Continuous Roll Forming Method of Stainless Steel Corrugated Plate for Heat Exchanger

A roll forming, stainless steel technology, applied in the direction of heat exchange equipment, etc., can solve the problems of reducing the yield of heat exchanger plates, prone to cracks in corrugated belts, and aggravating mold wear, so as to increase gaps, improve stability, increase The effect of greater than positive deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

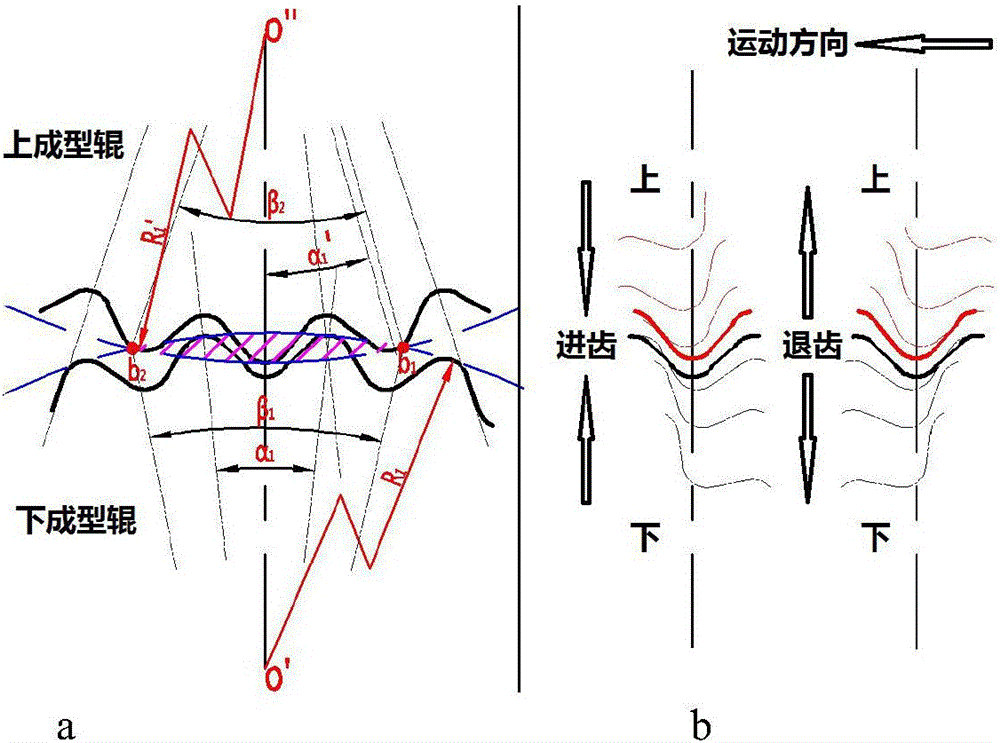

[0025] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

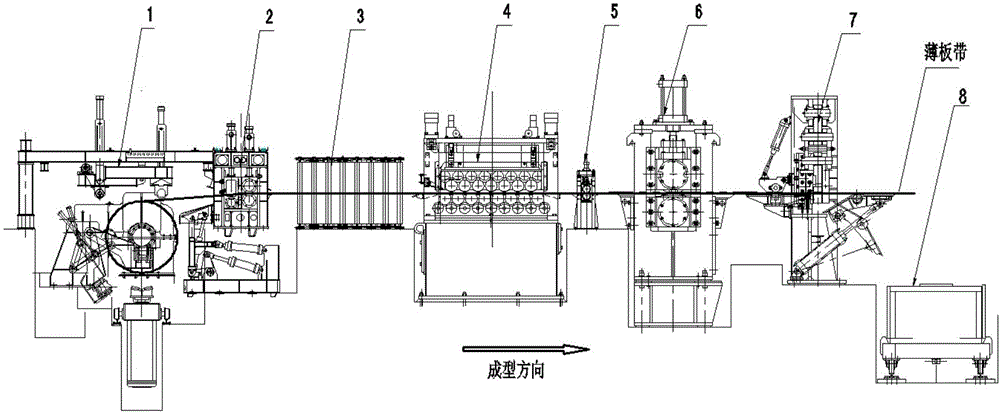

[0026] Such as figure 2 As shown in the continuous roll forming process, the stainless steel sheet strip is uncoiled by the uncoiler, enters the guide pinch roller, and then enters the heating furnace. The temperature automatic induction heating furnace device is heated according to the process preset model (304 stainless steel), and then enters the straightening The unit straightens the strip, and then the guide pinch roller drives the thin strip into the special pass rolling mill for roll forming, and prepares the corrugated sheet for the heat exchanger, and finally cuts it to length by the flying shears, and the sheet Material collection device for collection.

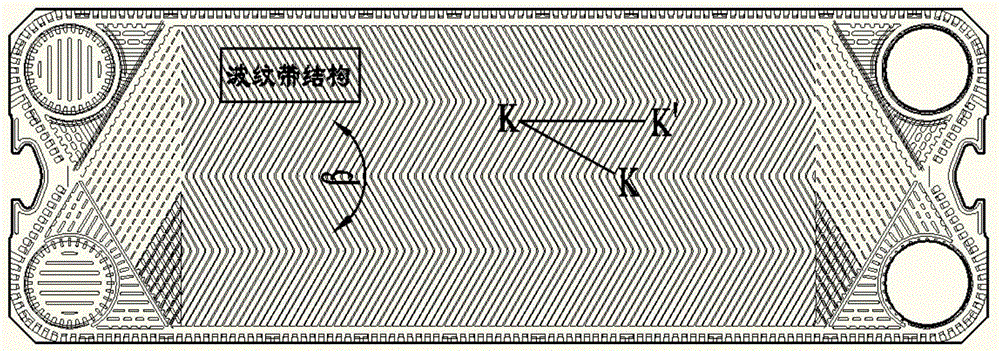

[0027] Select a certain type of plate from an enterprise to verify the above theoretical analysis. The design parameters of the corrugated belt of the plate are shown in Table 1:

[0028] Table 1 Parameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com