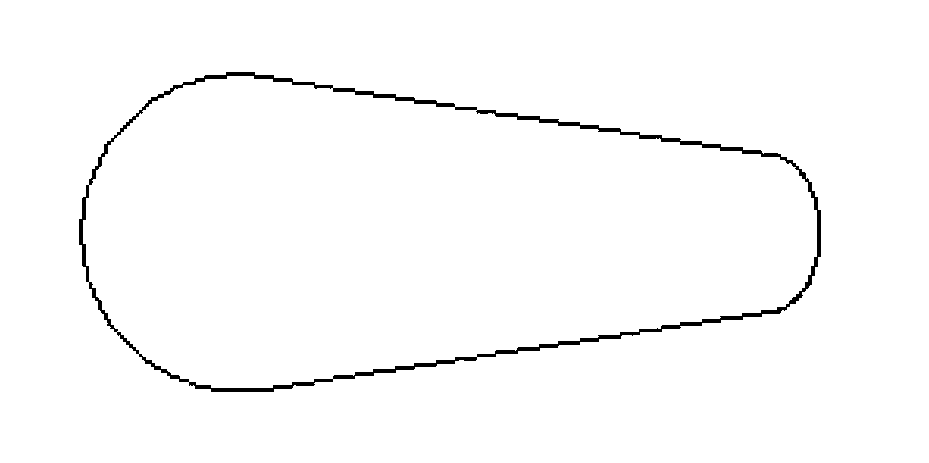

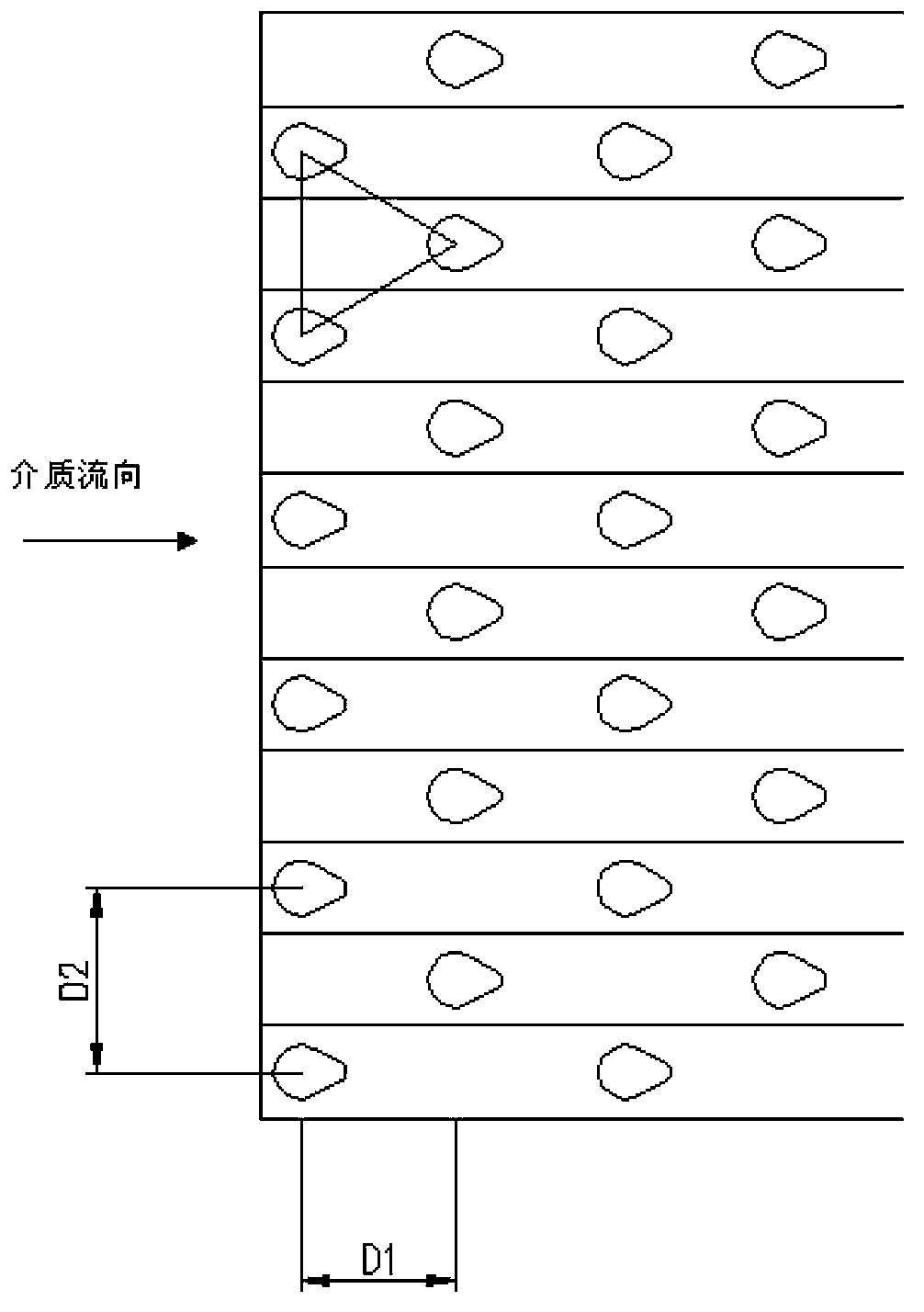

[0038] Comparing Example 2 and Example 3, the arrangement and spacing of the enhanced heat transfer elements in the two embodiments are the same, the height and length of the enhanced heat transfer elements in Example 3 are greater than the size of the enhanced heat transfer elements in Example 2, However, its heat transfer capacity is lower than that of Example 2; compared with Example 2, the length of the enhanced heat transfer element in Example 4 is reduced, and its heat transfer capacity is lower than that of Example 2. The results are similar to the above. From the comparison results of the above two groups, it can be seen that the external dimensions of the enhanced heat transfer element have a significant impact on the pressure drop and heat transfer effect. Since the enhanced heat transfer element in Example 2 is closer to the streamlined shape, the pressure drop must At the same time, the heat transfer effect is better than that of Example 4, so it is very important t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical distance | aaaaa | aaaaa |

| Lateral distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com