A cooling device for an automobile engine

A technology for automobile engines and heat sinks, which is applied in the cooling of engines, components of pumping devices for elastic fluids, engine components, etc., can solve the problems of eddy currents at the top of blades, uneven pressure distribution, and small fan air volume, etc. The effect of increasing fan air volume, reducing turbulence and uniform pressure distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

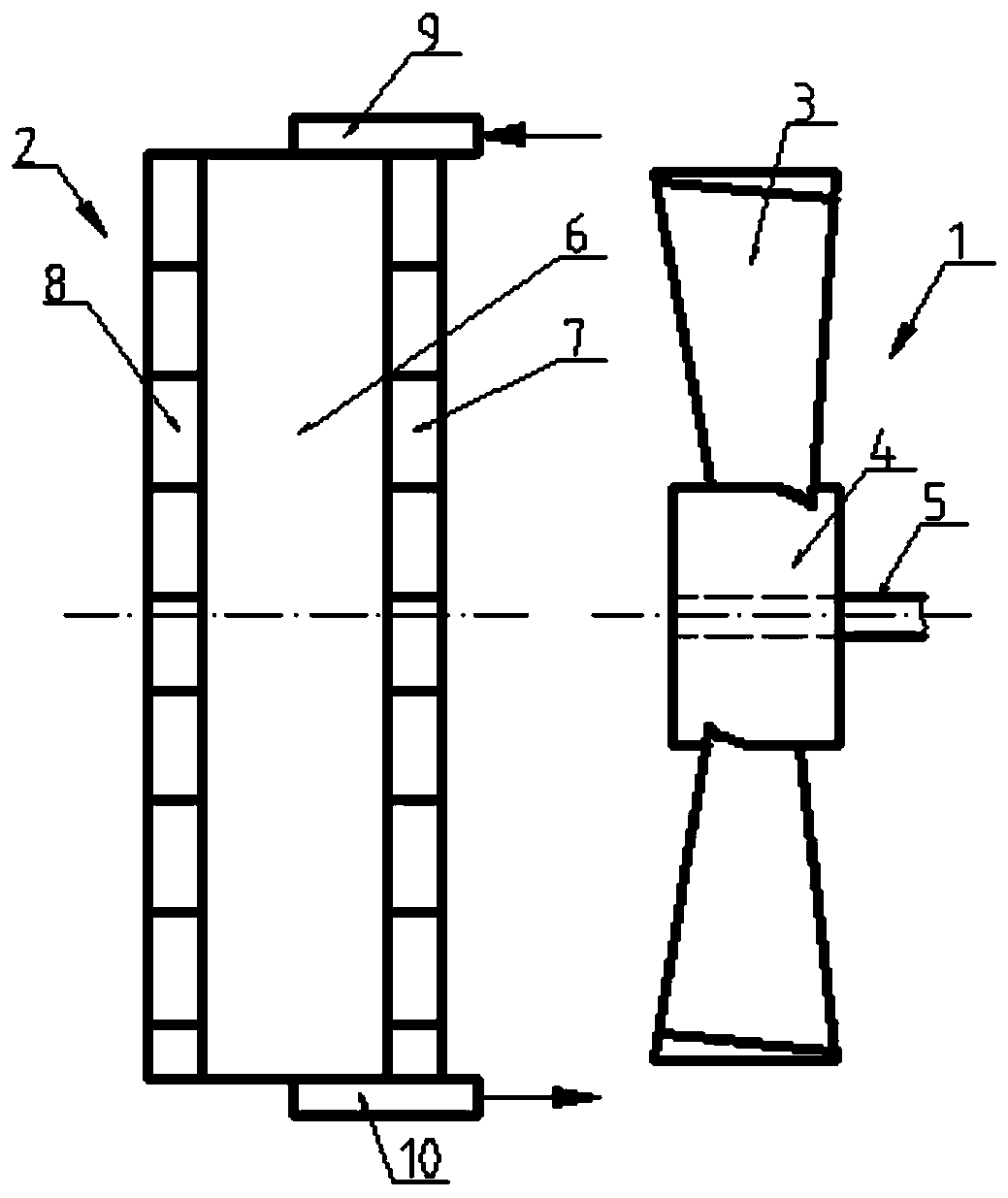

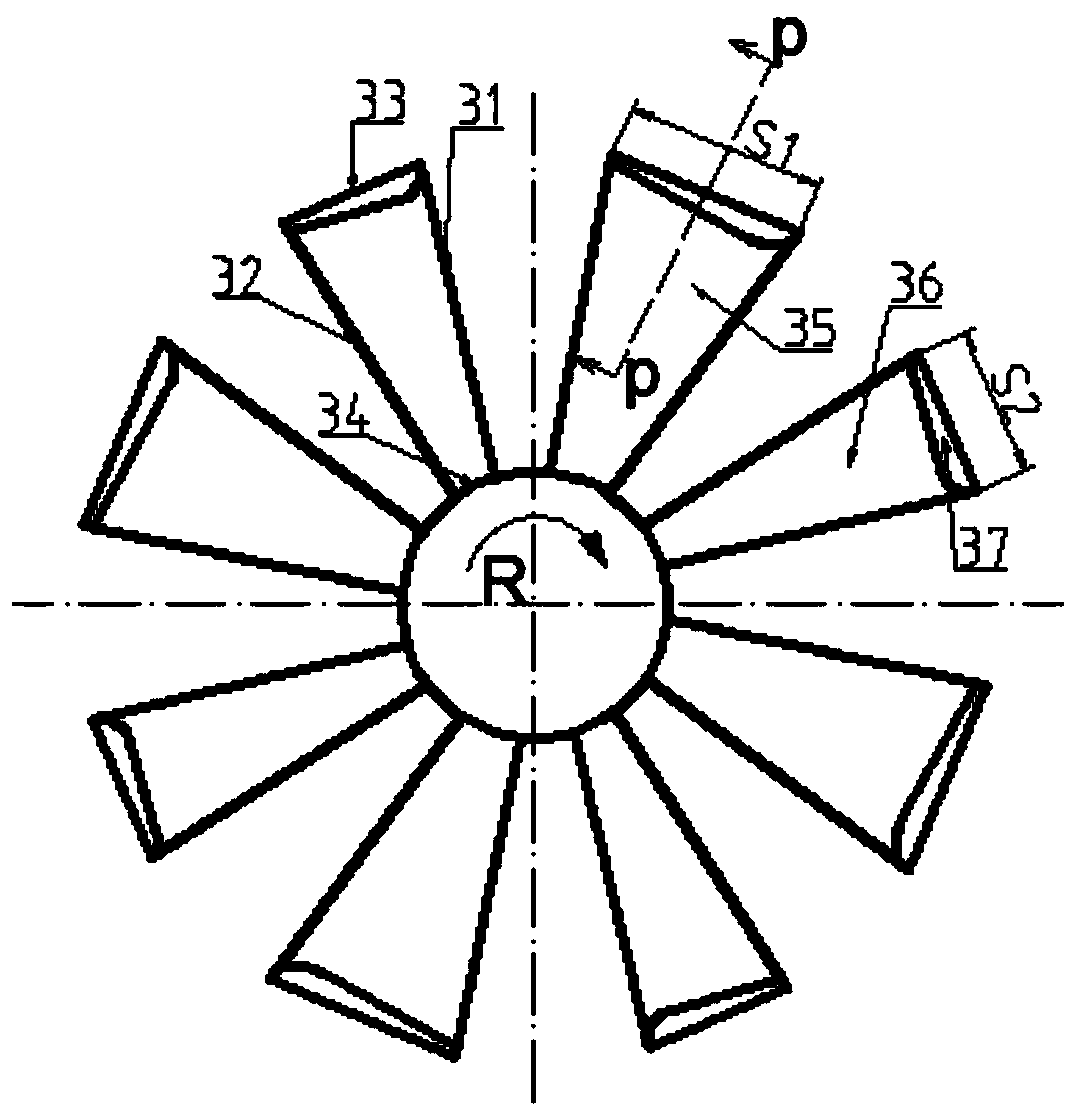

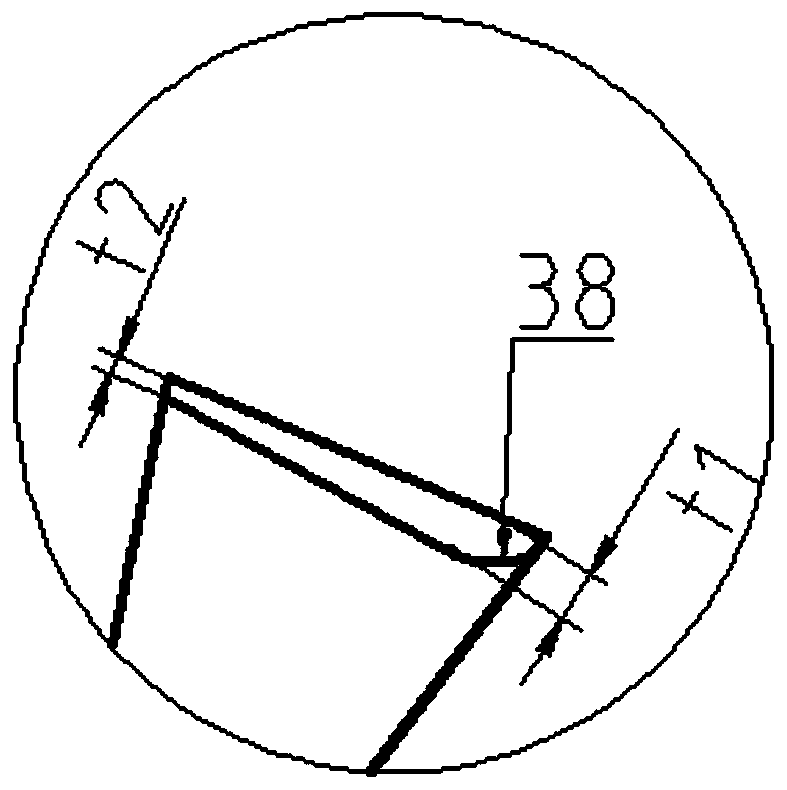

[0019] See attached Figure 1-4 : The cooling device includes a fan 1, a heat exchanger 2, a main blade 3, a hub 4, a rotating shaft 5, a heat exchanger body 6, a first cooling fin 7, a second cooling fin 8, a heat exchange fluid inlet 9, a heat exchange fluid Outlet 10 , leading edge 31 , trailing edge 32 , top 33 , root 34 , first vane 35 , second vane 36 , auxiliary vane 37 , first arcuate portion 38 , second arcuate portion 39 .

[0020] The heat dissipation device includes an axial flow fan 1 and a heat exchanger 2. The fan 1 is located on one side of the heat exchanger 2. The fan 1 includes a main blade 3, a hub 4, and a rotating shaft 5. A plurality of main blades 3 are located on the outer periphery of the hub 4, and radially extend. The left and right sides of the heat exchanger 2 are respectively provided with a first cooling fin 7 and a second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com