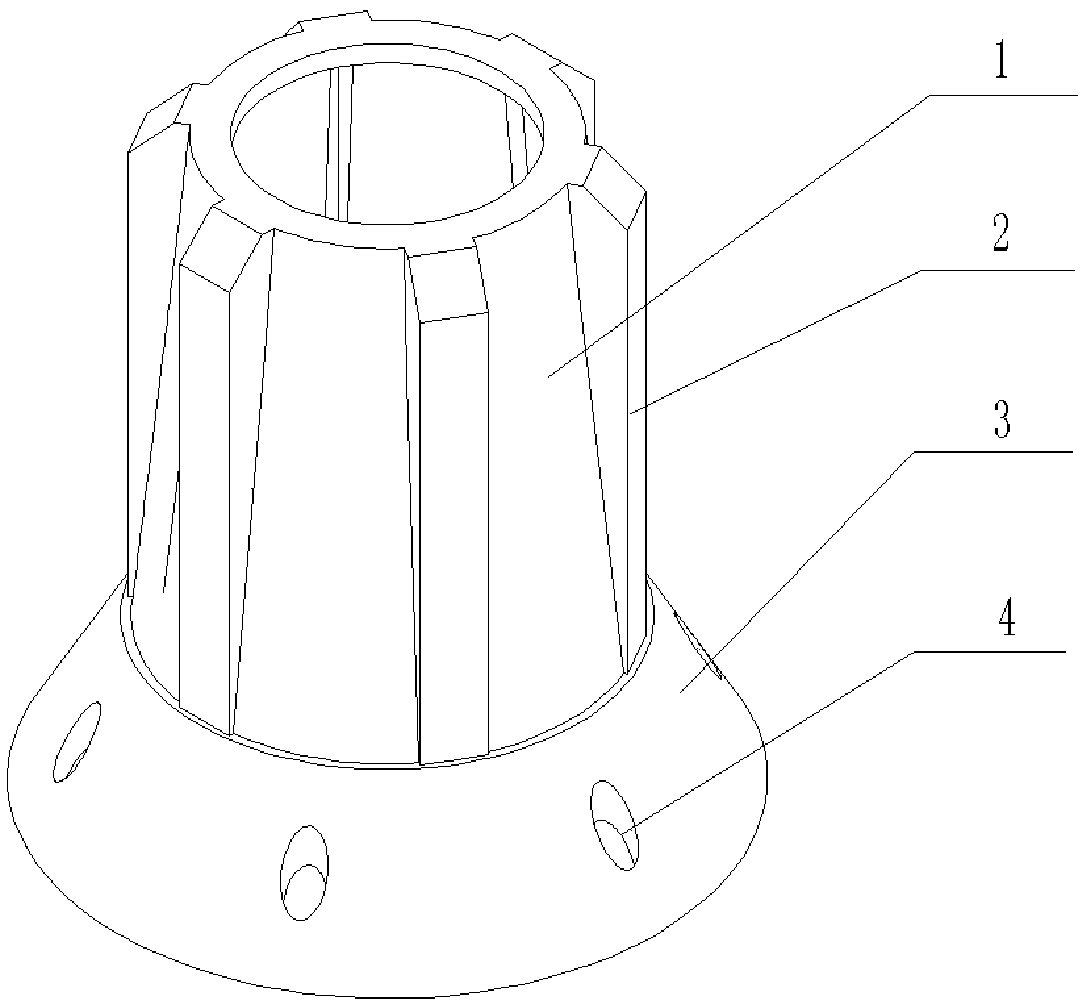

Conical disc rack of disc centrifugal machine

A disc centrifuge and disc technology, applied in centrifuges and other directions, can solve problems such as reducing the separation efficiency of disc centrifuges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] like figure 1 Shown: When the present invention is used with the disc set, the material containing the mixture of light and heavy phases enters the disc gap, the heavy phase is thrown to the drum wall under the action of centrifugal force, and the light phase flows to the axial direction of the disc frame. As the volume of the light phase channel gradually increases, the distribution of fluid pressure in the gap between the bottom layer and the upper layer disc is improved, so that the fluid distribution in each layer tends to be uniform, and the separation effect of the disc centrifuge is improved.

[0020] The invention increases the volume in the flow channel by controlling the cross-sectional area of the light-phase fluid flow channel from small to large, and changes the structure of the disc frame of the disc centrifuge to change the pressure of the fluid in the gap between the inner diameter of the disc and the disc frame Therefore, the fluid flow in the disc ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com