Centrifugal pumps with cavitation surge suppression

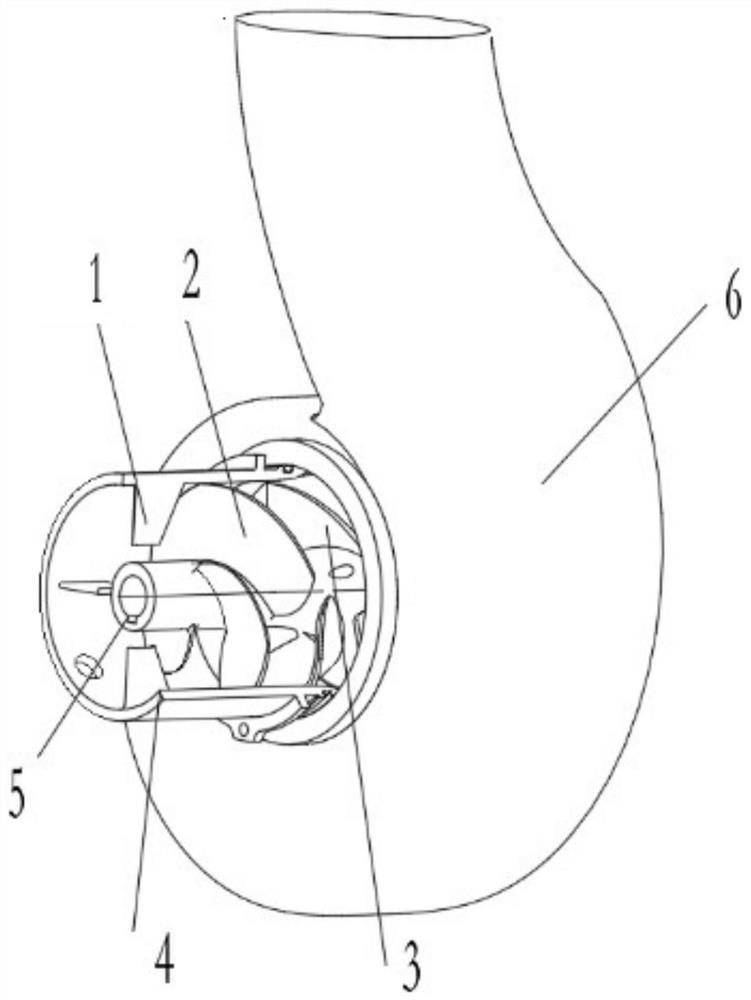

A centrifugal pump and cavitation technology, applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve problems such as vibration and noise, affecting the stable operation of the pump, and severe fluctuations in system flow and pressure. Achieve the effects of reducing vibration and noise, improving flow instability, and suppressing the generation of backflow vortices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] According to the above description, this application provides a preferred embodiment.

