Centrifugal pump with cavitation-resisting impeller

A centrifugal pump and impeller technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, and can solve problems such as the influence of the stable operation of the centrifugal pump, the influence of the hydraulic performance of the centrifugal pump, and the influence of the service life of the centrifugal pump. , to achieve the effect of inhibiting cavitation, improving operating stability, and improving flow instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

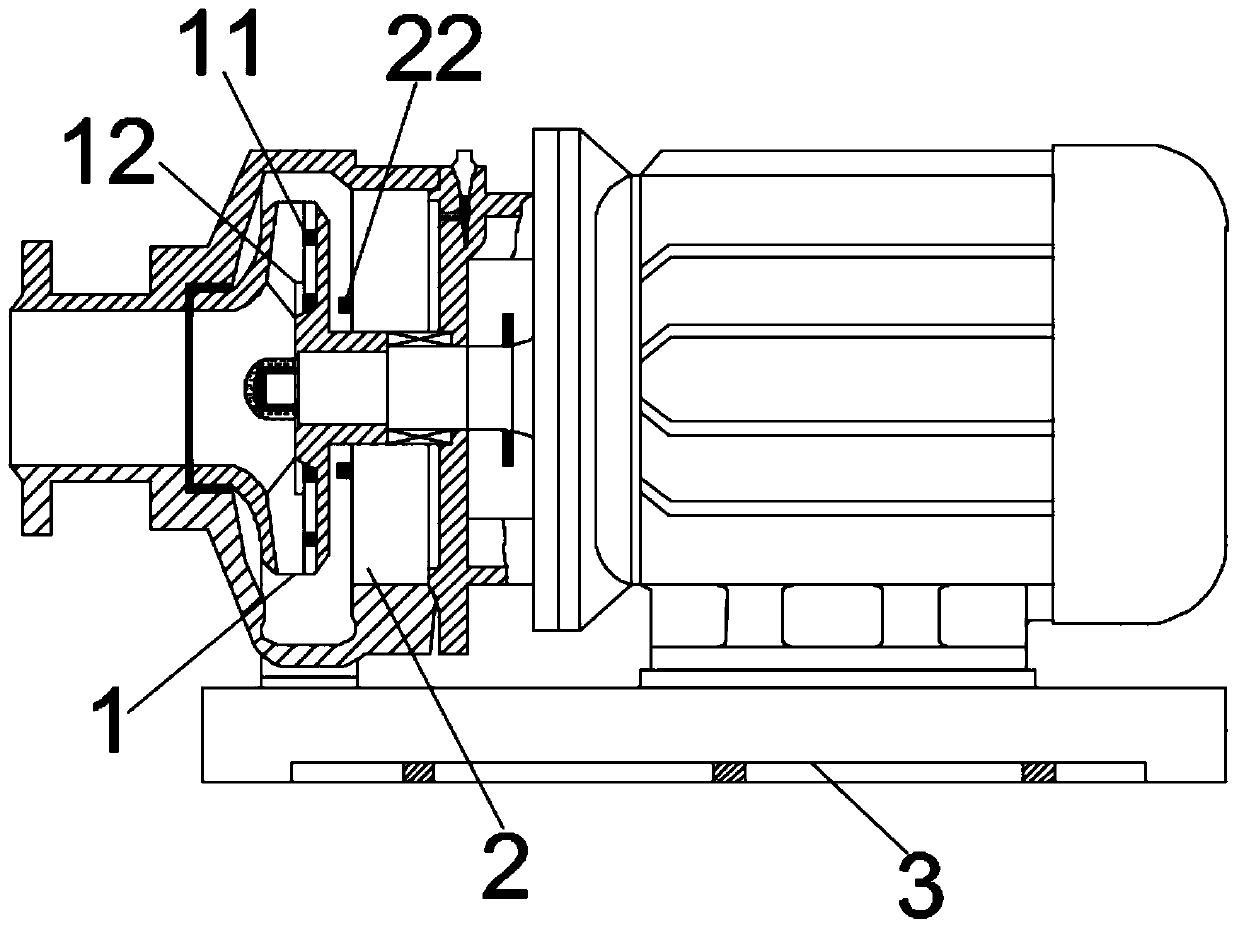

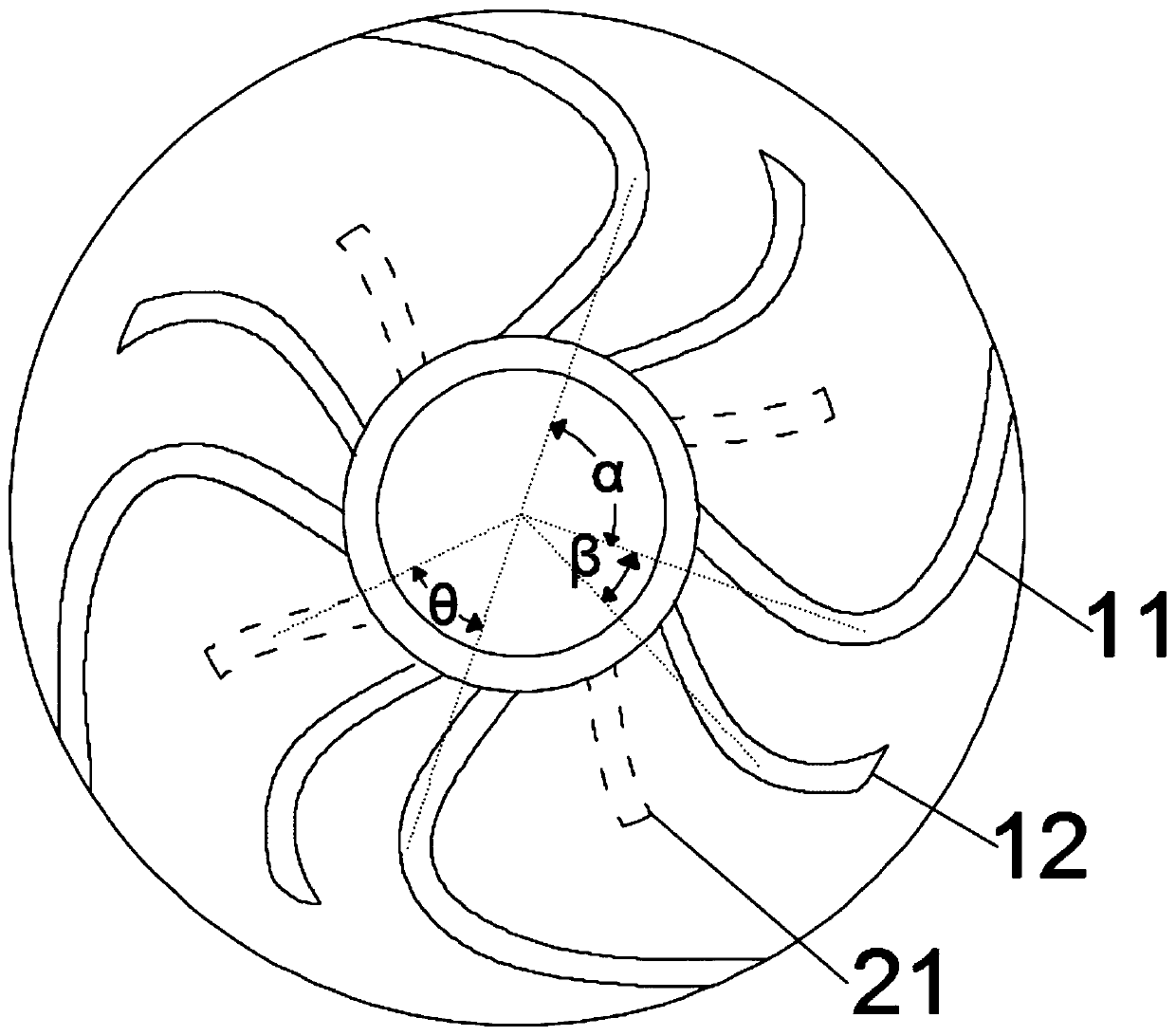

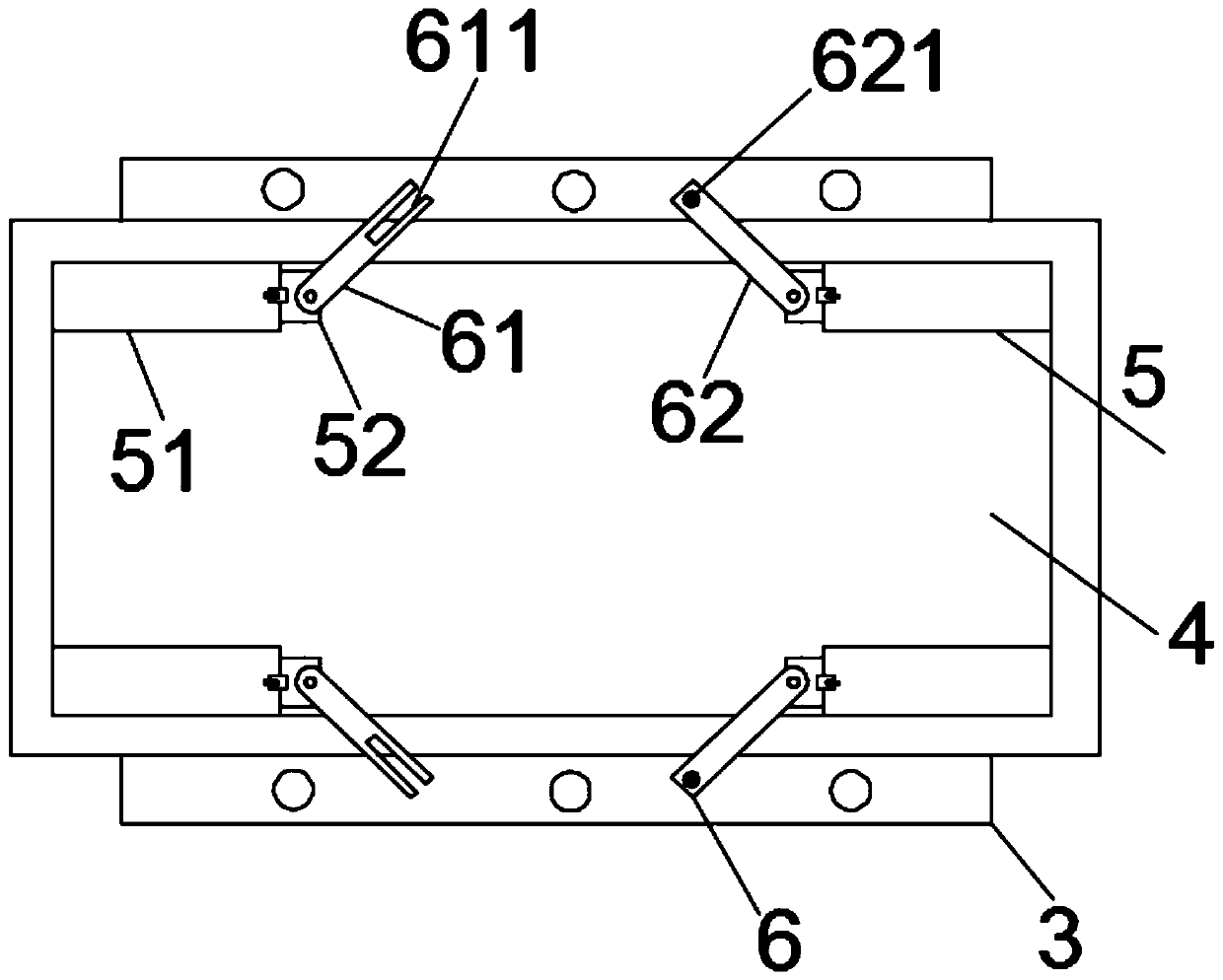

[0033]A centrifugal pump with an anti-cavitation impeller, including a pump body and a base, the pump body includes an impeller 1, an impeller front cover and an impeller rear cover 2, and the impeller 1 is fixedly connected between the impeller front