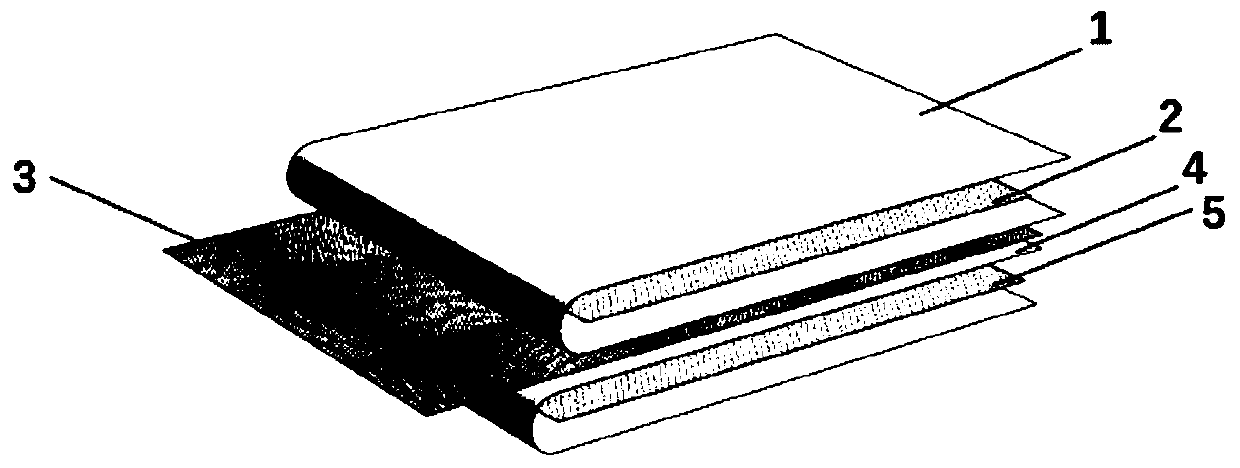

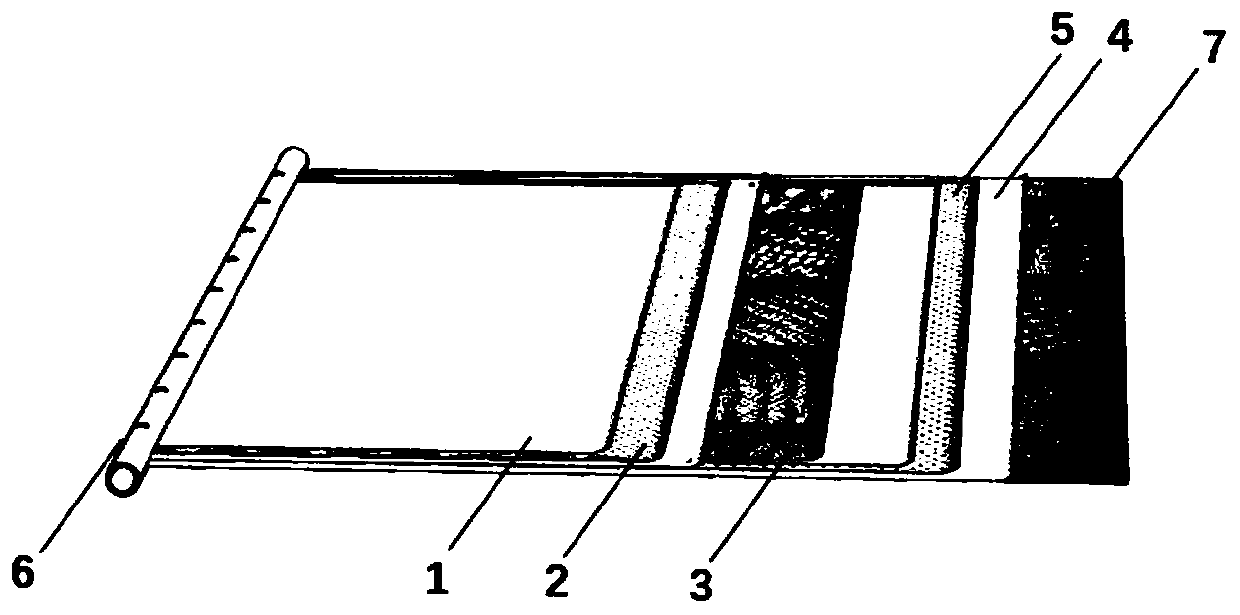

Composite membrane element suitable for water different in quality and manufacturing method

A manufacturing method and composite membrane technology, which is applied in the field of water treatment, can solve the problems of low desalination rate of single nanofiltration membrane, scaling of boiling water, and low flux, so as to reduce the tendency of inorganic scaling, change flow conditions, and stabilize production The effect of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

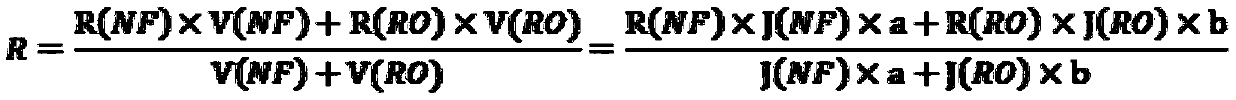

[0038] Taking the water quality of a certain city in Yunnan as the influent water, the total solid salt content (TDS) of the influent water is 94.3mg / L, the water pressure is 0.2-0.6MPa, and the recovery rate is 60%. After the tap water is filtered through PP cotton and activated carbon filter elements, it enters the composite membrane Element, the membrane area ratio of the reverse osmosis membrane and the nanofiltration membrane in the composite membrane element is 1. The TDS of produced water under different pressures is shown in the table below, and the TDS of produced water falls between 30-90mg / L to ensure healthy drinking water.

[0039] Table 3. The quality of the water produced by the water purification filter with the influent TDS less than 100mg / L

[0040]

Embodiment 2

[0042] The water quality of a district in Beijing (TDS is 290.2mg / L) and a city in Fujian (TDS is 160.8mg / L) are respectively used as influent water, the water pressure is 0.2-0.6MPa, the recovery rate is 60%, and the tap water is filtered through PP cotton and activated carbon filter elements Finally, it enters the composite membrane element, and the membrane area ratio of the reverse osmosis membrane and the nanofiltration membrane in the composite membrane element is 2. The TDS of produced water under different pressures is shown in the table below. The TDS of produced water falls between 30-90mg / L, and a certain amount of calcium, magnesium, potassium and other beneficial minerals are retained, making drinking water healthy.

[0043] Table 4. The quality of water produced by the water purification filter with an influent TDS of 100-300mg / L

[0044]

[0045]

Embodiment 3

[0047] The water source of a city in Shanxi (TDS is 480.7mg / L) and a city in Anhui (TDS is 350.2mg / L) is used as influent water, the water pressure is 0.2-0.6MPa, the recovery rate is 60%, and the tap water is filtered through PP cotton and activated carbon filter element , into the composite membrane element, the membrane area ratio of reverse osmosis membrane and nanofiltration membrane in the composite membrane element is ratio 3. The TDS of produced water under different pressures is shown in the table below. The TDS of produced water falls between 30-90mg / L, and a certain amount of calcium, magnesium, potassium and other beneficial minerals are retained, making drinking water healthy.

[0048] Table 5. Water quality produced by nanofiltration / reverse osmosis composite water purification filter element with influent TDS of 300-500mg / L

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com