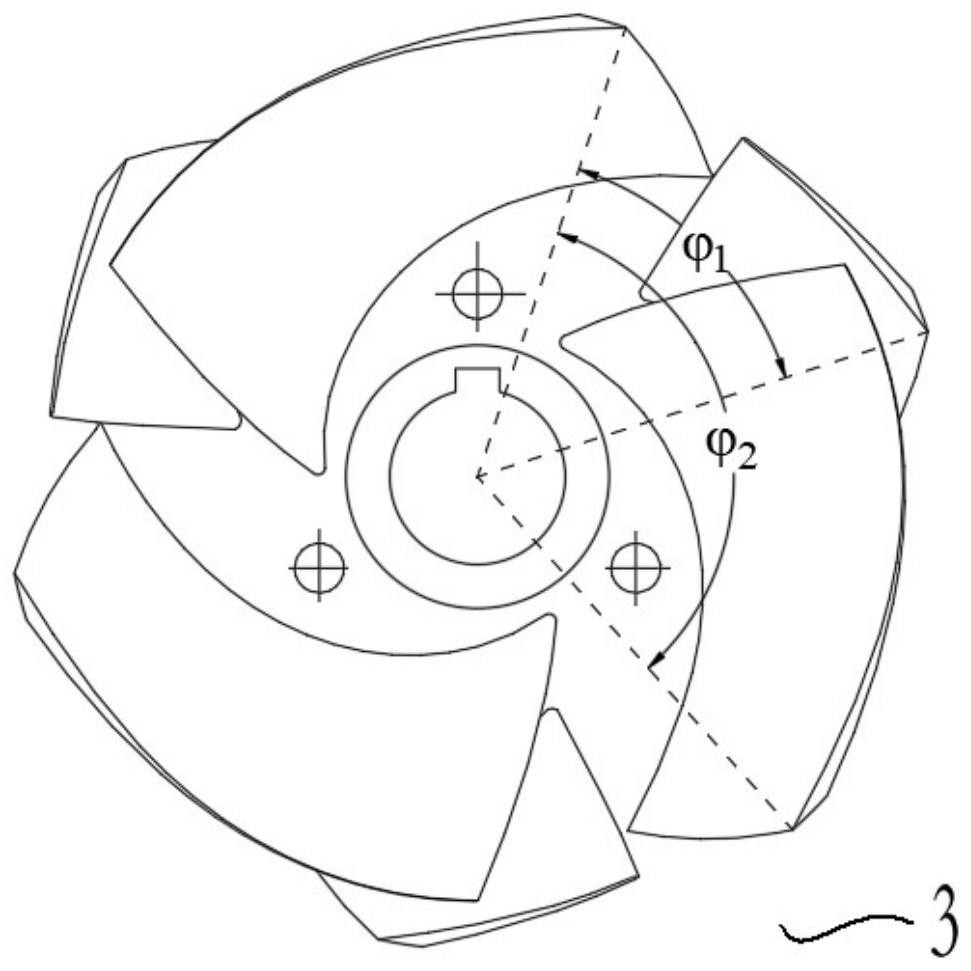

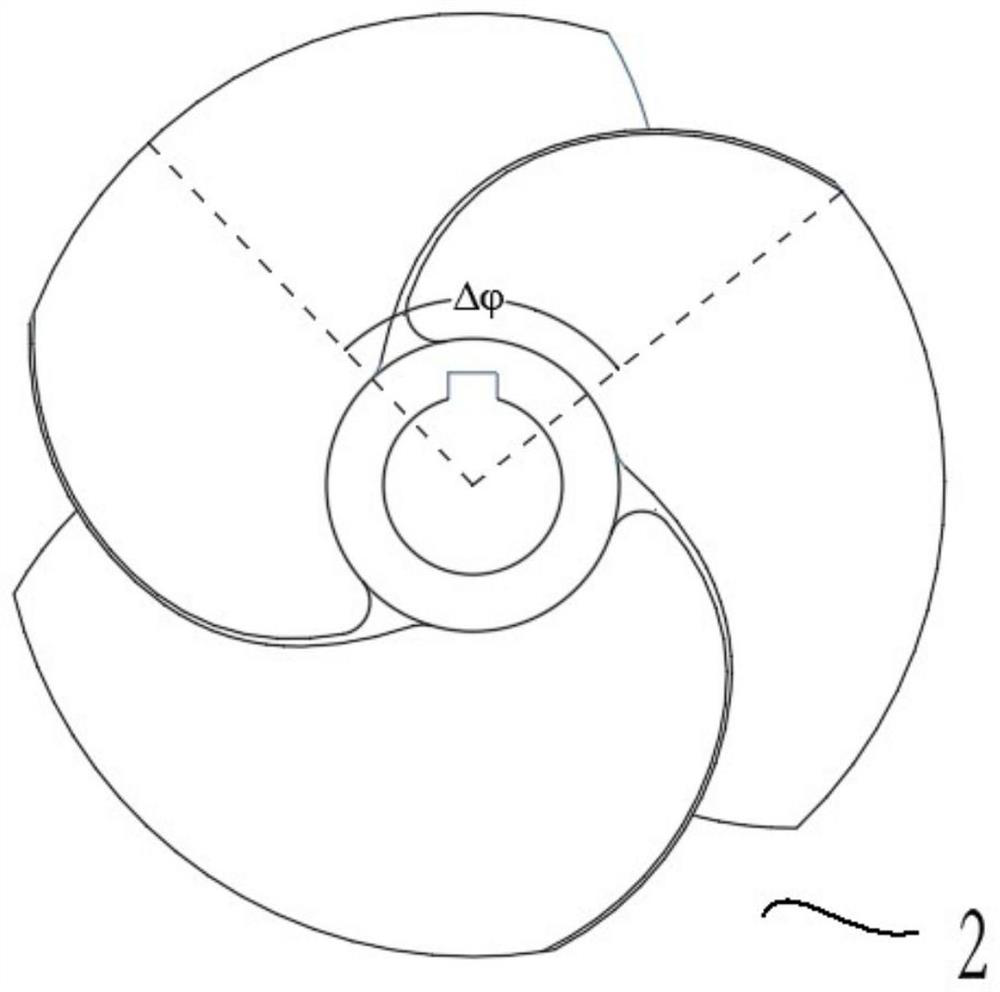

[0079] The number of long blades of the impeller 3 blades of the present embodiment is 3, and the angle between the backs of adjacent long blades The angle between the back of the long leaf and the back of the adjacent short leaf Sweep angle of inducer 2 is 130°, the design head of the inducer 2 is 5m, the number of rectifying plates 1 is 4, and the circumferential direction is evenly and symmetrically arranged; the thickness of the rectifying plate 1 is H 2 =1.6mm; the connection between the rectifying plate 1 and the water inlet section of the inducer 2 can be welded or integrally cast, and the side of the rectifying plate 1 and the connection between the rectifying plate 1 and the water inlet section of the inducer 2 are rounded, the size of the rounded corners is 0.8mm; the installation angle θ=0° between the rectifying plate 1 and the axis; the side of the rectifying plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com