cover and the impeller rear cover 2 Among them, the impeller 1 includes long blades 11 and short blades 12. The long blades 11 and short blades 12 are alternately designed to guide and limit the generation and development of the backflow vortex at the water inlet section, improve the flow instability in the flow channel of the impeller 1, and suppress The occurrence of cavitation reduces system pressure fluctuations and improves the operational stability of the centrifugal pump. The number of long blades 11 and short blades 12 is 4, and the angle between the backs of two adjacent long blades 11 is α, α =90 °, the angle between the back of the long blade 11 and the back of the adjacent short blade 12 is β, β=0.33α; the impeller rea...

Embodiment 2

[0035] A centrifugal pump with an anti-cavitation impeller, including a pump body and a base, the pump body includes an impeller 1, an impeller front cover and an impeller rear cover 2, and the impeller 1 is fixedly connected between the impeller front cover and the impeller rear cover 2 Among them, the impeller 1 includes long blades 11 and short blades 12. The long blades 11 and short blades 12 are alternately designed to guide and limit the generation and development of the backflow vortex at the water inlet section, improve the flow instability in the flow channel of the impeller 1, and suppress The occurrence of cavitation reduces system pressure fluctuations and improves the operational stability of the centrifugal pump. The number of long blades 11 and short blades 12 is 4, and the angle between the backs of two adjacent long blades 11 is α, α =90 °, the angle between the back of the long blade 11 and the back of the adjacent short blade 12 is β, β=0.35α; the impeller re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com