Static pressure gas bearing

A static pressure gas bearing and bearing technology, which is applied in the field of bearing manufacturing, can solve problems such as poor stability, and achieve the effects of preventing friction, reasonable control, and increasing the force in the opposite direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

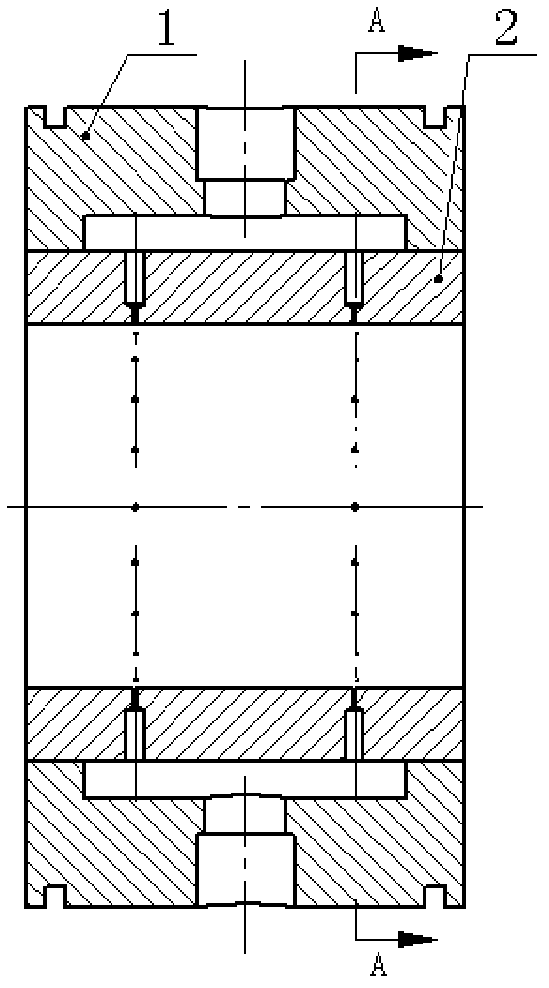

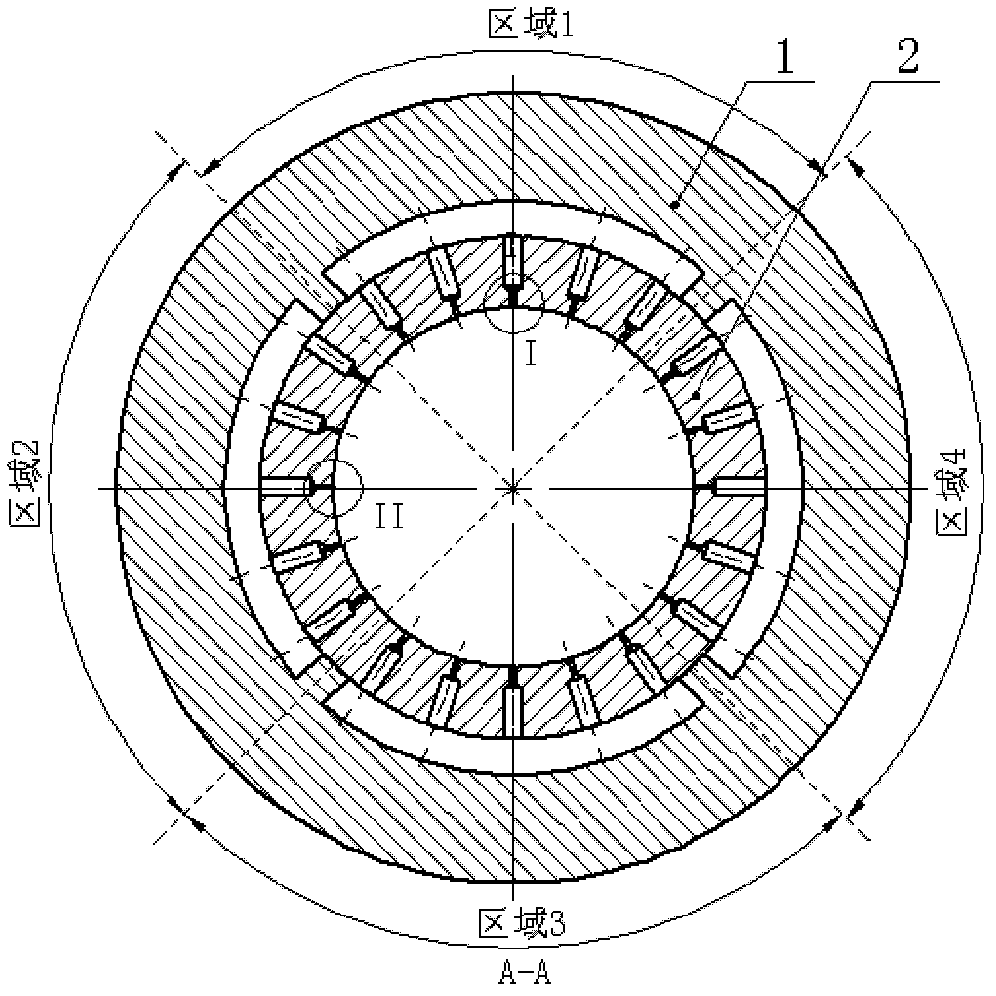

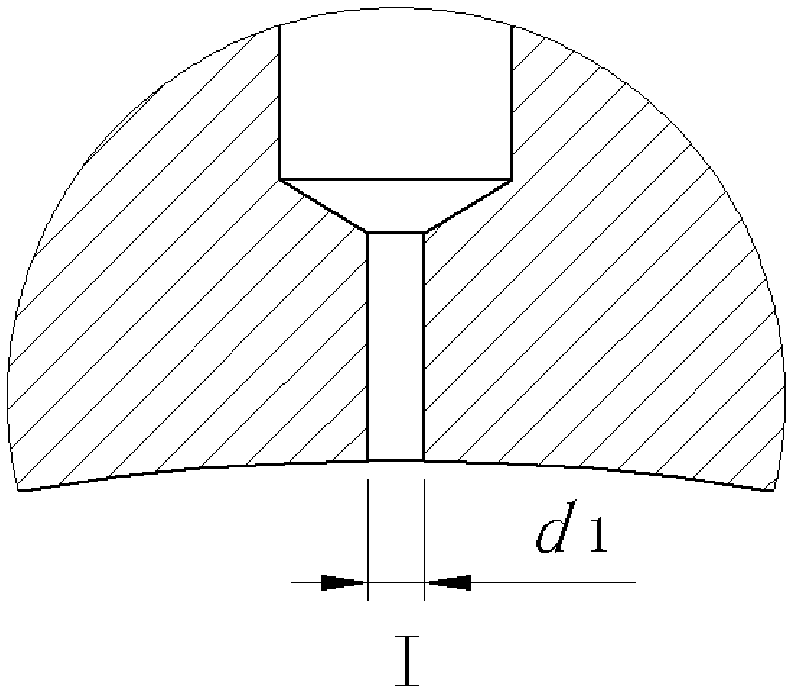

[0023] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-9 As shown, a static pressure gas bearing includes a bearing base 1 and an air supply hole ring sleeve 2. The air supply hole on the air supply hole ring sleeve 2 adopts an annular throttling form; the air supply hole ring sleeve 2 is along the circumference The direction is divided into several independent areas, and the diameter of the air supply hole in each area is different; each area has an independent air supply channel, and each air supply channel is connected to the industrial computer through an electric proportional valve and amplifier. The rotor running condition measured by the displacement sensor sends a control signal to the amplifier to adjust the air supply pressure.

[0024] The air supply holes on the air supply hole collar 2 of the present invention adopt the reverse tangential air supply form or the vertical air supply form.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com